SERS Substrates in EV Battery Electrolyte Development

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Technology Background and Objectives

Surface-Enhanced Raman Spectroscopy (SERS) has evolved significantly since its discovery in the 1970s, transitioning from a laboratory curiosity to a powerful analytical technique with diverse applications. The enhancement mechanism, primarily driven by electromagnetic and chemical effects, allows for detection sensitivities reaching single-molecule levels. This exceptional sensitivity has positioned SERS as a transformative tool across multiple scientific disciplines, including materials science, biochemistry, and energy storage research.

In the context of electric vehicle (EV) battery development, SERS offers unprecedented capabilities for real-time, in-situ monitoring of electrolyte composition and interfacial reactions. The technology enables researchers to observe molecular interactions at electrode-electrolyte interfaces with nanoscale precision, providing critical insights into degradation mechanisms and performance limitations that conventional analytical methods cannot capture.

The historical trajectory of SERS substrate development has seen remarkable innovation, progressing from rough metal surfaces to precisely engineered nanostructures. Early substrates suffered from reproducibility issues and limited enhancement factors. Modern fabrication techniques, including lithography, self-assembly, and template-assisted growth, have enabled the creation of substrates with controlled morphology, composition, and optical properties, dramatically improving performance consistency and signal enhancement.

Recent advances in SERS substrate design specifically for battery applications have focused on creating platforms resistant to the harsh chemical environment of battery electrolytes while maintaining high sensitivity. These developments include corrosion-resistant noble metal nanostructures, core-shell architectures, and composite materials that combine SERS activity with electrochemical functionality.

The primary objective of SERS technology in EV battery electrolyte development is to establish a reliable analytical platform for monitoring electrolyte composition, degradation products, and interfacial phenomena under operating conditions. This includes tracking the formation and evolution of the solid-electrolyte interphase (SEI), identifying decomposition products, and characterizing concentration gradients within the cell.

Secondary objectives include developing standardized SERS methodologies for battery research, creating reference spectral databases for common electrolyte components and their degradation products, and integrating SERS with complementary techniques such as electrochemical impedance spectroscopy for comprehensive battery diagnostics.

The ultimate technological goal is to transition from ex-situ analysis to operando SERS monitoring systems that can be integrated into battery testing protocols and potentially into battery management systems for advanced diagnostics. This would enable real-time quality control during manufacturing and early warning systems for battery health monitoring, significantly advancing both fundamental understanding and practical applications in EV battery technology.

In the context of electric vehicle (EV) battery development, SERS offers unprecedented capabilities for real-time, in-situ monitoring of electrolyte composition and interfacial reactions. The technology enables researchers to observe molecular interactions at electrode-electrolyte interfaces with nanoscale precision, providing critical insights into degradation mechanisms and performance limitations that conventional analytical methods cannot capture.

The historical trajectory of SERS substrate development has seen remarkable innovation, progressing from rough metal surfaces to precisely engineered nanostructures. Early substrates suffered from reproducibility issues and limited enhancement factors. Modern fabrication techniques, including lithography, self-assembly, and template-assisted growth, have enabled the creation of substrates with controlled morphology, composition, and optical properties, dramatically improving performance consistency and signal enhancement.

Recent advances in SERS substrate design specifically for battery applications have focused on creating platforms resistant to the harsh chemical environment of battery electrolytes while maintaining high sensitivity. These developments include corrosion-resistant noble metal nanostructures, core-shell architectures, and composite materials that combine SERS activity with electrochemical functionality.

The primary objective of SERS technology in EV battery electrolyte development is to establish a reliable analytical platform for monitoring electrolyte composition, degradation products, and interfacial phenomena under operating conditions. This includes tracking the formation and evolution of the solid-electrolyte interphase (SEI), identifying decomposition products, and characterizing concentration gradients within the cell.

Secondary objectives include developing standardized SERS methodologies for battery research, creating reference spectral databases for common electrolyte components and their degradation products, and integrating SERS with complementary techniques such as electrochemical impedance spectroscopy for comprehensive battery diagnostics.

The ultimate technological goal is to transition from ex-situ analysis to operando SERS monitoring systems that can be integrated into battery testing protocols and potentially into battery management systems for advanced diagnostics. This would enable real-time quality control during manufacturing and early warning systems for battery health monitoring, significantly advancing both fundamental understanding and practical applications in EV battery technology.

Market Analysis for SERS in Battery Applications

The global market for Surface-Enhanced Raman Spectroscopy (SERS) in battery applications is experiencing significant growth, driven by the increasing demand for advanced battery technologies in electric vehicles (EVs) and energy storage systems. The market size for SERS technology in battery applications was valued at approximately $320 million in 2022 and is projected to reach $780 million by 2028, representing a compound annual growth rate (CAGR) of 16.1%.

The EV battery market itself is expanding rapidly, with global sales expected to exceed $135 billion by 2027. Within this ecosystem, analytical technologies like SERS are gaining traction as essential tools for battery development and quality control. SERS substrates specifically designed for electrolyte analysis represent about 18% of the total SERS market, with this segment growing faster than the overall market at nearly 20% annually.

Regional analysis indicates that Asia-Pacific dominates the market with approximately 45% share, led by China, Japan, and South Korea where major battery manufacturers are concentrated. North America follows with 30% market share, while Europe accounts for 20%, with particularly strong growth in Germany and the Nordic countries due to their aggressive EV adoption policies.

The demand for SERS in battery applications is primarily driven by several factors. First, stringent safety regulations for EV batteries require more sophisticated analytical methods for electrolyte composition monitoring. Second, the push for higher energy density batteries necessitates advanced characterization techniques to understand electrolyte-electrode interactions at the molecular level. Third, the industry's focus on extending battery lifespan creates demand for technologies that can detect early signs of electrolyte degradation.

Market segmentation reveals that automotive OEMs and battery manufacturers constitute the largest customer segment (55%), followed by research institutions (25%) and material suppliers (15%). The remaining 5% includes testing laboratories and recycling facilities. This distribution highlights the technology's importance across the entire battery value chain.

Price sensitivity analysis indicates that while SERS substrates remain relatively expensive compared to conventional analytical methods, the cost-benefit ratio is increasingly favorable as manufacturing scales up and the technology matures. Current price points range from $50-200 per substrate depending on specificity and reusability features, with prices projected to decrease by 30-40% over the next five years as production volumes increase.

Customer adoption patterns show that early adopters have primarily been premium EV manufacturers and advanced research institutions, but the technology is now penetrating mid-market segments as costs decrease and awareness of benefits increases.

The EV battery market itself is expanding rapidly, with global sales expected to exceed $135 billion by 2027. Within this ecosystem, analytical technologies like SERS are gaining traction as essential tools for battery development and quality control. SERS substrates specifically designed for electrolyte analysis represent about 18% of the total SERS market, with this segment growing faster than the overall market at nearly 20% annually.

Regional analysis indicates that Asia-Pacific dominates the market with approximately 45% share, led by China, Japan, and South Korea where major battery manufacturers are concentrated. North America follows with 30% market share, while Europe accounts for 20%, with particularly strong growth in Germany and the Nordic countries due to their aggressive EV adoption policies.

The demand for SERS in battery applications is primarily driven by several factors. First, stringent safety regulations for EV batteries require more sophisticated analytical methods for electrolyte composition monitoring. Second, the push for higher energy density batteries necessitates advanced characterization techniques to understand electrolyte-electrode interactions at the molecular level. Third, the industry's focus on extending battery lifespan creates demand for technologies that can detect early signs of electrolyte degradation.

Market segmentation reveals that automotive OEMs and battery manufacturers constitute the largest customer segment (55%), followed by research institutions (25%) and material suppliers (15%). The remaining 5% includes testing laboratories and recycling facilities. This distribution highlights the technology's importance across the entire battery value chain.

Price sensitivity analysis indicates that while SERS substrates remain relatively expensive compared to conventional analytical methods, the cost-benefit ratio is increasingly favorable as manufacturing scales up and the technology matures. Current price points range from $50-200 per substrate depending on specificity and reusability features, with prices projected to decrease by 30-40% over the next five years as production volumes increase.

Customer adoption patterns show that early adopters have primarily been premium EV manufacturers and advanced research institutions, but the technology is now penetrating mid-market segments as costs decrease and awareness of benefits increases.

Current SERS Substrate Technologies and Limitations

Surface-Enhanced Raman Spectroscopy (SERS) substrates have emerged as critical analytical tools for monitoring electrolyte composition and degradation in electric vehicle batteries. Current SERS substrate technologies can be categorized into several major types, each with distinct advantages and limitations when applied to battery electrolyte analysis.

Metal nanoparticle-based substrates represent the most widely used SERS platform, typically employing gold or silver nanoparticles with controlled size distributions (20-100 nm). While these substrates offer excellent enhancement factors (10^6-10^8) and relatively straightforward synthesis protocols, they suffer from colloidal instability in complex electrolyte environments. The aggressive nature of battery electrolytes, containing high concentrations of lithium salts and organic solvents, often leads to nanoparticle aggregation and subsequent signal inconsistency.

Nanopatterned solid substrates, including nanopillar arrays, nanoholes, and nanogratings fabricated through lithographic techniques, provide more stable platforms with reproducible enhancement factors. These substrates demonstrate superior mechanical robustness and signal reproducibility compared to colloidal systems. However, their application in battery electrolyte analysis is hindered by limited active surface area and relatively high production costs, particularly for large-scale implementation in battery manufacturing environments.

Core-shell nanostructures, designed with protective outer layers surrounding plasmonic cores, offer improved chemical stability in harsh electrolyte environments. Despite this advantage, these structures often exhibit reduced enhancement factors compared to unprotected nanoparticles and face challenges in maintaining consistent shell thickness during synthesis.

Flexible SERS substrates, typically constructed on polymer backings, provide conformability to various battery cell geometries but demonstrate insufficient durability when exposed to organic carbonate solvents common in battery electrolytes. The polymer substrates tend to swell or dissolve upon prolonged contact with these solvents, compromising measurement reliability.

A significant limitation across all current SERS substrate technologies is their insufficient stability in the presence of common battery electrolyte components. Lithium hexafluorophosphate (LiPF6) and other fluorinated salts can cause corrosion of silver-based substrates, while organic carbonates may dissolve protective coatings. Additionally, most substrates lack specificity for detecting trace-level electrolyte decomposition products, which are critical indicators of battery health and aging.

Temperature sensitivity presents another challenge, as SERS measurements in operational battery environments (often exceeding 60°C) can lead to thermal degradation of the substrates and subsequent signal drift. This limitation restricts real-time monitoring capabilities during battery cycling under realistic conditions.

Metal nanoparticle-based substrates represent the most widely used SERS platform, typically employing gold or silver nanoparticles with controlled size distributions (20-100 nm). While these substrates offer excellent enhancement factors (10^6-10^8) and relatively straightforward synthesis protocols, they suffer from colloidal instability in complex electrolyte environments. The aggressive nature of battery electrolytes, containing high concentrations of lithium salts and organic solvents, often leads to nanoparticle aggregation and subsequent signal inconsistency.

Nanopatterned solid substrates, including nanopillar arrays, nanoholes, and nanogratings fabricated through lithographic techniques, provide more stable platforms with reproducible enhancement factors. These substrates demonstrate superior mechanical robustness and signal reproducibility compared to colloidal systems. However, their application in battery electrolyte analysis is hindered by limited active surface area and relatively high production costs, particularly for large-scale implementation in battery manufacturing environments.

Core-shell nanostructures, designed with protective outer layers surrounding plasmonic cores, offer improved chemical stability in harsh electrolyte environments. Despite this advantage, these structures often exhibit reduced enhancement factors compared to unprotected nanoparticles and face challenges in maintaining consistent shell thickness during synthesis.

Flexible SERS substrates, typically constructed on polymer backings, provide conformability to various battery cell geometries but demonstrate insufficient durability when exposed to organic carbonate solvents common in battery electrolytes. The polymer substrates tend to swell or dissolve upon prolonged contact with these solvents, compromising measurement reliability.

A significant limitation across all current SERS substrate technologies is their insufficient stability in the presence of common battery electrolyte components. Lithium hexafluorophosphate (LiPF6) and other fluorinated salts can cause corrosion of silver-based substrates, while organic carbonates may dissolve protective coatings. Additionally, most substrates lack specificity for detecting trace-level electrolyte decomposition products, which are critical indicators of battery health and aging.

Temperature sensitivity presents another challenge, as SERS measurements in operational battery environments (often exceeding 60°C) can lead to thermal degradation of the substrates and subsequent signal drift. This limitation restricts real-time monitoring capabilities during battery cycling under realistic conditions.

Existing SERS Substrate Solutions for Electrolyte Analysis

01 Metal nanostructure-based SERS substrates

Metal nanostructures, particularly those made of gold, silver, and copper, serve as effective SERS substrates due to their plasmonic properties. These substrates can be fabricated in various forms including nanoparticles, nanorods, and nanopatterned surfaces. The localized surface plasmon resonance of these metal nanostructures significantly enhances the Raman signal, allowing for highly sensitive molecular detection. The enhancement factor can reach several orders of magnitude, making these substrates suitable for trace analysis applications.- Metal nanostructure-based SERS substrates: Metal nanostructures, particularly those made of gold, silver, and copper, serve as effective SERS substrates due to their plasmonic properties. These substrates can be fabricated in various forms including nanoparticles, nanorods, and nanopatterned surfaces. The localized surface plasmon resonance generated by these metal nanostructures significantly enhances the Raman signal, allowing for highly sensitive molecular detection. The enhancement factor can reach several orders of magnitude, making these substrates suitable for trace analysis applications.

- Semiconductor-based SERS substrates: Semiconductor materials can be used as SERS substrates, offering advantages such as stability and tunable optical properties. These substrates often incorporate materials like silicon, titanium dioxide, or zinc oxide, sometimes in combination with metal nanoparticles to create hybrid structures. Semiconductor-based SERS substrates can provide controlled enhancement of Raman signals through charge-transfer mechanisms in addition to electromagnetic enhancement, making them suitable for specific analytical applications where traditional metal substrates may be limited.

- Flexible and portable SERS substrates: Flexible SERS substrates are designed for portable and field-deployable Raman spectroscopy applications. These substrates are typically fabricated on polymer or paper-based materials with deposited metal nanostructures. Their flexibility allows them to conform to various sample surfaces, enhancing contact and signal collection. These substrates enable point-of-care diagnostics, environmental monitoring, and food safety applications where traditional laboratory equipment is not available. The development of these substrates focuses on maintaining high enhancement factors while providing mechanical durability and ease of use.

- Fabrication methods for SERS substrates: Various fabrication techniques are employed to create SERS substrates with optimized performance. These methods include lithography, self-assembly, template-assisted growth, and chemical synthesis approaches. Advanced fabrication techniques allow for precise control over nanostructure size, shape, spacing, and arrangement, which are critical parameters affecting SERS enhancement. Some methods focus on creating large-area, uniform substrates suitable for commercial applications, while others aim to produce highly specialized substrates with extreme sensitivity for specific target molecules.

- SERS substrate applications and detection systems: SERS substrates are integrated into various detection systems for applications in biomedical diagnostics, environmental monitoring, food safety, and security screening. These systems often combine the SERS substrate with microfluidics, optical components, and data processing algorithms to create complete analytical platforms. Some applications focus on multiplexed detection of multiple analytes simultaneously, while others aim for ultra-sensitive detection of specific biomarkers or contaminants. Recent developments include smartphone-compatible SERS platforms and automated systems for high-throughput analysis.

02 Semiconductor-based SERS substrates

Semiconductor materials can be used as SERS substrates, offering advantages such as stability and tunable optical properties. These substrates often incorporate materials like silicon, titanium dioxide, or zinc oxide, sometimes in combination with metal nanoparticles for enhanced performance. Semiconductor-based SERS substrates can provide controlled enhancement of Raman signals through charge-transfer mechanisms in addition to electromagnetic enhancement. These materials are particularly useful for applications requiring specific wavelength sensitivity or resistance to harsh environmental conditions.Expand Specific Solutions03 Flexible and portable SERS substrates

Flexible SERS substrates are designed for portable and field-deployable Raman spectroscopy applications. These substrates are typically fabricated on polymer or paper-based materials with deposited metal nanostructures. The flexibility allows for conforming to irregular surfaces while maintaining SERS enhancement capabilities. These substrates enable on-site detection in various environments without requiring sophisticated laboratory equipment, making them valuable for environmental monitoring, food safety testing, and point-of-care diagnostics.Expand Specific Solutions04 Fabrication methods for SERS substrates

Various fabrication techniques are employed to create SERS substrates with optimized enhancement properties. These methods include lithography, chemical synthesis, self-assembly, electrochemical deposition, and laser ablation. Advanced fabrication approaches focus on creating reproducible hot spots with consistent enhancement factors across the substrate surface. The manufacturing processes aim to control the size, shape, spacing, and arrangement of nanostructures to maximize SERS enhancement while ensuring batch-to-batch consistency for reliable analytical applications.Expand Specific Solutions05 Functionalized SERS substrates for specific detection

Functionalized SERS substrates incorporate specific recognition elements to target particular analytes of interest. These substrates are modified with molecules such as antibodies, aptamers, or molecularly imprinted polymers that can selectively bind to target compounds. The functionalization enhances both selectivity and sensitivity of detection in complex sample matrices. These specialized SERS substrates find applications in biosensing, environmental monitoring, food safety, and medical diagnostics where specific detection of biomarkers, pathogens, or contaminants is required.Expand Specific Solutions

Leading Companies in SERS and Battery Electrolyte Research

The SERS substrates market for EV battery electrolyte development is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The market size remains relatively modest but is expanding as battery manufacturers seek advanced analytical tools for electrolyte optimization. From a technological maturity perspective, the field shows a diverse competitive landscape with academic institutions (Tsinghua University, Cornell University, Harvard) driving fundamental research while established industrial players (Corning, Panasonic, Samsung Electro-Mechanics) focus on practical applications. Chinese research institutions (Shanghai Institute of Ceramics, SINANO) are particularly active, suggesting regional strength. Battery specialists (Celgard, Rivian, Solid Energies) are increasingly exploring SERS technology to enhance electrolyte performance and safety in next-generation EV batteries.

Corning, Inc.

Technical Solution: Corning has developed specialized SERS substrates utilizing their expertise in glass and ceramic materials for EV battery electrolyte analysis. Their proprietary technology incorporates nanopatterned metallic structures (primarily silver and gold) on glass substrates with precisely controlled geometries to create consistent "hot spots" for enhanced Raman signal detection. These substrates feature a unique protective coating that maintains stability when exposed to aggressive battery electrolytes while preserving SERS enhancement factors of 10^6-10^8. Corning's manufacturing process leverages their established large-scale production capabilities to create uniform SERS substrates with batch-to-batch reproducibility exceeding 95%, enabling reliable in-situ monitoring of electrolyte decomposition products and interfacial reactions at electrode surfaces during battery cycling.

Strengths: Superior manufacturing consistency and scalability; excellent chemical stability in harsh electrolyte environments; established supply chain and quality control systems. Weaknesses: Higher production costs compared to academic solutions; potentially limited flexibility for customization to specific battery chemistries.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has developed an integrated SERS substrate system specifically for EV battery electrolyte analysis. Their approach combines nanostructured noble metal surfaces (primarily gold and silver) with specialized microfluidic channels that enable real-time monitoring of electrolyte composition during battery operation. The system incorporates temperature control elements (operating from -20°C to 80°C) to simulate various battery conditions and utilizes proprietary surface treatments to enhance durability in contact with aggressive electrolyte components. Panasonic's SERS substrates achieve enhancement factors of approximately 10^7, allowing detection of trace contaminants and decomposition products at concentrations below 10 ppm. The technology has been integrated into their battery manufacturing quality control processes, enabling early detection of electrolyte degradation issues and facilitating the development of more stable formulations for next-generation EV batteries.

Strengths: Seamless integration with existing battery production and testing infrastructure; comprehensive temperature control capabilities; proven application in commercial battery development. Weaknesses: Closed proprietary system with limited compatibility with non-Panasonic battery technologies; higher implementation costs compared to standalone SERS solutions.

Key SERS Enhancement Mechanisms for Battery Electrolytes

Surface enhanced raman spectroscopy (SERS) substrates exhibiting uniform high enhancement and stability

PatentWO2006137885A8

Innovation

- The development of porous metal substrates, such as gold-silver alloy films that are acid-etched or electrochemically roughened, providing uniform and high enhancement factors for SERS, with methods like sputter deposition and electrochemical roughening to enhance substrate properties.

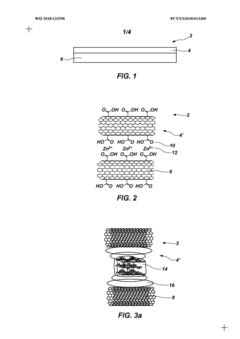

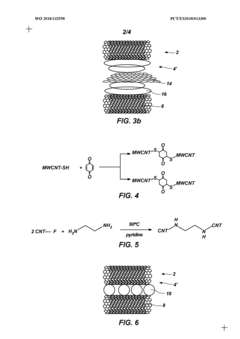

Thin film substrates including crosslinked carbon nanostructures and related methods

PatentWO2018132558A1

Innovation

- Crosslinking carbon nanostructures using multivalent cations, pi-orbital source compounds, covalent bonding, or electrostatic interactions to form stable thin film substrates that can be used without a support substrate, enhancing mechanical integrity and preventing swelling when exposed to liquids.

Safety and Environmental Considerations in SERS-Based Analysis

The integration of SERS technology in EV battery electrolyte development necessitates careful consideration of safety and environmental factors. Laboratory analysis of battery electrolytes using SERS substrates involves handling potentially hazardous materials, including organic solvents, lithium salts, and additives that may be flammable, toxic, or corrosive. Proper safety protocols must be established, including appropriate personal protective equipment, ventilation systems, and emergency response procedures to mitigate risks associated with chemical exposure.

SERS substrate materials themselves present specific safety considerations. Nanostructured noble metals like gold and silver, while generally considered biologically inert in bulk form, may exhibit unique toxicological properties at the nanoscale. Recent studies indicate potential cytotoxicity of metal nanoparticles depending on size, shape, and surface chemistry. Researchers must implement proper handling and disposal procedures to prevent environmental contamination and occupational exposure.

Environmental sustainability represents another critical dimension in SERS-based electrolyte analysis. The fabrication of high-performance SERS substrates often involves energy-intensive processes and hazardous chemicals such as strong acids, reducing agents, and metal precursors. Life cycle assessment (LCA) studies suggest that the environmental footprint of nanomaterial production can be substantial, necessitating the development of greener synthesis routes and recycling protocols for precious metals used in substrates.

Waste management presents particular challenges in SERS-based electrolyte analysis. Used substrates may contain residual battery electrolyte components, including fluorinated compounds and lithium salts that require specialized disposal methods. The environmental persistence of certain electrolyte components, particularly fluorinated species, raises concerns about potential long-term ecological impacts if improperly managed.

Regulatory compliance frameworks for nanomaterial-based analytical technologies continue to evolve globally. Organizations implementing SERS-based electrolyte analysis must navigate complex regulatory landscapes spanning chemical safety, nanomaterial handling, and electronic waste management. Proactive engagement with regulatory developments can help ensure compliance while supporting responsible innovation.

Emerging green chemistry approaches offer promising pathways to enhance the sustainability of SERS-based electrolyte analysis. These include the development of biodegradable substrate materials, solvent-free fabrication methods, and regeneration protocols that extend substrate lifetime. Additionally, miniaturization of analytical systems through microfluidic integration can significantly reduce reagent consumption and waste generation while maintaining analytical performance.

SERS substrate materials themselves present specific safety considerations. Nanostructured noble metals like gold and silver, while generally considered biologically inert in bulk form, may exhibit unique toxicological properties at the nanoscale. Recent studies indicate potential cytotoxicity of metal nanoparticles depending on size, shape, and surface chemistry. Researchers must implement proper handling and disposal procedures to prevent environmental contamination and occupational exposure.

Environmental sustainability represents another critical dimension in SERS-based electrolyte analysis. The fabrication of high-performance SERS substrates often involves energy-intensive processes and hazardous chemicals such as strong acids, reducing agents, and metal precursors. Life cycle assessment (LCA) studies suggest that the environmental footprint of nanomaterial production can be substantial, necessitating the development of greener synthesis routes and recycling protocols for precious metals used in substrates.

Waste management presents particular challenges in SERS-based electrolyte analysis. Used substrates may contain residual battery electrolyte components, including fluorinated compounds and lithium salts that require specialized disposal methods. The environmental persistence of certain electrolyte components, particularly fluorinated species, raises concerns about potential long-term ecological impacts if improperly managed.

Regulatory compliance frameworks for nanomaterial-based analytical technologies continue to evolve globally. Organizations implementing SERS-based electrolyte analysis must navigate complex regulatory landscapes spanning chemical safety, nanomaterial handling, and electronic waste management. Proactive engagement with regulatory developments can help ensure compliance while supporting responsible innovation.

Emerging green chemistry approaches offer promising pathways to enhance the sustainability of SERS-based electrolyte analysis. These include the development of biodegradable substrate materials, solvent-free fabrication methods, and regeneration protocols that extend substrate lifetime. Additionally, miniaturization of analytical systems through microfluidic integration can significantly reduce reagent consumption and waste generation while maintaining analytical performance.

Scalability and Manufacturing Challenges for SERS Substrates

The scaling of SERS substrates from laboratory to industrial production represents a significant challenge in their application for EV battery electrolyte development. Current manufacturing processes for high-quality SERS substrates typically involve sophisticated nanofabrication techniques such as electron-beam lithography, focused ion beam milling, and nanosphere lithography. These methods, while producing excellent results in controlled laboratory environments, face substantial barriers when considered for mass production scenarios.

One primary challenge is the precision required at the nanoscale. SERS substrates demand consistent nanogap structures with dimensions of 10-100 nm to generate reliable enhancement factors. Maintaining this precision across large-scale production batches requires advanced process control systems and specialized equipment that may not be readily available or economically viable for many manufacturers.

Cost considerations further complicate scalability. The materials used in high-performance SERS substrates often include noble metals like gold and silver, which contribute significantly to production expenses. Additionally, the complex fabrication processes involve multiple steps, specialized equipment, and highly trained personnel, all adding to the overall cost structure. These factors create substantial barriers to entry for commercial-scale production.

Reproducibility presents another critical challenge. The enhancement factor of SERS substrates is highly sensitive to minor variations in surface morphology and nanostructure arrangement. Achieving consistent performance across thousands or millions of substrates requires stringent quality control measures that are difficult to implement in high-throughput manufacturing environments.

Environmental and safety concerns also impact manufacturing scalability. Some fabrication processes involve hazardous chemicals or generate waste products that require specialized handling and disposal procedures. These considerations add complexity to facility design and operational protocols, potentially limiting production capacity.

Recent innovations are beginning to address these challenges. Roll-to-roll nanoimprint lithography shows promise for continuous production of SERS substrates with reasonable consistency. Self-assembly techniques utilizing block copolymers or DNA origami as templates offer alternative approaches that may reduce dependence on expensive equipment while maintaining acceptable performance characteristics.

Collaborative efforts between academic institutions and industry partners are exploring hybrid manufacturing approaches that combine the precision of traditional methods with the throughput capabilities of emerging technologies. These developments suggest potential pathways toward economically viable mass production of SERS substrates for battery electrolyte analysis applications, though significant technical hurdles remain to be overcome before widespread industrial adoption becomes feasible.

One primary challenge is the precision required at the nanoscale. SERS substrates demand consistent nanogap structures with dimensions of 10-100 nm to generate reliable enhancement factors. Maintaining this precision across large-scale production batches requires advanced process control systems and specialized equipment that may not be readily available or economically viable for many manufacturers.

Cost considerations further complicate scalability. The materials used in high-performance SERS substrates often include noble metals like gold and silver, which contribute significantly to production expenses. Additionally, the complex fabrication processes involve multiple steps, specialized equipment, and highly trained personnel, all adding to the overall cost structure. These factors create substantial barriers to entry for commercial-scale production.

Reproducibility presents another critical challenge. The enhancement factor of SERS substrates is highly sensitive to minor variations in surface morphology and nanostructure arrangement. Achieving consistent performance across thousands or millions of substrates requires stringent quality control measures that are difficult to implement in high-throughput manufacturing environments.

Environmental and safety concerns also impact manufacturing scalability. Some fabrication processes involve hazardous chemicals or generate waste products that require specialized handling and disposal procedures. These considerations add complexity to facility design and operational protocols, potentially limiting production capacity.

Recent innovations are beginning to address these challenges. Roll-to-roll nanoimprint lithography shows promise for continuous production of SERS substrates with reasonable consistency. Self-assembly techniques utilizing block copolymers or DNA origami as templates offer alternative approaches that may reduce dependence on expensive equipment while maintaining acceptable performance characteristics.

Collaborative efforts between academic institutions and industry partners are exploring hybrid manufacturing approaches that combine the precision of traditional methods with the throughput capabilities of emerging technologies. These developments suggest potential pathways toward economically viable mass production of SERS substrates for battery electrolyte analysis applications, though significant technical hurdles remain to be overcome before widespread industrial adoption becomes feasible.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!