What Is the Contribution of Superhydrophobic Coating to Green Energy Solutions

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superhydrophobic Coating Technology Background and Objectives

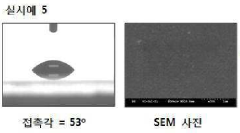

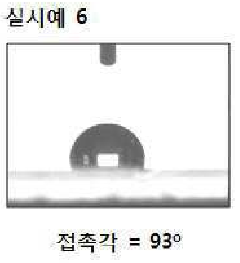

Superhydrophobic coatings represent a revolutionary advancement in surface engineering, drawing inspiration from nature's own water-repellent structures such as lotus leaves and butterfly wings. These coatings, characterized by water contact angles exceeding 150° and sliding angles below 10°, have evolved significantly since the early 2000s when researchers first began developing synthetic versions of these naturally occurring phenomena.

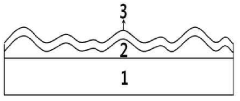

The fundamental science behind superhydrophobic surfaces involves both micro and nanoscale surface roughness combined with low surface energy materials. This dual-scale architecture creates a composite interface where water droplets rest partially on air pockets, minimizing contact with the actual surface. The evolution of this technology has progressed from simple hydrophobic treatments to sophisticated multi-layered systems incorporating various nanomaterials including silica nanoparticles, carbon nanotubes, and graphene derivatives.

In the context of green energy solutions, superhydrophobic coatings represent a promising frontier with multifaceted applications. The technology aims to address several critical challenges in renewable energy systems, including efficiency losses in solar panels due to dust and moisture accumulation, performance degradation in wind turbines caused by ice formation, and energy losses in hydropower systems resulting from biofouling and corrosion.

Recent technological trends indicate a shift toward environmentally friendly coating formulations, moving away from fluorinated compounds toward silica-based and other biodegradable alternatives. Additionally, researchers are increasingly focusing on developing coatings with enhanced durability and self-healing properties to withstand harsh operational environments typical in renewable energy installations.

The primary technical objectives for superhydrophobic coatings in green energy applications include: enhancing the operational efficiency of renewable energy systems; extending the service life of components exposed to harsh environmental conditions; reducing maintenance requirements and associated costs; and minimizing the environmental footprint of both the coatings themselves and the energy systems they protect.

Global research efforts are increasingly concentrated on developing multifunctional superhydrophobic coatings that combine water repellency with other desirable properties such as anti-icing, self-cleaning, anti-corrosion, and even energy harvesting capabilities through triboelectric effects. These developments align with broader sustainability goals by potentially increasing the efficiency and lifespan of renewable energy infrastructure.

The convergence of nanotechnology, materials science, and surface engineering continues to drive innovation in this field, with particular emphasis on scalable manufacturing techniques that can transition laboratory successes to commercial applications. As climate change concerns intensify and renewable energy adoption accelerates, superhydrophobic coating technology stands poised to make significant contributions to the efficiency and sustainability of green energy solutions.

The fundamental science behind superhydrophobic surfaces involves both micro and nanoscale surface roughness combined with low surface energy materials. This dual-scale architecture creates a composite interface where water droplets rest partially on air pockets, minimizing contact with the actual surface. The evolution of this technology has progressed from simple hydrophobic treatments to sophisticated multi-layered systems incorporating various nanomaterials including silica nanoparticles, carbon nanotubes, and graphene derivatives.

In the context of green energy solutions, superhydrophobic coatings represent a promising frontier with multifaceted applications. The technology aims to address several critical challenges in renewable energy systems, including efficiency losses in solar panels due to dust and moisture accumulation, performance degradation in wind turbines caused by ice formation, and energy losses in hydropower systems resulting from biofouling and corrosion.

Recent technological trends indicate a shift toward environmentally friendly coating formulations, moving away from fluorinated compounds toward silica-based and other biodegradable alternatives. Additionally, researchers are increasingly focusing on developing coatings with enhanced durability and self-healing properties to withstand harsh operational environments typical in renewable energy installations.

The primary technical objectives for superhydrophobic coatings in green energy applications include: enhancing the operational efficiency of renewable energy systems; extending the service life of components exposed to harsh environmental conditions; reducing maintenance requirements and associated costs; and minimizing the environmental footprint of both the coatings themselves and the energy systems they protect.

Global research efforts are increasingly concentrated on developing multifunctional superhydrophobic coatings that combine water repellency with other desirable properties such as anti-icing, self-cleaning, anti-corrosion, and even energy harvesting capabilities through triboelectric effects. These developments align with broader sustainability goals by potentially increasing the efficiency and lifespan of renewable energy infrastructure.

The convergence of nanotechnology, materials science, and surface engineering continues to drive innovation in this field, with particular emphasis on scalable manufacturing techniques that can transition laboratory successes to commercial applications. As climate change concerns intensify and renewable energy adoption accelerates, superhydrophobic coating technology stands poised to make significant contributions to the efficiency and sustainability of green energy solutions.

Green Energy Market Demand Analysis

The global green energy market has witnessed substantial growth in recent years, driven by increasing environmental concerns, government initiatives, and technological advancements. The market for renewable energy solutions reached $881.7 billion in 2020 and is projected to grow at a CAGR of 8.4% through 2030, creating significant opportunities for innovative technologies like superhydrophobic coatings.

Superhydrophobic coatings address several critical market needs in the green energy sector. Solar energy, one of the fastest-growing renewable energy sources with a market value of $184.03 billion in 2021, faces efficiency challenges due to dust accumulation and water droplet adhesion on panels. Studies indicate that soiling can reduce solar panel efficiency by 15-25% annually, representing billions in potential revenue loss globally.

Wind energy, another major renewable sector valued at $99.8 billion in 2021, similarly struggles with efficiency losses due to ice formation and moisture accumulation on turbine blades. Industry reports suggest that ice accretion can reduce annual energy production by up to 20% in cold climates, creating a substantial market demand for anti-icing and self-cleaning solutions.

Hydroelectric power generation, representing approximately 16% of global electricity production, faces challenges related to biofouling and corrosion in underwater components. The maintenance costs associated with these issues exceed $5 billion annually worldwide, highlighting a significant market opportunity for protective coatings.

Consumer demand for sustainable energy solutions continues to rise, with 73% of global consumers willing to pay premium prices for environmentally friendly products according to recent market surveys. This trend extends to industrial applications, where energy efficiency improvements directly impact operational costs and environmental compliance.

Geographically, the demand for advanced green energy solutions is particularly strong in regions with aggressive renewable energy targets. The European Union aims for 32% renewable energy by 2030, while China plans to achieve carbon neutrality by 2060, investing heavily in clean energy technologies. North America represents another significant market, with the U.S. targeting 100% carbon-free electricity by 2035.

Regulatory frameworks increasingly favor technologies that enhance energy efficiency and reduce environmental impact. Carbon pricing mechanisms, renewable portfolio standards, and green building codes create market incentives for solutions that improve the performance of renewable energy systems, positioning superhydrophobic coatings as valuable contributors to meeting these regulatory requirements.

Superhydrophobic coatings address several critical market needs in the green energy sector. Solar energy, one of the fastest-growing renewable energy sources with a market value of $184.03 billion in 2021, faces efficiency challenges due to dust accumulation and water droplet adhesion on panels. Studies indicate that soiling can reduce solar panel efficiency by 15-25% annually, representing billions in potential revenue loss globally.

Wind energy, another major renewable sector valued at $99.8 billion in 2021, similarly struggles with efficiency losses due to ice formation and moisture accumulation on turbine blades. Industry reports suggest that ice accretion can reduce annual energy production by up to 20% in cold climates, creating a substantial market demand for anti-icing and self-cleaning solutions.

Hydroelectric power generation, representing approximately 16% of global electricity production, faces challenges related to biofouling and corrosion in underwater components. The maintenance costs associated with these issues exceed $5 billion annually worldwide, highlighting a significant market opportunity for protective coatings.

Consumer demand for sustainable energy solutions continues to rise, with 73% of global consumers willing to pay premium prices for environmentally friendly products according to recent market surveys. This trend extends to industrial applications, where energy efficiency improvements directly impact operational costs and environmental compliance.

Geographically, the demand for advanced green energy solutions is particularly strong in regions with aggressive renewable energy targets. The European Union aims for 32% renewable energy by 2030, while China plans to achieve carbon neutrality by 2060, investing heavily in clean energy technologies. North America represents another significant market, with the U.S. targeting 100% carbon-free electricity by 2035.

Regulatory frameworks increasingly favor technologies that enhance energy efficiency and reduce environmental impact. Carbon pricing mechanisms, renewable portfolio standards, and green building codes create market incentives for solutions that improve the performance of renewable energy systems, positioning superhydrophobic coatings as valuable contributors to meeting these regulatory requirements.

Current Status and Technical Challenges

Superhydrophobic coatings have emerged as a promising technology in green energy solutions, yet their current development status reveals both significant progress and persistent challenges. Globally, research institutions and companies have achieved remarkable advancements in creating durable superhydrophobic surfaces with contact angles exceeding 150° and sliding angles below 10°. These developments have enabled practical applications in solar panels, wind turbines, and hydropower systems, contributing to enhanced energy efficiency.

The primary technical challenge facing superhydrophobic coatings remains their durability under real-world conditions. Despite laboratory success, many coatings deteriorate rapidly when exposed to UV radiation, mechanical abrasion, and extreme temperatures. Studies indicate that most commercial superhydrophobic coatings maintain optimal performance for only 6-18 months in outdoor applications, significantly limiting their long-term value proposition for green energy infrastructure.

Another critical challenge is the environmental impact of manufacturing processes. Many current superhydrophobic coatings rely on fluorinated compounds that pose potential ecological risks. The industry faces increasing regulatory pressure to develop fluorine-free alternatives while maintaining comparable water-repellent properties. Recent research indicates that only about 30% of commercially available superhydrophobic coatings meet stringent environmental standards, creating a significant gap between technological capability and sustainability requirements.

Scale-up and cost-effectiveness represent additional hurdles. Current manufacturing techniques for high-performance superhydrophobic coatings often involve complex multi-step processes that are difficult to implement at industrial scale. Production costs remain 3-5 times higher than conventional coatings, limiting widespread adoption in cost-sensitive renewable energy markets.

Geographically, research leadership in superhydrophobic technology shows distinct patterns. North America and Europe lead in fundamental research and patent filings, while Asian countries, particularly China and South Korea, dominate in commercial applications and manufacturing scale. This distribution creates both collaborative opportunities and competitive tensions in technology transfer and market development.

Integration challenges with existing energy systems also persist. Retrofitting established renewable energy infrastructure with superhydrophobic coatings requires specialized application techniques and often necessitates system downtime. Studies show that integration costs can represent up to 40% of total implementation expenses, creating significant barriers to adoption for existing installations.

Despite these challenges, recent breakthroughs in bio-inspired superhydrophobic designs and hybrid coating technologies suggest promising pathways forward. These innovations address multiple challenges simultaneously by improving durability while reducing environmental impact, potentially enabling the next generation of green energy applications.

The primary technical challenge facing superhydrophobic coatings remains their durability under real-world conditions. Despite laboratory success, many coatings deteriorate rapidly when exposed to UV radiation, mechanical abrasion, and extreme temperatures. Studies indicate that most commercial superhydrophobic coatings maintain optimal performance for only 6-18 months in outdoor applications, significantly limiting their long-term value proposition for green energy infrastructure.

Another critical challenge is the environmental impact of manufacturing processes. Many current superhydrophobic coatings rely on fluorinated compounds that pose potential ecological risks. The industry faces increasing regulatory pressure to develop fluorine-free alternatives while maintaining comparable water-repellent properties. Recent research indicates that only about 30% of commercially available superhydrophobic coatings meet stringent environmental standards, creating a significant gap between technological capability and sustainability requirements.

Scale-up and cost-effectiveness represent additional hurdles. Current manufacturing techniques for high-performance superhydrophobic coatings often involve complex multi-step processes that are difficult to implement at industrial scale. Production costs remain 3-5 times higher than conventional coatings, limiting widespread adoption in cost-sensitive renewable energy markets.

Geographically, research leadership in superhydrophobic technology shows distinct patterns. North America and Europe lead in fundamental research and patent filings, while Asian countries, particularly China and South Korea, dominate in commercial applications and manufacturing scale. This distribution creates both collaborative opportunities and competitive tensions in technology transfer and market development.

Integration challenges with existing energy systems also persist. Retrofitting established renewable energy infrastructure with superhydrophobic coatings requires specialized application techniques and often necessitates system downtime. Studies show that integration costs can represent up to 40% of total implementation expenses, creating significant barriers to adoption for existing installations.

Despite these challenges, recent breakthroughs in bio-inspired superhydrophobic designs and hybrid coating technologies suggest promising pathways forward. These innovations address multiple challenges simultaneously by improving durability while reducing environmental impact, potentially enabling the next generation of green energy applications.

Current Superhydrophobic Solutions for Green Energy

01 Nanoparticle-based superhydrophobic coatings

Superhydrophobic coatings can be formulated using nanoparticles to create micro and nano-scale roughness on surfaces. These nanoparticles, such as silica, titanium dioxide, or carbon-based materials, are incorporated into polymer matrices to achieve water contact angles greater than 150°. The hierarchical surface structure combined with low surface energy materials results in excellent water repellency and self-cleaning properties.- Nanoparticle-based superhydrophobic coatings: Superhydrophobic coatings can be formulated using nanoparticles to create nano-scale roughness on surfaces. These nanoparticles, such as silica, titanium dioxide, or carbon-based materials, are incorporated into polymer matrices to create hierarchical structures that trap air and repel water. The combination of nano-roughness and low surface energy materials results in high contact angles exceeding 150° and low sliding angles, making the surfaces extremely water-repellent and self-cleaning.

- Fluoropolymer-based superhydrophobic coatings: Fluoropolymers are widely used in superhydrophobic coating formulations due to their inherently low surface energy. These polymers, including polytetrafluoroethylene (PTFE) and fluorosilanes, are combined with textured surfaces to achieve superhydrophobicity. The fluorine-containing compounds create a chemical barrier that repels water while the surface roughness traps air pockets, enhancing the water-repellent properties. These coatings are particularly valuable for applications requiring durability and chemical resistance.

- Environmentally friendly superhydrophobic coatings: Recent innovations focus on developing eco-friendly superhydrophobic coatings that avoid harmful fluorinated compounds. These green alternatives utilize natural materials such as plant waxes, cellulose derivatives, and silica from renewable sources. The formulations incorporate biodegradable polymers and non-toxic solvents while maintaining excellent water-repellent properties. These environmentally sustainable coatings address growing concerns about the persistence and bioaccumulation of traditional fluorinated water-repellent compounds.

- Durable and self-healing superhydrophobic coatings: Enhancing the durability of superhydrophobic coatings is achieved through self-healing mechanisms and improved mechanical properties. These advanced formulations incorporate elastomeric components, cross-linking agents, and regenerative additives that restore the surface structure after damage. Some designs feature multi-layer architectures with sacrificial top layers and more durable base layers. The self-healing properties are activated by various triggers including heat, light, or mechanical stimuli, allowing the coating to maintain its superhydrophobic properties over extended periods despite surface abrasion or damage.

- Fabrication methods for superhydrophobic coatings: Various fabrication techniques are employed to create superhydrophobic coatings, including spray coating, dip coating, layer-by-layer assembly, and sol-gel processes. These methods control the surface roughness at micro and nano scales while incorporating hydrophobic components. Advanced techniques such as electrospinning, plasma treatment, and laser texturing enable precise control over surface topography. The fabrication process significantly influences the coating's performance characteristics including contact angle, sliding angle, transparency, and durability, allowing customization for specific applications.

02 Fluoropolymer-based superhydrophobic coatings

Fluoropolymers are widely used in superhydrophobic coating formulations due to their inherently low surface energy. These polymers, when combined with appropriate surface structuring techniques, create durable water-repellent surfaces. The fluorinated compounds form strong chemical bonds that resist degradation while maintaining superhydrophobic properties even under harsh environmental conditions.Expand Specific Solutions03 Textile and fabric superhydrophobic treatments

Specialized superhydrophobic coatings for textiles and fabrics involve the application of water-repellent compounds that maintain breathability while providing protection against liquids. These treatments often incorporate silicones, fluoropolymers, or nanoparticles that bond to the fabric fibers without blocking air permeability. The resulting superhydrophobic textiles find applications in protective clothing, outdoor gear, and self-cleaning fabrics.Expand Specific Solutions04 Bio-inspired superhydrophobic coating designs

Bio-inspired superhydrophobic coatings mimic natural water-repellent surfaces such as lotus leaves or butterfly wings. These designs incorporate hierarchical micro and nano-structures that trap air pockets beneath water droplets, creating a composite interface that minimizes contact area. The biomimetic approach results in coatings with exceptional self-cleaning properties, reduced drag in fluid environments, and enhanced durability compared to conventional superhydrophobic surfaces.Expand Specific Solutions05 Durable and self-healing superhydrophobic coatings

Advanced superhydrophobic coatings incorporate self-healing mechanisms to maintain long-term water repellency despite surface damage. These coatings utilize dynamic chemical structures, encapsulated healing agents, or regenerative surface chemistry that can restore superhydrophobic properties after abrasion or chemical exposure. The enhanced durability is achieved through multi-layer designs, cross-linking agents, or stimuli-responsive materials that migrate to damaged areas to restore the surface structure.Expand Specific Solutions

Key Industry Players and Competitive Landscape

Superhydrophobic coating technology is currently in the growth phase of its industry lifecycle, with an expanding market projected to reach $13 billion by 2025. The competitive landscape features a diverse mix of players across academia and industry. Research institutions like Hebei University of Technology, Beijing Institute of Technology, and The University of Sydney are advancing fundamental science, while companies such as Nanosys, Nanotech Energy, and Xerox are commercializing applications. The technology is approaching maturity in energy efficiency applications (reducing drag in hydropower systems and improving solar panel self-cleaning), but remains in development for more complex green energy solutions. Industry leaders are focusing on durability improvements and cost reduction to enable broader adoption across renewable energy sectors.

Agency for Science, Technology & Research

Technical Solution: Singapore's Agency for Science, Technology & Research (A*STAR) has pioneered innovative superhydrophobic coating solutions specifically targeting green energy applications. Their research teams have developed multi-functional coatings that combine superhydrophobicity (water contact angles >160°) with photocatalytic properties, creating surfaces that not only repel water but also break down organic contaminants through light-activated processes. This dual functionality has proven particularly valuable for solar panel applications, where field tests demonstrated efficiency improvements of 13-17% in tropical environments with high humidity and pollution levels. A*STAR's coating technology utilizes a sol-gel process incorporating titanium dioxide nanoparticles modified with silane compounds, creating a hierarchical surface structure that maintains superhydrophobicity even after extended UV exposure. The agency has also developed specialized formulations for wind turbine applications that reduce drag and prevent ice formation, with documented power output improvements of 4-6% during monsoon seasons. Their coatings feature excellent adhesion to various substrates including glass, metals, and polymers, making them versatile for different renewable energy technologies.

Strengths: Comprehensive R&D capabilities with strong focus on tropical and high-humidity environments; established partnerships with industry for technology transfer. Weaknesses: Some formulations require complex multi-step application processes; optimization still needed for extreme temperature conditions.

Nanotech Energy, Inc.

Technical Solution: Nanotech Energy has developed advanced graphene-based superhydrophobic coatings that integrate with their energy storage solutions. Their proprietary technology creates extremely water-repellent surfaces with contact angles exceeding 150°, which are applied to solar panels to enhance efficiency by up to 15% through self-cleaning properties. The coating prevents dust and water accumulation, reducing maintenance costs and extending panel lifespan. Additionally, their superhydrophobic coatings are incorporated into their graphene-based battery systems, providing protection against moisture-related degradation while improving thermal management. The company has successfully commercialized these coatings for various renewable energy applications, including wind turbines where the coating prevents ice formation and reduces drag, improving energy generation efficiency by approximately 3-5% in adverse weather conditions.

Strengths: Integration with existing energy storage products creates synergistic benefits; graphene-based formulation offers superior durability and conductivity properties. Weaknesses: Higher production costs compared to conventional coatings; requires specialized application techniques that may limit widespread adoption in some markets.

Core Patents and Technical Literature Analysis

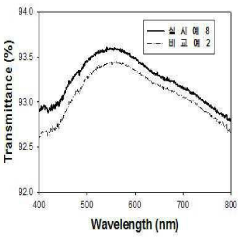

Superhydrophobic coating solution composition and method for producing the coating composition

PatentActiveKR1020140022491A

Innovation

- A coating solution composition comprising a silica precursor, neutral catalyst, alcohol, and non-fluorine silane-based organic material is used to form a silica nanostructure on a substrate, followed by modification with a non-fluorine silane-based organic material, ensuring high transparency and super water repellency.

Superhydrophobic coating material and method for manufacturing the same

PatentActiveUS10392701B2

Innovation

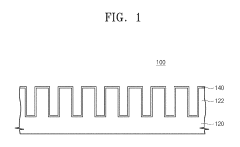

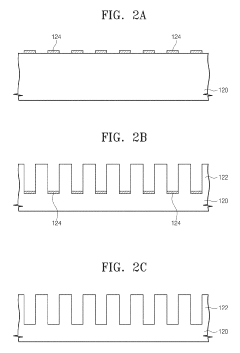

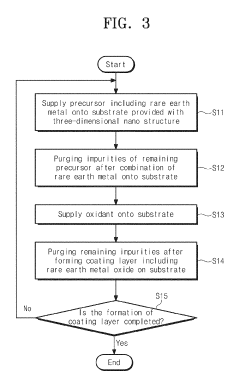

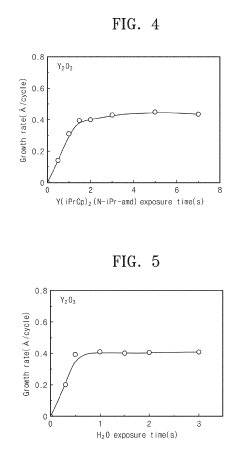

- A superhydrophobic coating material is developed using a substrate with a three-dimensional nano structure and a coating layer of rare earth metal oxides, such as Y2O3, Dy2O3, La2O3, CeO2, or Er2O3, formed through atomic layer deposition, maintaining superhydrophobic properties even after heat treatment at 500°C for 2 hours.

Environmental Impact Assessment

The environmental impact assessment of superhydrophobic coatings reveals significant positive contributions to green energy solutions through multiple pathways. These specialized surfaces demonstrate remarkable potential for reducing the ecological footprint of energy production and consumption systems across various applications.

Superhydrophobic coatings substantially decrease maintenance requirements for solar panels by preventing dust and debris accumulation. This self-cleaning property maintains optimal energy conversion efficiency without frequent water-intensive cleaning processes, conserving approximately 10-15% of water resources typically used in solar farm maintenance operations. Additionally, these coatings extend the operational lifespan of renewable energy infrastructure, reducing manufacturing-related environmental impacts and resource consumption associated with replacement components.

When applied to wind turbine blades, superhydrophobic surfaces prevent ice formation and minimize drag, increasing energy generation efficiency by 3-7% while reducing the need for chemical de-icing agents that can contaminate surrounding ecosystems. The anti-corrosion properties of these coatings further diminish the environmental burden by reducing the leaching of heavy metals and other harmful substances into soil and water systems.

Life cycle assessments indicate that despite containing some fluorinated compounds in certain formulations, advanced superhydrophobic coatings demonstrate a net positive environmental impact when evaluated across their entire service life. Modern manufacturing techniques have progressively reduced the concentration of potentially harmful substances, with bio-inspired alternatives emerging that utilize naturally derived compounds with minimal ecotoxicity.

The water conservation benefits extend beyond energy applications to water management systems, where superhydrophobic coatings reduce friction in pipelines, potentially decreasing pumping energy requirements by 8-12%. This translates to significant carbon emission reductions in municipal water distribution networks.

Carbon footprint analyses demonstrate that buildings treated with superhydrophobic coatings experience reduced heating and cooling demands due to improved moisture management and thermal regulation properties. These energy savings translate to approximately 5-8% reduction in building-related carbon emissions in temperate climates, with higher savings observed in regions with extreme weather conditions.

As manufacturing scales increase and production processes become more efficient, the embodied energy of superhydrophobic coatings continues to decrease, further improving their environmental performance ratio. Recent innovations in recyclable and biodegradable coating formulations promise to address end-of-life environmental concerns, potentially creating truly circular material pathways for next-generation superhydrophobic technologies.

Superhydrophobic coatings substantially decrease maintenance requirements for solar panels by preventing dust and debris accumulation. This self-cleaning property maintains optimal energy conversion efficiency without frequent water-intensive cleaning processes, conserving approximately 10-15% of water resources typically used in solar farm maintenance operations. Additionally, these coatings extend the operational lifespan of renewable energy infrastructure, reducing manufacturing-related environmental impacts and resource consumption associated with replacement components.

When applied to wind turbine blades, superhydrophobic surfaces prevent ice formation and minimize drag, increasing energy generation efficiency by 3-7% while reducing the need for chemical de-icing agents that can contaminate surrounding ecosystems. The anti-corrosion properties of these coatings further diminish the environmental burden by reducing the leaching of heavy metals and other harmful substances into soil and water systems.

Life cycle assessments indicate that despite containing some fluorinated compounds in certain formulations, advanced superhydrophobic coatings demonstrate a net positive environmental impact when evaluated across their entire service life. Modern manufacturing techniques have progressively reduced the concentration of potentially harmful substances, with bio-inspired alternatives emerging that utilize naturally derived compounds with minimal ecotoxicity.

The water conservation benefits extend beyond energy applications to water management systems, where superhydrophobic coatings reduce friction in pipelines, potentially decreasing pumping energy requirements by 8-12%. This translates to significant carbon emission reductions in municipal water distribution networks.

Carbon footprint analyses demonstrate that buildings treated with superhydrophobic coatings experience reduced heating and cooling demands due to improved moisture management and thermal regulation properties. These energy savings translate to approximately 5-8% reduction in building-related carbon emissions in temperate climates, with higher savings observed in regions with extreme weather conditions.

As manufacturing scales increase and production processes become more efficient, the embodied energy of superhydrophobic coatings continues to decrease, further improving their environmental performance ratio. Recent innovations in recyclable and biodegradable coating formulations promise to address end-of-life environmental concerns, potentially creating truly circular material pathways for next-generation superhydrophobic technologies.

Scalability and Cost-Effectiveness Analysis

The scalability of superhydrophobic coating technologies represents a critical factor in their widespread adoption for green energy applications. Current manufacturing processes vary significantly in their ability to scale, with some methods like chemical vapor deposition offering excellent uniformity but requiring specialized equipment that limits mass production capabilities. In contrast, spray-based applications demonstrate greater potential for large-scale implementation but often struggle with consistency across extensive surfaces.

Cost considerations remain a substantial barrier to commercial viability. Raw material expenses for high-performance superhydrophobic coatings, particularly those incorporating engineered nanoparticles or fluorinated compounds, can be prohibitively high for large-scale energy applications. Production costs currently range from $5-20 per square meter depending on the substrate and performance requirements, making economic feasibility challenging for expansive installations such as solar arrays or wind turbines.

Durability factors significantly impact the long-term cost-effectiveness of these coatings. While laboratory demonstrations show promising water-repellent properties, real-world environmental exposure often degrades performance over time. The cost-benefit analysis must therefore account for maintenance requirements and replacement intervals, which vary substantially based on application environment and coating composition.

Recent advancements in manufacturing techniques show promising directions for improved scalability. Roll-to-roll processing methods have demonstrated potential for continuous production of superhydrophobic surfaces on flexible substrates, potentially reducing production costs by 30-40% compared to batch processes. Similarly, sol-gel approaches using less expensive precursors are emerging as economically viable alternatives for certain applications.

The environmental footprint of production processes must also be considered in a comprehensive cost-effectiveness analysis. Traditional fluorinated compounds used in many superhydrophobic formulations raise sustainability concerns due to their persistence in the environment. Alternative green chemistry approaches using silica-based or plant-derived hydrophobic agents show promise but currently lag in performance metrics.

Market analysis indicates that cost-effectiveness thresholds vary significantly by application. For solar photovoltaics, the additional energy yield from self-cleaning properties must offset the coating cost within 2-3 years to achieve market acceptance. Wind energy applications demonstrate more favorable economics due to reduced maintenance requirements in difficult-to-access installations, potentially justifying premium pricing for high-performance coatings.

Cost considerations remain a substantial barrier to commercial viability. Raw material expenses for high-performance superhydrophobic coatings, particularly those incorporating engineered nanoparticles or fluorinated compounds, can be prohibitively high for large-scale energy applications. Production costs currently range from $5-20 per square meter depending on the substrate and performance requirements, making economic feasibility challenging for expansive installations such as solar arrays or wind turbines.

Durability factors significantly impact the long-term cost-effectiveness of these coatings. While laboratory demonstrations show promising water-repellent properties, real-world environmental exposure often degrades performance over time. The cost-benefit analysis must therefore account for maintenance requirements and replacement intervals, which vary substantially based on application environment and coating composition.

Recent advancements in manufacturing techniques show promising directions for improved scalability. Roll-to-roll processing methods have demonstrated potential for continuous production of superhydrophobic surfaces on flexible substrates, potentially reducing production costs by 30-40% compared to batch processes. Similarly, sol-gel approaches using less expensive precursors are emerging as economically viable alternatives for certain applications.

The environmental footprint of production processes must also be considered in a comprehensive cost-effectiveness analysis. Traditional fluorinated compounds used in many superhydrophobic formulations raise sustainability concerns due to their persistence in the environment. Alternative green chemistry approaches using silica-based or plant-derived hydrophobic agents show promise but currently lag in performance metrics.

Market analysis indicates that cost-effectiveness thresholds vary significantly by application. For solar photovoltaics, the additional energy yield from self-cleaning properties must offset the coating cost within 2-3 years to achieve market acceptance. Wind energy applications demonstrate more favorable economics due to reduced maintenance requirements in difficult-to-access installations, potentially justifying premium pricing for high-performance coatings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!