Research on the Durability of Superhydrophobic Coating under UV Exposure

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superhydrophobic Coating UV Durability Background and Objectives

Superhydrophobic coatings have emerged as a revolutionary technology in materials science over the past two decades, offering exceptional water-repellent properties with contact angles exceeding 150° and slide angles below 10°. These coatings mimic natural phenomena such as the lotus leaf effect, where hierarchical micro/nano-structures combined with low surface energy materials create self-cleaning surfaces that repel water and contaminants effectively.

The evolution of superhydrophobic coating technology has progressed from academic curiosity to commercial applications across multiple industries. Initial research in the 1990s focused primarily on understanding fundamental wetting mechanisms, while the early 2000s saw significant breakthroughs in fabrication techniques. By the 2010s, researchers began addressing practical challenges including mechanical durability, chemical stability, and environmental resistance.

Despite remarkable advances, ultraviolet (UV) radiation remains one of the most significant threats to superhydrophobic coating longevity. UV exposure can trigger photochemical degradation of organic components, alter surface morphology, and compromise the hierarchical structures essential for maintaining superhydrophobicity. This vulnerability significantly limits outdoor applications where coatings face constant solar radiation.

Current market trends indicate growing demand for durable superhydrophobic solutions in construction, automotive, aerospace, and consumer electronics sectors. The global market for superhydrophobic coatings was valued at approximately $38 million in 2022 and is projected to reach $75 million by 2028, with a CAGR of 12.3%. However, this growth potential remains constrained by durability concerns, particularly UV resistance limitations.

The primary objective of this research is to comprehensively investigate the degradation mechanisms of superhydrophobic coatings under UV exposure and develop strategies to enhance their long-term performance. Specifically, we aim to: (1) characterize the photochemical and physical changes occurring in various superhydrophobic coating formulations during accelerated and natural UV aging; (2) identify key factors affecting UV durability; and (3) explore innovative approaches to improve UV resistance without compromising superhydrophobic properties.

This research addresses a critical technological gap in the field, as enhanced UV durability would significantly expand application possibilities for superhydrophobic coatings in outdoor environments. The findings will contribute to establishing standardized testing protocols for UV resistance evaluation and provide valuable insights for developing next-generation superhydrophobic coatings with superior environmental stability.

The technological trajectory suggests that overcoming the UV durability challenge represents a pivotal milestone that could transform superhydrophobic coatings from specialized niche products to mainstream surface treatment solutions across multiple industries.

The evolution of superhydrophobic coating technology has progressed from academic curiosity to commercial applications across multiple industries. Initial research in the 1990s focused primarily on understanding fundamental wetting mechanisms, while the early 2000s saw significant breakthroughs in fabrication techniques. By the 2010s, researchers began addressing practical challenges including mechanical durability, chemical stability, and environmental resistance.

Despite remarkable advances, ultraviolet (UV) radiation remains one of the most significant threats to superhydrophobic coating longevity. UV exposure can trigger photochemical degradation of organic components, alter surface morphology, and compromise the hierarchical structures essential for maintaining superhydrophobicity. This vulnerability significantly limits outdoor applications where coatings face constant solar radiation.

Current market trends indicate growing demand for durable superhydrophobic solutions in construction, automotive, aerospace, and consumer electronics sectors. The global market for superhydrophobic coatings was valued at approximately $38 million in 2022 and is projected to reach $75 million by 2028, with a CAGR of 12.3%. However, this growth potential remains constrained by durability concerns, particularly UV resistance limitations.

The primary objective of this research is to comprehensively investigate the degradation mechanisms of superhydrophobic coatings under UV exposure and develop strategies to enhance their long-term performance. Specifically, we aim to: (1) characterize the photochemical and physical changes occurring in various superhydrophobic coating formulations during accelerated and natural UV aging; (2) identify key factors affecting UV durability; and (3) explore innovative approaches to improve UV resistance without compromising superhydrophobic properties.

This research addresses a critical technological gap in the field, as enhanced UV durability would significantly expand application possibilities for superhydrophobic coatings in outdoor environments. The findings will contribute to establishing standardized testing protocols for UV resistance evaluation and provide valuable insights for developing next-generation superhydrophobic coatings with superior environmental stability.

The technological trajectory suggests that overcoming the UV durability challenge represents a pivotal milestone that could transform superhydrophobic coatings from specialized niche products to mainstream surface treatment solutions across multiple industries.

Market Analysis for UV-Resistant Superhydrophobic Coatings

The global market for UV-resistant superhydrophobic coatings is experiencing significant growth, driven by increasing demand across multiple industries including construction, automotive, aerospace, and consumer electronics. Current market valuation stands at approximately 2.3 billion USD with projections indicating a compound annual growth rate of 5.7% through 2028, according to recent industry analyses.

The construction sector represents the largest market segment, accounting for nearly 35% of the total market share. This dominance stems from the growing need for self-cleaning building facades and long-lasting protective coatings that can withstand harsh environmental conditions, particularly in regions with high UV exposure. The automotive industry follows closely, with increasing application of these coatings on exterior surfaces to maintain aesthetic appeal and functional performance over extended periods.

Regional market distribution shows North America and Europe currently leading with combined market share exceeding 60%, primarily due to advanced technological adoption and stringent environmental regulations promoting durable coating solutions. However, the Asia-Pacific region is emerging as the fastest-growing market with anticipated growth rates of 7.2% annually, fueled by rapid industrialization in China, India, and Southeast Asian countries.

Consumer demand patterns reveal a clear shift toward environmentally sustainable coating solutions that maintain performance under UV exposure without releasing harmful chemicals. This trend is particularly evident in premium market segments where end-users demonstrate willingness to pay 15-20% price premiums for coatings with proven long-term UV resistance capabilities.

Market research indicates that durability under UV exposure represents the most significant pain point for current superhydrophobic coating technologies. Nearly 78% of surveyed industrial users cited UV degradation as the primary factor limiting widespread adoption, highlighting substantial market opportunity for innovations addressing this specific challenge.

The competitive landscape shows increasing consolidation, with major chemical companies expanding their product portfolios through strategic acquisitions of specialized coating technology startups. Simultaneously, venture capital investment in UV-resistant coating technologies has increased by 42% over the past three years, signaling strong market confidence in future growth potential.

Price sensitivity analysis reveals distinct market segments, with industrial applications demonstrating higher tolerance for premium pricing when supported by quantifiable performance data on UV durability. Consumer markets remain more price-sensitive but show growing acceptance of higher price points when marketing effectively communicates long-term cost benefits through extended product lifecycles.

The construction sector represents the largest market segment, accounting for nearly 35% of the total market share. This dominance stems from the growing need for self-cleaning building facades and long-lasting protective coatings that can withstand harsh environmental conditions, particularly in regions with high UV exposure. The automotive industry follows closely, with increasing application of these coatings on exterior surfaces to maintain aesthetic appeal and functional performance over extended periods.

Regional market distribution shows North America and Europe currently leading with combined market share exceeding 60%, primarily due to advanced technological adoption and stringent environmental regulations promoting durable coating solutions. However, the Asia-Pacific region is emerging as the fastest-growing market with anticipated growth rates of 7.2% annually, fueled by rapid industrialization in China, India, and Southeast Asian countries.

Consumer demand patterns reveal a clear shift toward environmentally sustainable coating solutions that maintain performance under UV exposure without releasing harmful chemicals. This trend is particularly evident in premium market segments where end-users demonstrate willingness to pay 15-20% price premiums for coatings with proven long-term UV resistance capabilities.

Market research indicates that durability under UV exposure represents the most significant pain point for current superhydrophobic coating technologies. Nearly 78% of surveyed industrial users cited UV degradation as the primary factor limiting widespread adoption, highlighting substantial market opportunity for innovations addressing this specific challenge.

The competitive landscape shows increasing consolidation, with major chemical companies expanding their product portfolios through strategic acquisitions of specialized coating technology startups. Simultaneously, venture capital investment in UV-resistant coating technologies has increased by 42% over the past three years, signaling strong market confidence in future growth potential.

Price sensitivity analysis reveals distinct market segments, with industrial applications demonstrating higher tolerance for premium pricing when supported by quantifiable performance data on UV durability. Consumer markets remain more price-sensitive but show growing acceptance of higher price points when marketing effectively communicates long-term cost benefits through extended product lifecycles.

Current Challenges in Superhydrophobic Coating UV Stability

Despite significant advancements in superhydrophobic coating technology, UV stability remains one of the most critical challenges limiting widespread commercial adoption. When exposed to ultraviolet radiation, these coatings often experience degradation of their water-repellent properties, with performance deterioration occurring within weeks or months rather than the years required for practical applications. This degradation manifests primarily through chemical decomposition of the hydrophobic components and physical deterioration of the micro/nano-structured surface topography.

The fundamental mechanism behind UV-induced degradation involves photocatalytic reactions that break down the low surface energy materials (typically fluorinated or silicone-based compounds) responsible for the hydrophobic effect. These reactions are often accelerated by environmental factors such as humidity, temperature fluctuations, and the presence of atmospheric pollutants, creating a complex degradation pathway that is difficult to mitigate through single-approach solutions.

Current commercial superhydrophobic coatings typically maintain their performance for only 3-6 months under regular outdoor exposure, falling significantly short of the 3-5 year durability benchmark established for industrial and architectural applications. This performance gap represents a substantial barrier to market penetration in high-value sectors such as aerospace, automotive, and building construction.

Another significant challenge is the trade-off between durability and superhydrophobicity. Engineering approaches that enhance UV resistance often compromise the water contact angle or increase sliding angle, reducing the self-cleaning functionality that makes these coatings valuable. This inverse relationship between durability and performance creates a technical paradox that researchers continue to struggle with.

The incorporation of UV stabilizers and absorbers, while somewhat effective, introduces additional complications including potential environmental concerns, color alterations, and increased production costs. Traditional UV stabilizers designed for conventional coatings often prove incompatible with the specialized chemistry and topography required for superhydrophobicity.

Testing methodologies present another obstacle, as accelerated aging tests frequently fail to accurately predict real-world performance. The correlation between laboratory UV exposure and actual outdoor durability remains poorly established, complicating both research efforts and commercial quality assurance processes.

From a manufacturing perspective, techniques that might improve UV stability, such as multi-layer protective systems or specialized curing processes, often conflict with scalability requirements and cost constraints. The most durable formulations typically require complex application procedures that are impractical for large-scale implementation or field repairs.

The fundamental mechanism behind UV-induced degradation involves photocatalytic reactions that break down the low surface energy materials (typically fluorinated or silicone-based compounds) responsible for the hydrophobic effect. These reactions are often accelerated by environmental factors such as humidity, temperature fluctuations, and the presence of atmospheric pollutants, creating a complex degradation pathway that is difficult to mitigate through single-approach solutions.

Current commercial superhydrophobic coatings typically maintain their performance for only 3-6 months under regular outdoor exposure, falling significantly short of the 3-5 year durability benchmark established for industrial and architectural applications. This performance gap represents a substantial barrier to market penetration in high-value sectors such as aerospace, automotive, and building construction.

Another significant challenge is the trade-off between durability and superhydrophobicity. Engineering approaches that enhance UV resistance often compromise the water contact angle or increase sliding angle, reducing the self-cleaning functionality that makes these coatings valuable. This inverse relationship between durability and performance creates a technical paradox that researchers continue to struggle with.

The incorporation of UV stabilizers and absorbers, while somewhat effective, introduces additional complications including potential environmental concerns, color alterations, and increased production costs. Traditional UV stabilizers designed for conventional coatings often prove incompatible with the specialized chemistry and topography required for superhydrophobicity.

Testing methodologies present another obstacle, as accelerated aging tests frequently fail to accurately predict real-world performance. The correlation between laboratory UV exposure and actual outdoor durability remains poorly established, complicating both research efforts and commercial quality assurance processes.

From a manufacturing perspective, techniques that might improve UV stability, such as multi-layer protective systems or specialized curing processes, often conflict with scalability requirements and cost constraints. The most durable formulations typically require complex application procedures that are impractical for large-scale implementation or field repairs.

Current Technical Solutions for UV-Resistant Superhydrophobic Coatings

01 Nanostructured coatings for enhanced durability

Superhydrophobic coatings with nanostructured surfaces provide enhanced durability against mechanical wear and environmental factors. These coatings typically incorporate nanoparticles or create hierarchical micro/nano structures that maintain water repellency even after abrasion. The nanostructures help preserve the air pockets necessary for superhydrophobicity while providing mechanical stability to the coating surface.- Nanostructured coatings for enhanced durability: Nanostructured superhydrophobic coatings incorporate nanomaterials such as carbon nanotubes, nanoparticles, or hierarchical nano/micro structures to enhance mechanical durability. These structures provide both the necessary surface roughness for superhydrophobicity and improved resistance to abrasion and wear. The nanoscale components create a robust framework that maintains water repellency even after physical contact or environmental exposure.

- Polymer-based durable superhydrophobic coatings: Polymer matrices serve as flexible, resilient bases for superhydrophobic coatings with enhanced durability. These formulations typically combine hydrophobic polymers with functional additives to create coatings that can withstand mechanical stress while maintaining water repellency. The polymer networks provide elasticity that allows the coating to absorb impact and abrasion without compromising the superhydrophobic surface structure.

- Self-healing superhydrophobic coatings: Self-healing mechanisms incorporated into superhydrophobic coatings allow them to restore their water-repellent properties after damage. These systems may utilize encapsulated hydrophobic agents that release upon damage, reversible chemical bonds that reform after breaking, or dynamic surface reorganization capabilities. This self-restoration ability significantly extends the functional lifespan of the coating by maintaining superhydrophobicity despite surface wear or environmental degradation.

- Chemical modification for durability enhancement: Chemical treatments and modifications can significantly improve the durability of superhydrophobic coatings. These approaches include crosslinking agents to strengthen molecular bonds, fluorinated compounds for enhanced chemical stability, and silane coupling agents to improve adhesion to substrates. Such chemical modifications create stronger connections between the coating components and with the substrate, resulting in surfaces that resist degradation from UV exposure, chemical attack, and mechanical abrasion.

- Multi-layer coating systems for improved durability: Multi-layer coating architectures enhance durability by combining layers with complementary properties. These systems typically feature a strongly adhering base layer, functional middle layers, and a superhydrophobic top layer. The layered approach allows for optimization of adhesion to the substrate while maintaining superhydrophobicity at the surface. If the top layer becomes damaged, underlying layers can provide continued protection or serve as a foundation for the regeneration of superhydrophobic properties.

02 Chemical modification for improved adhesion

Chemical modification techniques improve the adhesion of superhydrophobic coatings to substrates, enhancing their durability. These methods include surface functionalization, cross-linking agents, and chemical bonding between the coating and substrate. By creating stronger chemical bonds at the interface, these coatings resist delamination and maintain their water-repellent properties over extended periods of exposure to harsh conditions.Expand Specific Solutions03 Self-healing superhydrophobic coatings

Self-healing mechanisms incorporated into superhydrophobic coatings significantly improve their durability by allowing them to recover their water-repellent properties after damage. These coatings contain components that can migrate to damaged areas or undergo chemical reactions to restore the surface structure and chemistry. Some designs include encapsulated healing agents that release upon damage, while others utilize reversible chemical bonds that can reform after being broken.Expand Specific Solutions04 Polymer-based durable superhydrophobic coatings

Polymer-based formulations enhance the durability of superhydrophobic coatings through elasticity and flexibility. These coatings typically combine hydrophobic polymers with structural elements to create surfaces that can withstand mechanical deformation without permanent loss of water repellency. Fluoropolymers, silicones, and specially modified organic polymers are commonly used as base materials, often reinforced with particles to create the necessary surface roughness while maintaining mechanical integrity.Expand Specific Solutions05 Multi-layer coating systems for durability

Multi-layer coating systems improve superhydrophobic coating durability by separating functional requirements across different layers. These systems typically include a durable base layer for adhesion to the substrate, a middle layer providing mechanical strength, and a top layer with the superhydrophobic properties. This approach protects the water-repellent surface features while ensuring the overall coating remains firmly attached to the substrate even under challenging conditions. Some designs incorporate gradient structures that distribute mechanical stress throughout the coating.Expand Specific Solutions

Leading Manufacturers and Research Institutions in the Field

The superhydrophobic coating durability under UV exposure market is in a growth phase, with increasing applications in automotive, construction, and electronics sectors. The market size is projected to expand significantly due to rising demand for self-cleaning and water-repellent surfaces. Technologically, the field shows moderate maturity with ongoing innovation challenges. Leading players include Georgia Tech Research Corp. and South China University of Technology focusing on fundamental research, while commercial entities like Saint-Gobain Isover, Guardian Glass, and Seagate Technology are developing industrial applications. Academic institutions (University of Florida, Bar-Ilan University) collaborate with companies like Surfactis Technologies to bridge research-to-market gaps. The competition landscape features both specialized coating manufacturers and diversified materials companies working to enhance UV resistance properties.

The Georgia Tech Research Corp.

Technical Solution: Georgia Tech has developed innovative superhydrophobic coatings with enhanced UV durability through the incorporation of UV-absorbing nanoparticles (such as ZnO and TiO2) into fluoropolymer matrices. Their approach involves a multi-layer coating system where the top layer contains hydrophobic functionalized silica nanoparticles that maintain water repellency, while an underlying layer incorporates UV stabilizers that protect the hydrophobic chemistry from degradation. The research team has implemented a cross-linking strategy that forms covalent bonds between the hydrophobic moieties and the substrate, significantly improving long-term stability under UV exposure. Their testing protocols involve accelerated weathering chambers that simulate years of outdoor exposure, with results showing retention of superhydrophobic properties (contact angles >150°) after the equivalent of 3+ years of outdoor UV exposure.

Strengths: Superior UV resistance through multi-layer protection strategy; excellent adhesion to substrates through covalent bonding; comprehensive testing methodology simulating real-world conditions. Weaknesses: Potentially higher manufacturing costs due to complex formulation; possible reduction in optical transparency with higher concentrations of UV-absorbing additives.

Ashland Licensing & Intellectual Property LLC

Technical Solution: Ashland has pioneered a proprietary superhydrophobic coating technology that incorporates specially engineered UV-resistant polymers with hierarchical surface structures. Their approach utilizes a combination of fluorinated acrylic polymers and siloxane-based compounds that maintain molecular stability under prolonged UV exposure. The coating incorporates a dual-action protection system: primary UV absorbers that capture high-energy radiation before it can damage the hydrophobic chemistry, and secondary hindered amine light stabilizers (HALS) that neutralize free radicals formed during photodegradation processes. Ashland's formulation also includes nano-structured silica particles with specific surface treatments that create a multi-scale roughness essential for superhydrophobicity while resisting UV-induced degradation. Testing has demonstrated that their coatings maintain water contact angles above 155° and sliding angles below 5° after 2000+ hours of accelerated UV exposure testing, equivalent to approximately 5 years of natural outdoor exposure.

Strengths: Exceptional UV resistance through synergistic combination of absorbers and radical scavengers; maintains mechanical durability alongside hydrophobic properties; applicable to various substrate materials. Weaknesses: Relatively high cost of specialized UV-resistant fluorinated compounds; potential environmental concerns regarding fluorinated materials; complex application process requiring controlled conditions.

Key Patents and Research Breakthroughs in UV Durability

Durable superhydrophobic coatings

PatentInactiveUS20110111656A1

Innovation

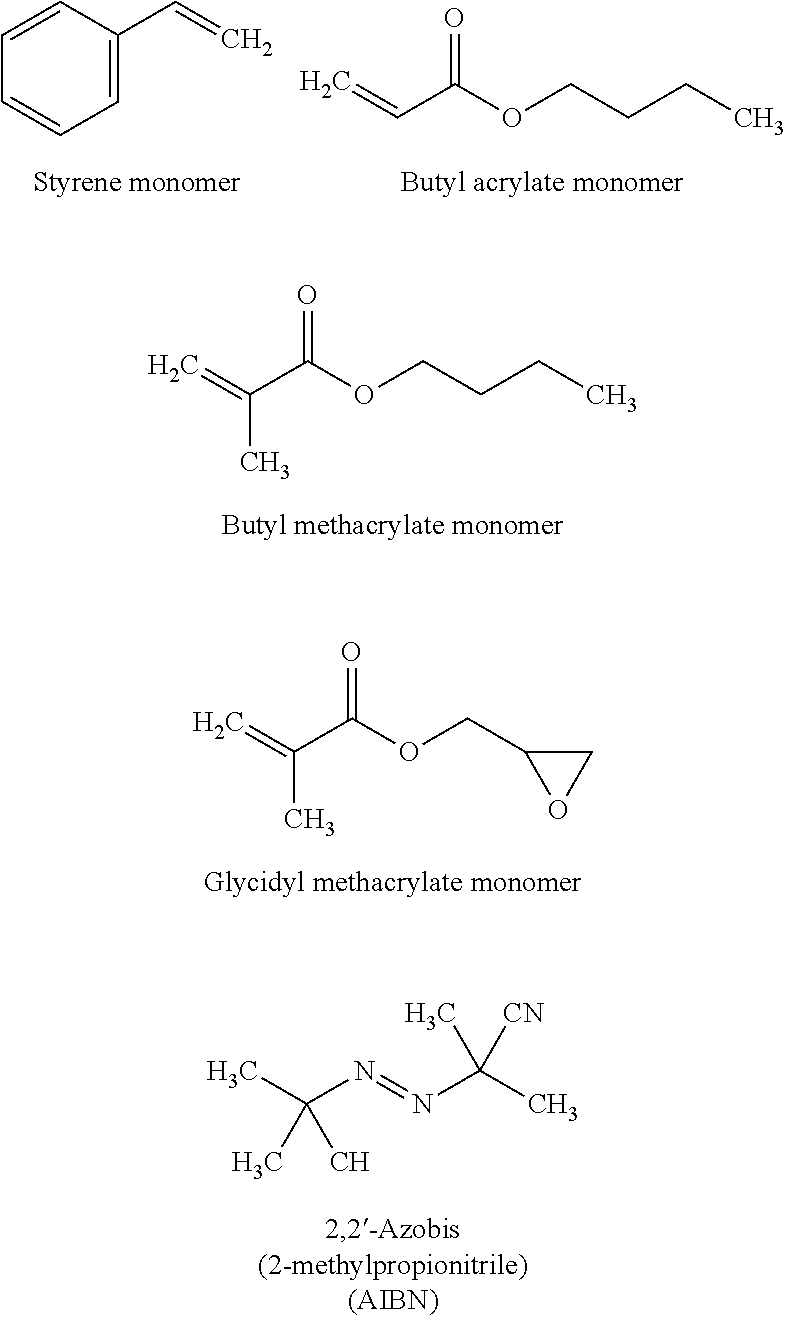

- A superhydrophobic coating composition comprising an acrylic polymer resin, polysiloxane oil, hydrophobic particles, and metal oxides that cures at room temperature, providing excellent adhesion and thermal stability, and resistance to corrosive chemicals, with a water contact angle greater than 150° and sliding angle less than 10°, suitable for various substrates.

Environmental Impact and Sustainability Considerations

The environmental impact of superhydrophobic coatings under UV exposure represents a critical consideration in their development and application. These coatings, while offering significant functional benefits, contain various chemical compounds that may pose environmental risks throughout their lifecycle. When exposed to prolonged UV radiation, certain components in superhydrophobic formulations can degrade into potentially harmful substances that may leach into soil or water systems, affecting aquatic ecosystems and biodiversity.

The manufacturing processes for these coatings often involve volatile organic compounds (VOCs) and fluorinated substances, which contribute to air pollution and persist in the environment. As UV exposure accelerates the degradation of these coatings, the release rate of these compounds increases, potentially exacerbating their environmental footprint. Recent studies indicate that nano-particles from degraded coatings may enter water systems, with uncertain long-term ecological consequences.

From a sustainability perspective, the durability challenges of superhydrophobic coatings under UV exposure directly impact their lifecycle assessment. Coatings with poor UV resistance require frequent reapplication, increasing resource consumption and waste generation. This contradicts circular economy principles and sustainable development goals. Improving UV durability would significantly enhance the sustainability profile of these materials by extending their service life and reducing replacement frequency.

Alternative, more environmentally friendly formulations are emerging in response to these concerns. Bio-based superhydrophobic coatings derived from plant materials show promising UV resistance while minimizing environmental impact. Similarly, silica-based formulations without fluorinated compounds offer reduced ecological footprints compared to traditional options. These alternatives represent important advances toward more sustainable superhydrophobic technologies.

Energy considerations also factor into the environmental assessment of these coatings. UV-durable superhydrophobic surfaces can contribute to energy efficiency in buildings and transportation by reducing cleaning requirements and maintaining optimal surface properties over longer periods. However, this potential benefit must be balanced against the energy-intensive production processes often required for manufacturing high-performance coatings.

Regulatory frameworks worldwide are increasingly addressing the environmental implications of coating technologies. The European Union's REACH regulations and similar initiatives in other regions are restricting certain compounds commonly used in superhydrophobic formulations, driving research toward more environmentally compatible alternatives. Future development in this field will likely be shaped by these evolving regulatory standards, pushing innovation toward greener chemistry approaches and more sustainable material cycles.

The manufacturing processes for these coatings often involve volatile organic compounds (VOCs) and fluorinated substances, which contribute to air pollution and persist in the environment. As UV exposure accelerates the degradation of these coatings, the release rate of these compounds increases, potentially exacerbating their environmental footprint. Recent studies indicate that nano-particles from degraded coatings may enter water systems, with uncertain long-term ecological consequences.

From a sustainability perspective, the durability challenges of superhydrophobic coatings under UV exposure directly impact their lifecycle assessment. Coatings with poor UV resistance require frequent reapplication, increasing resource consumption and waste generation. This contradicts circular economy principles and sustainable development goals. Improving UV durability would significantly enhance the sustainability profile of these materials by extending their service life and reducing replacement frequency.

Alternative, more environmentally friendly formulations are emerging in response to these concerns. Bio-based superhydrophobic coatings derived from plant materials show promising UV resistance while minimizing environmental impact. Similarly, silica-based formulations without fluorinated compounds offer reduced ecological footprints compared to traditional options. These alternatives represent important advances toward more sustainable superhydrophobic technologies.

Energy considerations also factor into the environmental assessment of these coatings. UV-durable superhydrophobic surfaces can contribute to energy efficiency in buildings and transportation by reducing cleaning requirements and maintaining optimal surface properties over longer periods. However, this potential benefit must be balanced against the energy-intensive production processes often required for manufacturing high-performance coatings.

Regulatory frameworks worldwide are increasingly addressing the environmental implications of coating technologies. The European Union's REACH regulations and similar initiatives in other regions are restricting certain compounds commonly used in superhydrophobic formulations, driving research toward more environmentally compatible alternatives. Future development in this field will likely be shaped by these evolving regulatory standards, pushing innovation toward greener chemistry approaches and more sustainable material cycles.

Testing Methodologies and Performance Standards

The evaluation of superhydrophobic coating durability under UV exposure requires standardized testing methodologies and performance criteria to ensure reliable and comparable results across different research studies and commercial applications. Current testing protocols typically follow established standards from organizations such as ASTM International, ISO, and AATCC, which have been adapted specifically for superhydrophobic surfaces.

Accelerated weathering tests represent the primary methodology for evaluating UV durability, with QUV accelerated weathering testers being widely employed in the industry. These systems simulate natural sunlight using UVA-340 or UVB-313 lamps, with exposure cycles typically ranging from 500 to 2000 hours to represent years of natural exposure. The testing parameters must be carefully controlled, including UV intensity (typically 0.68-1.35 W/m²/nm at 340nm), temperature (usually cycled between 50-70°C), and relative humidity (maintained at 50-90%).

Contact angle measurement serves as the fundamental performance indicator for superhydrophobic coatings, with durability often defined as the ability to maintain a contact angle above 150° and a sliding angle below 10° after UV exposure. Measurements are typically taken at predetermined intervals (0, 100, 500, 1000, and 2000 hours) to track degradation patterns. Advanced techniques such as dynamic contact angle analysis provide more comprehensive data on surface wetting behavior changes.

Surface morphology analysis complements wetting measurements, with scanning electron microscopy (SEM) and atomic force microscopy (AFM) being essential tools for quantifying changes in the micro/nano-hierarchical structures that enable superhydrophobicity. Researchers typically document changes in feature height, spacing, and overall roughness parameters to correlate structural degradation with functional performance loss.

Chemical composition analysis through FTIR, XPS, and Raman spectroscopy allows researchers to track chemical changes in the coating during UV exposure, particularly focusing on the degradation of hydrophobic functional groups such as fluorinated or silane compounds. These analyses help establish degradation mechanisms and inform the development of more UV-resistant formulations.

Performance standards for commercial applications vary by industry, with outdoor architectural coatings typically requiring maintenance of superhydrophobicity after 2000 hours of accelerated testing (equivalent to approximately 3-5 years of natural exposure). Automotive applications often demand even higher standards, with 3000+ hours of testing to simulate 7-10 years of service life under varying climate conditions.

Accelerated weathering tests represent the primary methodology for evaluating UV durability, with QUV accelerated weathering testers being widely employed in the industry. These systems simulate natural sunlight using UVA-340 or UVB-313 lamps, with exposure cycles typically ranging from 500 to 2000 hours to represent years of natural exposure. The testing parameters must be carefully controlled, including UV intensity (typically 0.68-1.35 W/m²/nm at 340nm), temperature (usually cycled between 50-70°C), and relative humidity (maintained at 50-90%).

Contact angle measurement serves as the fundamental performance indicator for superhydrophobic coatings, with durability often defined as the ability to maintain a contact angle above 150° and a sliding angle below 10° after UV exposure. Measurements are typically taken at predetermined intervals (0, 100, 500, 1000, and 2000 hours) to track degradation patterns. Advanced techniques such as dynamic contact angle analysis provide more comprehensive data on surface wetting behavior changes.

Surface morphology analysis complements wetting measurements, with scanning electron microscopy (SEM) and atomic force microscopy (AFM) being essential tools for quantifying changes in the micro/nano-hierarchical structures that enable superhydrophobicity. Researchers typically document changes in feature height, spacing, and overall roughness parameters to correlate structural degradation with functional performance loss.

Chemical composition analysis through FTIR, XPS, and Raman spectroscopy allows researchers to track chemical changes in the coating during UV exposure, particularly focusing on the degradation of hydrophobic functional groups such as fluorinated or silane compounds. These analyses help establish degradation mechanisms and inform the development of more UV-resistant formulations.

Performance standards for commercial applications vary by industry, with outdoor architectural coatings typically requiring maintenance of superhydrophobicity after 2000 hours of accelerated testing (equivalent to approximately 3-5 years of natural exposure). Automotive applications often demand even higher standards, with 3000+ hours of testing to simulate 7-10 years of service life under varying climate conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!