What Is the Role of Superhydrophobic Coatings in Eco-Friendly Packaging

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superhydrophobic Coating Technology Background and Objectives

Superhydrophobic surfaces, characterized by water contact angles exceeding 150° and low sliding angles, have emerged as a revolutionary technology inspired by natural phenomena such as the lotus leaf effect. The development of these surfaces has evolved significantly over the past two decades, transitioning from academic curiosity to practical applications across multiple industries. The fundamental principle behind superhydrophobicity involves creating surfaces with micro and nano-scale roughness combined with low surface energy materials, resulting in minimal water adhesion.

The historical trajectory of superhydrophobic coating technology began with observations of natural water-repellent surfaces in the 1990s, followed by laboratory synthesis methods in the early 2000s. Recent advancements have focused on durability enhancement, cost reduction, and environmentally friendly fabrication processes, making these coatings increasingly viable for commercial applications. The technology has now reached a critical juncture where industrial scalability is becoming feasible.

In the context of eco-friendly packaging, superhydrophobic coatings represent a promising alternative to traditional plastic-based moisture barriers and fluorinated compounds that pose significant environmental concerns. The primary technical objective is to develop superhydrophobic coatings that can provide effective moisture protection while meeting stringent environmental standards, including biodegradability, non-toxicity, and compatibility with recycling processes.

Current research aims to achieve several specific goals: developing superhydrophobic coatings from renewable resources, ensuring coating stability throughout the packaging lifecycle, maintaining effectiveness under various environmental conditions, and establishing cost-effective manufacturing processes suitable for high-volume production. Additionally, these coatings must comply with food safety regulations when applied to food packaging materials.

The technology trend indicates a shift toward bio-based superhydrophobic coatings utilizing cellulose nanocrystals, chitosan, and plant-derived waxes as alternatives to synthetic polymers and fluorinated compounds. Concurrently, advanced deposition techniques such as layer-by-layer assembly, spray coating, and roll-to-roll processing are being optimized to enable industrial-scale application while minimizing environmental impact.

The ultimate objective of this technological development is to create a new generation of packaging materials that maintain or exceed the performance characteristics of conventional packaging while dramatically reducing environmental footprint. This aligns with global sustainability initiatives, including circular economy principles and plastic reduction targets established by international agreements and corporate sustainability commitments.

The historical trajectory of superhydrophobic coating technology began with observations of natural water-repellent surfaces in the 1990s, followed by laboratory synthesis methods in the early 2000s. Recent advancements have focused on durability enhancement, cost reduction, and environmentally friendly fabrication processes, making these coatings increasingly viable for commercial applications. The technology has now reached a critical juncture where industrial scalability is becoming feasible.

In the context of eco-friendly packaging, superhydrophobic coatings represent a promising alternative to traditional plastic-based moisture barriers and fluorinated compounds that pose significant environmental concerns. The primary technical objective is to develop superhydrophobic coatings that can provide effective moisture protection while meeting stringent environmental standards, including biodegradability, non-toxicity, and compatibility with recycling processes.

Current research aims to achieve several specific goals: developing superhydrophobic coatings from renewable resources, ensuring coating stability throughout the packaging lifecycle, maintaining effectiveness under various environmental conditions, and establishing cost-effective manufacturing processes suitable for high-volume production. Additionally, these coatings must comply with food safety regulations when applied to food packaging materials.

The technology trend indicates a shift toward bio-based superhydrophobic coatings utilizing cellulose nanocrystals, chitosan, and plant-derived waxes as alternatives to synthetic polymers and fluorinated compounds. Concurrently, advanced deposition techniques such as layer-by-layer assembly, spray coating, and roll-to-roll processing are being optimized to enable industrial-scale application while minimizing environmental impact.

The ultimate objective of this technological development is to create a new generation of packaging materials that maintain or exceed the performance characteristics of conventional packaging while dramatically reducing environmental footprint. This aligns with global sustainability initiatives, including circular economy principles and plastic reduction targets established by international agreements and corporate sustainability commitments.

Market Demand for Eco-Friendly Packaging Solutions

The global market for eco-friendly packaging solutions has experienced significant growth in recent years, driven by increasing environmental awareness and regulatory pressures. Consumer demand for sustainable packaging alternatives has risen dramatically, with market research indicating that over 70% of global consumers consider environmental impact when making purchasing decisions. This shift in consumer behavior has created substantial market opportunities for innovative solutions like superhydrophobic coatings in packaging applications.

The food and beverage industry represents the largest segment demanding eco-friendly packaging solutions, accounting for approximately 40% of the sustainable packaging market. Superhydrophobic coatings offer particular value in this sector by extending shelf life, reducing food waste, and eliminating the need for additional plastic barriers while maintaining product integrity. Major food corporations have publicly committed to transitioning to fully recyclable, reusable, or compostable packaging by 2025-2030, creating immediate market pull for advanced coating technologies.

E-commerce has emerged as another significant driver for eco-friendly packaging innovations. With global e-commerce sales growing at double-digit rates annually, the environmental impact of shipping materials has become a critical concern. Superhydrophobic coatings can enhance the performance of paper-based shipping materials, potentially replacing plastic bubble wrap and foam inserts that contribute to environmental pollution. Market analysis shows that e-commerce businesses implementing sustainable packaging solutions report improved customer loyalty and brand perception.

Healthcare and pharmaceutical packaging represents a high-value growth segment for superhydrophobic coating applications. This sector requires packaging that maintains sterility while reducing environmental impact. The global medical packaging market is projected to grow substantially, with increasing pressure to replace traditional plastic and composite materials with more sustainable alternatives that maintain the same protective properties.

Regulatory developments worldwide are accelerating market demand for eco-friendly packaging solutions. The European Union's Single-Use Plastics Directive, China's plastic waste import ban, and similar legislation in other regions have created urgent need for alternative packaging technologies. Companies face potential taxation on non-recyclable packaging in many jurisdictions, creating economic incentives to adopt innovations like superhydrophobic coatings that can enhance the performance of recyclable materials.

Consumer packaged goods companies are increasingly willing to pay premium prices for packaging solutions that align with their sustainability commitments while maintaining or improving functionality. This price tolerance creates favorable market conditions for the commercialization of advanced coating technologies, despite potentially higher initial costs compared to conventional packaging materials.

The food and beverage industry represents the largest segment demanding eco-friendly packaging solutions, accounting for approximately 40% of the sustainable packaging market. Superhydrophobic coatings offer particular value in this sector by extending shelf life, reducing food waste, and eliminating the need for additional plastic barriers while maintaining product integrity. Major food corporations have publicly committed to transitioning to fully recyclable, reusable, or compostable packaging by 2025-2030, creating immediate market pull for advanced coating technologies.

E-commerce has emerged as another significant driver for eco-friendly packaging innovations. With global e-commerce sales growing at double-digit rates annually, the environmental impact of shipping materials has become a critical concern. Superhydrophobic coatings can enhance the performance of paper-based shipping materials, potentially replacing plastic bubble wrap and foam inserts that contribute to environmental pollution. Market analysis shows that e-commerce businesses implementing sustainable packaging solutions report improved customer loyalty and brand perception.

Healthcare and pharmaceutical packaging represents a high-value growth segment for superhydrophobic coating applications. This sector requires packaging that maintains sterility while reducing environmental impact. The global medical packaging market is projected to grow substantially, with increasing pressure to replace traditional plastic and composite materials with more sustainable alternatives that maintain the same protective properties.

Regulatory developments worldwide are accelerating market demand for eco-friendly packaging solutions. The European Union's Single-Use Plastics Directive, China's plastic waste import ban, and similar legislation in other regions have created urgent need for alternative packaging technologies. Companies face potential taxation on non-recyclable packaging in many jurisdictions, creating economic incentives to adopt innovations like superhydrophobic coatings that can enhance the performance of recyclable materials.

Consumer packaged goods companies are increasingly willing to pay premium prices for packaging solutions that align with their sustainability commitments while maintaining or improving functionality. This price tolerance creates favorable market conditions for the commercialization of advanced coating technologies, despite potentially higher initial costs compared to conventional packaging materials.

Current State and Challenges in Superhydrophobic Coating Development

Superhydrophobic coatings have emerged as a significant technological advancement in the global packaging industry, with research and development efforts intensifying over the past decade. Currently, these coatings are being developed using various approaches including chemical modification, surface texturing, and nanoparticle incorporation. The global landscape shows concentrated research activities in North America, Europe, and East Asia, with China, the United States, and Germany leading in patent applications and scientific publications.

The fundamental technology relies on creating surfaces with water contact angles exceeding 150° and low sliding angles, typically achieved through a combination of micro/nano-scale surface roughness and low surface energy materials. Recent advancements have focused on improving durability, cost-effectiveness, and environmental compatibility of these coatings, with significant progress in developing bio-based and biodegradable formulations.

Despite promising developments, several critical challenges persist in the widespread adoption of superhydrophobic coatings for eco-friendly packaging. Durability remains a primary concern, as many coatings lose their superhydrophobic properties under mechanical abrasion, UV exposure, and temperature fluctuations. This limitation significantly restricts their practical application in packaging that undergoes handling, transportation, and various environmental conditions.

Cost-effectiveness presents another substantial barrier. Current manufacturing processes for high-performance superhydrophobic coatings often involve complex multi-step procedures and expensive materials, making them economically unfeasible for mass-market packaging applications. The industry requires scalable, low-cost production methods to achieve commercial viability.

Environmental concerns also pose significant challenges. Many traditional superhydrophobic formulations contain fluorinated compounds and other potentially harmful chemicals that contradict the eco-friendly packaging objective. The development of truly sustainable alternatives that maintain performance while eliminating environmentally persistent substances remains technically challenging.

Regulatory hurdles further complicate advancement in this field. Food safety regulations in major markets impose strict requirements on materials that come into contact with consumables, necessitating extensive testing and certification processes for new coating technologies. The lack of standardized testing protocols specifically for superhydrophobic coatings in packaging applications creates additional uncertainty for developers and manufacturers.

Technical integration challenges also exist when incorporating these coatings into existing packaging production lines. Many current superhydrophobic coating application methods are not compatible with high-speed packaging manufacturing processes, requiring significant modifications to production equipment or entirely new manufacturing approaches.

The fundamental technology relies on creating surfaces with water contact angles exceeding 150° and low sliding angles, typically achieved through a combination of micro/nano-scale surface roughness and low surface energy materials. Recent advancements have focused on improving durability, cost-effectiveness, and environmental compatibility of these coatings, with significant progress in developing bio-based and biodegradable formulations.

Despite promising developments, several critical challenges persist in the widespread adoption of superhydrophobic coatings for eco-friendly packaging. Durability remains a primary concern, as many coatings lose their superhydrophobic properties under mechanical abrasion, UV exposure, and temperature fluctuations. This limitation significantly restricts their practical application in packaging that undergoes handling, transportation, and various environmental conditions.

Cost-effectiveness presents another substantial barrier. Current manufacturing processes for high-performance superhydrophobic coatings often involve complex multi-step procedures and expensive materials, making them economically unfeasible for mass-market packaging applications. The industry requires scalable, low-cost production methods to achieve commercial viability.

Environmental concerns also pose significant challenges. Many traditional superhydrophobic formulations contain fluorinated compounds and other potentially harmful chemicals that contradict the eco-friendly packaging objective. The development of truly sustainable alternatives that maintain performance while eliminating environmentally persistent substances remains technically challenging.

Regulatory hurdles further complicate advancement in this field. Food safety regulations in major markets impose strict requirements on materials that come into contact with consumables, necessitating extensive testing and certification processes for new coating technologies. The lack of standardized testing protocols specifically for superhydrophobic coatings in packaging applications creates additional uncertainty for developers and manufacturers.

Technical integration challenges also exist when incorporating these coatings into existing packaging production lines. Many current superhydrophobic coating application methods are not compatible with high-speed packaging manufacturing processes, requiring significant modifications to production equipment or entirely new manufacturing approaches.

Current Superhydrophobic Solutions for Sustainable Packaging

01 Nanoparticle-based superhydrophobic coatings

Superhydrophobic coatings can be formulated using nanoparticles to create micro and nano-scale roughness on surfaces. These nanoparticles, such as silica, titanium dioxide, or carbon-based materials, are incorporated into polymer matrices to achieve water contact angles greater than 150 degrees. The hierarchical surface structure combined with low surface energy materials creates the lotus effect, allowing water droplets to roll off easily while carrying away contaminants.- Nanoparticle-based superhydrophobic coatings: Superhydrophobic coatings can be formulated using nanoparticles to create nano-scale roughness on surfaces. These nanoparticles, such as silica, titanium dioxide, or carbon-based materials, create a hierarchical structure that traps air and prevents water from penetrating the surface. The combination of these nanoparticles with hydrophobic binders results in surfaces with water contact angles greater than 150° and low sliding angles, making them highly water-repellent and self-cleaning.

- Fluoropolymer-based superhydrophobic coatings: Fluoropolymers are widely used in superhydrophobic coating formulations due to their inherently low surface energy. These polymers, including polytetrafluoroethylene (PTFE) and fluorosilanes, create highly water-repellent surfaces when combined with structured substrates. The fluorine-containing compounds reduce surface energy while maintaining durability and chemical resistance, making them suitable for various applications including textiles, glass, and industrial surfaces where extreme water repellency is required.

- Biomimetic superhydrophobic coatings: Inspired by natural superhydrophobic surfaces like lotus leaves and butterfly wings, biomimetic coatings replicate the micro and nano-scale structures found in nature. These coatings typically combine hierarchical surface textures with hydrophobic chemistry to achieve water contact angles exceeding 150°. The biomimetic approach often involves creating dual-scale roughness patterns through techniques such as etching, lithography, or template-based methods, resulting in highly efficient water-repellent surfaces with self-cleaning properties.

- Sol-gel derived superhydrophobic coatings: Sol-gel technology offers a versatile approach for developing superhydrophobic coatings through controlled hydrolysis and condensation reactions. This method allows for the creation of silica-based networks with precisely engineered surface roughness and chemistry. By incorporating hydrophobic modifiers such as alkylsilanes or fluoroalkylsilanes into the sol-gel matrix, these coatings achieve excellent water repellency while maintaining optical transparency and durability. The process typically involves simple application methods like dip-coating or spray-coating followed by thermal curing.

- Durable and self-healing superhydrophobic coatings: Advanced superhydrophobic coatings with enhanced durability and self-healing capabilities address the common issue of mechanical degradation. These coatings incorporate resilient polymers, elastomers, or dynamic chemical bonds that can restore the surface structure after damage. Some formulations include encapsulated hydrophobic agents that release upon mechanical damage, automatically restoring the water-repellent properties. This approach significantly extends coating lifetime in harsh environments and under abrasive conditions, making them suitable for long-term outdoor applications.

02 Fluoropolymer-based superhydrophobic coatings

Fluoropolymers are widely used in superhydrophobic coating formulations due to their inherently low surface energy. These polymers, including polytetrafluoroethylene (PTFE) and fluorosilanes, create water-repellent surfaces when combined with appropriate surface texturing techniques. The fluorine-containing compounds form strong bonds that resist degradation while maintaining excellent water and oil repellency properties, making them suitable for durable outdoor applications.Expand Specific Solutions03 Self-healing superhydrophobic coatings

Self-healing superhydrophobic coatings incorporate mechanisms to restore water-repellent properties after physical or chemical damage. These coatings may contain encapsulated hydrophobic agents that are released upon damage, or dynamic chemical structures that can rearrange to expose new hydrophobic groups at the surface. This technology extends coating lifetime and maintains performance in harsh environments where conventional superhydrophobic surfaces would quickly degrade.Expand Specific Solutions04 Environmentally friendly superhydrophobic coatings

Eco-friendly superhydrophobic coatings utilize sustainable materials and processes to achieve water repellency without harmful fluorinated compounds. These formulations may incorporate plant-derived waxes, modified cellulose, silica from renewable sources, or biodegradable polymers. The coatings achieve superhydrophobicity through biomimetic surface structures while minimizing environmental impact and addressing regulatory concerns about persistent chemicals.Expand Specific Solutions05 Application-specific superhydrophobic coatings

Specialized superhydrophobic coatings are designed for specific applications such as anti-icing, anti-corrosion, self-cleaning, or medical devices. These formulations balance water repellency with other required properties like transparency, conductivity, or biocompatibility. The coatings may incorporate additional functional components such as antimicrobial agents, UV stabilizers, or conductive materials while maintaining the core superhydrophobic characteristics needed for their intended use.Expand Specific Solutions

Leading Companies in Superhydrophobic Coating Industry

The superhydrophobic coatings market in eco-friendly packaging is currently in a growth phase, with increasing adoption driven by sustainability demands. The market is expanding rapidly, projected to reach significant value as industries seek alternatives to traditional packaging materials. Technologically, the field shows varying maturity levels across applications. Leading academic institutions like California Institute of Technology, University of Florida, and Queen Mary University of London are advancing fundamental research, while commercial players such as DSM IP Assets BV and Xerox Holdings Corp. are developing practical applications. Research collaborations between universities and industry partners like Agency for Science, Technology & Research are accelerating innovation in biodegradable superhydrophobic materials, suggesting the technology is transitioning from laboratory research to commercial implementation across global markets.

DSM IP Assets BV

Technical Solution: DSM IP Assets BV has developed an innovative superhydrophobic coating technology for sustainable packaging applications that combines bio-based polymers with specially engineered surface topographies. Their approach utilizes renewable resources such as plant oils and cellulose derivatives to create hierarchical micro/nano structures that achieve water contact angles exceeding 160°. The company's proprietary manufacturing process employs UV-curing techniques that significantly reduce energy consumption compared to traditional thermal curing methods. DSM's coatings are designed with end-of-life considerations, incorporating trigger mechanisms that allow the superhydrophobic properties to degrade under specific environmental conditions after disposal, facilitating biodegradation or recycling processes. The technology also incorporates oxygen barrier properties, extending product shelf life and reducing food waste without compromising the packaging's environmental credentials.

Strengths: Extensive materials science expertise allowing for customized solutions across different packaging applications; strong integration with existing manufacturing infrastructure. Weaknesses: Higher initial cost compared to conventional coatings; potential regulatory hurdles in certain markets due to novel material combinations.

Xerox Holdings Corp.

Technical Solution: Xerox Holdings Corp. has leveraged its extensive expertise in surface science and materials engineering to develop advanced superhydrophobic coatings for sustainable packaging applications. Their technology utilizes a proprietary combination of cellulose nanocrystals and bio-based hydrophobic modifiers to create hierarchical surface structures that achieve water contact angles exceeding 150°. The company's approach focuses on printable superhydrophobic formulations that can be applied using modified versions of their existing digital printing technologies, enabling mass customization and on-demand production. Xerox's coatings incorporate phase-change materials that respond to environmental conditions, providing adaptive barrier properties that optimize product protection while minimizing material usage. Their manufacturing process employs water-based carrier systems that eliminate VOC emissions during application and curing, significantly reducing the environmental footprint compared to solvent-based alternatives.

Strengths: Unparalleled precision in coating application through digital printing technologies; excellent scalability for both small and large production runs. Weaknesses: Currently higher cost structure compared to conventional packaging solutions; limited experience in food-contact applications compared to established packaging companies.

Key Innovations in Biomimetic Superhydrophobic Materials

Superhydrophobic coatings

PatentWO2025191162A1

Innovation

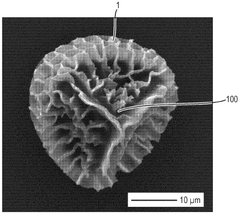

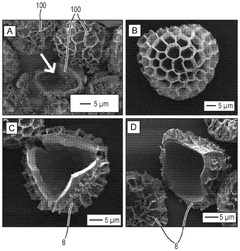

- Development of superhydrophobic coatings using chemically modified plant spore shells, such as lycopodium and pine pollen shells, combined with plant-based waxes, to maintain hydrophobicity and extend coating longevity by removing genetic and cytoplasmic materials through chemical treatments.

Environmental Impact Assessment of Superhydrophobic Materials

The environmental impact of superhydrophobic materials used in eco-friendly packaging requires comprehensive assessment across their entire lifecycle. These materials, while offering significant benefits in packaging applications, also present potential environmental concerns that must be carefully evaluated.

When examining the production phase, superhydrophobic coatings often involve nanomaterials and fluorinated compounds that may require energy-intensive manufacturing processes. The synthesis of these materials typically consumes substantial resources and may generate hazardous byproducts. However, recent advancements have introduced more sustainable production methods, including bio-inspired approaches that mimic natural superhydrophobic surfaces found in lotus leaves and butterfly wings.

During the usage phase, superhydrophobic coatings demonstrate notable environmental advantages. By creating water-repellent surfaces on packaging materials, these coatings reduce the need for additional plastic layers traditionally used for moisture protection. This results in significant material reduction, with some studies reporting up to 30% decrease in plastic usage for certain packaging applications. Furthermore, the enhanced protection against moisture contamination extends product shelf life, potentially reducing food waste—a major environmental concern globally.

The end-of-life considerations present both challenges and opportunities. Conventional superhydrophobic materials containing perfluorinated compounds pose persistence issues in the environment, with potential bioaccumulation concerns. These compounds may resist natural degradation processes, remaining in ecosystems for extended periods. However, emerging biodegradable superhydrophobic coatings derived from natural waxes, cellulose, and silica nanoparticles offer promising alternatives with significantly reduced environmental persistence.

Water consumption and pollution impacts also warrant attention. While superhydrophobic coatings reduce water needed for cleaning packaging materials, their production may involve water-intensive processes. Additionally, potential leaching of coating components into aquatic environments during disposal requires careful monitoring and mitigation strategies.

Carbon footprint analysis reveals mixed results. The energy-intensive production of some superhydrophobic materials contributes to higher initial carbon emissions. However, lifecycle assessments indicate that these emissions may be offset by benefits during use and disposal phases, particularly through reduced material usage and extended product lifespans. Recent studies suggest that advanced bio-based superhydrophobic coatings can achieve carbon neutrality when considering their complete lifecycle impact.

When examining the production phase, superhydrophobic coatings often involve nanomaterials and fluorinated compounds that may require energy-intensive manufacturing processes. The synthesis of these materials typically consumes substantial resources and may generate hazardous byproducts. However, recent advancements have introduced more sustainable production methods, including bio-inspired approaches that mimic natural superhydrophobic surfaces found in lotus leaves and butterfly wings.

During the usage phase, superhydrophobic coatings demonstrate notable environmental advantages. By creating water-repellent surfaces on packaging materials, these coatings reduce the need for additional plastic layers traditionally used for moisture protection. This results in significant material reduction, with some studies reporting up to 30% decrease in plastic usage for certain packaging applications. Furthermore, the enhanced protection against moisture contamination extends product shelf life, potentially reducing food waste—a major environmental concern globally.

The end-of-life considerations present both challenges and opportunities. Conventional superhydrophobic materials containing perfluorinated compounds pose persistence issues in the environment, with potential bioaccumulation concerns. These compounds may resist natural degradation processes, remaining in ecosystems for extended periods. However, emerging biodegradable superhydrophobic coatings derived from natural waxes, cellulose, and silica nanoparticles offer promising alternatives with significantly reduced environmental persistence.

Water consumption and pollution impacts also warrant attention. While superhydrophobic coatings reduce water needed for cleaning packaging materials, their production may involve water-intensive processes. Additionally, potential leaching of coating components into aquatic environments during disposal requires careful monitoring and mitigation strategies.

Carbon footprint analysis reveals mixed results. The energy-intensive production of some superhydrophobic materials contributes to higher initial carbon emissions. However, lifecycle assessments indicate that these emissions may be offset by benefits during use and disposal phases, particularly through reduced material usage and extended product lifespans. Recent studies suggest that advanced bio-based superhydrophobic coatings can achieve carbon neutrality when considering their complete lifecycle impact.

Regulatory Compliance for Food-Contact Superhydrophobic Surfaces

The regulatory landscape for food-contact superhydrophobic surfaces represents a complex intersection of materials science, food safety, and environmental protection. In the United States, the FDA regulates food-contact materials through the Food, Drug, and Cosmetic Act, requiring that all substances used in food packaging must be either Generally Recognized as Safe (GRAS) or approved as Food Contact Substances (FCS). For superhydrophobic coatings, this presents unique challenges due to their multi-component nature, often incorporating nanomaterials and fluorinated compounds.

European regulations, particularly the EU Framework Regulation (EC) No 1935/2004, establish even more stringent requirements, mandating that materials in contact with food must not transfer constituents to food in quantities that could endanger human health or bring unacceptable changes to food composition. The EU has also implemented specific migration limits (SMLs) for various substances, which superhydrophobic coating manufacturers must carefully consider.

The migration potential of superhydrophobic coating components represents a primary regulatory concern. Testing protocols typically involve food simulants under various temperature and time conditions to assess potential migration of coating components into food. For eco-friendly packaging applications, manufacturers must demonstrate that their superhydrophobic coatings maintain their integrity throughout the product lifecycle without leaching harmful substances.

Nanomaterials, frequently used in advanced superhydrophobic formulations, face additional regulatory scrutiny. The EU, through Regulation (EU) 2023/1400, requires specific safety assessments for nanomaterials in food contact applications, including detailed characterization of particle size, distribution, and potential for aggregation or agglomeration.

Fluorinated compounds, traditionally used in many superhydrophobic applications, face increasing regulatory restrictions globally due to their environmental persistence. The Stockholm Convention on Persistent Organic Pollutants has led to phase-outs of certain perfluorinated compounds, pushing manufacturers toward alternative chemistries for superhydrophobic effects.

Certification pathways for novel superhydrophobic coatings typically involve comprehensive toxicological assessments, migration studies, and environmental impact evaluations. Third-party certifications such as those from NSF International or EFSA positive listings can facilitate market acceptance and regulatory compliance.

Global regulatory harmonization efforts, including those through the Codex Alimentarius Commission, aim to standardize requirements for food-contact materials, though significant regional variations persist. Manufacturers developing superhydrophobic coatings for eco-friendly packaging must navigate these diverse regulatory frameworks, often necessitating multiple compliance strategies for different markets.

European regulations, particularly the EU Framework Regulation (EC) No 1935/2004, establish even more stringent requirements, mandating that materials in contact with food must not transfer constituents to food in quantities that could endanger human health or bring unacceptable changes to food composition. The EU has also implemented specific migration limits (SMLs) for various substances, which superhydrophobic coating manufacturers must carefully consider.

The migration potential of superhydrophobic coating components represents a primary regulatory concern. Testing protocols typically involve food simulants under various temperature and time conditions to assess potential migration of coating components into food. For eco-friendly packaging applications, manufacturers must demonstrate that their superhydrophobic coatings maintain their integrity throughout the product lifecycle without leaching harmful substances.

Nanomaterials, frequently used in advanced superhydrophobic formulations, face additional regulatory scrutiny. The EU, through Regulation (EU) 2023/1400, requires specific safety assessments for nanomaterials in food contact applications, including detailed characterization of particle size, distribution, and potential for aggregation or agglomeration.

Fluorinated compounds, traditionally used in many superhydrophobic applications, face increasing regulatory restrictions globally due to their environmental persistence. The Stockholm Convention on Persistent Organic Pollutants has led to phase-outs of certain perfluorinated compounds, pushing manufacturers toward alternative chemistries for superhydrophobic effects.

Certification pathways for novel superhydrophobic coatings typically involve comprehensive toxicological assessments, migration studies, and environmental impact evaluations. Third-party certifications such as those from NSF International or EFSA positive listings can facilitate market acceptance and regulatory compliance.

Global regulatory harmonization efforts, including those through the Codex Alimentarius Commission, aim to standardize requirements for food-contact materials, though significant regional variations persist. Manufacturers developing superhydrophobic coatings for eco-friendly packaging must navigate these diverse regulatory frameworks, often necessitating multiple compliance strategies for different markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!