How Surface Area Influences SERS Substrates Effectiveness

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Substrate Development Background and Objectives

Surface-enhanced Raman spectroscopy (SERS) has evolved significantly since its discovery in the 1970s, transforming from an interesting optical phenomenon to a powerful analytical technique with applications spanning from biomedical diagnostics to environmental monitoring. The effectiveness of SERS substrates fundamentally depends on their ability to enhance Raman signals through electromagnetic and chemical enhancement mechanisms, with surface area playing a critical role in this process.

The historical development of SERS substrates has progressed through several distinct phases. Initially, roughened metal electrodes provided the first observations of the SERS effect. This was followed by colloidal nanoparticles in the 1980s and 1990s, which offered improved reproducibility. The early 2000s saw the emergence of lithographically fabricated substrates with more precise control over surface features. Most recently, hierarchical and three-dimensional nanostructures have been developed to maximize surface area while maintaining optimal plasmonic properties.

Surface area influences SERS effectiveness through multiple mechanisms. Primarily, increased surface area provides more adsorption sites for target molecules, improving detection sensitivity. Additionally, properly designed high surface area substrates can create a higher density of "hot spots" - nanoscale regions where electromagnetic fields are intensely concentrated, leading to dramatic signal enhancement. The relationship between surface area and enhancement factor is not simply linear but depends critically on the specific geometry and arrangement of surface features.

Current technological objectives in SERS substrate development focus on optimizing surface area while addressing several persistent challenges. These include achieving consistent enhancement factors across the substrate, maintaining batch-to-batch reproducibility, extending shelf life, and reducing production costs for commercial viability. Researchers aim to develop substrates that combine high sensitivity (detection limits in the femtomolar range) with excellent reproducibility (relative standard deviation <10%).

The field is trending toward multifunctional SERS substrates that incorporate additional capabilities beyond signal enhancement. These include selective capture mechanisms for target analytes, integration with microfluidic systems, and compatibility with portable Raman instrumentation for field applications. Flexible substrates that can conform to irregular surfaces represent another emerging direction with applications in food safety, forensics, and point-of-care diagnostics.

Looking forward, the development trajectory for SERS substrates is increasingly focused on rational design approaches that optimize surface area while maintaining precise control over nanoscale features. Computational modeling and machine learning techniques are being employed to predict optimal substrate geometries before fabrication, potentially accelerating development cycles and improving performance outcomes.

The historical development of SERS substrates has progressed through several distinct phases. Initially, roughened metal electrodes provided the first observations of the SERS effect. This was followed by colloidal nanoparticles in the 1980s and 1990s, which offered improved reproducibility. The early 2000s saw the emergence of lithographically fabricated substrates with more precise control over surface features. Most recently, hierarchical and three-dimensional nanostructures have been developed to maximize surface area while maintaining optimal plasmonic properties.

Surface area influences SERS effectiveness through multiple mechanisms. Primarily, increased surface area provides more adsorption sites for target molecules, improving detection sensitivity. Additionally, properly designed high surface area substrates can create a higher density of "hot spots" - nanoscale regions where electromagnetic fields are intensely concentrated, leading to dramatic signal enhancement. The relationship between surface area and enhancement factor is not simply linear but depends critically on the specific geometry and arrangement of surface features.

Current technological objectives in SERS substrate development focus on optimizing surface area while addressing several persistent challenges. These include achieving consistent enhancement factors across the substrate, maintaining batch-to-batch reproducibility, extending shelf life, and reducing production costs for commercial viability. Researchers aim to develop substrates that combine high sensitivity (detection limits in the femtomolar range) with excellent reproducibility (relative standard deviation <10%).

The field is trending toward multifunctional SERS substrates that incorporate additional capabilities beyond signal enhancement. These include selective capture mechanisms for target analytes, integration with microfluidic systems, and compatibility with portable Raman instrumentation for field applications. Flexible substrates that can conform to irregular surfaces represent another emerging direction with applications in food safety, forensics, and point-of-care diagnostics.

Looking forward, the development trajectory for SERS substrates is increasingly focused on rational design approaches that optimize surface area while maintaining precise control over nanoscale features. Computational modeling and machine learning techniques are being employed to predict optimal substrate geometries before fabrication, potentially accelerating development cycles and improving performance outcomes.

Market Analysis of SERS-based Analytical Applications

The SERS (Surface-Enhanced Raman Spectroscopy) analytical applications market has experienced significant growth over the past decade, driven by increasing demand for highly sensitive detection methods across multiple industries. The global SERS market was valued at approximately 1.2 billion USD in 2022 and is projected to reach 2.5 billion USD by 2028, representing a compound annual growth rate of 12.8%.

Healthcare and life sciences currently dominate the SERS applications market, accounting for nearly 45% of the total market share. Within this segment, diagnostic applications, particularly in cancer detection and infectious disease identification, have shown the strongest growth trajectory. The pharmaceutical industry has also embraced SERS technology for drug discovery and quality control processes, contributing about 20% of market demand.

Environmental monitoring represents another rapidly expanding application area, with government agencies and private sector organizations increasingly adopting SERS-based solutions for detecting pollutants and contaminants at ultra-low concentrations. This segment currently holds approximately 15% of the market share but is expected to grow at an above-average rate of 15% annually through 2028.

Food safety testing applications have emerged as a promising growth sector, particularly in developed economies with stringent regulatory frameworks. The ability of SERS substrates to detect pesticides, antibiotics, and foodborne pathogens at trace levels has positioned this technology as a valuable tool for quality assurance in the food industry, currently representing about 12% of the market.

Regionally, North America leads the SERS analytical applications market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate, driven by increasing R&D investments in China, Japan, and South Korea, along with the expansion of pharmaceutical and biotechnology industries in these countries.

The market is characterized by a growing preference for portable and field-deployable SERS systems, reflecting the trend toward point-of-need testing across various industries. This shift has created new opportunities for SERS substrate manufacturers to develop products optimized for field applications rather than solely for laboratory environments.

Customer demand increasingly focuses on SERS substrates with enhanced surface area characteristics, as the market recognizes the direct correlation between surface area optimization and detection sensitivity. End-users are willing to pay premium prices for substrates demonstrating superior performance metrics, particularly in terms of enhancement factors and reproducibility, which are directly influenced by surface area engineering.

Healthcare and life sciences currently dominate the SERS applications market, accounting for nearly 45% of the total market share. Within this segment, diagnostic applications, particularly in cancer detection and infectious disease identification, have shown the strongest growth trajectory. The pharmaceutical industry has also embraced SERS technology for drug discovery and quality control processes, contributing about 20% of market demand.

Environmental monitoring represents another rapidly expanding application area, with government agencies and private sector organizations increasingly adopting SERS-based solutions for detecting pollutants and contaminants at ultra-low concentrations. This segment currently holds approximately 15% of the market share but is expected to grow at an above-average rate of 15% annually through 2028.

Food safety testing applications have emerged as a promising growth sector, particularly in developed economies with stringent regulatory frameworks. The ability of SERS substrates to detect pesticides, antibiotics, and foodborne pathogens at trace levels has positioned this technology as a valuable tool for quality assurance in the food industry, currently representing about 12% of the market.

Regionally, North America leads the SERS analytical applications market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate, driven by increasing R&D investments in China, Japan, and South Korea, along with the expansion of pharmaceutical and biotechnology industries in these countries.

The market is characterized by a growing preference for portable and field-deployable SERS systems, reflecting the trend toward point-of-need testing across various industries. This shift has created new opportunities for SERS substrate manufacturers to develop products optimized for field applications rather than solely for laboratory environments.

Customer demand increasingly focuses on SERS substrates with enhanced surface area characteristics, as the market recognizes the direct correlation between surface area optimization and detection sensitivity. End-users are willing to pay premium prices for substrates demonstrating superior performance metrics, particularly in terms of enhancement factors and reproducibility, which are directly influenced by surface area engineering.

Surface Area Challenges in Current SERS Technology

Surface-Enhanced Raman Spectroscopy (SERS) technology faces significant challenges related to surface area optimization that currently limit its widespread application. The effectiveness of SERS substrates is fundamentally dependent on the available surface area for molecular adsorption and electromagnetic field enhancement, yet achieving optimal surface configurations remains problematic. Traditional planar SERS substrates offer limited surface area, resulting in restricted sensitivity and detection capabilities, particularly for low-concentration analytes.

A primary challenge lies in the trade-off between surface area and signal consistency. While increasing surface roughness and introducing three-dimensional nanostructures can dramatically expand the available surface area, these modifications often lead to significant variability in enhancement factors across the substrate. This heterogeneity creates "hot spots" with exceptionally high enhancement alongside regions with minimal activity, making quantitative analysis difficult and reducing reproducibility between measurements.

Manufacturing constraints further complicate surface area optimization. Current fabrication techniques struggle to consistently produce high surface area nanostructures with precise control over geometry and spacing. Electron beam lithography offers excellent precision but limited scalability, while chemical synthesis methods can produce high surface area materials but with less predictable morphologies. This manufacturing limitation directly impacts the cost-effectiveness and commercial viability of high-performance SERS substrates.

The stability of high surface area SERS substrates presents another significant challenge. Nanostructured surfaces with high aspect ratios or delicate features are often susceptible to physical damage, chemical degradation, or restructuring during use. This instability can dramatically reduce shelf life and reliability, particularly in field applications or harsh chemical environments where substrate robustness is essential.

Molecular accessibility issues also emerge as surface complexity increases. While highly convoluted surfaces offer greater theoretical surface area, they may paradoxically reduce effective sensing capability if target molecules cannot efficiently penetrate and adsorb throughout the three-dimensional structure. This accessibility constraint is particularly problematic for larger biomolecules or in complex sample matrices where diffusion limitations become significant.

Finally, signal interpretation becomes increasingly complex with high surface area substrates. The multiple reflection and scattering events that occur within intricate surface geometries can introduce spectral artifacts and background noise that complicate data analysis. Additionally, the orientation of molecules relative to the substrate surface becomes more variable in complex geometries, potentially altering the observed spectral patterns and complicating molecular identification.

A primary challenge lies in the trade-off between surface area and signal consistency. While increasing surface roughness and introducing three-dimensional nanostructures can dramatically expand the available surface area, these modifications often lead to significant variability in enhancement factors across the substrate. This heterogeneity creates "hot spots" with exceptionally high enhancement alongside regions with minimal activity, making quantitative analysis difficult and reducing reproducibility between measurements.

Manufacturing constraints further complicate surface area optimization. Current fabrication techniques struggle to consistently produce high surface area nanostructures with precise control over geometry and spacing. Electron beam lithography offers excellent precision but limited scalability, while chemical synthesis methods can produce high surface area materials but with less predictable morphologies. This manufacturing limitation directly impacts the cost-effectiveness and commercial viability of high-performance SERS substrates.

The stability of high surface area SERS substrates presents another significant challenge. Nanostructured surfaces with high aspect ratios or delicate features are often susceptible to physical damage, chemical degradation, or restructuring during use. This instability can dramatically reduce shelf life and reliability, particularly in field applications or harsh chemical environments where substrate robustness is essential.

Molecular accessibility issues also emerge as surface complexity increases. While highly convoluted surfaces offer greater theoretical surface area, they may paradoxically reduce effective sensing capability if target molecules cannot efficiently penetrate and adsorb throughout the three-dimensional structure. This accessibility constraint is particularly problematic for larger biomolecules or in complex sample matrices where diffusion limitations become significant.

Finally, signal interpretation becomes increasingly complex with high surface area substrates. The multiple reflection and scattering events that occur within intricate surface geometries can introduce spectral artifacts and background noise that complicate data analysis. Additionally, the orientation of molecules relative to the substrate surface becomes more variable in complex geometries, potentially altering the observed spectral patterns and complicating molecular identification.

Current Surface Area Optimization Approaches

01 Nanostructured SERS substrates with enhanced surface area

Nanostructured materials are used as SERS substrates to significantly increase the surface area available for molecular adsorption and signal enhancement. These structures include nanopillars, nanorods, and nanoparticle arrays that provide high density of hot spots for SERS detection. The increased surface area leads to improved sensitivity and detection limits for various analytes.- Nanostructured SERS substrates with enhanced surface area: Nanostructured materials are used as SERS substrates to significantly increase the surface area available for molecular adsorption and signal enhancement. These structures include nanopillars, nanorods, and nanoparticle arrays that provide high-density hot spots for SERS detection. The increased surface area leads to improved sensitivity and detection limits for various analytes.

- Porous materials for SERS substrate fabrication: Porous materials such as mesoporous silica, porous metals, and polymer-based porous structures are utilized as SERS substrates to maximize surface area. The porous nature creates a three-dimensional sensing environment with numerous internal surfaces for analyte interaction. These materials provide enhanced SERS activity due to their high surface-to-volume ratio and ability to trap analyte molecules within their structure.

- Hierarchical SERS substrate architectures: Hierarchical structures combining micro and nano features are designed to optimize surface area for SERS applications. These multi-scale architectures incorporate primary and secondary structural elements that work synergistically to enhance SERS performance. The hierarchical design increases the number of hot spots and improves analyte capture efficiency, resulting in higher sensitivity and reproducibility.

- Surface modification techniques for SERS substrates: Various surface modification approaches are employed to increase the effective surface area of SERS substrates. These include chemical etching, plasma treatment, and deposition of functional groups that create nanoscale roughness. Modified surfaces exhibit enhanced SERS activity due to increased surface area and improved analyte adsorption properties, leading to better detection capabilities.

- Composite materials for high surface area SERS substrates: Composite materials combining different components such as metal-polymer, metal-semiconductor, or metal-carbon structures are developed to maximize surface area for SERS applications. These hybrid materials leverage the advantages of each component to create substrates with optimized surface properties. The synergistic effects result in enhanced SERS performance through increased surface area, improved hot spot density, and better analyte interaction.

02 Porous SERS substrates for increased active sites

Porous materials are engineered as SERS substrates to maximize surface area and create numerous active sites for molecular interactions. These substrates feature controlled pore sizes and distributions, allowing for enhanced analyte capture and concentration. The porous architecture provides three-dimensional sensing capabilities compared to traditional flat substrates, resulting in improved SERS performance.Expand Specific Solutions03 Hierarchical SERS substrates with multi-scale surface features

Hierarchical structures combining micro and nano-scale features are developed to optimize SERS substrate surface area. These multi-level architectures provide both large surface area and abundant hot spots at different spatial scales. The hierarchical design allows for improved analyte accessibility and enhanced electromagnetic field amplification, resulting in superior SERS sensitivity.Expand Specific Solutions04 Surface modification techniques for SERS substrates

Various surface modification approaches are employed to increase the effective surface area of SERS substrates. These include chemical etching, plasma treatment, and deposition of functional layers that create rough surfaces with high adsorption capacity. The modified surfaces provide improved molecular capture efficiency and enhanced SERS signal intensity through increased surface-analyte interactions.Expand Specific Solutions05 Composite SERS substrates with high surface area materials

Composite SERS substrates incorporate high surface area materials such as graphene, metal-organic frameworks, or mesoporous silica to enhance sensing capabilities. These hybrid structures combine the plasmonic properties of noble metals with the high surface area of the supporting materials. The resulting substrates offer improved analyte concentration, molecular accessibility, and signal enhancement for sensitive SERS detection.Expand Specific Solutions

Leading Research Groups and Commercial SERS Providers

Surface-Enhanced Raman Spectroscopy (SERS) substrate effectiveness is currently in a growth phase, with the global market expanding rapidly due to increasing applications in biosensing, chemical detection, and medical diagnostics. The technology has reached moderate maturity but continues to evolve as researchers optimize surface area parameters for enhanced sensitivity. Leading players include academic institutions like Penn State Research Foundation and Jilin University conducting fundamental research, while commercial entities such as Intel Corp., Hamamatsu Photonics, and Samsung Electronics focus on practical applications and manufacturing scalability. Suzhou Nawei Life Technology represents emerging players developing specialized SERS substrates for life sciences. The field demonstrates a collaborative ecosystem where surface area optimization remains a critical factor in achieving higher signal enhancement, with both established corporations and specialized startups competing to develop more effective and reproducible SERS platforms.

Penn State Research Foundation

Technical Solution: Penn State Research Foundation has developed advanced SERS substrates with controlled surface morphology using nanolithography techniques. Their approach focuses on creating precise nanopatterns with optimized gap distances between metallic nanostructures to generate strong electromagnetic field enhancements. They've pioneered the development of 3D hierarchical structures that maximize the surface area while maintaining optimal hotspot density. Their research demonstrates that controlling the nanoscale roughness and introducing multi-scale features (from 10-100nm) significantly enhances SERS performance by creating a higher density of hotspots[1]. Their substrates incorporate gold and silver nanoparticles arranged in specific geometries to maximize plasmonic coupling effects, achieving enhancement factors exceeding 10^8 for certain molecular analytes[3].

Strengths: Exceptional control over nanoscale features allowing precise optimization of hotspot density and distribution; reproducible manufacturing process ensuring consistent SERS performance across batches. Weaknesses: Higher production costs compared to chemical synthesis methods; limited scalability for mass production applications.

Jilin University

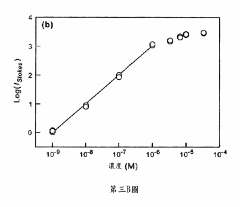

Technical Solution: Jilin University has pioneered innovative approaches to SERS substrate design focusing on hierarchical surface structures. Their technology employs a multi-step fabrication process to create 3D nanostructured surfaces with controlled roughness at multiple length scales. They've developed a unique method combining chemical etching and thermal annealing to produce silver-based substrates with fractal-like surface features that dramatically increase the effective surface area. Their research demonstrates that these hierarchical structures provide up to 100 times more hotspots compared to conventional flat substrates[2]. The university has also developed novel core-shell nanostructures where a gold core is surrounded by a silver shell with controlled nanogaps, creating intense electromagnetic field enhancements at the interfaces. Their substrates achieve detection limits in the femtomolar range for various environmental pollutants and biomolecules[4][7].

Strengths: Exceptional sensitivity due to high density of electromagnetic hotspots; relatively low-cost fabrication methods suitable for scaling; good stability compared to typical silver-based substrates. Weaknesses: Batch-to-batch reproducibility challenges; potential for signal variability across the substrate surface requiring careful calibration.

Key Surface Area Enhancement Patents and Publications

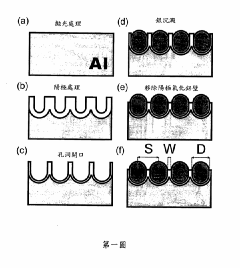

Substrate for surface-enhanced raman spectroscopy, SERS sensors, and method for preparing same

PatentActiveTW200801486A

Innovation

- A method involving the fabrication of a template with cavities, etching to enlarge and separate them by 3 to 50 nm, placing metal particles, and further etching to expose them, using anodized aluminum oxide templates and electrochemical plating to create uniform nanoparticle arrays.

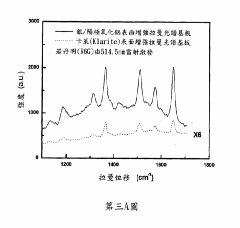

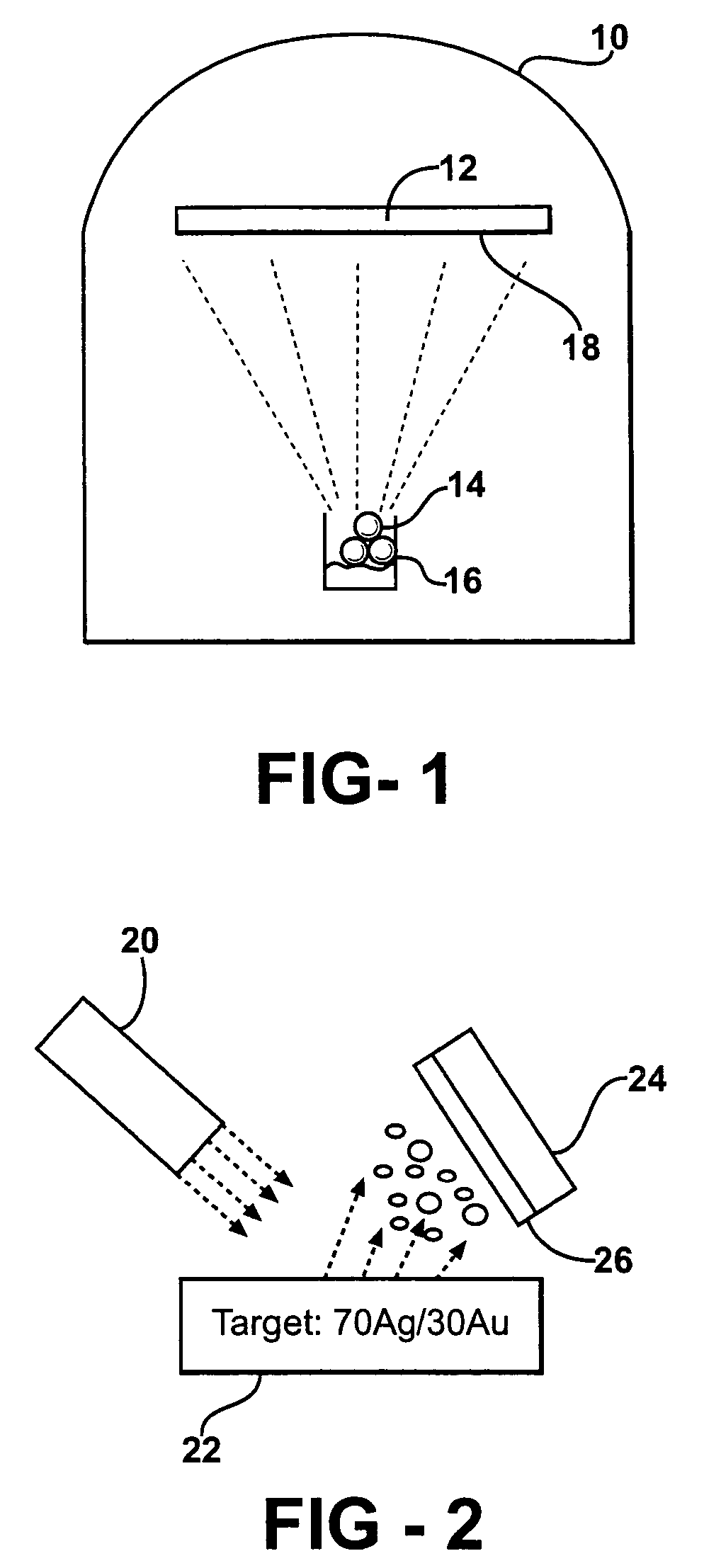

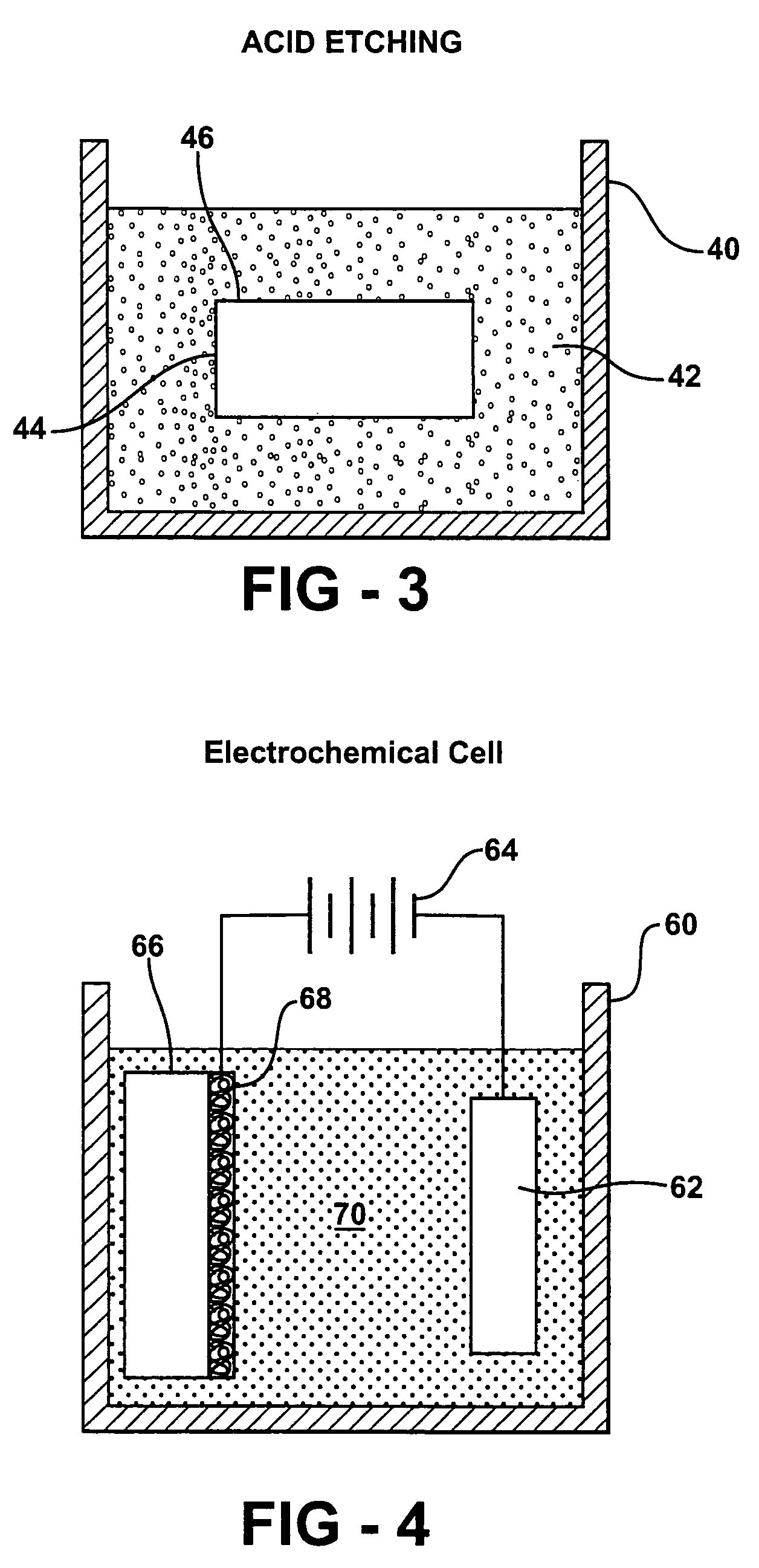

Surface enhanced Raman spectroscopy (SERS) substrates exhibiting uniform high enhancement and stability

PatentInactiveUS7450227B2

Innovation

- The development of porous metal substrates, specifically gold substrates created by depositing a gold-silver alloy film and removing the silver through acid etching or electrochemical roughening, resulting in a textured surface that enhances SERS signals uniformly and stably.

Nanofabrication Techniques for SERS Substrate Production

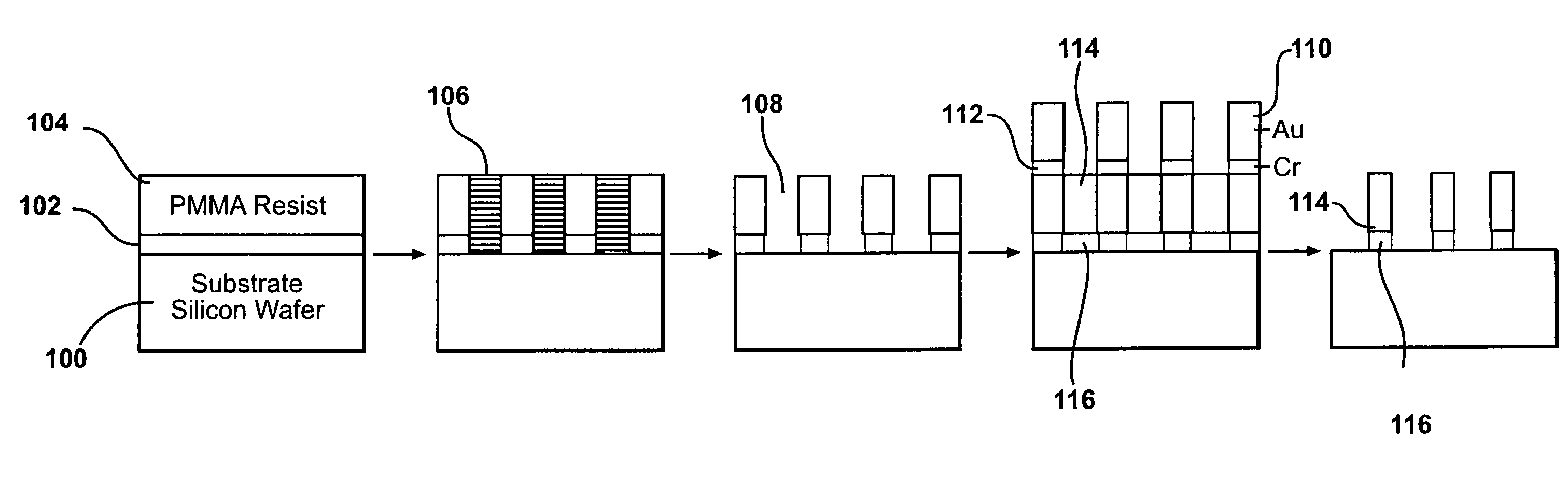

Nanofabrication techniques for SERS substrate production have evolved significantly over the past decade, with several methodologies emerging as industry standards. Electron beam lithography (EBL) represents one of the most precise approaches, enabling the creation of highly ordered nanostructures with controlled spacing and dimensions down to sub-10 nm resolution. This technique allows for exceptional control over surface area parameters, which directly correlates with SERS enhancement factors. However, EBL remains limited by its low throughput and high equipment costs, making it primarily suitable for research applications rather than mass production.

Focused ion beam (FIB) milling offers comparable precision to EBL but with the added capability of direct three-dimensional structuring. This technique has proven particularly valuable for creating hierarchical surface structures with multiple scales of roughness, significantly increasing the effective surface area available for molecular adsorption. The ability to precisely control the depth profile of nanostructures allows for optimization of electromagnetic field enhancement at specific wavelengths.

Nanosphere lithography has emerged as a cost-effective alternative that enables the production of large-area SERS substrates with triangular array patterns. By controlling the size of polystyrene spheres used as masks, researchers can tune the density and dimensions of resulting nanostructures, directly influencing the available surface area for analyte interaction. This technique bridges the gap between high-precision methods and scalable manufacturing processes.

Template-assisted methods, including anodic aluminum oxide (AAO) templates, have gained prominence for creating highly ordered arrays of nanopillars and nanoholes with exceptional uniformity across large areas. The aspect ratio and packing density of these structures can be precisely controlled, allowing for systematic studies of how surface area parameters affect SERS performance. These templates enable the creation of substrates with surface area enhancements exceeding 100-fold compared to planar surfaces.

Chemical synthesis approaches, particularly seed-mediated growth of nanoparticles, offer unparalleled versatility in creating complex morphologies with extremely high surface-to-volume ratios. Techniques such as galvanic replacement reactions can produce hollow nanostructures with both internal and external surfaces available for molecular interactions, dramatically increasing effective surface area. Recent advances in surfactant-directed synthesis have enabled the production of nanoflowers and nanostars with numerous sharp tips that serve as electromagnetic hotspots.

Advanced deposition techniques, including glancing angle deposition (GLAD) and oblique angle deposition (OAD), enable the creation of slanted columnar structures with controlled porosity. By manipulating deposition parameters, the surface area can be systematically varied while maintaining consistent chemical composition, making these techniques valuable for fundamental studies of surface area effects on SERS enhancement.

Focused ion beam (FIB) milling offers comparable precision to EBL but with the added capability of direct three-dimensional structuring. This technique has proven particularly valuable for creating hierarchical surface structures with multiple scales of roughness, significantly increasing the effective surface area available for molecular adsorption. The ability to precisely control the depth profile of nanostructures allows for optimization of electromagnetic field enhancement at specific wavelengths.

Nanosphere lithography has emerged as a cost-effective alternative that enables the production of large-area SERS substrates with triangular array patterns. By controlling the size of polystyrene spheres used as masks, researchers can tune the density and dimensions of resulting nanostructures, directly influencing the available surface area for analyte interaction. This technique bridges the gap between high-precision methods and scalable manufacturing processes.

Template-assisted methods, including anodic aluminum oxide (AAO) templates, have gained prominence for creating highly ordered arrays of nanopillars and nanoholes with exceptional uniformity across large areas. The aspect ratio and packing density of these structures can be precisely controlled, allowing for systematic studies of how surface area parameters affect SERS performance. These templates enable the creation of substrates with surface area enhancements exceeding 100-fold compared to planar surfaces.

Chemical synthesis approaches, particularly seed-mediated growth of nanoparticles, offer unparalleled versatility in creating complex morphologies with extremely high surface-to-volume ratios. Techniques such as galvanic replacement reactions can produce hollow nanostructures with both internal and external surfaces available for molecular interactions, dramatically increasing effective surface area. Recent advances in surfactant-directed synthesis have enabled the production of nanoflowers and nanostars with numerous sharp tips that serve as electromagnetic hotspots.

Advanced deposition techniques, including glancing angle deposition (GLAD) and oblique angle deposition (OAD), enable the creation of slanted columnar structures with controlled porosity. By manipulating deposition parameters, the surface area can be systematically varied while maintaining consistent chemical composition, making these techniques valuable for fundamental studies of surface area effects on SERS enhancement.

Environmental and Sample Matrix Effects on SERS Performance

The performance of Surface-Enhanced Raman Spectroscopy (SERS) substrates is significantly influenced by environmental conditions and sample matrix composition. These external factors can dramatically alter the effectiveness of SERS measurements, regardless of the substrate's inherent surface area characteristics. Understanding these interactions is crucial for developing robust analytical protocols and interpreting results accurately.

Temperature variations represent a primary environmental factor affecting SERS performance. Higher temperatures can induce thermal motion that disrupts the precise positioning of analytes on the substrate surface, potentially reducing enhancement factors. Conversely, extremely low temperatures may alter molecular adsorption kinetics, affecting the reproducibility of measurements. Studies have demonstrated that temperature fluctuations as small as 5°C can produce measurable differences in SERS intensity for certain substrate-analyte combinations.

Humidity levels similarly impact SERS substrate effectiveness by altering the surface chemistry of metallic nanostructures. Excessive moisture can lead to oxidation of silver-based substrates, diminishing their plasmonic properties over time. Additionally, water molecules can compete with analytes for adsorption sites, particularly in substrates with high surface area, thereby reducing detection sensitivity for target molecules.

The pH of the sample matrix represents another critical parameter influencing SERS measurements. Acidic or basic conditions can alter the surface charge of both the substrate and analyte molecules, affecting adsorption efficiency and orientation. This is particularly relevant for biomolecule detection, where protein conformation and nucleic acid structure are highly pH-dependent. Optimal SERS performance often requires careful pH adjustment to maximize analyte-substrate interactions while maintaining the integrity of the target molecules.

Ionic strength of the sample solution directly impacts the electrical double layer at the substrate surface, influencing the effective distance between analytes and plasmonic hotspots. High salt concentrations can shield electrostatic interactions, potentially preventing optimal positioning of charged analytes near high-enhancement regions. Conversely, extremely low ionic strength may lead to aggregation issues in colloidal SERS systems, creating challenges for reproducibility.

Organic solvents present in sample matrices can significantly alter SERS performance through multiple mechanisms. These include changing the solvation state of analytes, modifying surface tension at the substrate interface, and potentially dissolving or altering surface coatings on engineered SERS substrates. The compatibility between substrate surface chemistry and solvent properties must be carefully considered when developing SERS-based analytical methods.

Interfering compounds in complex matrices represent perhaps the most challenging aspect of real-world SERS applications. Biological samples, environmental specimens, and industrial mixtures often contain numerous components that can competitively bind to high surface area substrates, blocking access to enhancement sites or contributing confounding spectral features. Developing selective surface functionalization strategies has emerged as a promising approach to mitigate these matrix effects while maintaining the advantages of high surface area SERS substrates.

Temperature variations represent a primary environmental factor affecting SERS performance. Higher temperatures can induce thermal motion that disrupts the precise positioning of analytes on the substrate surface, potentially reducing enhancement factors. Conversely, extremely low temperatures may alter molecular adsorption kinetics, affecting the reproducibility of measurements. Studies have demonstrated that temperature fluctuations as small as 5°C can produce measurable differences in SERS intensity for certain substrate-analyte combinations.

Humidity levels similarly impact SERS substrate effectiveness by altering the surface chemistry of metallic nanostructures. Excessive moisture can lead to oxidation of silver-based substrates, diminishing their plasmonic properties over time. Additionally, water molecules can compete with analytes for adsorption sites, particularly in substrates with high surface area, thereby reducing detection sensitivity for target molecules.

The pH of the sample matrix represents another critical parameter influencing SERS measurements. Acidic or basic conditions can alter the surface charge of both the substrate and analyte molecules, affecting adsorption efficiency and orientation. This is particularly relevant for biomolecule detection, where protein conformation and nucleic acid structure are highly pH-dependent. Optimal SERS performance often requires careful pH adjustment to maximize analyte-substrate interactions while maintaining the integrity of the target molecules.

Ionic strength of the sample solution directly impacts the electrical double layer at the substrate surface, influencing the effective distance between analytes and plasmonic hotspots. High salt concentrations can shield electrostatic interactions, potentially preventing optimal positioning of charged analytes near high-enhancement regions. Conversely, extremely low ionic strength may lead to aggregation issues in colloidal SERS systems, creating challenges for reproducibility.

Organic solvents present in sample matrices can significantly alter SERS performance through multiple mechanisms. These include changing the solvation state of analytes, modifying surface tension at the substrate interface, and potentially dissolving or altering surface coatings on engineered SERS substrates. The compatibility between substrate surface chemistry and solvent properties must be carefully considered when developing SERS-based analytical methods.

Interfering compounds in complex matrices represent perhaps the most challenging aspect of real-world SERS applications. Biological samples, environmental specimens, and industrial mixtures often contain numerous components that can competitively bind to high surface area substrates, blocking access to enhancement sites or contributing confounding spectral features. Developing selective surface functionalization strategies has emerged as a promising approach to mitigate these matrix effects while maintaining the advantages of high surface area SERS substrates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!