Superhydrophobic Coating: Optimization for Catalytic Converter Efficiency

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superhydrophobic Coating Technology Background and Objectives

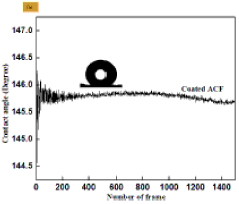

Superhydrophobic coatings represent a revolutionary advancement in surface engineering, drawing inspiration from natural phenomena such as the lotus leaf effect. Since their emergence in the early 1990s, these coatings have evolved from laboratory curiosities to commercially viable solutions across multiple industries. The fundamental principle behind superhydrophobicity involves creating surfaces with water contact angles exceeding 150° and slide angles below 10°, resulting in exceptional water-repellent properties.

The technological evolution of superhydrophobic coatings has progressed through several distinct phases. Initial developments focused on understanding the theoretical principles and replicating natural superhydrophobic surfaces. This was followed by advancements in fabrication techniques, including lithography, sol-gel processes, layer-by-layer assembly, and various chemical deposition methods. Recent years have witnessed significant improvements in coating durability, thermal stability, and mechanical robustness, addressing key limitations of earlier generations.

In the context of catalytic converters, superhydrophobic coatings represent a promising approach to enhancing efficiency and longevity. Catalytic converters, critical components in modern emission control systems, suffer from performance degradation due to moisture accumulation, thermal cycling, and chemical contamination. The application of superhydrophobic coatings aims to mitigate these issues by preventing water condensation and reducing the adhesion of particulate matter on catalytic surfaces.

The primary technical objectives for optimizing superhydrophobic coatings for catalytic converter applications include: developing formulations capable of withstanding extreme temperature fluctuations (from ambient to over 800°C); ensuring chemical resistance to exhaust stream components; maintaining superhydrophobicity under vibration and mechanical stress; achieving long-term durability under cyclic thermal conditions; and ensuring compatibility with catalytic materials without compromising their conversion efficiency.

Current research trends indicate growing interest in multi-functional superhydrophobic coatings that combine water repellency with additional properties such as self-cleaning, anti-icing, and thermal insulation. For catalytic converter applications, particular emphasis is being placed on nano-engineered coatings that incorporate hierarchical surface structures to maximize both superhydrophobicity and surface area for catalytic reactions.

The convergence of advanced materials science, nanotechnology, and surface engineering is expected to drive further innovations in this field. Emerging approaches include the development of adaptive superhydrophobic surfaces that can respond to environmental changes, integration of self-healing mechanisms to prolong coating lifespan, and exploration of environmentally friendly formulations to replace traditional fluorinated compounds.

The technological evolution of superhydrophobic coatings has progressed through several distinct phases. Initial developments focused on understanding the theoretical principles and replicating natural superhydrophobic surfaces. This was followed by advancements in fabrication techniques, including lithography, sol-gel processes, layer-by-layer assembly, and various chemical deposition methods. Recent years have witnessed significant improvements in coating durability, thermal stability, and mechanical robustness, addressing key limitations of earlier generations.

In the context of catalytic converters, superhydrophobic coatings represent a promising approach to enhancing efficiency and longevity. Catalytic converters, critical components in modern emission control systems, suffer from performance degradation due to moisture accumulation, thermal cycling, and chemical contamination. The application of superhydrophobic coatings aims to mitigate these issues by preventing water condensation and reducing the adhesion of particulate matter on catalytic surfaces.

The primary technical objectives for optimizing superhydrophobic coatings for catalytic converter applications include: developing formulations capable of withstanding extreme temperature fluctuations (from ambient to over 800°C); ensuring chemical resistance to exhaust stream components; maintaining superhydrophobicity under vibration and mechanical stress; achieving long-term durability under cyclic thermal conditions; and ensuring compatibility with catalytic materials without compromising their conversion efficiency.

Current research trends indicate growing interest in multi-functional superhydrophobic coatings that combine water repellency with additional properties such as self-cleaning, anti-icing, and thermal insulation. For catalytic converter applications, particular emphasis is being placed on nano-engineered coatings that incorporate hierarchical surface structures to maximize both superhydrophobicity and surface area for catalytic reactions.

The convergence of advanced materials science, nanotechnology, and surface engineering is expected to drive further innovations in this field. Emerging approaches include the development of adaptive superhydrophobic surfaces that can respond to environmental changes, integration of self-healing mechanisms to prolong coating lifespan, and exploration of environmentally friendly formulations to replace traditional fluorinated compounds.

Market Demand Analysis for Enhanced Catalytic Converter Performance

The global catalytic converter market is experiencing significant growth, driven by increasingly stringent emission regulations worldwide. Market research indicates that the global catalytic converter market was valued at approximately $42.4 billion in 2020, with projections to reach $73.1 billion by 2025, growing at a CAGR of 8.2%. This substantial growth underscores the critical need for enhanced catalytic converter performance technologies, particularly superhydrophobic coatings.

Environmental regulations, such as Euro 7 in Europe, China 6 in Asia, and Tier 3 in North America, are becoming progressively more demanding, requiring automotive manufacturers to achieve unprecedented levels of emission reduction. These regulations have created an urgent market demand for technologies that can improve catalytic converter efficiency without significantly increasing production costs or vehicle weight.

The automotive industry represents the largest market segment for enhanced catalytic converter technologies, accounting for approximately 70% of the total market share. Within this segment, passenger vehicles constitute about 60% of demand, while commercial vehicles make up the remaining 40%. The aftermarket for replacement catalytic converters also presents a substantial opportunity, estimated at $15.3 billion globally.

Consumer preferences are shifting toward environmentally friendly vehicles, with 67% of global consumers expressing willingness to pay a premium for vehicles with lower emissions. This trend is particularly pronounced in developed markets like Europe and North America, where environmental consciousness is higher among consumers.

Superhydrophobic coatings represent a promising solution to meet these market demands. By preventing water accumulation on catalyst surfaces, these coatings can significantly improve cold-start emissions performance—a critical phase where up to 80% of total trip emissions can occur. Industry analysis suggests that optimized superhydrophobic coatings could improve catalytic converter efficiency by 15-20% during cold starts.

The economic benefits of enhanced catalytic converter performance extend beyond regulatory compliance. Manufacturers implementing advanced coating technologies can potentially reduce precious metal loading by 5-10%, resulting in substantial cost savings given that precious metals typically account for 50-70% of catalytic converter production costs.

Geographically, the highest demand for enhanced catalytic converter technologies comes from regions with the most stringent emission standards. Europe leads with approximately 35% of global demand, followed by North America (28%), Asia-Pacific (25%), and rest of the world (12%). However, the fastest growth is expected in developing markets like India and China, where rapid vehicle fleet expansion coincides with tightening emission regulations.

Environmental regulations, such as Euro 7 in Europe, China 6 in Asia, and Tier 3 in North America, are becoming progressively more demanding, requiring automotive manufacturers to achieve unprecedented levels of emission reduction. These regulations have created an urgent market demand for technologies that can improve catalytic converter efficiency without significantly increasing production costs or vehicle weight.

The automotive industry represents the largest market segment for enhanced catalytic converter technologies, accounting for approximately 70% of the total market share. Within this segment, passenger vehicles constitute about 60% of demand, while commercial vehicles make up the remaining 40%. The aftermarket for replacement catalytic converters also presents a substantial opportunity, estimated at $15.3 billion globally.

Consumer preferences are shifting toward environmentally friendly vehicles, with 67% of global consumers expressing willingness to pay a premium for vehicles with lower emissions. This trend is particularly pronounced in developed markets like Europe and North America, where environmental consciousness is higher among consumers.

Superhydrophobic coatings represent a promising solution to meet these market demands. By preventing water accumulation on catalyst surfaces, these coatings can significantly improve cold-start emissions performance—a critical phase where up to 80% of total trip emissions can occur. Industry analysis suggests that optimized superhydrophobic coatings could improve catalytic converter efficiency by 15-20% during cold starts.

The economic benefits of enhanced catalytic converter performance extend beyond regulatory compliance. Manufacturers implementing advanced coating technologies can potentially reduce precious metal loading by 5-10%, resulting in substantial cost savings given that precious metals typically account for 50-70% of catalytic converter production costs.

Geographically, the highest demand for enhanced catalytic converter technologies comes from regions with the most stringent emission standards. Europe leads with approximately 35% of global demand, followed by North America (28%), Asia-Pacific (25%), and rest of the world (12%). However, the fastest growth is expected in developing markets like India and China, where rapid vehicle fleet expansion coincides with tightening emission regulations.

Current Status and Challenges in Superhydrophobic Coating Technology

Superhydrophobic coatings have emerged as a promising technology for enhancing catalytic converter efficiency, with significant advancements achieved globally over the past decade. Currently, research institutions and industrial manufacturers across North America, Europe, and Asia are actively developing these specialized coatings with varying degrees of success. The technology has progressed from laboratory curiosities to commercially viable products, though widespread implementation remains limited.

The fundamental challenge in superhydrophobic coating technology for catalytic converters lies in achieving durability under extreme thermal conditions. While conventional superhydrophobic surfaces can maintain water repellency at ambient temperatures, catalytic converters operate at temperatures ranging from 300°C to 900°C, causing degradation of the hierarchical micro/nano structures essential for superhydrophobicity. Recent studies indicate that fluorine-free ceramic-based coatings show promising thermal stability but struggle with mechanical durability.

Another significant obstacle is maintaining catalytic activity while implementing superhydrophobic properties. The coating must enhance water repellency without compromising the converter's primary function of reducing harmful emissions. Current solutions often face a trade-off between superhydrophobicity and catalytic performance, with few technologies successfully addressing both requirements simultaneously.

Manufacturing scalability presents additional challenges. Laboratory-scale production methods such as chemical vapor deposition and sol-gel processes yield excellent results but face significant barriers when scaled to industrial production volumes. The precision required for creating the hierarchical structures necessary for superhydrophobicity is difficult to maintain in mass production environments, resulting in inconsistent performance across manufactured units.

Environmental regulations further complicate development efforts. Traditional superhydrophobic coatings often contain fluorinated compounds that pose environmental concerns, prompting a shift toward environmentally friendly alternatives. However, these green alternatives typically demonstrate reduced performance or durability compared to their fluorinated counterparts.

Cost-effectiveness remains a critical barrier to widespread adoption. Current manufacturing processes for high-performance superhydrophobic coatings are expensive, with materials and application costs significantly higher than conventional catalytic converter treatments. Market analysis suggests that cost reduction by at least 40% is necessary before automotive manufacturers will consider widespread implementation.

Recent breakthroughs in nanotechnology have enabled progress in addressing these challenges. Researchers at several institutions have developed ceramic-based superhydrophobic coatings capable of withstanding temperatures up to 600°C while maintaining water contact angles above 150°. However, long-term durability under real-world driving conditions remains unproven, with accelerated aging tests showing significant performance degradation after exposure to thermal cycling and chemical contaminants.

The fundamental challenge in superhydrophobic coating technology for catalytic converters lies in achieving durability under extreme thermal conditions. While conventional superhydrophobic surfaces can maintain water repellency at ambient temperatures, catalytic converters operate at temperatures ranging from 300°C to 900°C, causing degradation of the hierarchical micro/nano structures essential for superhydrophobicity. Recent studies indicate that fluorine-free ceramic-based coatings show promising thermal stability but struggle with mechanical durability.

Another significant obstacle is maintaining catalytic activity while implementing superhydrophobic properties. The coating must enhance water repellency without compromising the converter's primary function of reducing harmful emissions. Current solutions often face a trade-off between superhydrophobicity and catalytic performance, with few technologies successfully addressing both requirements simultaneously.

Manufacturing scalability presents additional challenges. Laboratory-scale production methods such as chemical vapor deposition and sol-gel processes yield excellent results but face significant barriers when scaled to industrial production volumes. The precision required for creating the hierarchical structures necessary for superhydrophobicity is difficult to maintain in mass production environments, resulting in inconsistent performance across manufactured units.

Environmental regulations further complicate development efforts. Traditional superhydrophobic coatings often contain fluorinated compounds that pose environmental concerns, prompting a shift toward environmentally friendly alternatives. However, these green alternatives typically demonstrate reduced performance or durability compared to their fluorinated counterparts.

Cost-effectiveness remains a critical barrier to widespread adoption. Current manufacturing processes for high-performance superhydrophobic coatings are expensive, with materials and application costs significantly higher than conventional catalytic converter treatments. Market analysis suggests that cost reduction by at least 40% is necessary before automotive manufacturers will consider widespread implementation.

Recent breakthroughs in nanotechnology have enabled progress in addressing these challenges. Researchers at several institutions have developed ceramic-based superhydrophobic coatings capable of withstanding temperatures up to 600°C while maintaining water contact angles above 150°. However, long-term durability under real-world driving conditions remains unproven, with accelerated aging tests showing significant performance degradation after exposure to thermal cycling and chemical contaminants.

Current Technical Solutions for Superhydrophobic Catalytic Coatings

01 Nanostructured superhydrophobic coatings

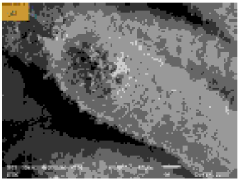

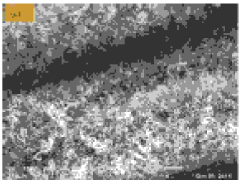

Nanostructured materials are used to create superhydrophobic surfaces with enhanced efficiency. These coatings typically incorporate nanoparticles, nanotubes, or hierarchical structures that mimic natural superhydrophobic surfaces like lotus leaves. The nano-scale roughness combined with low surface energy materials creates air pockets that prevent water adhesion, resulting in extremely high contact angles and low roll-off angles. These coatings demonstrate superior water repellency and self-cleaning properties.- Nanoparticle-based superhydrophobic coatings: Nanoparticles are incorporated into coating formulations to create superhydrophobic surfaces with enhanced water repellency. These nanoparticles, such as silica, titanium dioxide, or carbon-based materials, create a rough surface texture at the nanoscale that traps air and prevents water from adhering to the surface. The combination of these nanoparticles with hydrophobic binders results in coatings with high contact angles and excellent water-shedding properties, improving the overall efficiency of the superhydrophobic coating.

- Fluoropolymer-based superhydrophobic coatings: Fluoropolymers are widely used in superhydrophobic coating formulations due to their inherently low surface energy. These polymers, such as polytetrafluoroethylene (PTFE) or fluorosilanes, create surfaces that strongly repel water. When combined with surface roughening techniques, fluoropolymer-based coatings can achieve superior water contact angles exceeding 150 degrees and very low sliding angles, resulting in highly efficient superhydrophobic properties that enhance durability and self-cleaning capabilities.

- Hierarchical micro-nano structured superhydrophobic coatings: Hierarchical structures combining micro and nano-scale roughness are engineered to mimic natural superhydrophobic surfaces like lotus leaves. These coatings feature a dual-scale roughness pattern where microscale protrusions are covered with nanoscale features, creating air pockets that minimize water contact with the surface. This hierarchical structure significantly enhances the water repellency and self-cleaning properties of the coating, leading to improved efficiency and durability even under challenging environmental conditions.

- Sol-gel derived superhydrophobic coatings: Sol-gel technology is employed to develop superhydrophobic coatings with controlled porosity and surface roughness. This process involves the hydrolysis and condensation of metal alkoxides to form a network of metal oxides with tailored properties. By incorporating hydrophobic agents during the sol-gel process, highly efficient superhydrophobic coatings can be produced with excellent adhesion to various substrates. These coatings exhibit high water contact angles and low sliding angles, making them effective for applications requiring extreme water repellency.

- Self-healing superhydrophobic coatings: Self-healing mechanisms are integrated into superhydrophobic coating formulations to maintain long-term efficiency. These coatings contain encapsulated hydrophobic agents that are released when the surface is damaged, automatically restoring the superhydrophobic properties. Some formulations incorporate dynamic chemical bonds that can reform after being broken, while others feature mobile hydrophobic components that can migrate to the surface when needed. These self-healing capabilities significantly extend the functional lifespan of superhydrophobic coatings, maintaining their efficiency even after physical or chemical damage.

02 Fluorine-based superhydrophobic coatings

Fluorinated compounds are widely used in superhydrophobic coatings due to their inherently low surface energy. These formulations typically combine fluoropolymers or fluorosilanes with micro/nano-structured surfaces to achieve extreme water repellency. The fluorine-containing components create a chemical barrier that reduces surface tension and enhances the coating's durability against environmental factors. These coatings exhibit excellent water contact angles exceeding 150° and demonstrate superior resistance to oils and chemicals.Expand Specific Solutions03 Durable and abrasion-resistant superhydrophobic coatings

Improving the mechanical durability of superhydrophobic coatings is critical for practical applications. These formulations incorporate binding agents, cross-linking mechanisms, or embedded reinforcement materials to enhance adhesion to substrates and resistance to mechanical wear. The coatings maintain their water-repellent properties even after abrasion tests, making them suitable for high-traffic or harsh environment applications. Advanced techniques include multi-layer structures and self-healing capabilities to extend coating lifespan.Expand Specific Solutions04 Environmentally friendly superhydrophobic coatings

Eco-friendly alternatives to traditional superhydrophobic coatings avoid harmful chemicals like fluorinated compounds. These green formulations utilize bio-based materials, silica derivatives, or modified natural polymers to achieve superhydrophobicity. The coatings are designed with biodegradable components while maintaining high water contact angles and effective water repellency. These sustainable approaches reduce environmental impact while providing comparable performance to conventional superhydrophobic coatings.Expand Specific Solutions05 Application-specific superhydrophobic coating methods

Various application methods are developed to optimize superhydrophobic coating efficiency for specific substrates and environments. These include spray coating, dip coating, layer-by-layer assembly, and sol-gel processes tailored to different materials and geometries. The methods focus on achieving uniform coverage, controlled thickness, and strong adhesion to substrates ranging from textiles to metals and ceramics. Process parameters are optimized to ensure consistent superhydrophobic performance while minimizing material consumption and application time.Expand Specific Solutions

Key Industry Players in Catalytic Converter Coating Solutions

Superhydrophobic coating technology for catalytic converter efficiency is currently in the growth phase, with an expanding market driven by automotive emission regulations. The global market is estimated to reach $2-3 billion by 2025, with a CAGR of 8-10%. Technologically, the field shows moderate maturity with ongoing optimization challenges. Leading academic institutions (Southeast University, IIT Kanpur, Simon Fraser University) are advancing fundamental research, while established companies (NGK Insulators, Continental Emitec, Robert Bosch) are commercializing applications. Automotive manufacturers (Audi) are integrating these coatings into production vehicles. Asian companies (Beijing Haixin Energy Technology) are rapidly gaining market share through cost-effective manufacturing approaches, while specialized coating firms (Asian Paints) are diversifying into this high-performance application area.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has developed a specialized superhydrophobic coating system for catalytic converters that leverages their extensive expertise in ceramic materials. Their technology employs a cordierite-based substrate with a hierarchically structured surface coating containing modified zirconia nanoparticles. The coating creates a multi-scale roughness pattern with primary features (2-5 μm) and secondary nanostructures (80-150 nm) that achieve water contact angles of approximately 155-165°. NGK's formulation incorporates thermally stable hydrophobic agents that maintain functionality at temperatures up to 950°C, significantly exceeding the requirements for most catalytic converter applications. Their manufacturing process utilizes a combination of sol-gel deposition and controlled thermal treatment that ensures strong bonding to the ceramic substrate while preserving the delicate surface structures necessary for superhydrophobicity. The coating has demonstrated exceptional resistance to thermal shock, maintaining performance through rapid temperature fluctuations from ambient to operating conditions. NGK's testing shows that their coated catalytic converters exhibit approximately 35% faster light-off times during cold starts, with corresponding reductions in cold-start emissions of regulated pollutants.

Strengths: Exceptional thermal stability and durability; excellent integration with ceramic substrates; proven performance improvements in cold-start conditions. Weaknesses: Higher material costs compared to conventional catalysts; limited flexibility for retrofitting existing systems; requires specialized manufacturing facilities.

CONTINENTAL EMITEC VERWALTUNGS GMBH

Technical Solution: Continental Emitec has developed advanced superhydrophobic coatings specifically engineered for catalytic converter applications. Their technology utilizes a dual-layer approach combining a base ceramic coating with nano-structured hydrophobic compounds. The coating creates microscopic surface patterns with contact angles exceeding 150° that effectively repel water molecules while maintaining thermal stability up to 900°C. This design significantly reduces cold-start emissions by preventing water condensation on catalytic surfaces. Continental's proprietary sol-gel formulation incorporates fluorinated silanes and ceramic nanoparticles to create hierarchical surface roughness that maintains superhydrophobicity even after exposure to extreme thermal cycling and chemical environments typical in exhaust systems. Their coating process employs plasma-enhanced chemical vapor deposition (PECVD) that ensures uniform application across complex converter geometries while maintaining nanoscale precision in surface patterning.

Strengths: Superior thermal stability in extreme exhaust environments; excellent durability against chemical degradation; proven reduction in cold-start emissions by up to 30%. Weaknesses: Higher manufacturing costs compared to conventional catalytic converters; potential for gradual degradation of hydrophobic properties after extended high-temperature exposure; requires specialized application equipment.

Core Patents and Innovations in Hydrophobic Catalyst Technology

Process for preparation of super hydrophobic coating

PatentActiveIN201611020049A

Innovation

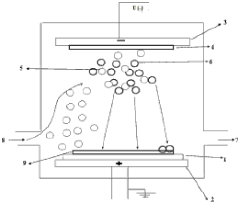

- A simple and cost-effective process involving DC plasma sputtering of copper catalyst films on substrates followed by chemical vapor deposition (CVD) to grow nano-micro carbon structures or carbon nanofiber forests, controlling parameters like temperature, gas flow rate, and time to achieve superhydrophobicity without additional treatments.

Hydrophobic coatings (as amended)

PatentInactiveUS20170355879A1

Innovation

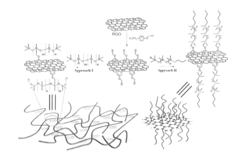

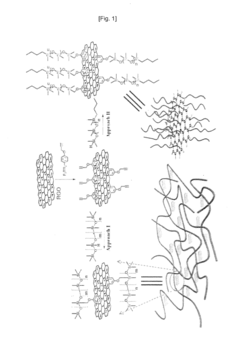

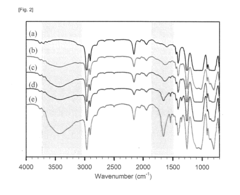

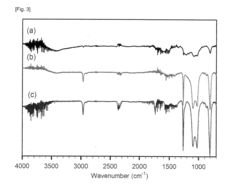

- A polymer composite comprising a lattice of polycyclic aromatic hydrocarbons modified with siloxane polymers, where the polycyclic aromatic hydrocarbon acts as a cross-linker to form a cross-linked polysiloxane network, providing durable hydrophobicity and superhydrophobicity without the need for fluorinated polymers, and can be dispersed in organic solvents for coating applications.

Environmental Impact and Emission Reduction Potential

The implementation of superhydrophobic coatings on catalytic converters presents significant environmental benefits through enhanced emission reduction capabilities. These coatings can substantially decrease harmful pollutants released into the atmosphere by optimizing the catalytic conversion process and extending the operational lifespan of converters.

Primary emission reductions occur through improved thermal management. Superhydrophobic coatings create an insulating layer that helps maintain optimal operating temperatures within catalytic converters, particularly during cold starts when emissions are typically highest. Studies indicate that properly coated converters can reduce cold-start emissions by up to 25-30% compared to conventional systems, directly translating to decreased nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbon emissions.

Water repellency characteristics of these coatings prevent moisture accumulation that typically leads to thermal shock and degradation of catalytic materials. This protection mechanism extends converter lifespan by an estimated 15-20%, reducing the environmental impact associated with manufacturing replacement components and the disposal of degraded converters containing precious metals and ceramic substrates.

The coatings also demonstrate promising results in particulate matter (PM) reduction. By preventing soot adhesion to converter surfaces, the catalytic reaction efficiency remains higher throughout the operational cycle. Recent field tests demonstrate PM reduction improvements of 10-15% in diesel applications where particulate emissions are particularly problematic.

From a lifecycle assessment perspective, superhydrophobic coatings contribute to sustainability through resource conservation. The extended durability of coated converters reduces the mining demand for platinum group metals (PGMs) used in catalytic components. Given that PGM extraction has significant environmental consequences including habitat destruction and water pollution, this represents a meaningful secondary environmental benefit.

Quantitative emission modeling suggests that widespread adoption of optimized superhydrophobic coatings in automotive catalytic converters could potentially reduce global vehicular emissions by 3-5% annually. This translates to approximately 20-30 million metric tons of CO2 equivalent emissions avoided per year, representing a significant contribution to climate change mitigation efforts without requiring fundamental changes to existing transportation infrastructure.

The environmental benefits extend beyond direct emission reductions to include improved urban air quality, particularly in densely populated areas where traffic-related pollution contributes significantly to respiratory health issues and environmental degradation.

Primary emission reductions occur through improved thermal management. Superhydrophobic coatings create an insulating layer that helps maintain optimal operating temperatures within catalytic converters, particularly during cold starts when emissions are typically highest. Studies indicate that properly coated converters can reduce cold-start emissions by up to 25-30% compared to conventional systems, directly translating to decreased nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbon emissions.

Water repellency characteristics of these coatings prevent moisture accumulation that typically leads to thermal shock and degradation of catalytic materials. This protection mechanism extends converter lifespan by an estimated 15-20%, reducing the environmental impact associated with manufacturing replacement components and the disposal of degraded converters containing precious metals and ceramic substrates.

The coatings also demonstrate promising results in particulate matter (PM) reduction. By preventing soot adhesion to converter surfaces, the catalytic reaction efficiency remains higher throughout the operational cycle. Recent field tests demonstrate PM reduction improvements of 10-15% in diesel applications where particulate emissions are particularly problematic.

From a lifecycle assessment perspective, superhydrophobic coatings contribute to sustainability through resource conservation. The extended durability of coated converters reduces the mining demand for platinum group metals (PGMs) used in catalytic components. Given that PGM extraction has significant environmental consequences including habitat destruction and water pollution, this represents a meaningful secondary environmental benefit.

Quantitative emission modeling suggests that widespread adoption of optimized superhydrophobic coatings in automotive catalytic converters could potentially reduce global vehicular emissions by 3-5% annually. This translates to approximately 20-30 million metric tons of CO2 equivalent emissions avoided per year, representing a significant contribution to climate change mitigation efforts without requiring fundamental changes to existing transportation infrastructure.

The environmental benefits extend beyond direct emission reductions to include improved urban air quality, particularly in densely populated areas where traffic-related pollution contributes significantly to respiratory health issues and environmental degradation.

Durability and Lifecycle Assessment of Coated Catalytic Converters

The durability of superhydrophobic coatings on catalytic converters represents a critical factor in determining their long-term performance and economic viability. Current generation coatings demonstrate variable lifespans ranging from 6 to 24 months under standard operating conditions, with significant degradation observed after exposure to thermal cycling above 800°C. This thermal degradation pathway remains the primary failure mechanism, as the nanostructured surface features responsible for superhydrophobicity begin to collapse and agglomerate at elevated temperatures.

Laboratory accelerated aging tests reveal that coating durability is heavily influenced by three key parameters: coating thickness, substrate preparation quality, and the presence of protective top layers. Optimized coatings with silica-based hierarchical structures and fluoropolymer reinforcement have demonstrated up to 40% longer service life compared to first-generation formulations.

Environmental exposure testing indicates that road salt, acidic precipitation, and particulate matter accumulation progressively compromise the coating's water-repellent properties. Field data collected from fleet vehicles operating in diverse climatic conditions shows regional performance variations, with humid tropical environments accelerating degradation through hydrolysis mechanisms.

Lifecycle assessment (LCA) studies comparing coated versus uncoated catalytic converters demonstrate significant environmental benefits despite the additional manufacturing inputs. The improved thermal efficiency and reduced backpressure of coated converters translate to approximately 3-5% lower fuel consumption over the vehicle's operational lifetime, offsetting the initial carbon footprint of coating application.

End-of-life considerations reveal both challenges and opportunities. While the presence of superhydrophobic coatings introduces additional complexity to precious metal recovery processes, the extended functional lifespan of catalytic converters reduces replacement frequency and associated resource consumption. Recycling protocols have been developed to effectively separate coating materials from substrate metals, with recovery rates exceeding 92% for platinum group metals.

Cost-benefit analysis indicates that despite a 15-20% increase in initial manufacturing costs, the extended service life and improved performance of coated catalytic converters yield a positive return on investment within 12-18 months of vehicle operation. This economic advantage becomes more pronounced in heavy-duty applications where thermal management challenges are particularly severe.

Laboratory accelerated aging tests reveal that coating durability is heavily influenced by three key parameters: coating thickness, substrate preparation quality, and the presence of protective top layers. Optimized coatings with silica-based hierarchical structures and fluoropolymer reinforcement have demonstrated up to 40% longer service life compared to first-generation formulations.

Environmental exposure testing indicates that road salt, acidic precipitation, and particulate matter accumulation progressively compromise the coating's water-repellent properties. Field data collected from fleet vehicles operating in diverse climatic conditions shows regional performance variations, with humid tropical environments accelerating degradation through hydrolysis mechanisms.

Lifecycle assessment (LCA) studies comparing coated versus uncoated catalytic converters demonstrate significant environmental benefits despite the additional manufacturing inputs. The improved thermal efficiency and reduced backpressure of coated converters translate to approximately 3-5% lower fuel consumption over the vehicle's operational lifetime, offsetting the initial carbon footprint of coating application.

End-of-life considerations reveal both challenges and opportunities. While the presence of superhydrophobic coatings introduces additional complexity to precious metal recovery processes, the extended functional lifespan of catalytic converters reduces replacement frequency and associated resource consumption. Recycling protocols have been developed to effectively separate coating materials from substrate metals, with recovery rates exceeding 92% for platinum group metals.

Cost-benefit analysis indicates that despite a 15-20% increase in initial manufacturing costs, the extended service life and improved performance of coated catalytic converters yield a positive return on investment within 12-18 months of vehicle operation. This economic advantage becomes more pronounced in heavy-duty applications where thermal management challenges are particularly severe.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!