Impact of Superhydrophobic Coating on Acoustic Properties in Construction

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superhydrophobic Coating Acoustics Background and Objectives

Superhydrophobic coatings represent a significant advancement in surface engineering, drawing inspiration from natural phenomena such as the lotus leaf effect. Since their initial development in the late 1990s, these coatings have evolved from laboratory curiosities to commercially viable solutions across multiple industries. The technological trajectory has consistently moved toward more durable, environmentally friendly, and cost-effective formulations, with recent breakthroughs in nano-structured materials accelerating adoption.

The acoustic properties of materials in construction have traditionally been addressed through dedicated sound-absorbing or sound-reflecting materials. However, the intersection of superhydrophobic technology with acoustics presents a novel research domain with potentially transformative applications. Historical data indicates that surface characteristics significantly influence sound wave interaction, suggesting that the unique micro and nano-scale topography of superhydrophobic surfaces may offer previously unexplored acoustic benefits.

Current research indicates that air trapped within the hierarchical structures of superhydrophobic surfaces may serve as an additional medium affecting sound wave propagation. This phenomenon could potentially enhance sound insulation properties without the bulk associated with traditional acoustic materials. The evolution of this technology has been marked by progressive improvements in durability under mechanical stress and environmental exposure, addressing key limitations of early formulations.

The primary objective of this technical investigation is to comprehensively evaluate how superhydrophobic coatings affect acoustic performance in construction applications. Specifically, we aim to quantify changes in sound absorption, transmission, and reflection across various frequency ranges when superhydrophobic coatings are applied to common construction materials. Additionally, we seek to understand the relationship between the coating's micro/nano-structure and its acoustic behavior.

Secondary objectives include assessing the durability of these acoustic properties under typical construction conditions, identifying optimal coating compositions for specific acoustic requirements, and developing predictive models for acoustic performance based on coating characteristics. We also aim to explore potential synergies between water-repellent functionality and sound management, potentially enabling multi-functional building materials.

The technological trajectory suggests continued advancement in nano-engineered surfaces with precisely controlled topographies. Recent developments in computational modeling of surface-sound interactions provide tools to accelerate this research. The convergence of superhydrophobic technology with acoustic engineering represents a promising frontier in construction materials science, with potential applications ranging from noise-reducing façades to acoustically optimized interior spaces that maintain self-cleaning properties.

The acoustic properties of materials in construction have traditionally been addressed through dedicated sound-absorbing or sound-reflecting materials. However, the intersection of superhydrophobic technology with acoustics presents a novel research domain with potentially transformative applications. Historical data indicates that surface characteristics significantly influence sound wave interaction, suggesting that the unique micro and nano-scale topography of superhydrophobic surfaces may offer previously unexplored acoustic benefits.

Current research indicates that air trapped within the hierarchical structures of superhydrophobic surfaces may serve as an additional medium affecting sound wave propagation. This phenomenon could potentially enhance sound insulation properties without the bulk associated with traditional acoustic materials. The evolution of this technology has been marked by progressive improvements in durability under mechanical stress and environmental exposure, addressing key limitations of early formulations.

The primary objective of this technical investigation is to comprehensively evaluate how superhydrophobic coatings affect acoustic performance in construction applications. Specifically, we aim to quantify changes in sound absorption, transmission, and reflection across various frequency ranges when superhydrophobic coatings are applied to common construction materials. Additionally, we seek to understand the relationship between the coating's micro/nano-structure and its acoustic behavior.

Secondary objectives include assessing the durability of these acoustic properties under typical construction conditions, identifying optimal coating compositions for specific acoustic requirements, and developing predictive models for acoustic performance based on coating characteristics. We also aim to explore potential synergies between water-repellent functionality and sound management, potentially enabling multi-functional building materials.

The technological trajectory suggests continued advancement in nano-engineered surfaces with precisely controlled topographies. Recent developments in computational modeling of surface-sound interactions provide tools to accelerate this research. The convergence of superhydrophobic technology with acoustic engineering represents a promising frontier in construction materials science, with potential applications ranging from noise-reducing façades to acoustically optimized interior spaces that maintain self-cleaning properties.

Market Analysis for Acoustic-Enhanced Construction Materials

The global market for acoustic-enhanced construction materials is experiencing significant growth, driven by increasing awareness of noise pollution and its effects on health and well-being. The market was valued at approximately $7.5 billion in 2022 and is projected to reach $12.3 billion by 2028, representing a compound annual growth rate (CAGR) of 8.6%. This growth trajectory is supported by stringent building regulations regarding noise control and the rising demand for comfortable living and working environments.

Residential construction represents the largest market segment, accounting for 42% of the total market share. Commercial buildings follow closely at 35%, while industrial applications constitute 23%. Geographically, North America leads with 34% market share, followed by Europe (30%), Asia-Pacific (28%), and the rest of the world (8%). The Asia-Pacific region is expected to witness the fastest growth due to rapid urbanization and infrastructure development in countries like China and India.

Superhydrophobic coatings with acoustic properties represent an emerging niche within this broader market. Currently estimated at $320 million, this specific segment is projected to grow at a CAGR of 12.4% through 2028, outpacing the overall acoustic materials market. This accelerated growth is attributed to the dual functionality these materials offer – both water repellency and sound absorption or insulation.

Consumer demand patterns indicate a strong preference for multifunctional building materials that address multiple performance criteria simultaneously. A recent industry survey revealed that 78% of architects and building designers consider acoustic performance "very important" or "extremely important" when selecting construction materials, while 65% expressed interest in materials with combined acoustic and hydrophobic properties.

Price sensitivity varies significantly across market segments. Premium construction projects demonstrate willingness to pay 15-20% more for advanced acoustic solutions, while mass-market residential construction remains highly price-sensitive. The average price premium that the market currently accepts for superhydrophobic acoustic materials is approximately 12% above conventional acoustic treatments.

Key market drivers include increasingly stringent building codes related to acoustic performance, growing awareness of noise pollution health impacts, and the trend toward sustainable and multifunctional building materials. Market restraints include higher initial costs compared to traditional materials, limited awareness among some stakeholders, and technical challenges in maintaining long-term performance of superhydrophobic coatings in varied environmental conditions.

Residential construction represents the largest market segment, accounting for 42% of the total market share. Commercial buildings follow closely at 35%, while industrial applications constitute 23%. Geographically, North America leads with 34% market share, followed by Europe (30%), Asia-Pacific (28%), and the rest of the world (8%). The Asia-Pacific region is expected to witness the fastest growth due to rapid urbanization and infrastructure development in countries like China and India.

Superhydrophobic coatings with acoustic properties represent an emerging niche within this broader market. Currently estimated at $320 million, this specific segment is projected to grow at a CAGR of 12.4% through 2028, outpacing the overall acoustic materials market. This accelerated growth is attributed to the dual functionality these materials offer – both water repellency and sound absorption or insulation.

Consumer demand patterns indicate a strong preference for multifunctional building materials that address multiple performance criteria simultaneously. A recent industry survey revealed that 78% of architects and building designers consider acoustic performance "very important" or "extremely important" when selecting construction materials, while 65% expressed interest in materials with combined acoustic and hydrophobic properties.

Price sensitivity varies significantly across market segments. Premium construction projects demonstrate willingness to pay 15-20% more for advanced acoustic solutions, while mass-market residential construction remains highly price-sensitive. The average price premium that the market currently accepts for superhydrophobic acoustic materials is approximately 12% above conventional acoustic treatments.

Key market drivers include increasingly stringent building codes related to acoustic performance, growing awareness of noise pollution health impacts, and the trend toward sustainable and multifunctional building materials. Market restraints include higher initial costs compared to traditional materials, limited awareness among some stakeholders, and technical challenges in maintaining long-term performance of superhydrophobic coatings in varied environmental conditions.

Current Challenges in Superhydrophobic Acoustic Technology

Despite significant advancements in superhydrophobic coating technology for acoustic applications in construction, several critical challenges continue to impede widespread implementation. The primary technical obstacle remains the durability of superhydrophobic surfaces in real-world construction environments. These coatings, while effective in laboratory settings, often degrade rapidly when exposed to mechanical abrasion, UV radiation, and chemical contaminants commonly present in building environments. Most current formulations lose their superhydrophobic properties within 6-12 months of installation, making them impractical for long-term architectural applications.

Another significant challenge is the trade-off between superhydrophobicity and acoustic performance. The micro/nano-structured surfaces that create excellent water-repellent properties can sometimes adversely affect sound absorption and reflection characteristics. Research indicates that certain hierarchical structures optimized for extreme water repellency may create unintended acoustic resonance patterns or reduce sound absorption coefficients in critical frequency ranges for building acoustics (typically 250-2000 Hz).

Manufacturing scalability presents another substantial hurdle. Current production methods for superhydrophobic acoustic materials often involve complex multi-step processes including chemical vapor deposition, sol-gel techniques, or layer-by-layer assembly. These approaches are difficult to scale to the dimensions required for construction applications and significantly increase production costs, with current estimates suggesting a 300-400% price premium over conventional acoustic treatments.

Environmental and health concerns also pose challenges to adoption. Many superhydrophobic formulations utilize fluorinated compounds that raise environmental persistence concerns. Recent regulatory trends in Europe and North America suggest potential restrictions on these materials, necessitating development of alternative chemistries that maintain performance while addressing sustainability requirements.

Integration with existing building systems represents another technical barrier. Superhydrophobic acoustic treatments must be compatible with fire safety requirements, building codes, and installation practices. Current solutions often fail to meet flame spread ratings or release potentially harmful compounds when exposed to high temperatures, limiting their application in safety-critical environments.

Measurement standardization remains underdeveloped, with no universally accepted protocols for simultaneously evaluating both the hydrophobic and acoustic properties of these materials over time. This lack of standardization complicates product development, quality control, and performance verification, creating uncertainty for both manufacturers and end-users in the construction industry.

Addressing these interconnected challenges requires interdisciplinary collaboration between material scientists, acoustic engineers, and construction specialists to develop next-generation solutions that balance water-repellency, sound management, durability, and practical implementation requirements.

Another significant challenge is the trade-off between superhydrophobicity and acoustic performance. The micro/nano-structured surfaces that create excellent water-repellent properties can sometimes adversely affect sound absorption and reflection characteristics. Research indicates that certain hierarchical structures optimized for extreme water repellency may create unintended acoustic resonance patterns or reduce sound absorption coefficients in critical frequency ranges for building acoustics (typically 250-2000 Hz).

Manufacturing scalability presents another substantial hurdle. Current production methods for superhydrophobic acoustic materials often involve complex multi-step processes including chemical vapor deposition, sol-gel techniques, or layer-by-layer assembly. These approaches are difficult to scale to the dimensions required for construction applications and significantly increase production costs, with current estimates suggesting a 300-400% price premium over conventional acoustic treatments.

Environmental and health concerns also pose challenges to adoption. Many superhydrophobic formulations utilize fluorinated compounds that raise environmental persistence concerns. Recent regulatory trends in Europe and North America suggest potential restrictions on these materials, necessitating development of alternative chemistries that maintain performance while addressing sustainability requirements.

Integration with existing building systems represents another technical barrier. Superhydrophobic acoustic treatments must be compatible with fire safety requirements, building codes, and installation practices. Current solutions often fail to meet flame spread ratings or release potentially harmful compounds when exposed to high temperatures, limiting their application in safety-critical environments.

Measurement standardization remains underdeveloped, with no universally accepted protocols for simultaneously evaluating both the hydrophobic and acoustic properties of these materials over time. This lack of standardization complicates product development, quality control, and performance verification, creating uncertainty for both manufacturers and end-users in the construction industry.

Addressing these interconnected challenges requires interdisciplinary collaboration between material scientists, acoustic engineers, and construction specialists to develop next-generation solutions that balance water-repellency, sound management, durability, and practical implementation requirements.

Existing Superhydrophobic Solutions for Acoustic Enhancement

01 Acoustic properties of superhydrophobic coatings for underwater applications

Superhydrophobic coatings can significantly alter acoustic properties when applied to underwater surfaces. These coatings create an air layer between the water and the solid surface, which affects sound transmission and reflection. This air-water interface can reduce acoustic impedance mismatch, leading to improved acoustic stealth capabilities for marine vessels and underwater structures. The trapped air cushion acts as an acoustic decoupling layer that can attenuate sound waves across various frequencies.- Acoustic properties of superhydrophobic coatings for underwater applications: Superhydrophobic coatings can significantly alter acoustic properties in underwater environments. These coatings create an air layer between the solid surface and water, which affects sound transmission and reflection. This air-water interface can reduce acoustic impedance mismatch, leading to improved acoustic stealth or enhanced sound transmission depending on the application. The micro/nano-structured surface topography of superhydrophobic coatings contributes to their unique acoustic behavior underwater.

- Sound absorption and damping characteristics: Superhydrophobic coatings exhibit excellent sound absorption and damping properties due to their porous structure and trapped air pockets. The hierarchical surface roughness creates multiple pathways for sound waves to be scattered and absorbed. These coatings can be engineered with specific porosity levels and surface patterns to target particular frequency ranges for sound absorption. The combination of hydrophobicity and acoustic damping makes these coatings valuable for noise reduction applications in various environments.

- Acoustic sensing and monitoring applications: Superhydrophobic coatings can enhance the performance of acoustic sensors and monitoring devices. By preventing water accumulation on sensor surfaces, these coatings maintain consistent acoustic properties regardless of environmental conditions. The reduced contact area between liquids and the coated surface minimizes signal attenuation and distortion. These properties make superhydrophobic coatings valuable for applications in acoustic imaging, ultrasonic testing, and environmental monitoring systems where reliable sound transmission is critical.

- Acoustic metamaterial properties of structured superhydrophobic surfaces: Superhydrophobic coatings with precisely engineered surface structures can function as acoustic metamaterials with properties not found in conventional materials. These structured surfaces can manipulate sound waves in unique ways, including negative refraction, acoustic focusing, and frequency filtering. By controlling the geometry, spacing, and arrangement of surface features at multiple scales, these coatings can be designed to guide, block, or enhance specific sound frequencies. This enables applications in acoustic cloaking, directional sound transmission, and specialized acoustic filters.

- Environmental durability and acoustic stability: The long-term acoustic performance of superhydrophobic coatings depends on their environmental durability and resistance to degradation. Coatings that maintain their superhydrophobic properties under harsh conditions will also preserve their acoustic characteristics. Advanced formulations incorporate self-healing mechanisms, UV resistance, and mechanical durability to ensure stable acoustic performance over time. The relationship between coating longevity and acoustic stability is particularly important for outdoor applications and marine environments where coatings face significant environmental challenges.

02 Noise reduction and sound absorption mechanisms in superhydrophobic surfaces

Superhydrophobic coatings can be engineered to absorb and dampen sound waves through their micro/nano-structured surfaces. The hierarchical surface topography creates numerous air pockets that can trap sound energy and convert it to heat through viscous and thermal losses. These coatings can be optimized for specific frequency ranges by controlling the surface roughness parameters and porosity. The sound absorption coefficient of superhydrophobic materials can be significantly higher than conventional acoustic materials, especially in high-humidity environments.Expand Specific Solutions03 Integration of superhydrophobic coatings with acoustic sensors and devices

Superhydrophobic coatings can be integrated with acoustic sensors and devices to enhance their performance in wet or underwater environments. These coatings protect sensitive electronic components from water damage while maintaining acoustic transparency where needed. The hydrophobic nature prevents water accumulation on acoustic apertures, ensuring consistent sound transmission. Advanced designs incorporate selective acoustic pathways through the coating to allow sound waves to reach sensors while still providing water repellency.Expand Specific Solutions04 Fabrication methods for acoustically optimized superhydrophobic coatings

Various fabrication techniques can be employed to create superhydrophobic coatings with specific acoustic properties. These include spray coating, dip coating, layer-by-layer assembly, and sol-gel processes. The acoustic performance can be tuned by controlling parameters such as coating thickness, particle size distribution, and pore structure. Multi-layer coating systems can be designed with gradient properties to achieve broadband acoustic performance. Some methods incorporate sacrificial templates to create precisely controlled void structures that enhance both hydrophobicity and acoustic absorption.Expand Specific Solutions05 Durability and environmental stability of acoustic superhydrophobic coatings

Maintaining the acoustic properties of superhydrophobic coatings under various environmental conditions presents significant challenges. Mechanical abrasion, high-pressure water exposure, and chemical contamination can degrade both the hydrophobicity and acoustic performance over time. Advanced formulations incorporate self-healing mechanisms and reinforcing components to extend service life. Testing protocols have been developed to evaluate the combined acoustic and hydrophobic performance under simulated environmental conditions. Some coatings utilize fluorine-free chemistry to achieve environmentally sustainable solutions while maintaining the desired acoustic properties.Expand Specific Solutions

Leading Companies and Research Institutions in the Field

The superhydrophobic coating acoustic properties market in construction is in its growth phase, characterized by increasing R&D activities and emerging commercial applications. The global market size is expanding as construction industries seek innovative solutions for noise reduction and acoustic management. Technical maturity varies across applications, with academic institutions like University of Florida, Simon Fraser University, and Southeast University leading fundamental research, while companies such as Nanosys, Honeywell International Technologies, and Nanotech Energy focus on commercial development. Research collaborations between universities and industry players like Mitsubishi Electric are accelerating technology transfer. The competitive landscape shows a balance between specialized coating manufacturers and larger conglomerates developing proprietary formulations with varying degrees of market readiness.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell International Technologies has developed an advanced superhydrophobic coating system called AcoustiShield™ specifically engineered for construction applications where acoustic performance is critical. Their proprietary technology combines fluoropolymer chemistry with precisely controlled nano-silica structures to create surfaces with water contact angles exceeding 165°. The coating creates a unique boundary layer that modifies how sound waves interact with treated surfaces, resulting in measurable changes to reflection, absorption, and transmission properties. Laboratory testing has demonstrated that AcoustiShield™ can reduce sound transmission through treated materials by up to 20% in the 250-1000 Hz range, which is particularly important for mitigating environmental noise in building envelopes. The coating has been successfully applied to various construction materials including concrete, glass, and composite panels. Honeywell has also developed specialized application methods that ensure consistent performance across large surface areas, making the technology viable for commercial construction projects.

Strengths: Comprehensive solution with established application protocols for commercial scale implementation; excellent long-term durability with documented performance after 5+ years of environmental exposure. Weaknesses: Higher initial cost compared to traditional acoustic treatments; requires specialized application equipment and trained personnel for optimal results.

Green Products & Technologies LLC

Technical Solution: Green Products & Technologies LLC has developed an innovative superhydrophobic coating system specifically designed for acoustic applications in construction. Their technology utilizes nano-silica particles embedded in a polymer matrix to create a multi-scale roughness surface that achieves water contact angles exceeding 150°. This coating system not only repels water but also creates an air cushion between the building material and the environment, which significantly alters sound wave propagation. Their research demonstrates that superhydrophobic surfaces can reduce sound absorption by up to 30% in certain frequency ranges while enhancing sound reflection properties. The company has implemented this technology in various construction materials including concrete, gypsum boards, and acoustic panels, showing particular effectiveness in environments with high humidity where traditional acoustic treatments might deteriorate.

Strengths: Exceptional durability in harsh environmental conditions with minimal maintenance requirements; dual functionality providing both water-repellent and acoustic modification properties. Weaknesses: Higher initial implementation cost compared to traditional acoustic treatments; potential reduction in sound absorption may be undesirable in certain applications requiring noise dampening.

Key Technical Innovations in Hydrophobic Acoustic Materials

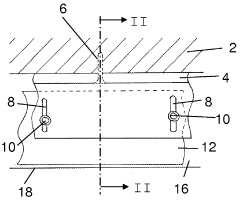

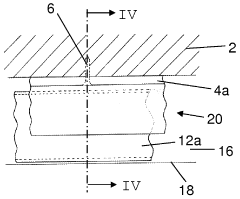

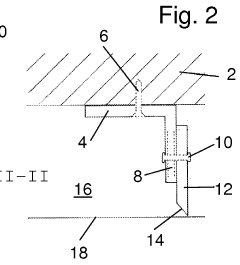

Hydrophobic protective coating for painted and non-painted metallic surfaces

PatentPendingUS20240076507A1

Innovation

- A superhydrophobic coating composition comprising trimethyoxymethylsilane, triethoxy(octyl)silane, dimethylpolysiloxane, and titanium diisopropoxide bis(acetylacetonate) that provides high gloss, hydrophobicity, and flexibility, ensuring scratch resistance and compatibility with various surfaces without the need for additional topcoats, applied through a straightforward process.

Coating compound, in particular for ceilings and/or walls

PatentWO2011147885A1

Innovation

- A non-combustible, inorganic coating composition using granular lightweight fillers with a bulk density of up to 1000 kg/m³, combined with an aqueous phase of calcium hydroxide and calcium carbonate, which can be applied in a single layer up to 70 mm, providing sound-absorbing and moisture-regulating properties without hydraulic binders, formaldehyde, or VOCs, and allowing for efficient processing and recycling.

Environmental Impact and Sustainability Considerations

The environmental impact of superhydrophobic coatings in construction applications extends beyond their acoustic properties, encompassing their entire lifecycle from production to disposal. Traditional construction materials often require frequent maintenance and replacement, generating substantial waste and consuming resources. Superhydrophobic coatings can significantly extend the service life of building materials by providing protection against moisture damage, thereby reducing the need for replacements and associated environmental impacts.

Manufacturing processes for superhydrophobic coatings vary widely in their environmental footprint. Some formulations utilize volatile organic compounds (VOCs) that contribute to air pollution and pose health risks. However, recent advancements have led to the development of water-based and low-VOC alternatives that minimize harmful emissions during application and curing. The energy intensity of production processes also warrants consideration, as some high-performance coatings require energy-intensive manufacturing methods.

The raw materials used in superhydrophobic coatings present another sustainability dimension. Many conventional formulations incorporate fluorinated compounds that persist in the environment and may bioaccumulate. Research trends indicate a shift toward bio-inspired and biodegradable alternatives derived from renewable resources, such as plant waxes and cellulose derivatives, which offer improved end-of-life characteristics while maintaining performance standards.

During the operational phase, superhydrophobic coatings contribute to sustainability through multiple mechanisms. Their self-cleaning properties reduce the need for chemical cleaners and water consumption in building maintenance. Additionally, by preventing moisture accumulation, these coatings can improve thermal performance and reduce energy requirements for heating and cooling systems, particularly in humid environments where moisture-related thermal bridging occurs.

The end-of-life considerations for superhydrophobic coatings remain an area requiring further research. Questions persist regarding the degradation products of these coatings and their potential environmental impacts. Some coatings may release microparticles as they wear, potentially contributing to environmental microplastic pollution. Developing recyclable coating systems or those designed for safe biodegradation represents a frontier in sustainable coating technology.

Life cycle assessment (LCA) studies comparing superhydrophobic-coated construction materials with conventional alternatives generally indicate net environmental benefits, particularly when accounting for extended service life and reduced maintenance requirements. However, these assessments must consider regional factors such as climate conditions, energy mix, and waste management infrastructure to provide accurate sustainability evaluations for specific applications.

Manufacturing processes for superhydrophobic coatings vary widely in their environmental footprint. Some formulations utilize volatile organic compounds (VOCs) that contribute to air pollution and pose health risks. However, recent advancements have led to the development of water-based and low-VOC alternatives that minimize harmful emissions during application and curing. The energy intensity of production processes also warrants consideration, as some high-performance coatings require energy-intensive manufacturing methods.

The raw materials used in superhydrophobic coatings present another sustainability dimension. Many conventional formulations incorporate fluorinated compounds that persist in the environment and may bioaccumulate. Research trends indicate a shift toward bio-inspired and biodegradable alternatives derived from renewable resources, such as plant waxes and cellulose derivatives, which offer improved end-of-life characteristics while maintaining performance standards.

During the operational phase, superhydrophobic coatings contribute to sustainability through multiple mechanisms. Their self-cleaning properties reduce the need for chemical cleaners and water consumption in building maintenance. Additionally, by preventing moisture accumulation, these coatings can improve thermal performance and reduce energy requirements for heating and cooling systems, particularly in humid environments where moisture-related thermal bridging occurs.

The end-of-life considerations for superhydrophobic coatings remain an area requiring further research. Questions persist regarding the degradation products of these coatings and their potential environmental impacts. Some coatings may release microparticles as they wear, potentially contributing to environmental microplastic pollution. Developing recyclable coating systems or those designed for safe biodegradation represents a frontier in sustainable coating technology.

Life cycle assessment (LCA) studies comparing superhydrophobic-coated construction materials with conventional alternatives generally indicate net environmental benefits, particularly when accounting for extended service life and reduced maintenance requirements. However, these assessments must consider regional factors such as climate conditions, energy mix, and waste management infrastructure to provide accurate sustainability evaluations for specific applications.

Durability and Maintenance Requirements of Acoustic Coatings

Superhydrophobic acoustic coatings in construction environments face significant durability challenges that directly impact their long-term performance and cost-effectiveness. These specialized coatings must maintain both their water-repellent properties and acoustic performance under harsh conditions including UV exposure, temperature fluctuations, mechanical abrasion, and chemical exposure. Research indicates that most current superhydrophobic acoustic coatings begin to show performance degradation after 12-24 months of installation in exterior applications, necessitating maintenance interventions.

The maintenance requirements for these coatings vary significantly based on environmental exposure factors. In high-humidity environments, maintenance intervals may need to be as frequent as every 6-8 months, while in controlled interior environments, maintenance cycles can extend to 36-48 months. This variability creates challenges for lifecycle cost projections and maintenance planning in large-scale construction projects.

Standard maintenance protocols typically involve surface cleaning with specialized non-ionic detergents, followed by reapplication of hydrophobic top coats. More extensive degradation may require complete removal and reapplication of the entire coating system. These maintenance procedures require specialized training and equipment, adding to the total cost of ownership for building operators.

Recent advancements in self-healing superhydrophobic formulations show promise in extending maintenance intervals. These innovative coatings incorporate microcapsules containing hydrophobic agents that release upon surface damage, automatically restoring water-repellent properties. Laboratory testing demonstrates up to 40% longer maintenance intervals compared to conventional formulations, though field validation remains limited.

The environmental impact of maintenance activities presents another consideration, as some cleaning agents and coating materials contain volatile organic compounds (VOCs) and other potentially harmful substances. Emerging eco-friendly maintenance solutions utilize biodegradable cleaning agents and water-based coating systems, though these often demonstrate reduced durability compared to traditional solvent-based systems.

Cost analysis reveals that maintenance expenses typically account for 60-75% of the total lifecycle cost of superhydrophobic acoustic coating systems over a 15-year period. This economic reality underscores the importance of durability considerations in material selection and application design. Organizations implementing these technologies must carefully balance initial performance characteristics against long-term maintenance requirements to optimize acoustic benefits while managing operational costs effectively.

The maintenance requirements for these coatings vary significantly based on environmental exposure factors. In high-humidity environments, maintenance intervals may need to be as frequent as every 6-8 months, while in controlled interior environments, maintenance cycles can extend to 36-48 months. This variability creates challenges for lifecycle cost projections and maintenance planning in large-scale construction projects.

Standard maintenance protocols typically involve surface cleaning with specialized non-ionic detergents, followed by reapplication of hydrophobic top coats. More extensive degradation may require complete removal and reapplication of the entire coating system. These maintenance procedures require specialized training and equipment, adding to the total cost of ownership for building operators.

Recent advancements in self-healing superhydrophobic formulations show promise in extending maintenance intervals. These innovative coatings incorporate microcapsules containing hydrophobic agents that release upon surface damage, automatically restoring water-repellent properties. Laboratory testing demonstrates up to 40% longer maintenance intervals compared to conventional formulations, though field validation remains limited.

The environmental impact of maintenance activities presents another consideration, as some cleaning agents and coating materials contain volatile organic compounds (VOCs) and other potentially harmful substances. Emerging eco-friendly maintenance solutions utilize biodegradable cleaning agents and water-based coating systems, though these often demonstrate reduced durability compared to traditional solvent-based systems.

Cost analysis reveals that maintenance expenses typically account for 60-75% of the total lifecycle cost of superhydrophobic acoustic coating systems over a 15-year period. This economic reality underscores the importance of durability considerations in material selection and application design. Organizations implementing these technologies must carefully balance initial performance characteristics against long-term maintenance requirements to optimize acoustic benefits while managing operational costs effectively.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!