Influence of Superhydrophobic Coating on Electronic Device Waterproofing

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superhydrophobic Coating Technology Evolution and Objectives

Superhydrophobic coatings represent a revolutionary advancement in surface engineering, drawing inspiration from nature's own water-repellent structures such as lotus leaves and butterfly wings. Since the early 2000s, research into these biomimetic surfaces has accelerated dramatically, transitioning from academic curiosity to practical applications across multiple industries, particularly in electronic device protection.

The evolution of superhydrophobic coating technology can be traced through several distinct phases. Initially, researchers focused on understanding the fundamental principles behind natural superhydrophobicity, identifying the critical combination of micro/nano-scale surface roughness and low surface energy materials. By 2005-2010, early synthetic approaches emerged, primarily utilizing complex multi-step processes that limited commercial viability.

A significant breakthrough occurred between 2010-2015 with the development of single-step application methods and more durable formulations. This period saw the first commercial applications in specialized industrial settings, though durability remained a significant challenge. The years 2015-2020 marked rapid advancement in coating resilience and application techniques, with spray-on and dip-coating methods becoming increasingly refined.

Most recently (2020-present), the field has experienced convergence with other advanced materials science disciplines, including the integration of self-healing properties, transparent formulations, and environmentally sustainable compositions. These developments have dramatically expanded potential applications in consumer electronics waterproofing.

The primary technical objectives in this domain now center on several key challenges. First, enhancing mechanical durability to withstand everyday wear and abrasion while maintaining superhydrophobic properties. Second, developing transparent formulations that preserve device aesthetics while providing protection. Third, creating application methods compatible with mass manufacturing processes for consumer electronics. Fourth, ensuring environmental sustainability through non-toxic formulations and biodegradable components.

Looking forward, the technology roadmap aims to achieve coatings capable of withstanding 5+ years of regular use without degradation, complete transparency with no impact on touch sensitivity or display quality, and application processes that integrate seamlessly into existing electronics manufacturing lines. Additionally, there is growing emphasis on developing formulations that provide not only water resistance but also resistance to oils, chemicals, and biological contaminants, creating truly comprehensive protection for sensitive electronic components.

The evolution of superhydrophobic coating technology can be traced through several distinct phases. Initially, researchers focused on understanding the fundamental principles behind natural superhydrophobicity, identifying the critical combination of micro/nano-scale surface roughness and low surface energy materials. By 2005-2010, early synthetic approaches emerged, primarily utilizing complex multi-step processes that limited commercial viability.

A significant breakthrough occurred between 2010-2015 with the development of single-step application methods and more durable formulations. This period saw the first commercial applications in specialized industrial settings, though durability remained a significant challenge. The years 2015-2020 marked rapid advancement in coating resilience and application techniques, with spray-on and dip-coating methods becoming increasingly refined.

Most recently (2020-present), the field has experienced convergence with other advanced materials science disciplines, including the integration of self-healing properties, transparent formulations, and environmentally sustainable compositions. These developments have dramatically expanded potential applications in consumer electronics waterproofing.

The primary technical objectives in this domain now center on several key challenges. First, enhancing mechanical durability to withstand everyday wear and abrasion while maintaining superhydrophobic properties. Second, developing transparent formulations that preserve device aesthetics while providing protection. Third, creating application methods compatible with mass manufacturing processes for consumer electronics. Fourth, ensuring environmental sustainability through non-toxic formulations and biodegradable components.

Looking forward, the technology roadmap aims to achieve coatings capable of withstanding 5+ years of regular use without degradation, complete transparency with no impact on touch sensitivity or display quality, and application processes that integrate seamlessly into existing electronics manufacturing lines. Additionally, there is growing emphasis on developing formulations that provide not only water resistance but also resistance to oils, chemicals, and biological contaminants, creating truly comprehensive protection for sensitive electronic components.

Market Demand for Advanced Electronic Device Waterproofing

The global market for electronic device waterproofing solutions has experienced significant growth in recent years, driven primarily by the increasing consumer demand for durable and reliable electronic products. According to industry reports, the waterproof electronics market was valued at approximately $68 billion in 2022 and is projected to reach $100 billion by 2028, representing a compound annual growth rate of 6.7%.

Consumer electronics, particularly smartphones and wearable devices, constitute the largest segment of this market. With the average consumer replacing their smartphone every 2-3 years, manufacturers are under pressure to provide devices with enhanced durability features, including water resistance, to differentiate their products in a highly competitive marketplace. Market research indicates that 82% of consumers consider water resistance an important feature when purchasing a new smartphone.

The outdoor recreation and sports sectors have emerged as significant drivers of waterproofing technology demand. The global sports electronics market, including waterproof fitness trackers, smartwatches, and action cameras, has seen robust growth, with consumers increasingly using electronic devices during outdoor activities regardless of weather conditions.

Industrial and military applications represent another substantial market segment. These sectors require electronic devices capable of functioning in extreme environments, including underwater operations and exposure to harsh weather conditions. The industrial IoT market, which often deploys sensors and monitoring equipment in challenging environments, is expected to grow at 22% annually through 2027, further driving demand for advanced waterproofing solutions.

Regional analysis reveals that Asia-Pacific dominates the market, accounting for approximately 40% of global demand, followed by North America and Europe. This regional distribution aligns with the concentration of consumer electronics manufacturing and consumption patterns worldwide.

Market trends indicate a growing preference for sustainable and environmentally friendly waterproofing solutions. Traditional waterproofing methods often involve chemicals that pose environmental concerns, creating market opportunities for eco-friendly alternatives such as superhydrophobic coatings derived from natural materials.

The COVID-19 pandemic has accelerated certain market trends, particularly the increased focus on device hygiene and cleanability. Waterproof devices that can withstand frequent cleaning and disinfection have seen heightened demand in healthcare settings and among hygiene-conscious consumers.

Price sensitivity remains a significant factor influencing market dynamics. While consumers express strong preference for waterproof devices, their willingness to pay premium prices varies considerably across different market segments and regions, creating opportunities for tiered product offerings with varying levels of water protection.

Consumer electronics, particularly smartphones and wearable devices, constitute the largest segment of this market. With the average consumer replacing their smartphone every 2-3 years, manufacturers are under pressure to provide devices with enhanced durability features, including water resistance, to differentiate their products in a highly competitive marketplace. Market research indicates that 82% of consumers consider water resistance an important feature when purchasing a new smartphone.

The outdoor recreation and sports sectors have emerged as significant drivers of waterproofing technology demand. The global sports electronics market, including waterproof fitness trackers, smartwatches, and action cameras, has seen robust growth, with consumers increasingly using electronic devices during outdoor activities regardless of weather conditions.

Industrial and military applications represent another substantial market segment. These sectors require electronic devices capable of functioning in extreme environments, including underwater operations and exposure to harsh weather conditions. The industrial IoT market, which often deploys sensors and monitoring equipment in challenging environments, is expected to grow at 22% annually through 2027, further driving demand for advanced waterproofing solutions.

Regional analysis reveals that Asia-Pacific dominates the market, accounting for approximately 40% of global demand, followed by North America and Europe. This regional distribution aligns with the concentration of consumer electronics manufacturing and consumption patterns worldwide.

Market trends indicate a growing preference for sustainable and environmentally friendly waterproofing solutions. Traditional waterproofing methods often involve chemicals that pose environmental concerns, creating market opportunities for eco-friendly alternatives such as superhydrophobic coatings derived from natural materials.

The COVID-19 pandemic has accelerated certain market trends, particularly the increased focus on device hygiene and cleanability. Waterproof devices that can withstand frequent cleaning and disinfection have seen heightened demand in healthcare settings and among hygiene-conscious consumers.

Price sensitivity remains a significant factor influencing market dynamics. While consumers express strong preference for waterproof devices, their willingness to pay premium prices varies considerably across different market segments and regions, creating opportunities for tiered product offerings with varying levels of water protection.

Current Waterproofing Technologies and Limitations

Electronic device waterproofing has traditionally relied on several established technologies, each with specific advantages and inherent limitations. Physical barriers represent the most common approach, including rubber gaskets, O-rings, and silicone seals that create mechanical barriers between sensitive components and water. While effective under normal conditions, these solutions often deteriorate over time due to mechanical stress, temperature fluctuations, and material aging, leading to eventual failure.

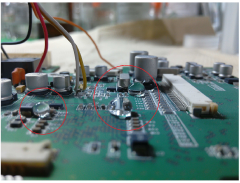

Conformal coatings—thin polymeric films applied directly to electronic components—offer another widely used solution. These coatings, typically made from acrylic, silicone, polyurethane, or epoxy materials, provide protection against moisture and contaminants. However, they generally offer only limited water resistance rather than complete waterproofing, and their application process requires precise control to avoid issues like trapped air bubbles or uneven coverage that can compromise protection.

Nano-coating technologies have emerged as a more advanced solution, utilizing plasma-enhanced chemical vapor deposition (PECVD) to create hydrophobic layers at the molecular level. These invisible coatings can be applied to both external and internal components, offering IPX7 or IPX8 water resistance ratings. Despite their effectiveness, these solutions typically add significant cost to manufacturing processes and may require specialized equipment and expertise.

Traditional encapsulation methods involve completely sealing electronic components within waterproof materials like epoxy resins. While highly effective for permanent protection, these approaches make device repair or component replacement extremely difficult or impossible, creating sustainability concerns and increasing lifecycle costs.

Current industry standards for waterproofing are defined by Ingress Protection (IP) ratings, with IPX7 (protection against temporary immersion) and IPX8 (protection against continuous immersion) being common targets for water-resistant electronic devices. However, achieving these ratings often involves design compromises that affect other device attributes such as weight, size, or thermal management.

A significant limitation across all conventional waterproofing technologies is their passive nature—they create physical barriers rather than actively repelling water. This fundamental approach means that eventual water ingress remains a possibility, particularly as devices age or experience physical stress. Additionally, most current solutions struggle to maintain effectiveness when exposed to other environmental factors like extreme temperatures, UV radiation, or chemical exposure.

The manufacturing complexity associated with implementing comprehensive waterproofing solutions also presents challenges for mass production, often resulting in increased production costs and potential quality control issues. This economic barrier has limited the widespread adoption of robust waterproofing in many consumer electronic categories.

Conformal coatings—thin polymeric films applied directly to electronic components—offer another widely used solution. These coatings, typically made from acrylic, silicone, polyurethane, or epoxy materials, provide protection against moisture and contaminants. However, they generally offer only limited water resistance rather than complete waterproofing, and their application process requires precise control to avoid issues like trapped air bubbles or uneven coverage that can compromise protection.

Nano-coating technologies have emerged as a more advanced solution, utilizing plasma-enhanced chemical vapor deposition (PECVD) to create hydrophobic layers at the molecular level. These invisible coatings can be applied to both external and internal components, offering IPX7 or IPX8 water resistance ratings. Despite their effectiveness, these solutions typically add significant cost to manufacturing processes and may require specialized equipment and expertise.

Traditional encapsulation methods involve completely sealing electronic components within waterproof materials like epoxy resins. While highly effective for permanent protection, these approaches make device repair or component replacement extremely difficult or impossible, creating sustainability concerns and increasing lifecycle costs.

Current industry standards for waterproofing are defined by Ingress Protection (IP) ratings, with IPX7 (protection against temporary immersion) and IPX8 (protection against continuous immersion) being common targets for water-resistant electronic devices. However, achieving these ratings often involves design compromises that affect other device attributes such as weight, size, or thermal management.

A significant limitation across all conventional waterproofing technologies is their passive nature—they create physical barriers rather than actively repelling water. This fundamental approach means that eventual water ingress remains a possibility, particularly as devices age or experience physical stress. Additionally, most current solutions struggle to maintain effectiveness when exposed to other environmental factors like extreme temperatures, UV radiation, or chemical exposure.

The manufacturing complexity associated with implementing comprehensive waterproofing solutions also presents challenges for mass production, often resulting in increased production costs and potential quality control issues. This economic barrier has limited the widespread adoption of robust waterproofing in many consumer electronic categories.

Existing Superhydrophobic Solutions for Electronics

01 Fluoropolymer-based superhydrophobic coatings

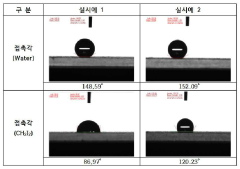

Fluoropolymer-based coatings provide excellent water repellency due to their low surface energy. These coatings typically incorporate fluorinated compounds such as polytetrafluoroethylene (PTFE) or fluorosilanes combined with nanoparticles to create hierarchical surface structures. The resulting superhydrophobic surfaces exhibit high contact angles exceeding 150° and low sliding angles, making them effective for waterproofing applications on various substrates including textiles, metals, and building materials.- Nanoparticle-based superhydrophobic coatings: Superhydrophobic coatings can be formulated using nanoparticles such as silica, titanium dioxide, or carbon nanotubes to create a rough surface texture at the nanoscale. These nanoparticles, when combined with hydrophobic binders or polymers, create a dual-scale roughness that enhances water repellency. The nano-structured surface minimizes the contact area between water droplets and the substrate, allowing them to roll off easily while maintaining excellent waterproofing properties.

- Fluoropolymer-based waterproofing coatings: Fluoropolymers and fluorinated compounds are widely used in superhydrophobic coating formulations due to their inherently low surface energy. These materials, such as polytetrafluoroethylene (PTFE) or fluorosilanes, create highly water-repellent surfaces when applied to substrates. The fluorine-carbon bonds in these compounds resist water adhesion, making them excellent choices for durable waterproofing applications on various surfaces including textiles, glass, and building materials.

- Sol-gel processing for superhydrophobic surfaces: Sol-gel technology enables the creation of superhydrophobic coatings through controlled hydrolysis and condensation reactions of metal alkoxides. This process allows for the formation of hierarchical micro and nano-structured surfaces with controlled porosity. By incorporating hydrophobic modifiers during the sol-gel process, the resulting coating exhibits excellent water repellency and durability. These coatings can be applied to various substrates including glass, metals, and ceramics for effective waterproofing.

- Biomimetic superhydrophobic coating designs: Inspired by natural water-repellent surfaces like lotus leaves and butterfly wings, biomimetic superhydrophobic coatings mimic these biological structures to achieve extreme water repellency. These coatings typically incorporate hierarchical micro and nano-structures that trap air pockets beneath water droplets, creating a composite interface that minimizes contact area. Various fabrication techniques including lithography, etching, and template-assisted methods are used to replicate these natural designs for effective waterproofing applications.

- Durable and self-healing superhydrophobic coatings: Advanced superhydrophobic coatings incorporate durability-enhancing features such as self-healing capabilities, abrasion resistance, and UV stability. These coatings often utilize elastomeric polymers, silicones, or specialized additives that can recover their water-repellent properties after physical damage. Some formulations include microcapsules containing hydrophobic agents that release upon damage, restoring the coating's functionality. These innovations extend the service life of waterproofing treatments in challenging environmental conditions.

02 Silica-based superhydrophobic coatings

Silica nanoparticles are widely used in superhydrophobic coatings to create the necessary surface roughness. These coatings typically combine modified silica particles with hydrophobic binders or silanes to achieve both micro and nano-scale roughness. The dual-scale roughness, combined with the low surface energy of the hydrophobic components, creates a surface that effectively repels water. These coatings are particularly useful for applications requiring transparency and durability in outdoor environments.Expand Specific Solutions03 Polymer-nanoparticle composite waterproofing coatings

These coatings combine various polymers with nanoparticles to create superhydrophobic surfaces. The polymer matrix provides adhesion to the substrate and durability, while the nanoparticles create the necessary surface roughness. Common polymers include polyurethanes, epoxies, and acrylics, while nanoparticles may include silica, titanium dioxide, or carbon-based materials. These composites can be applied through spray coating, dip coating, or brush application, making them versatile for different substrates and applications.Expand Specific Solutions04 Bio-inspired superhydrophobic coating technologies

Inspired by natural superhydrophobic surfaces like lotus leaves and butterfly wings, these coatings mimic the hierarchical micro/nano structures found in nature. They typically involve creating papillae-like microstructures covered with nanoscale features, combined with hydrophobic chemistry. These bio-inspired approaches often use environmentally friendly materials and processes, making them suitable for sustainable waterproofing applications. The resulting surfaces not only repel water but often exhibit self-cleaning properties as well.Expand Specific Solutions05 Durable and self-healing superhydrophobic coatings

These advanced waterproofing coatings address the durability limitations of traditional superhydrophobic surfaces. They incorporate self-healing mechanisms that restore water repellency after physical damage or weathering. Approaches include encapsulated hydrophobic agents that release upon damage, reversible chemical bonds that reform after breaking, or mobile hydrophobic components that can migrate to the surface. These coatings maintain their superhydrophobic properties for extended periods even under harsh environmental conditions, making them suitable for long-term outdoor waterproofing applications.Expand Specific Solutions

Leading Companies in Superhydrophobic Coating Industry

The superhydrophobic coating market for electronic device waterproofing is currently in a growth phase, with increasing adoption across consumer electronics and industrial applications. The market is projected to expand significantly due to rising demand for water-resistant devices. Technologically, the field shows varying maturity levels, with established players like Apple and Siemens implementing commercial solutions, while research institutions such as University of Florida, California Institute of Technology, and Georgia Tech Research Corp are advancing fundamental innovations. Companies like STMicroelectronics and Xerox are developing proprietary coating technologies, while specialized firms such as SPTS Technologies and GI Scientific are creating niche applications. The competitive landscape features collaboration between academic institutions and industry partners, with Asian universities and companies increasingly contributing to technological advancements in this space.

Apple, Inc.

Technical Solution: Apple has developed advanced superhydrophobic coating technologies for their electronic devices, particularly for iPhones and Apple Watches. Their approach combines nano-structured surface treatments with fluoropolymer chemistry to create water-repellent barriers on device exteriors and internal components. Apple's IP portfolio includes multi-layered coating systems that maintain superhydrophobic properties even after mechanical abrasion, addressing one of the key challenges in this field. Their technology incorporates self-healing mechanisms where the hydrophobic molecules can reorient themselves after minor surface damage. Apple has also pioneered vapor deposition techniques that allow for uniform application of these coatings on complex geometries and small components like microphones and speakers, achieving contact angles exceeding 150° while maintaining transparency where needed for displays and camera lenses.

Strengths: Exceptional durability compared to conventional coatings, with maintained performance after thousands of abrasion cycles. Integration with existing manufacturing processes allows for mass production. Weaknesses: Higher production costs compared to traditional waterproofing methods, and potential environmental concerns with some fluorinated compounds used in the coatings.

STMicroelectronics (Grenoble 2) SAS

Technical Solution: STMicroelectronics has developed advanced superhydrophobic coating technologies specifically designed for microelectronic components and MEMS (Micro-Electro-Mechanical Systems) devices. Their approach utilizes plasma-enhanced chemical vapor deposition (PECVD) to create nano-structured fluorocarbon films with precisely controlled surface roughness. This technique achieves water contact angles exceeding 155° while maintaining the electrical properties of the underlying components. ST's innovation includes selective patterning capabilities that allow for the application of superhydrophobic coatings only where needed, preserving electrical contacts and sensing elements. Their technology incorporates conformal coating processes that can protect complex 3D structures and the intricate geometries found in modern semiconductor packages. ST has demonstrated the effectiveness of these coatings in protecting sensitive electronic components from moisture ingress even under condensing conditions, significantly enhancing reliability in automotive and industrial applications where devices may be exposed to harsh environmental conditions.

Strengths: Exceptional compatibility with semiconductor manufacturing processes, allowing integration into existing production lines. Precise control over coating thickness down to nanometer scale enables protection without affecting device performance. Weaknesses: Higher implementation costs compared to conventional conformal coatings, and potential challenges with long-term adhesion to certain substrate materials used in advanced semiconductor packaging.

Key Patents and Research in Superhydrophobic Materials

Superhydrophobic coating

PatentWO2025094171A1

Innovation

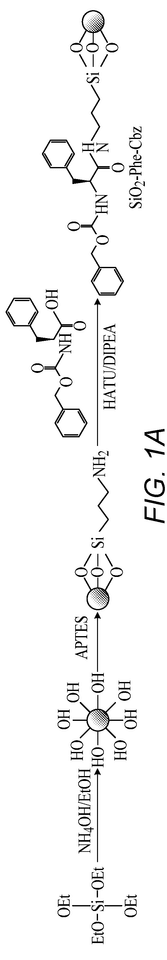

- Development of a fluorine-free, peptide-conjugated nanoparticle-based material that self-assembles to form a stable, superhydrophobic coating on various surfaces, including soft electroadhesive surfaces, using short peptides with hydrophobic aromatic functionalities and SiO2 nanoparticles.

Method for preparing super-hydrophobic coating solution to impart waterproof and dustproof to electronic device and electronic parts

PatentInactiveKR1020180051236A

Innovation

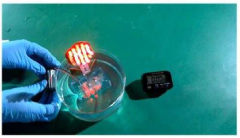

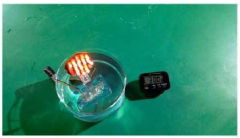

- A method involving immersion of electronic devices in a coating solution composed of a super-water-repellent agent and a perfluorinated compound, such as fluorinated ketones, to form a coating film that penetrates and adheres to gaps, providing waterproof and dustproof functions.

Environmental Impact and Sustainability Considerations

The environmental implications of superhydrophobic coatings for electronic device waterproofing extend beyond their primary functional benefits. Traditional waterproofing methods often rely on materials and processes that pose significant environmental concerns, including the use of perfluorinated compounds (PFCs) and volatile organic compounds (VOCs), which have been linked to persistent environmental contamination and adverse health effects.

Superhydrophobic coatings offer a potentially more sustainable alternative, particularly when formulated with environmentally benign materials. Recent advancements have focused on developing bio-inspired superhydrophobic surfaces using natural materials or environmentally friendly synthetic compounds. These innovations include silica-based coatings, plant-derived waxes, and cellulose-based materials that can achieve comparable water repellency while reducing environmental impact.

The manufacturing processes for superhydrophobic coatings also merit environmental consideration. Energy-intensive production methods contribute to carbon emissions, while certain fabrication techniques may generate hazardous waste. Research indicates that sol-gel processes and layer-by-layer deposition methods generally have lower environmental footprints compared to plasma-enhanced chemical vapor deposition techniques, though this varies based on specific implementation.

Durability represents another critical sustainability factor. More durable coatings reduce the need for frequent reapplication or device replacement, thereby decreasing electronic waste generation. Studies show that enhancing mechanical robustness through multi-layered structures or incorporating self-healing properties can significantly extend coating lifespans, though often at the cost of increased manufacturing complexity.

End-of-life considerations remain challenging for many superhydrophobic coatings. Some formulations contain nanomaterials whose environmental fate and ecotoxicological impacts are not fully understood. Additionally, composite coatings may complicate electronic device recycling processes by introducing materials that are difficult to separate or that contaminate recovered components.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's REACH regulations and similar initiatives in other regions have begun restricting certain compounds used in waterproofing applications, driving innovation toward greener alternatives. Companies developing superhydrophobic coatings for consumer electronics must navigate this evolving regulatory landscape while meeting performance requirements.

Life cycle assessment (LCA) studies comparing traditional waterproofing methods to superhydrophobic coating technologies generally indicate potential environmental benefits for the latter, particularly regarding reduced water pollution and hazardous waste generation. However, these advantages depend heavily on specific formulation choices and application methods, highlighting the importance of environmentally conscious design principles throughout the development process.

Superhydrophobic coatings offer a potentially more sustainable alternative, particularly when formulated with environmentally benign materials. Recent advancements have focused on developing bio-inspired superhydrophobic surfaces using natural materials or environmentally friendly synthetic compounds. These innovations include silica-based coatings, plant-derived waxes, and cellulose-based materials that can achieve comparable water repellency while reducing environmental impact.

The manufacturing processes for superhydrophobic coatings also merit environmental consideration. Energy-intensive production methods contribute to carbon emissions, while certain fabrication techniques may generate hazardous waste. Research indicates that sol-gel processes and layer-by-layer deposition methods generally have lower environmental footprints compared to plasma-enhanced chemical vapor deposition techniques, though this varies based on specific implementation.

Durability represents another critical sustainability factor. More durable coatings reduce the need for frequent reapplication or device replacement, thereby decreasing electronic waste generation. Studies show that enhancing mechanical robustness through multi-layered structures or incorporating self-healing properties can significantly extend coating lifespans, though often at the cost of increased manufacturing complexity.

End-of-life considerations remain challenging for many superhydrophobic coatings. Some formulations contain nanomaterials whose environmental fate and ecotoxicological impacts are not fully understood. Additionally, composite coatings may complicate electronic device recycling processes by introducing materials that are difficult to separate or that contaminate recovered components.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's REACH regulations and similar initiatives in other regions have begun restricting certain compounds used in waterproofing applications, driving innovation toward greener alternatives. Companies developing superhydrophobic coatings for consumer electronics must navigate this evolving regulatory landscape while meeting performance requirements.

Life cycle assessment (LCA) studies comparing traditional waterproofing methods to superhydrophobic coating technologies generally indicate potential environmental benefits for the latter, particularly regarding reduced water pollution and hazardous waste generation. However, these advantages depend heavily on specific formulation choices and application methods, highlighting the importance of environmentally conscious design principles throughout the development process.

Durability and Longevity Testing Methodologies

The assessment of durability and longevity is critical for superhydrophobic coatings in electronic device waterproofing applications. Standard testing methodologies must simulate real-world conditions while providing quantifiable metrics for performance evaluation over time. These methodologies can be categorized into mechanical durability tests, chemical resistance tests, and environmental exposure tests.

Mechanical durability testing typically includes abrasion resistance tests using linear or rotary abrasion testers with standardized abrasive materials. The Taber Abraser method (ASTM D4060) is widely employed, measuring weight loss and contact angle changes after specified cycles. Scratch resistance testing using nano-indentation techniques evaluates the coating's ability to withstand physical damage, while adhesion testing (ASTM D3359) assesses the bond strength between the coating and substrate.

Chemical resistance testing exposes coatings to various substances commonly encountered in electronic device usage environments. These include acidic and alkaline solutions, oils, solvents, and cleaning agents. The ASTM D1308 spot test and immersion tests (ASTM D870) are standard methods, with performance evaluated through contact angle measurements, visual inspection, and spectroscopic analysis before and after exposure.

Environmental exposure testing simulates accelerated aging under various conditions. UV resistance testing (ASTM G154) evaluates degradation under ultraviolet radiation, while thermal cycling tests (ASTM D6944) assess performance under temperature fluctuations typical of device operation. Salt spray testing (ASTM B117) evaluates corrosion resistance in maritime or high-humidity environments. Humidity cycling tests are particularly relevant for electronic devices operating in varying moisture conditions.

Long-term performance evaluation requires both accelerated and real-time testing approaches. Accelerated weathering chambers can compress years of exposure into weeks, while real-time field testing provides validation under actual use conditions. The correlation between accelerated and real-time testing results must be established through careful calibration studies.

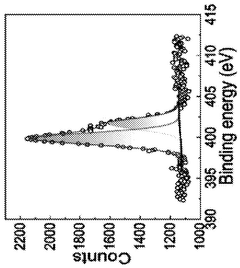

Quantitative performance metrics include water contact angle stability (maintaining angles >150° over time), contact angle hysteresis (remaining below 10° for effective water repellency), and functional performance indicators such as electrical resistance measurements and corrosion protection efficiency. These metrics should be monitored at regular intervals throughout the testing period to establish degradation curves and predict service life.

Standardized test protocols from organizations such as ASTM International, ISO, and IEC provide consistency in evaluation methods, enabling meaningful comparisons between different coating technologies and formulations. The development of industry-specific test protocols for electronic device waterproofing applications remains an active area of research and standardization.

Mechanical durability testing typically includes abrasion resistance tests using linear or rotary abrasion testers with standardized abrasive materials. The Taber Abraser method (ASTM D4060) is widely employed, measuring weight loss and contact angle changes after specified cycles. Scratch resistance testing using nano-indentation techniques evaluates the coating's ability to withstand physical damage, while adhesion testing (ASTM D3359) assesses the bond strength between the coating and substrate.

Chemical resistance testing exposes coatings to various substances commonly encountered in electronic device usage environments. These include acidic and alkaline solutions, oils, solvents, and cleaning agents. The ASTM D1308 spot test and immersion tests (ASTM D870) are standard methods, with performance evaluated through contact angle measurements, visual inspection, and spectroscopic analysis before and after exposure.

Environmental exposure testing simulates accelerated aging under various conditions. UV resistance testing (ASTM G154) evaluates degradation under ultraviolet radiation, while thermal cycling tests (ASTM D6944) assess performance under temperature fluctuations typical of device operation. Salt spray testing (ASTM B117) evaluates corrosion resistance in maritime or high-humidity environments. Humidity cycling tests are particularly relevant for electronic devices operating in varying moisture conditions.

Long-term performance evaluation requires both accelerated and real-time testing approaches. Accelerated weathering chambers can compress years of exposure into weeks, while real-time field testing provides validation under actual use conditions. The correlation between accelerated and real-time testing results must be established through careful calibration studies.

Quantitative performance metrics include water contact angle stability (maintaining angles >150° over time), contact angle hysteresis (remaining below 10° for effective water repellency), and functional performance indicators such as electrical resistance measurements and corrosion protection efficiency. These metrics should be monitored at regular intervals throughout the testing period to establish degradation curves and predict service life.

Standardized test protocols from organizations such as ASTM International, ISO, and IEC provide consistency in evaluation methods, enabling meaningful comparisons between different coating technologies and formulations. The development of industry-specific test protocols for electronic device waterproofing applications remains an active area of research and standardization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!