Investigation of Superhydrophobic Coating in Antimicrobial Applications

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superhydrophobic Antimicrobial Coating Background and Objectives

Superhydrophobic surfaces, characterized by water contact angles exceeding 150° and sliding angles less than 10°, have garnered significant attention in materials science over the past two decades. The concept draws inspiration from natural phenomena, most notably the lotus leaf effect, where water droplets roll off surfaces while carrying away contaminants. This self-cleaning property has evolved through millions of years of natural selection, providing plants and certain insects with protection against environmental threats.

The historical development of superhydrophobic materials began with fundamental studies in the 1940s, but significant breakthroughs emerged in the late 1990s with the detailed characterization of the lotus leaf's micro and nanostructured surface. Since then, research has expanded exponentially, with over 2,000 publications annually by 2020, demonstrating the growing scientific interest in this field.

Concurrently, antimicrobial resistance has emerged as one of the most pressing global health challenges. The World Health Organization estimates that by 2050, antimicrobial-resistant infections could cause 10 million deaths annually. This crisis has accelerated the search for alternative antimicrobial strategies that do not rely on conventional antibiotics or biocides, which often contribute to resistance development.

The convergence of superhydrophobicity and antimicrobial functionality represents a promising technological frontier. Unlike traditional antimicrobial approaches that kill microorganisms through chemical means, superhydrophobic antimicrobial coatings primarily function through physical mechanisms—preventing microbial attachment and promoting removal—potentially offering a solution that microbes cannot easily develop resistance against.

Recent technological advances have enabled the development of multifunctional coatings that combine superhydrophobicity with direct antimicrobial properties. These hybrid approaches incorporate antimicrobial agents such as silver nanoparticles, copper compounds, or photocatalytic materials within superhydrophobic matrices, creating surfaces that both repel and inactivate microorganisms.

The primary objectives of current research in this field include: developing scalable and cost-effective manufacturing processes for commercial viability; enhancing the mechanical durability of these coatings to withstand real-world conditions; ensuring long-term antimicrobial efficacy without leaching harmful substances; and creating environmentally friendly formulations that comply with increasingly stringent regulations.

Additionally, researchers aim to expand the application spectrum beyond traditional medical devices and hospital surfaces to include consumer products, food processing equipment, water treatment systems, and marine infrastructure. The ultimate goal is to establish superhydrophobic antimicrobial coatings as a mainstream technology that contributes significantly to infection control strategies and helps combat the growing threat of antimicrobial resistance.

The historical development of superhydrophobic materials began with fundamental studies in the 1940s, but significant breakthroughs emerged in the late 1990s with the detailed characterization of the lotus leaf's micro and nanostructured surface. Since then, research has expanded exponentially, with over 2,000 publications annually by 2020, demonstrating the growing scientific interest in this field.

Concurrently, antimicrobial resistance has emerged as one of the most pressing global health challenges. The World Health Organization estimates that by 2050, antimicrobial-resistant infections could cause 10 million deaths annually. This crisis has accelerated the search for alternative antimicrobial strategies that do not rely on conventional antibiotics or biocides, which often contribute to resistance development.

The convergence of superhydrophobicity and antimicrobial functionality represents a promising technological frontier. Unlike traditional antimicrobial approaches that kill microorganisms through chemical means, superhydrophobic antimicrobial coatings primarily function through physical mechanisms—preventing microbial attachment and promoting removal—potentially offering a solution that microbes cannot easily develop resistance against.

Recent technological advances have enabled the development of multifunctional coatings that combine superhydrophobicity with direct antimicrobial properties. These hybrid approaches incorporate antimicrobial agents such as silver nanoparticles, copper compounds, or photocatalytic materials within superhydrophobic matrices, creating surfaces that both repel and inactivate microorganisms.

The primary objectives of current research in this field include: developing scalable and cost-effective manufacturing processes for commercial viability; enhancing the mechanical durability of these coatings to withstand real-world conditions; ensuring long-term antimicrobial efficacy without leaching harmful substances; and creating environmentally friendly formulations that comply with increasingly stringent regulations.

Additionally, researchers aim to expand the application spectrum beyond traditional medical devices and hospital surfaces to include consumer products, food processing equipment, water treatment systems, and marine infrastructure. The ultimate goal is to establish superhydrophobic antimicrobial coatings as a mainstream technology that contributes significantly to infection control strategies and helps combat the growing threat of antimicrobial resistance.

Market Analysis for Antimicrobial Surface Solutions

The global market for antimicrobial surface solutions has experienced significant growth in recent years, driven primarily by increasing awareness of infection control and hygiene standards across various sectors. The market value reached approximately $3.6 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 12.3% through 2028, potentially reaching $7.2 billion by the end of the forecast period.

Healthcare facilities represent the largest market segment, accounting for roughly 38% of the total market share. This dominance stems from stringent infection control protocols and the critical need to prevent healthcare-associated infections (HAIs). The food processing industry follows as the second-largest consumer of antimicrobial surface technologies, representing about 24% of the market, where contamination prevention directly impacts product safety and shelf life.

Regional analysis reveals North America as the current market leader with approximately 35% market share, followed closely by Europe at 30%. However, the Asia-Pacific region is demonstrating the fastest growth rate at 14.7% annually, driven by rapid healthcare infrastructure development, increasing healthcare expenditure, and growing awareness about infection control in countries like China, India, and Japan.

Consumer preferences are shifting toward environmentally sustainable antimicrobial solutions, with 67% of institutional buyers expressing preference for non-toxic alternatives to traditional chemical-based antimicrobial agents. This trend has accelerated development in biomimetic approaches, including superhydrophobic coatings that provide physical rather than chemical antimicrobial properties.

Market penetration of superhydrophobic antimicrobial coatings specifically remains relatively low at approximately 8% of the total antimicrobial surfaces market, indicating substantial growth potential. Early adopters have primarily been premium healthcare facilities and high-end consumer products, with cost being cited as the primary barrier to wider adoption.

Price sensitivity analysis indicates that commercial viability for mass-market applications would require production cost reductions of 30-40% from current levels. However, the willingness to pay premium prices is notably higher in healthcare and food processing sectors, where the cost of contamination incidents far outweighs preventative investment.

Market forecasts suggest that technological advancements reducing application complexity and improving durability could trigger a market inflection point by 2025, potentially tripling the market share of superhydrophobic antimicrobial solutions within three years of such breakthroughs.

Healthcare facilities represent the largest market segment, accounting for roughly 38% of the total market share. This dominance stems from stringent infection control protocols and the critical need to prevent healthcare-associated infections (HAIs). The food processing industry follows as the second-largest consumer of antimicrobial surface technologies, representing about 24% of the market, where contamination prevention directly impacts product safety and shelf life.

Regional analysis reveals North America as the current market leader with approximately 35% market share, followed closely by Europe at 30%. However, the Asia-Pacific region is demonstrating the fastest growth rate at 14.7% annually, driven by rapid healthcare infrastructure development, increasing healthcare expenditure, and growing awareness about infection control in countries like China, India, and Japan.

Consumer preferences are shifting toward environmentally sustainable antimicrobial solutions, with 67% of institutional buyers expressing preference for non-toxic alternatives to traditional chemical-based antimicrobial agents. This trend has accelerated development in biomimetic approaches, including superhydrophobic coatings that provide physical rather than chemical antimicrobial properties.

Market penetration of superhydrophobic antimicrobial coatings specifically remains relatively low at approximately 8% of the total antimicrobial surfaces market, indicating substantial growth potential. Early adopters have primarily been premium healthcare facilities and high-end consumer products, with cost being cited as the primary barrier to wider adoption.

Price sensitivity analysis indicates that commercial viability for mass-market applications would require production cost reductions of 30-40% from current levels. However, the willingness to pay premium prices is notably higher in healthcare and food processing sectors, where the cost of contamination incidents far outweighs preventative investment.

Market forecasts suggest that technological advancements reducing application complexity and improving durability could trigger a market inflection point by 2025, potentially tripling the market share of superhydrophobic antimicrobial solutions within three years of such breakthroughs.

Current Challenges in Superhydrophobic Antimicrobial Technology

Despite significant advancements in superhydrophobic antimicrobial technology, several critical challenges persist that impede widespread commercial adoption and optimal performance. The integration of superhydrophobic properties with antimicrobial functionality presents complex technical hurdles that researchers and manufacturers continue to grapple with globally.

Durability remains perhaps the most significant obstacle in superhydrophobic antimicrobial coatings. These surfaces typically rely on delicate micro/nano hierarchical structures that are susceptible to mechanical abrasion, chemical degradation, and environmental stress. Studies indicate that many current formulations lose their superhydrophobic properties after repeated cleaning cycles or exposure to harsh conditions, with performance degradation often beginning within weeks of application.

The manufacturing scalability of these advanced coatings presents another substantial challenge. Laboratory-scale production methods such as chemical vapor deposition, lithography, and sol-gel processes yield excellent results but face significant barriers when scaled to industrial production. The precision required to create uniform nano-structures across large surface areas while maintaining cost-effectiveness has proven particularly problematic.

Biocompatibility concerns emerge when these technologies are considered for medical applications. Many superhydrophobic formulations incorporate potentially toxic components such as fluorinated compounds or silver nanoparticles, raising regulatory hurdles and safety concerns. The long-term effects of these materials on human health and the environment remain inadequately characterized, particularly when considering potential nanoparticle leaching.

The antimicrobial efficacy of superhydrophobic surfaces exhibits inconsistent performance across different pathogen types. While these surfaces demonstrate impressive results against certain bacteria, their effectiveness against fungi, viruses, and biofilm-forming microorganisms varies considerably. Research indicates that some microorganisms can adapt to superhydrophobic environments over time, potentially developing resistance mechanisms.

Cost considerations further complicate commercial viability. Current manufacturing processes for high-performance superhydrophobic antimicrobial coatings involve expensive raw materials, sophisticated equipment, and complex multi-step procedures. Market analysis suggests that production costs must decrease by 40-60% to achieve competitive pricing for mass-market applications outside of premium sectors.

Environmental sustainability presents growing concerns as regulations on persistent chemicals tighten globally. Many effective superhydrophobic formulations contain perfluorinated compounds that face increasing scrutiny and potential restrictions. Developing equally effective but environmentally benign alternatives represents a significant research challenge that has yet to be fully resolved.

Standardization issues also hinder industry adoption, as no universally accepted testing protocols exist for evaluating the combined superhydrophobic and antimicrobial properties. This lack of standardization complicates product comparison, quality control, and regulatory approval processes.

Durability remains perhaps the most significant obstacle in superhydrophobic antimicrobial coatings. These surfaces typically rely on delicate micro/nano hierarchical structures that are susceptible to mechanical abrasion, chemical degradation, and environmental stress. Studies indicate that many current formulations lose their superhydrophobic properties after repeated cleaning cycles or exposure to harsh conditions, with performance degradation often beginning within weeks of application.

The manufacturing scalability of these advanced coatings presents another substantial challenge. Laboratory-scale production methods such as chemical vapor deposition, lithography, and sol-gel processes yield excellent results but face significant barriers when scaled to industrial production. The precision required to create uniform nano-structures across large surface areas while maintaining cost-effectiveness has proven particularly problematic.

Biocompatibility concerns emerge when these technologies are considered for medical applications. Many superhydrophobic formulations incorporate potentially toxic components such as fluorinated compounds or silver nanoparticles, raising regulatory hurdles and safety concerns. The long-term effects of these materials on human health and the environment remain inadequately characterized, particularly when considering potential nanoparticle leaching.

The antimicrobial efficacy of superhydrophobic surfaces exhibits inconsistent performance across different pathogen types. While these surfaces demonstrate impressive results against certain bacteria, their effectiveness against fungi, viruses, and biofilm-forming microorganisms varies considerably. Research indicates that some microorganisms can adapt to superhydrophobic environments over time, potentially developing resistance mechanisms.

Cost considerations further complicate commercial viability. Current manufacturing processes for high-performance superhydrophobic antimicrobial coatings involve expensive raw materials, sophisticated equipment, and complex multi-step procedures. Market analysis suggests that production costs must decrease by 40-60% to achieve competitive pricing for mass-market applications outside of premium sectors.

Environmental sustainability presents growing concerns as regulations on persistent chemicals tighten globally. Many effective superhydrophobic formulations contain perfluorinated compounds that face increasing scrutiny and potential restrictions. Developing equally effective but environmentally benign alternatives represents a significant research challenge that has yet to be fully resolved.

Standardization issues also hinder industry adoption, as no universally accepted testing protocols exist for evaluating the combined superhydrophobic and antimicrobial properties. This lack of standardization complicates product comparison, quality control, and regulatory approval processes.

Current Superhydrophobic Antimicrobial Coating Solutions

01 Nanoparticle-based superhydrophobic coatings

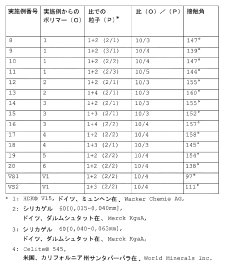

Superhydrophobic coatings can be formulated using nanoparticles to create nano-scale roughness on surfaces. These nanoparticles, such as silica, titanium dioxide, or carbon-based materials, are incorporated into polymer matrices to create hierarchical structures that trap air and repel water. The combination of nano-roughness and low surface energy materials results in water contact angles exceeding 150 degrees, characteristic of superhydrophobic surfaces.- Nanoparticle-based superhydrophobic coatings: Superhydrophobic coatings can be formulated using various nanoparticles to create nano-scale roughness on surfaces. These nanoparticles, such as silica, titanium dioxide, or carbon-based materials, create a hierarchical surface structure that traps air and prevents water from penetrating. The combination of these nanoparticles with hydrophobic binders results in surfaces with high water contact angles and low sliding angles, making them extremely water-repellent and self-cleaning.

- Fluoropolymer-based superhydrophobic coatings: Fluoropolymers are widely used in superhydrophobic coating formulations due to their inherently low surface energy. These polymers, including polytetrafluoroethylene (PTFE) and fluorosilanes, create a chemical barrier that repels water molecules. When combined with surface roughening techniques, fluoropolymer-based coatings can achieve superhydrophobicity with water contact angles exceeding 150 degrees. These coatings offer excellent durability and resistance to various environmental conditions.

- Biomimetic superhydrophobic coatings: Inspired by natural superhydrophobic surfaces like lotus leaves and butterfly wings, biomimetic coatings replicate the micro and nano-scale structures found in nature. These coatings typically involve creating hierarchical surface patterns through techniques such as lithography, etching, or templating. The biomimetic approach often combines structured surfaces with hydrophobic chemical treatments to achieve superhydrophobicity. These coatings can be applied to various substrates and offer additional functionalities such as anti-icing or anti-fouling properties.

- Spray-applied superhydrophobic coatings: Spray application methods provide a convenient and scalable approach for applying superhydrophobic coatings to various surfaces. These formulations typically contain hydrophobic particles suspended in a solvent with binding agents. Upon spraying and drying, the particles create the necessary surface roughness while the binders provide adhesion to the substrate. Spray-applied coatings can be formulated for specific substrates including textiles, metals, glass, and concrete, offering versatility for different industrial applications.

- Durable and self-healing superhydrophobic coatings: Enhancing the durability of superhydrophobic coatings is crucial for practical applications. Advanced formulations incorporate self-healing mechanisms that restore superhydrophobicity after physical damage. These coatings may contain encapsulated hydrophobic agents that are released upon damage, or dynamic chemical bonds that can reform after being broken. Additionally, multi-layer approaches with a robust base layer and a functional top layer can improve mechanical durability while maintaining superhydrophobic properties over extended periods of use and under harsh conditions.

02 Fluoropolymer-based superhydrophobic coatings

Fluoropolymers are widely used in superhydrophobic coating formulations due to their inherently low surface energy. These polymers, including polytetrafluoroethylene (PTFE) and fluorosilanes, create water-repellent surfaces when combined with structured substrates. The fluorine-containing compounds reduce surface tension and enhance the coating's durability against environmental factors while maintaining superhydrophobic properties.Expand Specific Solutions03 Fabrication methods for superhydrophobic coatings

Various fabrication techniques are employed to create superhydrophobic coatings, including spray coating, dip coating, layer-by-layer assembly, and sol-gel processes. These methods control the surface roughness and chemical composition necessary for superhydrophobicity. Advanced techniques like plasma treatment and chemical vapor deposition can further enhance the coating's performance by creating precise micro and nano-scale surface features.Expand Specific Solutions04 Self-cleaning and anti-fouling superhydrophobic coatings

Superhydrophobic coatings with self-cleaning and anti-fouling properties utilize the lotus effect, where water droplets roll off surfaces carrying away contaminants. These coatings incorporate both structural features and chemical compositions that prevent biological fouling and accumulation of dirt. Applications include marine structures, building exteriors, and industrial equipment where maintaining clean surfaces is critical for performance and longevity.Expand Specific Solutions05 Durable and environmentally resistant superhydrophobic coatings

Enhancing the durability of superhydrophobic coatings against mechanical abrasion, UV exposure, and chemical attack is achieved through cross-linking agents, adhesion promoters, and reinforcing additives. These formulations maintain superhydrophobicity under harsh environmental conditions and repeated mechanical stress. Recent innovations focus on self-healing capabilities that restore the superhydrophobic properties after damage, extending the coating's functional lifespan.Expand Specific Solutions

Leading Companies and Research Institutions in Antimicrobial Coatings

The superhydrophobic coating market for antimicrobial applications is in a growth phase, with increasing demand driven by healthcare concerns and surface hygiene requirements. The market size is expanding rapidly, projected to reach significant value as applications diversify across medical devices, food packaging, and public health infrastructure. Technologically, the field shows varying maturity levels, with established players like Technion Research & Development Foundation and Agency for Science, Technology & Research leading fundamental research, while companies such as Detrapel and Nanosys commercialize practical applications. Academic institutions including Sichuan University, IIT Kanpur, and Nanyang Technological University are advancing novel formulations, while industrial players like IBM and Philips explore integration into consumer and healthcare products. The competitive landscape features collaboration between research institutions and commercial entities to overcome challenges in durability, cost-effectiveness, and regulatory compliance.

Technion Research & Development Foundation Ltd.

Technical Solution: Technion has developed advanced superhydrophobic coatings with antimicrobial properties by incorporating silver nanoparticles into hierarchically structured surfaces. Their approach combines micro and nano-scale roughness with low surface energy materials to achieve water contact angles exceeding 150°. The foundation has pioneered a sol-gel based fabrication method that allows for durable antimicrobial coatings that maintain their superhydrophobicity even after extended exposure to harsh environments. Their technology incorporates controlled release mechanisms for antimicrobial agents, providing sustained protection against a broad spectrum of pathogens. Recent innovations include transparent superhydrophobic coatings with embedded quaternary ammonium compounds that demonstrate excellent antibacterial efficacy against both Gram-positive and Gram-negative bacteria, with kill rates exceeding 99.9% within 24 hours of contact.

Strengths: Superior durability compared to conventional coatings, excellent adhesion to various substrates, and controlled release of antimicrobial agents for prolonged effectiveness. Weaknesses: Higher production costs than traditional antimicrobial treatments, potential environmental concerns regarding nanoparticle leaching, and limited scalability for mass production applications.

Detrapel, Inc.

Technical Solution: Detrapel has engineered a superhydrophobic coating system specifically designed for antimicrobial applications in consumer and healthcare settings. Their technology utilizes fluorine-free chemistry to create a nanoscopic surface structure that achieves water contact angles of 160°+ while incorporating antimicrobial compounds that target cell wall synthesis in bacteria. The company's proprietary "BioShield" formulation combines superhydrophobicity with controlled-release antimicrobial agents that remain effective for up to 100 wash cycles on textiles. Detrapel's coating creates a physical barrier that prevents bacterial adhesion while simultaneously releasing antimicrobial compounds that disrupt microbial metabolism. Their latest innovation includes a spray-applied coating that forms covalent bonds with substrate materials, providing exceptional durability while maintaining flexibility. Independent laboratory testing has confirmed >99.7% reduction in MRSA, E. coli, and other common pathogens on treated surfaces within 24 hours.

Strengths: Environmentally friendly fluorine-free formulation, exceptional durability through covalent bonding to substrates, and consumer-friendly application methods. Weaknesses: Less effective against certain fungal species compared to bacterial pathogens, higher cost than conventional antimicrobial treatments, and potential for reduced efficacy in extremely humid environments.

Key Patents and Research Breakthroughs in Antimicrobial Surfaces

superhydrophobic coating

PatentInactiveJP2010510338A

Innovation

- A coating system using hydrophilic particles and specific organosilicon copolymers, produced through radical polymerization, eliminates the need for hydrophobic particle functionalization and achieves superhydrophobicity without external dispersing aids.

Environmental Impact and Sustainability Considerations

The environmental implications of superhydrophobic antimicrobial coatings warrant careful consideration as these technologies gain traction in various applications. Traditional antimicrobial solutions often contain heavy metals, quaternary ammonium compounds, or other potentially harmful substances that can leach into ecosystems and accumulate in the environment. Superhydrophobic coatings present an opportunity to reduce these impacts through their physical antimicrobial mechanisms, which may require fewer chemical biocides.

Life cycle assessment (LCA) studies indicate that superhydrophobic coatings can offer environmental advantages through extended product lifespans and reduced cleaning chemical usage. By preventing microbial adhesion and biofilm formation, these surfaces require less frequent replacement and maintenance, thereby decreasing waste generation and resource consumption. Additionally, the self-cleaning properties minimize the need for harsh cleaning agents, reducing chemical discharge into wastewater systems.

However, concerns persist regarding the nanomaterials often incorporated into these coatings. Nanoparticles such as silver, titanium dioxide, and zinc oxide may pose ecotoxicological risks if released into aquatic environments. Research indicates potential bioaccumulation in marine organisms and disruption of microbial communities essential for ecosystem functioning. The long-term environmental fate of these materials remains incompletely understood, necessitating precautionary approaches to their application.

Manufacturing processes for superhydrophobic coatings also present sustainability challenges. Many fabrication methods involve energy-intensive processes or volatile organic compounds (VOCs) that contribute to air pollution and climate change. Recent innovations in green chemistry approaches, including water-based formulations and bio-inspired manufacturing techniques, show promise for reducing these environmental footprints.

Regulatory frameworks are evolving to address these concerns, with the European Union's REACH regulations and the United States EPA providing guidelines for nanomaterial usage. Industry stakeholders are increasingly adopting sustainable design principles, incorporating biodegradable substrates and environmentally benign antimicrobial agents into coating formulations. Biomimetic approaches, which replicate natural antimicrobial surfaces without synthetic chemicals, represent a particularly promising direction for environmentally responsible innovation.

End-of-life considerations remain a critical challenge, as many composite coatings are difficult to recycle or safely dispose of. Research into degradable polymers and recoverable nanomaterials aims to address these issues, though commercial implementation lags behind laboratory developments. The establishment of take-back programs and specialized recycling processes could significantly improve the sustainability profile of these technologies.

Life cycle assessment (LCA) studies indicate that superhydrophobic coatings can offer environmental advantages through extended product lifespans and reduced cleaning chemical usage. By preventing microbial adhesion and biofilm formation, these surfaces require less frequent replacement and maintenance, thereby decreasing waste generation and resource consumption. Additionally, the self-cleaning properties minimize the need for harsh cleaning agents, reducing chemical discharge into wastewater systems.

However, concerns persist regarding the nanomaterials often incorporated into these coatings. Nanoparticles such as silver, titanium dioxide, and zinc oxide may pose ecotoxicological risks if released into aquatic environments. Research indicates potential bioaccumulation in marine organisms and disruption of microbial communities essential for ecosystem functioning. The long-term environmental fate of these materials remains incompletely understood, necessitating precautionary approaches to their application.

Manufacturing processes for superhydrophobic coatings also present sustainability challenges. Many fabrication methods involve energy-intensive processes or volatile organic compounds (VOCs) that contribute to air pollution and climate change. Recent innovations in green chemistry approaches, including water-based formulations and bio-inspired manufacturing techniques, show promise for reducing these environmental footprints.

Regulatory frameworks are evolving to address these concerns, with the European Union's REACH regulations and the United States EPA providing guidelines for nanomaterial usage. Industry stakeholders are increasingly adopting sustainable design principles, incorporating biodegradable substrates and environmentally benign antimicrobial agents into coating formulations. Biomimetic approaches, which replicate natural antimicrobial surfaces without synthetic chemicals, represent a particularly promising direction for environmentally responsible innovation.

End-of-life considerations remain a critical challenge, as many composite coatings are difficult to recycle or safely dispose of. Research into degradable polymers and recoverable nanomaterials aims to address these issues, though commercial implementation lags behind laboratory developments. The establishment of take-back programs and specialized recycling processes could significantly improve the sustainability profile of these technologies.

Regulatory Framework for Antimicrobial Coating Applications

The regulatory landscape for antimicrobial coatings, particularly those utilizing superhydrophobic technology, is complex and multifaceted across global markets. In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial coatings under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), requiring manufacturers to register products that make specific antimicrobial claims. The EPA distinguishes between treated articles (coatings that protect the surface itself) and those making public health claims, with the latter facing more stringent requirements for efficacy data and safety assessments.

The Food and Drug Administration (FDA) maintains oversight when these coatings are applied to medical devices or food-contact surfaces, requiring additional testing protocols under the Food, Drug, and Cosmetic Act. For medical applications, manufacturers must demonstrate that superhydrophobic antimicrobial coatings do not interfere with the primary function of devices while providing the claimed antimicrobial benefits.

In the European Union, the Biocidal Products Regulation (BPR) governs antimicrobial coatings, requiring active substances to undergo authorization before market entry. The EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation adds another layer of compliance for chemical components in these coatings. The European Medical Device Regulation (MDR) imposes additional requirements when such coatings are incorporated into healthcare products.

Asian markets present varying regulatory frameworks. Japan's Ministry of Health, Labor and Welfare enforces strict guidelines through their Pharmaceutical Affairs Law, while China's National Medical Products Administration has recently strengthened requirements for antimicrobial claims verification. South Korea implements the K-BPR (Korean Biocidal Products Regulation), modeled after the European system but with country-specific requirements.

International standards organizations play a crucial role in harmonizing testing methodologies. ISO 22196 and JIS Z 2801 provide standardized methods for evaluating antimicrobial activity on surfaces, while ASTM E2180 specifically addresses the efficacy of antimicrobial agents incorporated into polymeric materials. These standards facilitate global market access by providing universally recognized testing protocols.

Environmental regulations increasingly impact formulation choices, with many jurisdictions restricting certain biocides due to ecological concerns. The trend toward "green chemistry" has prompted regulatory bodies to favor environmentally sustainable antimicrobial solutions, potentially benefiting superhydrophobic coatings that achieve antimicrobial effects through physical rather than chemical mechanisms.

Regulatory compliance represents a significant market entry barrier, with testing and registration costs potentially exceeding $100,000 per product in major markets. Companies must develop comprehensive regulatory strategies that account for regional variations while planning for evolving requirements as scientific understanding of antimicrobial resistance and novel coating technologies advances.

The Food and Drug Administration (FDA) maintains oversight when these coatings are applied to medical devices or food-contact surfaces, requiring additional testing protocols under the Food, Drug, and Cosmetic Act. For medical applications, manufacturers must demonstrate that superhydrophobic antimicrobial coatings do not interfere with the primary function of devices while providing the claimed antimicrobial benefits.

In the European Union, the Biocidal Products Regulation (BPR) governs antimicrobial coatings, requiring active substances to undergo authorization before market entry. The EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation adds another layer of compliance for chemical components in these coatings. The European Medical Device Regulation (MDR) imposes additional requirements when such coatings are incorporated into healthcare products.

Asian markets present varying regulatory frameworks. Japan's Ministry of Health, Labor and Welfare enforces strict guidelines through their Pharmaceutical Affairs Law, while China's National Medical Products Administration has recently strengthened requirements for antimicrobial claims verification. South Korea implements the K-BPR (Korean Biocidal Products Regulation), modeled after the European system but with country-specific requirements.

International standards organizations play a crucial role in harmonizing testing methodologies. ISO 22196 and JIS Z 2801 provide standardized methods for evaluating antimicrobial activity on surfaces, while ASTM E2180 specifically addresses the efficacy of antimicrobial agents incorporated into polymeric materials. These standards facilitate global market access by providing universally recognized testing protocols.

Environmental regulations increasingly impact formulation choices, with many jurisdictions restricting certain biocides due to ecological concerns. The trend toward "green chemistry" has prompted regulatory bodies to favor environmentally sustainable antimicrobial solutions, potentially benefiting superhydrophobic coatings that achieve antimicrobial effects through physical rather than chemical mechanisms.

Regulatory compliance represents a significant market entry barrier, with testing and registration costs potentially exceeding $100,000 per product in major markets. Companies must develop comprehensive regulatory strategies that account for regional variations while planning for evolving requirements as scientific understanding of antimicrobial resistance and novel coating technologies advances.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!