Analysis of Superhydrophobic Coating in Construction Material Innovation

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superhydrophobic Coating Technology Background and Objectives

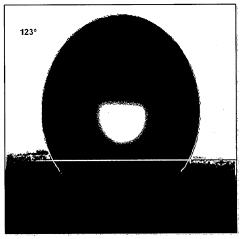

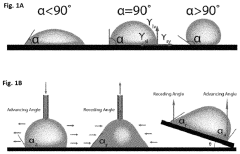

Superhydrophobic coatings represent a revolutionary advancement in materials science, drawing inspiration from nature's own water-repellent surfaces such as lotus leaves and butterfly wings. These coatings, characterized by water contact angles exceeding 150° and sliding angles below 10°, have evolved significantly since the early 2000s when researchers first began developing synthetic versions of these naturally occurring phenomena.

The technological evolution of superhydrophobic coatings has progressed through several distinct phases. Initial developments focused primarily on understanding the fundamental principles of superhydrophobicity, particularly the combination of micro/nano-scale surface roughness and low surface energy materials. By 2010, researchers had established reliable methods for creating these surfaces in laboratory settings, though durability remained a significant challenge.

Recent advancements have shifted toward addressing practical limitations, with particular emphasis on improving mechanical durability, chemical stability, and cost-effective manufacturing processes. The construction industry has emerged as a promising application field due to the potential for these coatings to address persistent challenges in building materials performance and maintenance.

The primary technical objectives for superhydrophobic coatings in construction applications include developing formulations that maintain their water-repellent properties for extended periods (10+ years) under harsh environmental conditions, creating application methods compatible with diverse construction materials (concrete, wood, metal, glass), and ensuring compliance with increasingly stringent environmental regulations regarding volatile organic compounds (VOCs) and other potentially harmful substances.

Current research is particularly focused on overcoming the inherent trade-off between superhydrophobicity and mechanical durability. Novel approaches include the incorporation of self-healing mechanisms, the development of hierarchical surface structures that can withstand abrasion while maintaining water repellency, and the creation of environmentally friendly formulations that eliminate fluorinated compounds traditionally used to achieve low surface energy.

The trajectory of superhydrophobic coating technology suggests continued rapid advancement, with increasing emphasis on multifunctional properties beyond water repellency, including anti-icing, self-cleaning, anti-corrosion, and even antimicrobial capabilities. These developments align with broader industry trends toward sustainable, high-performance building materials that reduce maintenance requirements and extend infrastructure lifespan.

As climate change intensifies weather extremes and urbanization accelerates, the demand for construction materials with enhanced protective properties is expected to grow substantially, positioning superhydrophobic coating technology as a critical innovation area with significant potential for transforming building practices and performance standards in the coming decade.

The technological evolution of superhydrophobic coatings has progressed through several distinct phases. Initial developments focused primarily on understanding the fundamental principles of superhydrophobicity, particularly the combination of micro/nano-scale surface roughness and low surface energy materials. By 2010, researchers had established reliable methods for creating these surfaces in laboratory settings, though durability remained a significant challenge.

Recent advancements have shifted toward addressing practical limitations, with particular emphasis on improving mechanical durability, chemical stability, and cost-effective manufacturing processes. The construction industry has emerged as a promising application field due to the potential for these coatings to address persistent challenges in building materials performance and maintenance.

The primary technical objectives for superhydrophobic coatings in construction applications include developing formulations that maintain their water-repellent properties for extended periods (10+ years) under harsh environmental conditions, creating application methods compatible with diverse construction materials (concrete, wood, metal, glass), and ensuring compliance with increasingly stringent environmental regulations regarding volatile organic compounds (VOCs) and other potentially harmful substances.

Current research is particularly focused on overcoming the inherent trade-off between superhydrophobicity and mechanical durability. Novel approaches include the incorporation of self-healing mechanisms, the development of hierarchical surface structures that can withstand abrasion while maintaining water repellency, and the creation of environmentally friendly formulations that eliminate fluorinated compounds traditionally used to achieve low surface energy.

The trajectory of superhydrophobic coating technology suggests continued rapid advancement, with increasing emphasis on multifunctional properties beyond water repellency, including anti-icing, self-cleaning, anti-corrosion, and even antimicrobial capabilities. These developments align with broader industry trends toward sustainable, high-performance building materials that reduce maintenance requirements and extend infrastructure lifespan.

As climate change intensifies weather extremes and urbanization accelerates, the demand for construction materials with enhanced protective properties is expected to grow substantially, positioning superhydrophobic coating technology as a critical innovation area with significant potential for transforming building practices and performance standards in the coming decade.

Construction Market Demand for Water-Repellent Materials

The global construction industry has witnessed a significant shift towards innovative materials that enhance building durability and reduce maintenance costs. Water-repellent materials, particularly superhydrophobic coatings, have emerged as a critical solution addressing these needs. The current market size for water-repellent construction materials is estimated at $7.5 billion globally, with projections indicating growth to reach $12.3 billion by 2028, representing a compound annual growth rate of 8.7%.

This robust market demand is primarily driven by increasing urbanization and infrastructure development in emerging economies. Countries like China, India, and Brazil are experiencing unprecedented construction booms, creating substantial demand for advanced building materials that can withstand harsh environmental conditions while reducing long-term maintenance expenses. In developed regions such as North America and Europe, the focus has shifted towards retrofitting existing structures with water-repellent solutions to extend building lifespans.

Climate change has become a significant market driver, with extreme weather events becoming more frequent and severe. Construction companies and property developers increasingly seek materials that can protect buildings against heavy rainfall, flooding, and moisture-related damage. This has expanded the application scope of superhydrophobic coatings beyond traditional exterior facades to include foundations, roofing systems, and interior surfaces in moisture-prone areas.

The commercial building sector represents the largest market segment for water-repellent materials, accounting for approximately 42% of total demand. This is followed by residential construction at 35% and infrastructure projects at 23%. Within these segments, concrete protection applications dominate, followed by metal surface treatments and wood preservation solutions.

Regional analysis reveals that Asia-Pacific currently leads the market with a 38% share, followed by North America (27%) and Europe (24%). However, the fastest growth is expected in the Middle East and Africa, where construction activities are accelerating alongside growing awareness of building sustainability and durability requirements.

Customer requirements have evolved significantly, with buyers now demanding multifunctional water-repellent materials that offer additional benefits beyond water resistance. These include enhanced UV protection, thermal insulation properties, self-cleaning capabilities, and environmental sustainability. The latter has become particularly important as regulatory frameworks increasingly favor green building materials with minimal environmental impact.

Price sensitivity varies across market segments, with high-end commercial projects willing to invest in premium superhydrophobic solutions, while the mass residential market remains more cost-conscious. This has created distinct market tiers, with manufacturers developing product lines at different price points to address various customer segments.

This robust market demand is primarily driven by increasing urbanization and infrastructure development in emerging economies. Countries like China, India, and Brazil are experiencing unprecedented construction booms, creating substantial demand for advanced building materials that can withstand harsh environmental conditions while reducing long-term maintenance expenses. In developed regions such as North America and Europe, the focus has shifted towards retrofitting existing structures with water-repellent solutions to extend building lifespans.

Climate change has become a significant market driver, with extreme weather events becoming more frequent and severe. Construction companies and property developers increasingly seek materials that can protect buildings against heavy rainfall, flooding, and moisture-related damage. This has expanded the application scope of superhydrophobic coatings beyond traditional exterior facades to include foundations, roofing systems, and interior surfaces in moisture-prone areas.

The commercial building sector represents the largest market segment for water-repellent materials, accounting for approximately 42% of total demand. This is followed by residential construction at 35% and infrastructure projects at 23%. Within these segments, concrete protection applications dominate, followed by metal surface treatments and wood preservation solutions.

Regional analysis reveals that Asia-Pacific currently leads the market with a 38% share, followed by North America (27%) and Europe (24%). However, the fastest growth is expected in the Middle East and Africa, where construction activities are accelerating alongside growing awareness of building sustainability and durability requirements.

Customer requirements have evolved significantly, with buyers now demanding multifunctional water-repellent materials that offer additional benefits beyond water resistance. These include enhanced UV protection, thermal insulation properties, self-cleaning capabilities, and environmental sustainability. The latter has become particularly important as regulatory frameworks increasingly favor green building materials with minimal environmental impact.

Price sensitivity varies across market segments, with high-end commercial projects willing to invest in premium superhydrophobic solutions, while the mass residential market remains more cost-conscious. This has created distinct market tiers, with manufacturers developing product lines at different price points to address various customer segments.

Current Status and Challenges in Superhydrophobic Technology

Superhydrophobic coating technology has witnessed significant advancements globally, with research institutions and companies across North America, Europe, and Asia making substantial contributions. In the United States, institutions like MIT and Harvard have pioneered fundamental research on biomimetic superhydrophobic surfaces, while European research centers in Germany and Switzerland have focused on durability improvements. Asian countries, particularly China and Japan, have made remarkable progress in cost-effective manufacturing techniques and industrial applications.

Despite these advancements, several critical challenges persist in superhydrophobic coating technology for construction materials. Durability remains the foremost concern, as most superhydrophobic coatings deteriorate under mechanical abrasion, UV exposure, and chemical attack. Field tests indicate that many commercial coatings lose their water-repellent properties within 6-12 months of outdoor exposure, significantly limiting their practical application in construction.

Cost-effectiveness presents another major hurdle. Current manufacturing processes for high-performance superhydrophobic coatings involve complex multi-step procedures and often require expensive materials like fluorinated compounds or specialized nanoparticles. This translates to prohibitive costs for large-scale construction applications, with premium coatings priced at $50-200 per square meter, restricting their use to high-value architectural projects.

Scalability challenges further complicate widespread adoption. Laboratory-scale production methods that yield excellent superhydrophobic properties often face significant difficulties when scaled to industrial levels. Maintaining consistent nano/micro-scale surface structures across large areas remains technically challenging, resulting in performance variations that undermine reliability in construction applications.

Environmental concerns have also emerged as a significant constraint. Many effective superhydrophobic formulations contain fluorinated compounds that pose potential environmental and health risks. Regulatory frameworks in Europe and North America are increasingly restricting these substances, necessitating alternative approaches that maintain performance while meeting sustainability requirements.

Standardization issues further impede market development. The construction industry lacks unified testing protocols and performance standards for superhydrophobic coatings, making it difficult for stakeholders to compare products or establish minimum performance requirements. This regulatory gap creates market uncertainty and slows adoption rates among conservative construction professionals.

Integration with existing construction practices represents another obstacle. Many superhydrophobic coatings require specialized application techniques or surface preparation that may not align with conventional construction methods. This compatibility gap necessitates either adaptation of the coating technology or modification of established construction processes, both presenting significant implementation barriers.

Despite these advancements, several critical challenges persist in superhydrophobic coating technology for construction materials. Durability remains the foremost concern, as most superhydrophobic coatings deteriorate under mechanical abrasion, UV exposure, and chemical attack. Field tests indicate that many commercial coatings lose their water-repellent properties within 6-12 months of outdoor exposure, significantly limiting their practical application in construction.

Cost-effectiveness presents another major hurdle. Current manufacturing processes for high-performance superhydrophobic coatings involve complex multi-step procedures and often require expensive materials like fluorinated compounds or specialized nanoparticles. This translates to prohibitive costs for large-scale construction applications, with premium coatings priced at $50-200 per square meter, restricting their use to high-value architectural projects.

Scalability challenges further complicate widespread adoption. Laboratory-scale production methods that yield excellent superhydrophobic properties often face significant difficulties when scaled to industrial levels. Maintaining consistent nano/micro-scale surface structures across large areas remains technically challenging, resulting in performance variations that undermine reliability in construction applications.

Environmental concerns have also emerged as a significant constraint. Many effective superhydrophobic formulations contain fluorinated compounds that pose potential environmental and health risks. Regulatory frameworks in Europe and North America are increasingly restricting these substances, necessitating alternative approaches that maintain performance while meeting sustainability requirements.

Standardization issues further impede market development. The construction industry lacks unified testing protocols and performance standards for superhydrophobic coatings, making it difficult for stakeholders to compare products or establish minimum performance requirements. This regulatory gap creates market uncertainty and slows adoption rates among conservative construction professionals.

Integration with existing construction practices represents another obstacle. Many superhydrophobic coatings require specialized application techniques or surface preparation that may not align with conventional construction methods. This compatibility gap necessitates either adaptation of the coating technology or modification of established construction processes, both presenting significant implementation barriers.

Current Superhydrophobic Solutions for Construction Materials

01 Nanoparticle-based superhydrophobic coatings

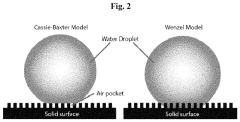

Superhydrophobic coatings can be formulated using nanoparticles such as silica, titanium dioxide, or carbon-based materials to create nano-scale roughness on surfaces. These nanoparticles, when combined with hydrophobic binders or polymers, create a hierarchical surface structure that traps air and prevents water from penetrating, resulting in water contact angles greater than 150 degrees. The nano-scale roughness combined with low surface energy materials is essential for achieving superhydrophobic properties.- Nanoparticle-based superhydrophobic coatings: Superhydrophobic coatings can be formulated using various nanoparticles to create nano-scale roughness on surfaces. These nanoparticles, such as silica, titanium dioxide, or carbon-based materials, are incorporated into polymer matrices to create hierarchical structures that trap air and repel water. The combination of nano-roughness and low surface energy materials results in water contact angles exceeding 150 degrees, achieving superhydrophobicity. These coatings offer excellent water repellency, self-cleaning properties, and can be applied to various substrates.

- Fluoropolymer-based superhydrophobic coatings: Fluoropolymers are widely used in superhydrophobic coating formulations due to their inherently low surface energy. These polymers, including polytetrafluoroethylene (PTFE) and fluorosilanes, create surfaces with minimal attraction to water molecules. When combined with surface roughening techniques, fluoropolymer coatings achieve extreme water repellency. These coatings provide durability, chemical resistance, and maintain their superhydrophobic properties over extended periods, making them suitable for industrial applications requiring long-term water repellency.

- Biomimetic superhydrophobic coatings: Inspired by natural superhydrophobic surfaces like lotus leaves and butterfly wings, biomimetic coatings replicate the micro and nano-scale structures found in nature. These coatings typically involve creating hierarchical surface patterns through techniques such as etching, lithography, or template-assisted fabrication. By mimicking natural designs, these coatings achieve exceptional water repellency while often incorporating additional functionalities such as self-cleaning, anti-icing, or anti-fouling properties. The biomimetic approach offers sustainable and efficient solutions for superhydrophobic surface development.

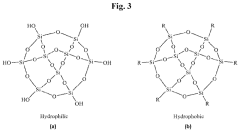

- Sol-gel derived superhydrophobic coatings: Sol-gel processing is a versatile method for creating superhydrophobic coatings through controlled hydrolysis and condensation reactions. This approach allows for the synthesis of silica-based or metal oxide networks with precisely engineered surface roughness. By incorporating hydrophobic modifiers like alkylsilanes during the sol-gel process, the resulting coatings exhibit both the required surface roughness and low surface energy. These coatings offer advantages including optical transparency, thermal stability, and the ability to be applied to complex geometries through dip, spray, or spin coating techniques.

- Durable and self-healing superhydrophobic coatings: Advanced superhydrophobic coatings incorporate durability and self-healing capabilities to overcome the challenge of mechanical damage. These coatings utilize strategies such as multi-layer architectures, embedded hydrophobic agents that can migrate to the surface, or stimuli-responsive materials that restore surface properties after damage. Some formulations include sacrificial components that protect the underlying superhydrophobic structure or incorporate microcapsules containing healing agents. These innovations extend coating lifespan and maintain water-repellent properties under harsh conditions, making them suitable for demanding applications in outdoor environments.

02 Fluoropolymer-based superhydrophobic coatings

Fluoropolymers and fluorinated compounds are widely used in superhydrophobic coating formulations due to their inherently low surface energy. These materials, such as polytetrafluoroethylene (PTFE) or fluorosilanes, when combined with appropriate surface structuring techniques, create durable water-repellent surfaces. The fluorine-containing compounds provide chemical stability and resistance to oils and other contaminants, making these coatings suitable for harsh environments and applications requiring long-term hydrophobicity.Expand Specific Solutions03 Environmentally friendly superhydrophobic coatings

Recent developments in superhydrophobic coatings focus on environmentally friendly formulations that avoid harmful fluorinated compounds. These green alternatives utilize natural hydrophobic materials such as plant waxes, modified cellulose, or silicone-based compounds combined with structured surfaces to achieve superhydrophobicity. These coatings are biodegradable or have reduced environmental impact while maintaining high water contact angles and self-cleaning properties.Expand Specific Solutions04 Fabrication methods for superhydrophobic surfaces

Various fabrication techniques are employed to create superhydrophobic coatings, including spray coating, dip coating, layer-by-layer assembly, and sol-gel processes. These methods control the micro and nano-scale roughness of the surface, which is crucial for superhydrophobicity. Advanced techniques such as plasma treatment, electrospinning, and lithography can also be used to create precisely structured surfaces with controlled wetting properties. The fabrication method significantly influences the durability, transparency, and other functional properties of the coating.Expand Specific Solutions05 Durable and self-healing superhydrophobic coatings

Enhancing the durability of superhydrophobic coatings is a significant challenge addressed through various approaches. Self-healing superhydrophobic coatings incorporate materials that can restore hydrophobicity after physical damage or chemical degradation. These coatings may use encapsulated hydrophobic agents that release upon damage, or dynamic chemical bonds that reform after breaking. Additionally, multi-layered structures and composite materials are employed to improve mechanical robustness while maintaining the necessary surface roughness and low surface energy for superhydrophobicity.Expand Specific Solutions

Leading Companies in Construction Coating Innovation

The superhydrophobic coating market in construction materials is experiencing rapid growth, currently in an early expansion phase with increasing commercial applications. The global market size is projected to reach significant value due to rising demand for water-resistant, self-cleaning building materials. Technologically, the field shows varying maturity levels, with companies like Detrapel and Nanosys leading commercial applications through nanotechnology innovations, while academic institutions such as Technische Universität Darmstadt and Southeast University drive fundamental research. Research organizations like CSIR and A*STAR are bridging the gap between laboratory discoveries and industrial implementation. The competitive landscape features specialized coating manufacturers alongside larger corporations like DIC Corp. and Honeywell that are integrating these technologies into broader product portfolios.

Detrapel, Inc.

Technical Solution: Detrapel has developed an advanced superhydrophobic coating technology specifically designed for construction materials that utilizes nano-scale particles to create a microscopic surface texture that repels water and other liquids. Their proprietary formulation combines fluorinated polymers with silica nanoparticles to create a durable barrier that maintains breathability while providing exceptional water repellency. The coating forms a microscopic "lotus effect" surface structure where water droplets maintain a contact angle greater than 150 degrees, allowing them to roll off surfaces carrying dirt particles with them. Detrapel's technology is particularly innovative in its application method, using a spray-on system that allows for easy field application without specialized equipment. Their formulation also incorporates UV stabilizers that prevent degradation from sun exposure, extending the coating's effective lifespan to 5-7 years in exterior applications[1]. The company has focused on making their superhydrophobic coatings environmentally friendly by eliminating harmful VOCs and PFAS chemicals traditionally used in water-repellent formulations.

Strengths: Detrapel's technology offers exceptional durability compared to conventional hydrophobic coatings, maintaining performance after multiple abrasion cycles. Their formulation achieves self-cleaning properties while remaining breathable, preventing moisture entrapment in building materials. Weaknesses: The coating requires specific application conditions regarding temperature and humidity for optimal performance, and may need reapplication in high-traffic areas or surfaces exposed to extreme conditions.

Anhui Fuguang Industrial Co. Ltd.

Technical Solution: Anhui Fuguang has pioneered a superhydrophobic coating system specifically engineered for concrete and masonry construction materials. Their technology utilizes a two-component siloxane-based formulation that penetrates deeply into porous building materials while forming a nanoscale textured surface layer. The coating creates a hierarchical surface structure with micro and nano roughness that achieves water contact angles exceeding 160 degrees. What distinguishes their approach is the incorporation of modified silica nanoparticles that bond chemically with cementitious substrates, providing exceptional adhesion and longevity even in harsh environmental conditions. Their proprietary cross-linking technology allows the coating to maintain flexibility while resisting alkaline degradation common in concrete applications. Testing has demonstrated water repellency retention after more than 2000 hours of accelerated weathering exposure[2]. The company has also developed specialized application protocols for different construction materials, optimizing performance on concrete, brick, natural stone, and other building substrates. Their formulation includes corrosion inhibitors that provide additional protection for reinforced concrete structures by preventing water and chloride ion penetration.

Strengths: The coating demonstrates exceptional adhesion to mineral substrates with minimal change to surface appearance, making it ideal for historic preservation applications. The technology provides freeze-thaw protection by preventing water absorption while maintaining vapor permeability. Weaknesses: The initial application cost is higher than conventional water repellents, and the coating requires careful surface preparation to achieve optimal performance. The technology is also less effective on already deteriorated surfaces with existing damage.

Key Patents and Research in Superhydrophobic Surface Engineering

A superhydrophobic anticorrosive coating without fluoro compounds and inhibitive pigments and the process thereof

PatentInactiveIN201711001141A

Innovation

- Development of a superhydrophobic anticorrosive coating with water contact angle of 152° and sliding angle of 20° without using environmentally harmful fluoro compounds and traditional inhibitive pigments.

- Utilization of a unique combination of silicone binder, nanotitania, nanosilica, magnesium silicate, and aluminum stearate to create micro/nano roughness that effectively entraps air and decreases the solid-liquid interface.

- Creation of a technically simple and easily manageable coating process suitable for large-scale industrial applications while maintaining excellent corrosion resistance, water vapor transmission, and abrasion resistance properties.

Superhydrophobic coating containing silica nanoparticles

PatentActiveUS11725110B2

Innovation

- A superhydrophobic coating is applied to PV panels, comprising a binding layer and a hydrophobic layer with perfluoroalkyl-functionalized silica nanoparticles, which enhances water repellency and self-cleaning properties while maintaining light transmittance and mechanical stability.

Environmental Impact and Sustainability Considerations

The environmental implications of superhydrophobic coatings in construction materials represent a critical dimension of their overall value proposition. These innovative coatings offer significant potential for reducing the environmental footprint of buildings throughout their lifecycle. By enhancing water repellency and self-cleaning properties, superhydrophobic surfaces minimize the need for chemical cleaning agents, thereby reducing harmful runoff into water systems and decreasing overall water consumption in building maintenance.

Energy efficiency constitutes another substantial environmental benefit. Buildings treated with superhydrophobic coatings demonstrate improved thermal performance due to reduced moisture penetration and subsequent heat loss. This translates directly into lower energy requirements for heating and cooling, contributing to decreased carbon emissions over the building's operational lifespan. Research indicates potential energy savings of 5-15% depending on climate conditions and building design.

Material longevity represents perhaps the most significant sustainability advantage. By protecting construction materials from water damage, freeze-thaw cycles, and biological growth, these coatings substantially extend service life. This reduction in replacement frequency translates to lower resource consumption and waste generation. Life cycle assessments suggest that properly applied superhydrophobic treatments can extend material lifespans by 30-50% under typical exposure conditions.

However, environmental concerns persist regarding the composition of many current superhydrophobic formulations. Traditional fluorinated compounds, while highly effective, present significant environmental hazards including bioaccumulation potential and persistence in ecosystems. Recent regulatory trends indicate increasing restrictions on these substances, driving research toward bio-based alternatives derived from plant oils and silica-based formulations with reduced environmental impact.

Manufacturing processes for these coatings also merit environmental scrutiny. Energy-intensive production methods and solvent-based application systems can partially offset the downstream environmental benefits. The industry is responding with water-based formulations and ambient-temperature curing systems that significantly reduce volatile organic compound (VOC) emissions during application.

End-of-life considerations remain an underdeveloped aspect of superhydrophobic coating sustainability. Questions regarding the recyclability of treated materials and potential contamination of waste streams require further investigation. Emerging research focuses on designing coatings that maintain their performance advantages while allowing for material recovery and recycling at end-of-life, potentially through biodegradable formulations or reversible bonding mechanisms.

Energy efficiency constitutes another substantial environmental benefit. Buildings treated with superhydrophobic coatings demonstrate improved thermal performance due to reduced moisture penetration and subsequent heat loss. This translates directly into lower energy requirements for heating and cooling, contributing to decreased carbon emissions over the building's operational lifespan. Research indicates potential energy savings of 5-15% depending on climate conditions and building design.

Material longevity represents perhaps the most significant sustainability advantage. By protecting construction materials from water damage, freeze-thaw cycles, and biological growth, these coatings substantially extend service life. This reduction in replacement frequency translates to lower resource consumption and waste generation. Life cycle assessments suggest that properly applied superhydrophobic treatments can extend material lifespans by 30-50% under typical exposure conditions.

However, environmental concerns persist regarding the composition of many current superhydrophobic formulations. Traditional fluorinated compounds, while highly effective, present significant environmental hazards including bioaccumulation potential and persistence in ecosystems. Recent regulatory trends indicate increasing restrictions on these substances, driving research toward bio-based alternatives derived from plant oils and silica-based formulations with reduced environmental impact.

Manufacturing processes for these coatings also merit environmental scrutiny. Energy-intensive production methods and solvent-based application systems can partially offset the downstream environmental benefits. The industry is responding with water-based formulations and ambient-temperature curing systems that significantly reduce volatile organic compound (VOC) emissions during application.

End-of-life considerations remain an underdeveloped aspect of superhydrophobic coating sustainability. Questions regarding the recyclability of treated materials and potential contamination of waste streams require further investigation. Emerging research focuses on designing coatings that maintain their performance advantages while allowing for material recovery and recycling at end-of-life, potentially through biodegradable formulations or reversible bonding mechanisms.

Durability and Performance Testing Methodologies

The evaluation of superhydrophobic coatings for construction materials requires rigorous testing methodologies to ensure their long-term performance in real-world applications. Standard testing protocols have been developed to assess durability under various environmental conditions, including ASTM D2247 for humidity resistance and ASTM G154 for UV exposure resistance. These standardized approaches provide consistent frameworks for comparing different coating formulations across the industry.

Accelerated weathering tests represent a critical component of performance assessment, simulating years of environmental exposure in compressed timeframes. QUV accelerators employ fluorescent UV lamps to replicate solar radiation damage, while xenon arc chambers provide full-spectrum light exposure that more closely mimics natural sunlight. These methods typically incorporate cyclic exposure to UV radiation, moisture, and temperature fluctuations to comprehensively evaluate coating degradation mechanisms.

Mechanical durability testing focuses on the coating's resistance to physical damage through abrasion resistance tests (ASTM D4060), adhesion tests (ASTM D3359), and impact resistance evaluations (ASTM D2794). These assessments quantify the coating's ability to maintain superhydrophobic properties despite mechanical stresses encountered in construction environments. Advanced protocols may include sand erosion tests that simulate windblown particulate impact or scratch resistance evaluations using calibrated instruments.

Chemical resistance testing examines how superhydrophobic coatings respond to exposure to common construction-related substances. Immersion tests in acidic, alkaline, and saline solutions help predict performance in polluted urban environments or coastal settings. Resistance to organic solvents, cleaning agents, and oils is particularly relevant for surfaces in high-traffic areas or industrial settings.

Performance metrics for superhydrophobic coatings extend beyond traditional coating evaluations to include specialized measurements. Water contact angle analysis (typically targeting >150° for superhydrophobicity) and sliding angle measurements (<10° for self-cleaning properties) provide quantitative data on water repellency. Surface morphology characterization through scanning electron microscopy (SEM) and atomic force microscopy (AFM) helps correlate performance with nano/microstructural features.

Long-term performance prediction models have emerged as valuable tools for translating accelerated test results into realistic service life estimates. These models incorporate multiple degradation factors and their synergistic effects to forecast coating performance over decades. Advanced computational approaches using machine learning algorithms have shown promise in improving prediction accuracy by analyzing complex datasets from multiple testing methodologies.

Accelerated weathering tests represent a critical component of performance assessment, simulating years of environmental exposure in compressed timeframes. QUV accelerators employ fluorescent UV lamps to replicate solar radiation damage, while xenon arc chambers provide full-spectrum light exposure that more closely mimics natural sunlight. These methods typically incorporate cyclic exposure to UV radiation, moisture, and temperature fluctuations to comprehensively evaluate coating degradation mechanisms.

Mechanical durability testing focuses on the coating's resistance to physical damage through abrasion resistance tests (ASTM D4060), adhesion tests (ASTM D3359), and impact resistance evaluations (ASTM D2794). These assessments quantify the coating's ability to maintain superhydrophobic properties despite mechanical stresses encountered in construction environments. Advanced protocols may include sand erosion tests that simulate windblown particulate impact or scratch resistance evaluations using calibrated instruments.

Chemical resistance testing examines how superhydrophobic coatings respond to exposure to common construction-related substances. Immersion tests in acidic, alkaline, and saline solutions help predict performance in polluted urban environments or coastal settings. Resistance to organic solvents, cleaning agents, and oils is particularly relevant for surfaces in high-traffic areas or industrial settings.

Performance metrics for superhydrophobic coatings extend beyond traditional coating evaluations to include specialized measurements. Water contact angle analysis (typically targeting >150° for superhydrophobicity) and sliding angle measurements (<10° for self-cleaning properties) provide quantitative data on water repellency. Surface morphology characterization through scanning electron microscopy (SEM) and atomic force microscopy (AFM) helps correlate performance with nano/microstructural features.

Long-term performance prediction models have emerged as valuable tools for translating accelerated test results into realistic service life estimates. These models incorporate multiple degradation factors and their synergistic effects to forecast coating performance over decades. Advanced computational approaches using machine learning algorithms have shown promise in improving prediction accuracy by analyzing complex datasets from multiple testing methodologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!