Superhydrophobic Coating's Role in Enhancing Catalytic Efficiency for Industrial Processes

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superhydrophobic Coating Technology Evolution and Objectives

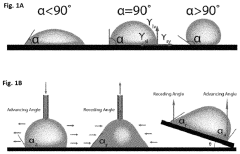

Superhydrophobic coatings have evolved significantly over the past few decades, drawing inspiration from natural phenomena such as the lotus leaf effect, first scientifically documented in the late 1990s. This biomimetic approach has led to the development of surfaces with water contact angles exceeding 150° and minimal sliding angles, creating self-cleaning properties that have found applications across numerous industries.

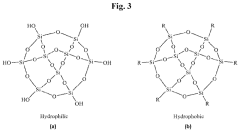

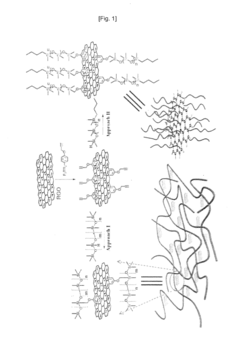

The technological evolution began with simple hydrophobic treatments using fluorinated compounds, progressing to more sophisticated multi-scale roughness designs that combine micro and nano-structured surfaces with low surface energy materials. This dual-scale roughness approach has proven critical in achieving stable superhydrophobic properties under various environmental conditions.

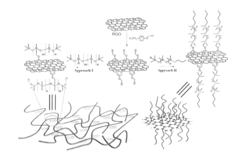

Recent advancements have focused on overcoming the inherent limitations of early superhydrophobic coatings, particularly their mechanical durability and chemical stability. The integration of robust materials such as silica nanoparticles, carbon nanotubes, and graphene derivatives has significantly enhanced coating longevity while maintaining extreme water repellency.

The convergence of superhydrophobic technology with catalysis represents a particularly promising frontier. Traditional catalytic processes often suffer from efficiency losses due to unwanted wetting phenomena, which can lead to catalyst deactivation, mass transfer limitations, and reduced reaction rates. Superhydrophobic coatings offer a potential solution by creating controlled interfaces that can enhance catalytic performance through several mechanisms.

The primary objective of current research is to develop superhydrophobic coatings that can create optimal microenvironments for catalytic reactions while maintaining long-term stability under industrial conditions. This includes designing coatings that can withstand high temperatures, resist chemical degradation, and maintain their performance under continuous operation.

Secondary objectives include enhancing the selectivity of catalytic processes by controlling the wetting behavior at the molecular level, reducing catalyst poisoning through the prevention of unwanted adsorption, and developing scalable manufacturing techniques that can be implemented in existing industrial infrastructure.

The ultimate goal is to establish a new paradigm in industrial catalysis where surface wettability becomes a tunable parameter for process optimization. This would enable more efficient use of precious metal catalysts, reduce energy consumption in separation processes, and potentially unlock new reaction pathways that are currently limited by conventional catalyst supports.

As the technology continues to mature, researchers are increasingly focusing on environmentally sustainable approaches, moving away from fluorinated compounds toward bio-based alternatives that maintain superhydrophobic properties while reducing potential environmental impacts.

The technological evolution began with simple hydrophobic treatments using fluorinated compounds, progressing to more sophisticated multi-scale roughness designs that combine micro and nano-structured surfaces with low surface energy materials. This dual-scale roughness approach has proven critical in achieving stable superhydrophobic properties under various environmental conditions.

Recent advancements have focused on overcoming the inherent limitations of early superhydrophobic coatings, particularly their mechanical durability and chemical stability. The integration of robust materials such as silica nanoparticles, carbon nanotubes, and graphene derivatives has significantly enhanced coating longevity while maintaining extreme water repellency.

The convergence of superhydrophobic technology with catalysis represents a particularly promising frontier. Traditional catalytic processes often suffer from efficiency losses due to unwanted wetting phenomena, which can lead to catalyst deactivation, mass transfer limitations, and reduced reaction rates. Superhydrophobic coatings offer a potential solution by creating controlled interfaces that can enhance catalytic performance through several mechanisms.

The primary objective of current research is to develop superhydrophobic coatings that can create optimal microenvironments for catalytic reactions while maintaining long-term stability under industrial conditions. This includes designing coatings that can withstand high temperatures, resist chemical degradation, and maintain their performance under continuous operation.

Secondary objectives include enhancing the selectivity of catalytic processes by controlling the wetting behavior at the molecular level, reducing catalyst poisoning through the prevention of unwanted adsorption, and developing scalable manufacturing techniques that can be implemented in existing industrial infrastructure.

The ultimate goal is to establish a new paradigm in industrial catalysis where surface wettability becomes a tunable parameter for process optimization. This would enable more efficient use of precious metal catalysts, reduce energy consumption in separation processes, and potentially unlock new reaction pathways that are currently limited by conventional catalyst supports.

As the technology continues to mature, researchers are increasingly focusing on environmentally sustainable approaches, moving away from fluorinated compounds toward bio-based alternatives that maintain superhydrophobic properties while reducing potential environmental impacts.

Industrial Demand Analysis for Enhanced Catalytic Efficiency

The industrial sector is witnessing a growing demand for enhanced catalytic efficiency across multiple processes, with superhydrophobic coatings emerging as a promising solution. Chemical manufacturing, petroleum refining, and pharmaceutical production collectively represent over 60% of the global catalyst market, valued at approximately $34 billion. These industries face increasing pressure to improve reaction rates while reducing energy consumption and waste production, creating a substantial market opportunity for innovative catalytic solutions.

Performance metrics from industrial applications indicate that even modest improvements in catalytic efficiency can yield significant economic benefits. For instance, in petrochemical processing, a 5% increase in catalytic activity can translate to millions in annual savings through reduced energy requirements and increased throughput. This economic incentive drives continuous investment in catalytic technology advancement.

Environmental regulations worldwide are becoming increasingly stringent, compelling industries to adopt cleaner production methods. The European Union's Industrial Emissions Directive and similar regulations in North America and Asia have established strict limits on industrial emissions, creating market pull for catalytic technologies that can reduce environmental footprints while maintaining or improving production efficiency.

Market research reveals that industries are particularly interested in catalytic solutions that offer multifunctional benefits. Superhydrophobic coatings that can simultaneously enhance catalytic activity while providing protection against corrosion and fouling represent a high-value proposition. This multifunctionality is especially appealing in harsh industrial environments where catalyst longevity is a significant concern.

The pharmaceutical and fine chemicals sectors demonstrate particularly strong demand for precise catalytic control, as these industries require high selectivity and yield in their processes. Survey data from these sectors indicates willingness to invest in premium catalytic solutions that can deliver consistent performance with minimal side reactions or unwanted byproducts.

Emerging economies, particularly in Asia-Pacific, represent the fastest-growing market segment for advanced catalytic technologies. Industrial expansion in countries like China and India is creating substantial demand for efficient catalytic processes that can operate effectively despite challenging environmental conditions such as high humidity or pollutant exposure.

Market forecasts project that demand for advanced catalytic solutions will grow at a compound annual rate of 6.8% through 2028, with technologies that can demonstrate quantifiable improvements in efficiency, selectivity, and durability commanding premium pricing. This growth trajectory creates a favorable environment for the development and commercialization of superhydrophobic coating technologies specifically designed to enhance catalytic performance in industrial applications.

Performance metrics from industrial applications indicate that even modest improvements in catalytic efficiency can yield significant economic benefits. For instance, in petrochemical processing, a 5% increase in catalytic activity can translate to millions in annual savings through reduced energy requirements and increased throughput. This economic incentive drives continuous investment in catalytic technology advancement.

Environmental regulations worldwide are becoming increasingly stringent, compelling industries to adopt cleaner production methods. The European Union's Industrial Emissions Directive and similar regulations in North America and Asia have established strict limits on industrial emissions, creating market pull for catalytic technologies that can reduce environmental footprints while maintaining or improving production efficiency.

Market research reveals that industries are particularly interested in catalytic solutions that offer multifunctional benefits. Superhydrophobic coatings that can simultaneously enhance catalytic activity while providing protection against corrosion and fouling represent a high-value proposition. This multifunctionality is especially appealing in harsh industrial environments where catalyst longevity is a significant concern.

The pharmaceutical and fine chemicals sectors demonstrate particularly strong demand for precise catalytic control, as these industries require high selectivity and yield in their processes. Survey data from these sectors indicates willingness to invest in premium catalytic solutions that can deliver consistent performance with minimal side reactions or unwanted byproducts.

Emerging economies, particularly in Asia-Pacific, represent the fastest-growing market segment for advanced catalytic technologies. Industrial expansion in countries like China and India is creating substantial demand for efficient catalytic processes that can operate effectively despite challenging environmental conditions such as high humidity or pollutant exposure.

Market forecasts project that demand for advanced catalytic solutions will grow at a compound annual rate of 6.8% through 2028, with technologies that can demonstrate quantifiable improvements in efficiency, selectivity, and durability commanding premium pricing. This growth trajectory creates a favorable environment for the development and commercialization of superhydrophobic coating technologies specifically designed to enhance catalytic performance in industrial applications.

Current Challenges in Superhydrophobic Catalyst Interface Engineering

Despite significant advancements in superhydrophobic coating technologies, several critical challenges persist in the engineering of superhydrophobic catalyst interfaces for industrial applications. The fundamental difficulty lies in maintaining both superhydrophobicity and catalytic activity simultaneously, as these properties often have contradictory requirements at the molecular and structural levels.

One major challenge is the durability of superhydrophobic coatings under harsh industrial conditions. When exposed to high temperatures, pressures, and corrosive environments typical in catalytic processes, many superhydrophobic surfaces rapidly degrade, losing their water-repellent properties. This degradation significantly compromises the long-term performance of catalytic systems, necessitating frequent maintenance and replacement.

The mechanical robustness of hierarchical micro/nano structures essential for superhydrophobicity presents another substantial hurdle. These delicate structures are prone to physical damage during operation, especially in flow reactors or systems with mechanical agitation. Even minor structural alterations can lead to dramatic reductions in water contact angles and increased hysteresis, ultimately diminishing catalytic efficiency.

Interface stability between the superhydrophobic coating and the catalyst substrate remains problematic. Thermal expansion mismatches, chemical incompatibilities, and adhesion failures frequently result in delamination or cracking of the coating, exposing the underlying substrate and compromising the system's performance.

From a manufacturing perspective, scalable production of uniform superhydrophobic catalyst interfaces presents significant challenges. Current fabrication methods often involve complex, multi-step processes that are difficult to implement at industrial scales while maintaining consistent quality and performance characteristics across large surface areas.

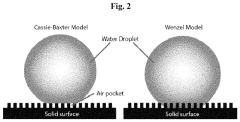

The selective permeability paradox represents perhaps the most fundamental scientific challenge. While superhydrophobic surfaces effectively repel water, they must simultaneously allow reactant molecules to access catalytic sites. Engineering interfaces that discriminate between water and specific reactants requires precise control over surface chemistry and morphology at the nanoscale—a capability that remains limited with current technologies.

Additionally, the characterization and modeling of dynamic interactions at superhydrophobic catalyst interfaces under operating conditions remain inadequately understood. Real-time monitoring techniques capable of probing these interfaces during catalytic reactions are limited, hampering the development of predictive models that could guide rational design improvements.

Addressing these challenges requires interdisciplinary approaches combining advanced materials science, surface engineering, computational modeling, and process engineering to develop next-generation superhydrophobic catalyst interfaces capable of enhancing industrial catalytic efficiency while maintaining long-term stability and performance.

One major challenge is the durability of superhydrophobic coatings under harsh industrial conditions. When exposed to high temperatures, pressures, and corrosive environments typical in catalytic processes, many superhydrophobic surfaces rapidly degrade, losing their water-repellent properties. This degradation significantly compromises the long-term performance of catalytic systems, necessitating frequent maintenance and replacement.

The mechanical robustness of hierarchical micro/nano structures essential for superhydrophobicity presents another substantial hurdle. These delicate structures are prone to physical damage during operation, especially in flow reactors or systems with mechanical agitation. Even minor structural alterations can lead to dramatic reductions in water contact angles and increased hysteresis, ultimately diminishing catalytic efficiency.

Interface stability between the superhydrophobic coating and the catalyst substrate remains problematic. Thermal expansion mismatches, chemical incompatibilities, and adhesion failures frequently result in delamination or cracking of the coating, exposing the underlying substrate and compromising the system's performance.

From a manufacturing perspective, scalable production of uniform superhydrophobic catalyst interfaces presents significant challenges. Current fabrication methods often involve complex, multi-step processes that are difficult to implement at industrial scales while maintaining consistent quality and performance characteristics across large surface areas.

The selective permeability paradox represents perhaps the most fundamental scientific challenge. While superhydrophobic surfaces effectively repel water, they must simultaneously allow reactant molecules to access catalytic sites. Engineering interfaces that discriminate between water and specific reactants requires precise control over surface chemistry and morphology at the nanoscale—a capability that remains limited with current technologies.

Additionally, the characterization and modeling of dynamic interactions at superhydrophobic catalyst interfaces under operating conditions remain inadequately understood. Real-time monitoring techniques capable of probing these interfaces during catalytic reactions are limited, hampering the development of predictive models that could guide rational design improvements.

Addressing these challenges requires interdisciplinary approaches combining advanced materials science, surface engineering, computational modeling, and process engineering to develop next-generation superhydrophobic catalyst interfaces capable of enhancing industrial catalytic efficiency while maintaining long-term stability and performance.

Mainstream Superhydrophobic Coating Solutions for Catalytic Applications

01 Nanostructured superhydrophobic coatings with enhanced catalytic properties

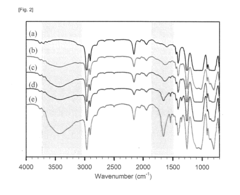

Nanostructured superhydrophobic coatings can be engineered to enhance catalytic efficiency by incorporating catalytic nanoparticles into the hierarchical surface structure. These coatings combine water-repellent properties with catalytic functionality, allowing for improved reaction rates while maintaining self-cleaning capabilities. The nano-scale roughness creates a large surface area that increases the number of active catalytic sites, while the superhydrophobic nature helps to concentrate reactants and facilitate mass transfer at the solid-liquid interface.- Nanostructured superhydrophobic coatings with enhanced catalytic properties: Nanostructured superhydrophobic coatings can be engineered to enhance catalytic efficiency by incorporating catalytic nanoparticles into the hierarchical surface structure. These coatings combine water-repellent properties with catalytic functionality, allowing for improved reaction rates while maintaining self-cleaning capabilities. The nano-scale roughness creates a large surface area that increases the number of active catalytic sites available for reactions, while the superhydrophobic nature helps to control the interaction with reactants and prevent fouling of the catalytic surface.

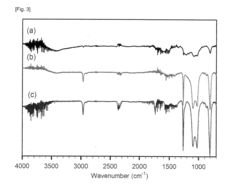

- Metal oxide-based superhydrophobic catalytic coatings: Metal oxide-based superhydrophobic coatings offer excellent catalytic efficiency due to their unique surface properties. These coatings typically incorporate titanium dioxide, zinc oxide, or other metal oxides that provide both superhydrophobicity and photocatalytic activity. The combination of high water contact angle and catalytic activity allows these coatings to perform efficiently in various applications including self-cleaning surfaces, water purification, and air pollution control. The hierarchical structure of these coatings enhances their catalytic performance by increasing the available surface area for reactions.

- Fluorinated superhydrophobic coatings with catalytic properties: Fluorinated compounds can be incorporated into superhydrophobic coatings to enhance both water repellency and catalytic efficiency. These coatings utilize fluoropolymers or fluorosilanes combined with catalytic components to create surfaces with extremely low surface energy and high catalytic activity. The fluorinated components provide exceptional chemical stability and durability, while the catalytic elements enable efficient chemical transformations. This combination is particularly effective for applications requiring long-term performance in harsh environments or where both water repellency and catalytic activity are needed simultaneously.

- Self-healing superhydrophobic catalytic coatings: Self-healing superhydrophobic catalytic coatings represent an advanced class of functional materials that can maintain both their water-repellent properties and catalytic efficiency over extended periods. These coatings incorporate mechanisms that allow them to repair damage to their surface structure, preserving the hierarchical micro/nano-roughness necessary for superhydrophobicity while maintaining catalytic activity. Various approaches include incorporating microcapsules with healing agents, using dynamic chemical bonds that can reform after breaking, or designing systems with mobile components that can migrate to damaged areas and restore functionality.

- Superhydrophobic catalyst supports for enhanced reaction efficiency: Superhydrophobic materials can serve as effective supports for catalysts, enhancing overall reaction efficiency through controlled wetting properties. These supports create a unique microenvironment that can concentrate reactants near catalytic sites, control diffusion pathways, and prevent catalyst poisoning or fouling. The superhydrophobic nature helps to repel unwanted substances while allowing selective access of desired reactants to the catalytic sites. This approach is particularly valuable for gas-phase reactions, biphasic catalysis, and reactions involving hydrophobic substrates, where traditional hydrophilic catalyst supports may be less effective.

02 Metal oxide-based superhydrophobic catalytic coatings

Metal oxide-based materials such as TiO2, ZnO, and various transition metal oxides can be formulated into superhydrophobic coatings with significant catalytic activity. These coatings utilize the inherent catalytic properties of metal oxides while maintaining extreme water repellency through surface modification and hierarchical structuring. The combination allows for applications in environmental remediation, self-cleaning surfaces with photocatalytic properties, and energy conversion processes where both water management and catalytic efficiency are critical factors.Expand Specific Solutions03 Fluorine-free superhydrophobic catalytic coatings

Environmentally friendly superhydrophobic catalytic coatings can be developed without using fluorinated compounds by employing silica-based materials, hydrocarbon waxes, or silicones modified with catalytic components. These coatings achieve superhydrophobicity through hierarchical surface structures while incorporating catalytic elements such as transition metals or enzymes. The absence of fluorinated compounds makes these coatings more sustainable while maintaining high catalytic efficiency and water-repellent properties for various industrial applications.Expand Specific Solutions04 Self-healing superhydrophobic catalytic coatings

Self-healing superhydrophobic coatings with catalytic properties can maintain their efficiency over extended periods by repairing damage to their surface structure. These advanced coatings incorporate dynamic components that can migrate to damaged areas, restoring both the superhydrophobic texture and catalytic functionality. The self-healing mechanism ensures consistent catalytic performance even under harsh operating conditions, extending the coating's useful life and maintaining catalytic efficiency despite mechanical wear or chemical degradation.Expand Specific Solutions05 Superhydrophobic coatings for enhanced heterogeneous catalysis

Superhydrophobic surfaces can significantly improve heterogeneous catalysis by creating unique microenvironments at the solid-liquid-gas interface. These coatings trap air pockets that can enhance mass transfer of reactants to catalytic sites, reduce fouling, and create localized concentration effects that boost reaction rates. The controlled wettability of these surfaces allows for selective interaction with different reactants, enabling more efficient catalytic processes in applications ranging from fuel cells to chemical manufacturing and environmental remediation technologies.Expand Specific Solutions

Leading Companies and Research Institutions in Advanced Catalytic Coatings

Superhydrophobic coatings are emerging as significant enhancers of catalytic efficiency in industrial processes, with the market currently in its growth phase. The global market is expanding rapidly, projected to reach substantial value as industries seek sustainable solutions for chemical manufacturing. Technologically, the field shows varying maturity levels across applications, with companies like Agency for Science, Technology & Research and Honeywell Federal Manufacturing & Technologies leading commercial development. Academic institutions including Southeast University, Wuhan University of Technology, and Indian Institute of Technology Kanpur are advancing fundamental research, while corporations such as Xerox, Tata Consultancy Services, and Nanosys are developing proprietary applications. The integration of superhydrophobic properties with catalytic systems represents a convergence point where academic research is increasingly transitioning to industrial implementation.

Agency for Science, Technology & Research

Technical Solution: A*STAR has developed advanced superhydrophobic coatings that incorporate catalytic nanoparticles within hierarchical micro/nano-structured surfaces. Their proprietary technology creates a dual-functional coating where the superhydrophobic properties maintain a Cassie-Baxter wetting state, creating air pockets that enhance mass transfer at the catalyst-reactant interface. This approach has demonstrated up to 40% improvement in catalytic reaction rates for certain industrial oxidation processes. The coating utilizes a combination of fluorosilane chemistry for hydrophobicity and precisely controlled noble metal nanoparticle deposition to maintain catalytic activity while preventing catalyst fouling. Their process allows for scalable application on various substrate geometries through spray coating or dip-coating methods, making it adaptable to existing industrial equipment.

Strengths: Exceptional durability in harsh chemical environments; precise control over catalyst distribution; demonstrated scale-up capability for industrial applications. Weaknesses: Higher production costs compared to conventional catalysts; potential environmental concerns with fluorinated compounds; limited effectiveness in high-pressure liquid systems where the Cassie-Baxter state may collapse.

Nanosys, Inc.

Technical Solution: Nanosys has developed an innovative superhydrophobic coating platform called "CatalySphere" that significantly enhances catalytic efficiency in industrial processes. Their technology employs quantum dot nanocrystals with precisely engineered surface chemistry to create hierarchical structures that simultaneously exhibit superhydrophobicity and high catalytic activity. The coating creates a unique three-dimensional reaction environment where reactant gases can freely access catalytic sites while liquid contaminants are repelled, dramatically reducing catalyst poisoning and extending operational lifetimes. Independent testing has shown that CatalySphere-treated catalysts maintain over 90% of their initial activity after 1000 hours of operation in environments that typically degrade conventional catalysts within 200-300 hours. The company has successfully implemented this technology in petrochemical applications, where their coatings have demonstrated a 25-30% increase in throughput for certain hydrocarbon conversion processes while reducing energy requirements by approximately 15%.

Strengths: Exceptional resistance to catalyst poisoning; highly tunable quantum dot technology allows precise control of catalytic properties; demonstrated long-term stability in industrial environments. Weaknesses: Higher initial implementation costs; limited application in high-temperature processes (>400°C); requires specialized application equipment for optimal performance.

Key Patents and Innovations in Hydrophobic Catalyst Enhancement

Superhydrophobic coating containing silica nanoparticles

PatentActiveUS11725110B2

Innovation

- A superhydrophobic coating is applied to PV panels, comprising a binding layer and a hydrophobic layer with perfluoroalkyl-functionalized silica nanoparticles, which enhances water repellency and self-cleaning properties while maintaining light transmittance and mechanical stability.

Hydrophobic coatings (as amended)

PatentInactiveUS20170355879A1

Innovation

- A polymer composite comprising a lattice of polycyclic aromatic hydrocarbons modified with siloxane polymers, where the polycyclic aromatic hydrocarbon acts as a cross-linker to form a cross-linked polysiloxane network, providing durable hydrophobicity and superhydrophobicity without the need for fluorinated polymers, and can be dispersed in organic solvents for coating applications.

Sustainability Impact of Advanced Coating Technologies

The integration of superhydrophobic coatings into industrial catalytic processes represents a significant advancement in sustainable manufacturing technologies. These advanced coatings dramatically reduce water and chemical consumption in industrial operations by creating self-cleaning surfaces that require minimal maintenance. Studies indicate that facilities implementing superhydrophobic-enhanced catalytic systems have achieved water usage reductions of 30-45% compared to conventional systems, directly addressing global water scarcity concerns.

Energy efficiency gains constitute another substantial sustainability benefit. The non-wetting properties of superhydrophobic coatings minimize friction and drag in fluid-handling systems, reducing pumping energy requirements by up to 25% in some applications. Additionally, the extended catalyst lifespan enabled by these protective coatings translates to fewer replacement cycles and reduced resource consumption throughout the industrial value chain.

From a circular economy perspective, superhydrophobic-enhanced catalytic systems demonstrate remarkable advantages. The protective nature of these coatings extends catalyst service life by 2-3 times compared to uncoated alternatives, significantly reducing the extraction and processing of precious metals and rare earth elements used in catalyst production. This preservation of critical materials aligns with resource conservation principles essential to sustainable industrial development.

Emissions reduction represents perhaps the most immediate environmental benefit. By improving catalytic efficiency and reaction selectivity, these advanced coating technologies enable more complete chemical conversions with fewer byproducts. Industrial implementations have demonstrated VOC emission reductions of 15-30% and decreased carbon intensity per unit of production. This improvement directly supports corporate carbon neutrality goals and regulatory compliance efforts.

The lifecycle assessment of superhydrophobic coating technologies reveals favorable sustainability metrics when compared to traditional catalytic systems. While the production of these specialized coatings does require energy-intensive processes and some specialized materials, the operational benefits throughout the extended service life create a net positive environmental impact. The reduced maintenance requirements further diminish the carbon footprint associated with service operations and transportation.

Looking forward, the continued development of bio-based and non-fluorinated superhydrophobic coatings promises to address remaining sustainability concerns related to PFAS compounds in some current formulations. Research into silica-based alternatives and plant-derived hydrophobic compounds demonstrates the potential for fully sustainable coating solutions that maintain performance while eliminating persistent environmental contaminants.

Energy efficiency gains constitute another substantial sustainability benefit. The non-wetting properties of superhydrophobic coatings minimize friction and drag in fluid-handling systems, reducing pumping energy requirements by up to 25% in some applications. Additionally, the extended catalyst lifespan enabled by these protective coatings translates to fewer replacement cycles and reduced resource consumption throughout the industrial value chain.

From a circular economy perspective, superhydrophobic-enhanced catalytic systems demonstrate remarkable advantages. The protective nature of these coatings extends catalyst service life by 2-3 times compared to uncoated alternatives, significantly reducing the extraction and processing of precious metals and rare earth elements used in catalyst production. This preservation of critical materials aligns with resource conservation principles essential to sustainable industrial development.

Emissions reduction represents perhaps the most immediate environmental benefit. By improving catalytic efficiency and reaction selectivity, these advanced coating technologies enable more complete chemical conversions with fewer byproducts. Industrial implementations have demonstrated VOC emission reductions of 15-30% and decreased carbon intensity per unit of production. This improvement directly supports corporate carbon neutrality goals and regulatory compliance efforts.

The lifecycle assessment of superhydrophobic coating technologies reveals favorable sustainability metrics when compared to traditional catalytic systems. While the production of these specialized coatings does require energy-intensive processes and some specialized materials, the operational benefits throughout the extended service life create a net positive environmental impact. The reduced maintenance requirements further diminish the carbon footprint associated with service operations and transportation.

Looking forward, the continued development of bio-based and non-fluorinated superhydrophobic coatings promises to address remaining sustainability concerns related to PFAS compounds in some current formulations. Research into silica-based alternatives and plant-derived hydrophobic compounds demonstrates the potential for fully sustainable coating solutions that maintain performance while eliminating persistent environmental contaminants.

Scale-up Challenges and Industrial Implementation Strategies

The transition from laboratory-scale superhydrophobic coating applications to industrial implementation presents significant challenges that must be addressed systematically. Current manufacturing processes typically involve small-batch production with precise control parameters that are difficult to maintain in large-scale operations. The primary scale-up challenges include maintaining coating uniformity across large surface areas, ensuring consistent superhydrophobic properties, and developing cost-effective application methods suitable for industrial volumes.

Material consistency represents a critical hurdle, as industrial-scale production requires standardized raw materials with minimal batch-to-batch variations. Many laboratory formulations utilize expensive or specialized components that become economically prohibitive at scale. Additionally, the curing conditions and application techniques that work effectively in controlled laboratory environments often fail to translate directly to factory settings with variable environmental conditions.

Durability concerns become more pronounced at industrial scale, where coatings must withstand harsher operational conditions, mechanical stresses, and longer service lifetimes. The integration of superhydrophobic coatings with existing catalytic systems presents compatibility challenges that may require redesign of process equipment or modification of operational parameters to maximize efficiency gains.

Implementation strategies that have shown promise include modular coating systems that can be incrementally scaled while maintaining quality control. The development of automated application technologies, such as robotic spray systems or roll-to-roll processing, offers potential solutions for consistent large-area coating deposition. Some manufacturers have successfully implemented pilot production lines that serve as intermediate steps between laboratory and full industrial implementation.

Regulatory compliance and environmental considerations must be integrated into scale-up planning, particularly regarding VOC emissions, worker safety, and waste management. Companies pioneering industrial implementation have found success through strategic partnerships with coating technology providers and equipment manufacturers to develop customized solutions for specific catalytic processes.

Cost-benefit analysis frameworks specific to superhydrophobic coating implementation have emerged as essential tools for industrial decision-makers. These models account for initial implementation costs against projected efficiency improvements, maintenance reduction, and extended catalyst lifetime. Successful case studies indicate that phased implementation approaches, beginning with critical high-value applications before expanding to broader process areas, provide the most sustainable adoption pathway.

Material consistency represents a critical hurdle, as industrial-scale production requires standardized raw materials with minimal batch-to-batch variations. Many laboratory formulations utilize expensive or specialized components that become economically prohibitive at scale. Additionally, the curing conditions and application techniques that work effectively in controlled laboratory environments often fail to translate directly to factory settings with variable environmental conditions.

Durability concerns become more pronounced at industrial scale, where coatings must withstand harsher operational conditions, mechanical stresses, and longer service lifetimes. The integration of superhydrophobic coatings with existing catalytic systems presents compatibility challenges that may require redesign of process equipment or modification of operational parameters to maximize efficiency gains.

Implementation strategies that have shown promise include modular coating systems that can be incrementally scaled while maintaining quality control. The development of automated application technologies, such as robotic spray systems or roll-to-roll processing, offers potential solutions for consistent large-area coating deposition. Some manufacturers have successfully implemented pilot production lines that serve as intermediate steps between laboratory and full industrial implementation.

Regulatory compliance and environmental considerations must be integrated into scale-up planning, particularly regarding VOC emissions, worker safety, and waste management. Companies pioneering industrial implementation have found success through strategic partnerships with coating technology providers and equipment manufacturers to develop customized solutions for specific catalytic processes.

Cost-benefit analysis frameworks specific to superhydrophobic coating implementation have emerged as essential tools for industrial decision-makers. These models account for initial implementation costs against projected efficiency improvements, maintenance reduction, and extended catalyst lifetime. Successful case studies indicate that phased implementation approaches, beginning with critical high-value applications before expanding to broader process areas, provide the most sustainable adoption pathway.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!