How Can Superhydrophobic Coating Enhance Textile Hydrophobicity

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superhydrophobic Coating Technology Background and Objectives

Superhydrophobic surfaces have fascinated scientists and engineers since the discovery of the "lotus effect" in the 1970s, where water droplets roll off lotus leaves while removing contaminants. This natural phenomenon has inspired decades of research into creating artificial superhydrophobic surfaces with contact angles exceeding 150° and sliding angles below 10°. The evolution of superhydrophobic coating technology has progressed from simple hydrophobic treatments to sophisticated multi-functional coatings that combine water repellency with additional properties such as self-cleaning, anti-icing, and antimicrobial capabilities.

The textile industry has traditionally relied on fluorocarbon-based treatments to achieve water repellency. However, environmental and health concerns regarding perfluorinated compounds have driven research toward more sustainable alternatives. This shift represents a critical inflection point in the technological evolution of hydrophobic textiles, creating both challenges and opportunities for innovation.

Recent advances in nanotechnology have revolutionized superhydrophobic coating approaches. The fundamental understanding that superhydrophobicity requires both low surface energy chemistry and hierarchical micro/nano-scale roughness has led to various fabrication techniques including sol-gel processes, layer-by-layer assembly, electrospinning, and plasma treatments. Each approach offers distinct advantages in terms of durability, scalability, and compatibility with different textile substrates.

The primary objective of superhydrophobic coating technology for textiles is to create durable water-repellent surfaces that maintain breathability and comfort while minimizing environmental impact. Secondary goals include developing coatings that can withstand mechanical abrasion, repeated laundering, and exposure to various environmental conditions without losing functionality. The ideal coating should also be cost-effective and compatible with existing textile manufacturing processes to facilitate industrial adoption.

Looking forward, the technology trajectory points toward multi-functional superhydrophobic coatings that can simultaneously address multiple performance requirements. These include self-healing capabilities to extend coating lifespan, stimuli-responsive properties that allow for controlled wettability, and integration with smart textile technologies for advanced applications in protective clothing, medical textiles, and technical textiles for extreme environments.

The convergence of materials science, surface engineering, and textile technology creates a rich innovation landscape for superhydrophobic coatings. As sustainability becomes increasingly important, bio-inspired and bio-based approaches are gaining traction, potentially offering environmentally friendly alternatives to traditional synthetic methods while maintaining or even enhancing performance characteristics.

The textile industry has traditionally relied on fluorocarbon-based treatments to achieve water repellency. However, environmental and health concerns regarding perfluorinated compounds have driven research toward more sustainable alternatives. This shift represents a critical inflection point in the technological evolution of hydrophobic textiles, creating both challenges and opportunities for innovation.

Recent advances in nanotechnology have revolutionized superhydrophobic coating approaches. The fundamental understanding that superhydrophobicity requires both low surface energy chemistry and hierarchical micro/nano-scale roughness has led to various fabrication techniques including sol-gel processes, layer-by-layer assembly, electrospinning, and plasma treatments. Each approach offers distinct advantages in terms of durability, scalability, and compatibility with different textile substrates.

The primary objective of superhydrophobic coating technology for textiles is to create durable water-repellent surfaces that maintain breathability and comfort while minimizing environmental impact. Secondary goals include developing coatings that can withstand mechanical abrasion, repeated laundering, and exposure to various environmental conditions without losing functionality. The ideal coating should also be cost-effective and compatible with existing textile manufacturing processes to facilitate industrial adoption.

Looking forward, the technology trajectory points toward multi-functional superhydrophobic coatings that can simultaneously address multiple performance requirements. These include self-healing capabilities to extend coating lifespan, stimuli-responsive properties that allow for controlled wettability, and integration with smart textile technologies for advanced applications in protective clothing, medical textiles, and technical textiles for extreme environments.

The convergence of materials science, surface engineering, and textile technology creates a rich innovation landscape for superhydrophobic coatings. As sustainability becomes increasingly important, bio-inspired and bio-based approaches are gaining traction, potentially offering environmentally friendly alternatives to traditional synthetic methods while maintaining or even enhancing performance characteristics.

Market Demand Analysis for Hydrophobic Textiles

The global market for hydrophobic textiles has witnessed substantial growth in recent years, driven by increasing consumer demand for functional fabrics with enhanced performance characteristics. The market size for hydrophobic textiles was valued at approximately $4.5 billion in 2022 and is projected to reach $7.2 billion by 2028, representing a compound annual growth rate of 8.3%. This growth trajectory underscores the significant commercial potential for superhydrophobic coating technologies in the textile industry.

Consumer preferences are increasingly shifting toward apparel and home textiles that offer practical benefits beyond aesthetic appeal. Market research indicates that 67% of consumers are willing to pay premium prices for textiles with advanced water-repellent properties, particularly in outdoor apparel, sportswear, and luxury fashion segments. This trend is further amplified by growing awareness of sustainability issues, with 58% of consumers expressing preference for durable, long-lasting products that require less frequent replacement.

The outdoor recreation industry represents a particularly strong market for hydrophobic textiles, with sales of water-resistant apparel reaching $12.4 billion globally in 2022. Major outdoor brands have reported 15-20% year-over-year growth in their water-resistant product lines, indicating robust consumer demand in this segment.

Healthcare and medical textiles constitute another rapidly expanding market for hydrophobic technologies. The medical textiles market, valued at $19.8 billion in 2022, is increasingly adopting hydrophobic fabrics for surgical gowns, drapes, and personal protective equipment due to their superior barrier properties against fluids and microorganisms. The COVID-19 pandemic has accelerated this trend, with demand for fluid-resistant medical textiles increasing by 34% between 2019 and 2022.

Automotive and transportation industries are also emerging as significant markets for hydrophobic textiles. Water-resistant upholstery, carpeting, and interior components are becoming standard features in premium vehicle segments, with the market for automotive textiles with hydrophobic properties growing at 7.2% annually.

Geographically, North America and Europe currently dominate the market for hydrophobic textiles, accounting for 38% and 29% of global demand respectively. However, the Asia-Pacific region is experiencing the fastest growth rate at 10.5% annually, driven by expanding middle-class populations, increasing disposable incomes, and growing awareness of performance textiles in countries like China, India, and Japan.

Industry analysts project that technological advancements in superhydrophobic coatings could potentially expand the addressable market by an additional $3.5 billion by 2030, particularly if durability and cost challenges can be overcome. This represents a significant opportunity for innovation in coating technologies that can deliver superior hydrophobic performance while meeting sustainability and cost requirements.

Consumer preferences are increasingly shifting toward apparel and home textiles that offer practical benefits beyond aesthetic appeal. Market research indicates that 67% of consumers are willing to pay premium prices for textiles with advanced water-repellent properties, particularly in outdoor apparel, sportswear, and luxury fashion segments. This trend is further amplified by growing awareness of sustainability issues, with 58% of consumers expressing preference for durable, long-lasting products that require less frequent replacement.

The outdoor recreation industry represents a particularly strong market for hydrophobic textiles, with sales of water-resistant apparel reaching $12.4 billion globally in 2022. Major outdoor brands have reported 15-20% year-over-year growth in their water-resistant product lines, indicating robust consumer demand in this segment.

Healthcare and medical textiles constitute another rapidly expanding market for hydrophobic technologies. The medical textiles market, valued at $19.8 billion in 2022, is increasingly adopting hydrophobic fabrics for surgical gowns, drapes, and personal protective equipment due to their superior barrier properties against fluids and microorganisms. The COVID-19 pandemic has accelerated this trend, with demand for fluid-resistant medical textiles increasing by 34% between 2019 and 2022.

Automotive and transportation industries are also emerging as significant markets for hydrophobic textiles. Water-resistant upholstery, carpeting, and interior components are becoming standard features in premium vehicle segments, with the market for automotive textiles with hydrophobic properties growing at 7.2% annually.

Geographically, North America and Europe currently dominate the market for hydrophobic textiles, accounting for 38% and 29% of global demand respectively. However, the Asia-Pacific region is experiencing the fastest growth rate at 10.5% annually, driven by expanding middle-class populations, increasing disposable incomes, and growing awareness of performance textiles in countries like China, India, and Japan.

Industry analysts project that technological advancements in superhydrophobic coatings could potentially expand the addressable market by an additional $3.5 billion by 2030, particularly if durability and cost challenges can be overcome. This represents a significant opportunity for innovation in coating technologies that can deliver superior hydrophobic performance while meeting sustainability and cost requirements.

Current Status and Challenges in Textile Hydrophobicity

The global landscape of superhydrophobic textile technologies has witnessed significant advancements in recent years, with research institutions and companies across North America, Europe, and Asia making substantial contributions. Currently, the most widely adopted approaches for enhancing textile hydrophobicity include fluorocarbon-based treatments, silicone-based coatings, and nano-structured surface modifications. These technologies have achieved water contact angles exceeding 150° in laboratory settings, demonstrating excellent water repellency properties.

Despite these achievements, several critical challenges persist in the field of textile hydrophobicity. Durability remains a primary concern, as most superhydrophobic coatings deteriorate significantly after multiple washing cycles or mechanical abrasion. Studies indicate that even premium commercial treatments typically lose effectiveness after 20-30 washing cycles, falling short of consumer expectations for everyday textiles.

Environmental and health considerations pose another significant challenge. Traditional fluorocarbon-based treatments containing perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS) face increasing regulatory scrutiny due to their persistence in the environment and potential health risks. The European Union's REACH regulations and similar frameworks in other regions are progressively restricting these compounds, creating an urgent need for eco-friendly alternatives.

Cost-effectiveness presents a substantial barrier to widespread commercial adoption. Current manufacturing processes for superhydrophobic textiles often involve complex multi-step procedures requiring specialized equipment and controlled environments. This complexity translates to production costs that are 30-50% higher than conventional textile finishing processes, limiting market penetration beyond premium segments.

Scalability challenges further complicate industrial implementation. Many laboratory-proven techniques for creating hierarchical micro/nano-structured surfaces demonstrate excellent hydrophobicity but face significant hurdles in scaling to industrial production volumes. The precision required for consistent nano-structure formation across large textile surfaces remains difficult to achieve in standard manufacturing environments.

The balance between breathability and hydrophobicity represents another technical challenge. As coating thickness increases to improve water repellency, air permeability often decreases, affecting the comfort and wearability of treated textiles. This trade-off is particularly problematic for apparel applications where both properties are essential for consumer acceptance.

Recent research has begun exploring biomimetic approaches inspired by natural superhydrophobic surfaces like lotus leaves and butterfly wings. These bio-inspired strategies show promise for creating more durable and environmentally friendly solutions, though they remain predominantly at the research stage rather than commercial implementation.

Despite these achievements, several critical challenges persist in the field of textile hydrophobicity. Durability remains a primary concern, as most superhydrophobic coatings deteriorate significantly after multiple washing cycles or mechanical abrasion. Studies indicate that even premium commercial treatments typically lose effectiveness after 20-30 washing cycles, falling short of consumer expectations for everyday textiles.

Environmental and health considerations pose another significant challenge. Traditional fluorocarbon-based treatments containing perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS) face increasing regulatory scrutiny due to their persistence in the environment and potential health risks. The European Union's REACH regulations and similar frameworks in other regions are progressively restricting these compounds, creating an urgent need for eco-friendly alternatives.

Cost-effectiveness presents a substantial barrier to widespread commercial adoption. Current manufacturing processes for superhydrophobic textiles often involve complex multi-step procedures requiring specialized equipment and controlled environments. This complexity translates to production costs that are 30-50% higher than conventional textile finishing processes, limiting market penetration beyond premium segments.

Scalability challenges further complicate industrial implementation. Many laboratory-proven techniques for creating hierarchical micro/nano-structured surfaces demonstrate excellent hydrophobicity but face significant hurdles in scaling to industrial production volumes. The precision required for consistent nano-structure formation across large textile surfaces remains difficult to achieve in standard manufacturing environments.

The balance between breathability and hydrophobicity represents another technical challenge. As coating thickness increases to improve water repellency, air permeability often decreases, affecting the comfort and wearability of treated textiles. This trade-off is particularly problematic for apparel applications where both properties are essential for consumer acceptance.

Recent research has begun exploring biomimetic approaches inspired by natural superhydrophobic surfaces like lotus leaves and butterfly wings. These bio-inspired strategies show promise for creating more durable and environmentally friendly solutions, though they remain predominantly at the research stage rather than commercial implementation.

Current Technical Solutions for Enhancing Textile Hydrophobicity

01 Nanostructured surface modifications for superhydrophobicity

Superhydrophobic coatings can be created by modifying surface structures at the nanoscale level. These modifications typically involve creating hierarchical micro and nano-roughness patterns that trap air between the surface and water droplets. This structural approach, often combined with low surface energy materials, creates surfaces with contact angles exceeding 150 degrees, demonstrating excellent water repellency and self-cleaning properties.- Nanostructured surfaces for superhydrophobicity: Superhydrophobic coatings can be created by engineering nanostructured surfaces that mimic natural water-repellent surfaces like lotus leaves. These surfaces typically combine nano-scale roughness with low surface energy materials to achieve water contact angles greater than 150 degrees. The hierarchical micro and nano structures create air pockets that prevent water from penetrating the surface, resulting in extreme water repellency and self-cleaning properties.

- Fluorinated compounds for enhancing hydrophobicity: Fluorinated compounds are widely used in superhydrophobic coatings due to their inherently low surface energy. These compounds, including fluoropolymers and fluorosilanes, create strong water-repellent surfaces when applied as coating materials. The carbon-fluorine bonds reduce surface energy significantly, allowing water droplets to maintain a nearly spherical shape on the surface with minimal contact area, thus achieving superior hydrophobicity and roll-off properties.

- Silica-based superhydrophobic coatings: Silica nanoparticles are commonly used to create superhydrophobic coatings with excellent durability and transparency. These coatings typically combine silica particles to create surface roughness with silane-based compounds to lower surface energy. The resulting hierarchical structure creates a composite interface where water droplets contact both the solid surface and trapped air pockets, leading to high contact angles and low roll-off angles. These coatings can be applied to various substrates including glass, metal, and polymers.

- Self-healing superhydrophobic surfaces: Self-healing superhydrophobic coatings are designed to maintain their water-repellent properties even after physical damage or chemical degradation. These advanced coatings incorporate mobile hydrophobic agents that can migrate to the surface when damage occurs, restoring the superhydrophobic properties. Some designs use encapsulated hydrophobic compounds that release upon damage, while others employ dynamic chemical bonds that can reform after being broken, ensuring long-term performance in harsh environments.

- Industrial applications of superhydrophobic coatings: Superhydrophobic coatings have diverse industrial applications including anti-corrosion protection for metals, anti-icing surfaces for aerospace, self-cleaning architectural materials, and water-repellent textiles. These coatings can be formulated for specific environmental conditions and substrate materials. The extreme water repellency prevents moisture accumulation, reduces drag in fluid systems, and minimizes biofouling on submerged surfaces. Recent developments focus on improving durability, adhesion to substrates, and maintaining superhydrophobicity under high-pressure or high-humidity conditions.

02 Fluorinated compounds for enhancing hydrophobicity

Fluorinated compounds are widely used in superhydrophobic coatings due to their inherently low surface energy. These compounds, including fluoropolymers and fluorosilanes, create strong water-repellent surfaces when applied to various substrates. The fluorine-carbon bonds reduce surface energy significantly, allowing water droplets to maintain minimal contact with the surface, resulting in high contact angles and low roll-off angles characteristic of superhydrophobic surfaces.Expand Specific Solutions03 Silica-based superhydrophobic coatings

Silica nanoparticles and silica-based composites are frequently employed in creating durable superhydrophobic coatings. These materials can be modified with hydrophobic agents and applied to various substrates to create rough surface textures. The combination of silica's mechanical durability with hydrophobic surface chemistry results in coatings that maintain their water-repellent properties under various environmental conditions and mechanical stresses.Expand Specific Solutions04 Self-healing superhydrophobic surfaces

Advanced superhydrophobic coatings incorporate self-healing capabilities to maintain long-term hydrophobicity despite surface damage. These coatings typically contain reservoirs of hydrophobic agents that can migrate to damaged areas, restoring the water-repellent properties. Various approaches include encapsulated hydrophobic compounds, regenerative polymer networks, and stimuli-responsive materials that can repair surface damage and maintain superhydrophobic performance over extended periods.Expand Specific Solutions05 Application-specific superhydrophobic formulations

Specialized superhydrophobic coating formulations are developed for specific applications such as anti-icing, anti-corrosion, and self-cleaning surfaces. These formulations combine hydrophobic chemistry with additional functional properties tailored to specific environmental challenges. For instance, coatings for marine applications focus on durability in saltwater, while those for electronic devices emphasize transparency and electrical insulation alongside water repellency.Expand Specific Solutions

Key Industry Players in Superhydrophobic Textile Coatings

The superhydrophobic coating market for textile hydrophobicity is in a growth phase, with increasing applications across protective clothing, sportswear, and technical textiles. The global market is expanding rapidly, driven by consumer demand for high-performance fabrics and sustainable solutions. Technologically, the field shows varying maturity levels, with established players like Soochow University, Donghua University, and Jiangnan University leading academic research, while companies such as Fibertex Nonwovens, Evonik Operations, and Nanotech Energy commercialize advanced solutions. Research institutions including Agency for Science, Technology & Research and Deutsche Institute für Textil- und Faserforschung Denkendorf are bridging fundamental science with industrial applications, focusing on durability, eco-friendliness, and scalable manufacturing processes to overcome current market limitations.

Agency for Science, Technology & Research

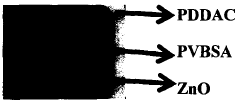

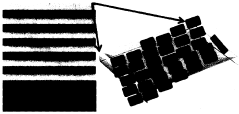

Technical Solution: The Agency for Science, Technology & Research (A*STAR) has developed a groundbreaking superhydrophobic coating technology for textiles through their Institute of Materials Research and Engineering. Their approach utilizes a biomimetic strategy inspired by the lotus leaf, combining zinc oxide nanostructures with low surface energy polymers to create hierarchical surface roughness. The coating process involves a two-step method: first, controlled growth of ZnO nanorods on textile surfaces through a low-temperature hydrothermal process, followed by modification with fluorinated silanes or environmentally-friendly alternatives like polydimethylsiloxane (PDMS). This creates a dual-scale roughness that achieves water contact angles exceeding 160° and extremely low sliding angles below 5°. A*STAR's technology stands out for its scalability and compatibility with roll-to-roll processing, making industrial implementation feasible. Their researchers have also developed self-healing variants that can restore superhydrophobicity after surface damage through incorporation of encapsulated hydrophobic agents that release upon mechanical damage. Additionally, they've pioneered photocatalytic superhydrophobic coatings that combine water repellency with self-cleaning properties under UV exposure, addressing the traditional cleanliness limitations of superhydrophobic surfaces.

Strengths: Exceptional water repellency with contact angles among the highest reported in literature; innovative self-healing capability that extends functional lifetime; multifunctional properties combining superhydrophobicity with photocatalytic self-cleaning. Weaknesses: More complex application process compared to conventional treatments; higher production costs due to multi-step manufacturing; potential durability concerns in harsh industrial washing conditions despite self-healing capabilities.

Donghua University

Technical Solution: Donghua University has developed advanced superhydrophobic coatings for textiles using a multi-layer approach that combines silica nanoparticles with fluoropolymers. Their technique involves creating hierarchical micro-nano structures on textile surfaces through a controlled sol-gel process, followed by fluoroalkylsilane modification. This dual-structure approach mimics the natural lotus leaf effect, creating surfaces with water contact angles exceeding 150° and sliding angles below 10°. The university's researchers have pioneered environmentally friendly application methods including spray coating, dip coating, and layer-by-layer assembly that can be integrated into existing textile production lines. Their coatings demonstrate remarkable durability, maintaining superhydrophobicity after 50+ washing cycles when properly cured and cross-linked with the fabric substrate. Recent innovations include incorporating antimicrobial agents like silver nanoparticles into the coating matrix, creating multifunctional textiles that are both water-repellent and antibacterial.

Strengths: Exceptional durability with wash resistance exceeding industry standards; environmentally conscious application methods compatible with existing manufacturing processes; multifunctional properties combining water repellency with antimicrobial benefits. Weaknesses: Higher production costs compared to conventional hydrophobic treatments; potential environmental concerns with fluorinated compounds despite efforts to minimize their use; requires precise application conditions for optimal performance.

Core Patents and Research in Superhydrophobic Coating Technology

UV blocking non wetting fabric using nanoparticles

PatentInactiveIN4188CHE2013A

Innovation

- A nano fabric coated with core-shell ZnO/Si02 nanoparticles is developed, where ZnO nanoparticles enhance UV blocking properties and Si02 nanoparticles impart non-wetting characteristics through surface roughening, eliminating the need for silver coatings and additional waterproofing materials like Teflon or PVC.

A superhydrophobic coating method

PatentPendingUS20250066639A1

Innovation

- A single-stage spray method using a polymer/nano-particle composite structure to create a transparent and durable superhydrophobic coating, where silica nanoparticles are produced using the sol-gel method and combined with PDMS polymer to reduce surface energy without using toxic chemicals.

Environmental Impact and Sustainability Considerations

The environmental impact of superhydrophobic coatings on textiles represents a critical consideration in their development and application. Traditional water-repellent treatments often rely on perfluorinated compounds (PFCs) such as perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS), which have been identified as persistent organic pollutants with bioaccumulative properties. These substances remain in the environment for extended periods and have been detected in wildlife, water systems, and human blood samples globally.

Modern superhydrophobic coating technologies are increasingly moving toward more sustainable alternatives. Silica-based nanoparticles combined with non-fluorinated hydrophobic agents offer promising environmental profiles while maintaining excellent water-repellent properties. Additionally, bio-inspired approaches utilizing natural waxes, plant extracts, and modified cellulose have emerged as environmentally friendly options that can achieve comparable hydrophobicity levels without the ecological concerns associated with synthetic fluorochemicals.

The manufacturing processes for superhydrophobic textiles also present environmental considerations. Solution-based methods often involve organic solvents that may contribute to air pollution and pose health risks to workers. Alternative approaches such as plasma treatment and layer-by-layer assembly can reduce solvent usage but may require higher energy inputs. Life cycle assessments indicate that the environmental footprint of superhydrophobic textiles depends significantly on the coating method selected and the durability of the treatment.

Durability represents another crucial environmental factor, as more durable coatings reduce the need for reapplication and extend product lifespans. Research indicates that many current superhydrophobic treatments suffer from limited wash resistance and mechanical durability, necessitating frequent reapplication or replacement. Innovations in covalent bonding techniques and self-healing superhydrophobic surfaces show promise for enhancing durability and consequently reducing environmental impact through extended product lifecycles.

End-of-life considerations for superhydrophobic textiles remain an underdeveloped area of research. The presence of nanoparticles and specialized chemical treatments may complicate recycling processes or create challenges for biodegradation. Some emerging coating technologies incorporate biodegradable components, but comprehensive studies on their decomposition behavior in various disposal environments are still limited.

Regulatory frameworks worldwide are increasingly restricting the use of environmentally harmful water-repellent compounds, driving innovation toward greener alternatives. The European Union's REACH regulations and similar initiatives in other regions have accelerated the transition away from persistent fluorinated compounds, creating market opportunities for sustainable superhydrophobic technologies that can deliver performance without environmental compromise.

Modern superhydrophobic coating technologies are increasingly moving toward more sustainable alternatives. Silica-based nanoparticles combined with non-fluorinated hydrophobic agents offer promising environmental profiles while maintaining excellent water-repellent properties. Additionally, bio-inspired approaches utilizing natural waxes, plant extracts, and modified cellulose have emerged as environmentally friendly options that can achieve comparable hydrophobicity levels without the ecological concerns associated with synthetic fluorochemicals.

The manufacturing processes for superhydrophobic textiles also present environmental considerations. Solution-based methods often involve organic solvents that may contribute to air pollution and pose health risks to workers. Alternative approaches such as plasma treatment and layer-by-layer assembly can reduce solvent usage but may require higher energy inputs. Life cycle assessments indicate that the environmental footprint of superhydrophobic textiles depends significantly on the coating method selected and the durability of the treatment.

Durability represents another crucial environmental factor, as more durable coatings reduce the need for reapplication and extend product lifespans. Research indicates that many current superhydrophobic treatments suffer from limited wash resistance and mechanical durability, necessitating frequent reapplication or replacement. Innovations in covalent bonding techniques and self-healing superhydrophobic surfaces show promise for enhancing durability and consequently reducing environmental impact through extended product lifecycles.

End-of-life considerations for superhydrophobic textiles remain an underdeveloped area of research. The presence of nanoparticles and specialized chemical treatments may complicate recycling processes or create challenges for biodegradation. Some emerging coating technologies incorporate biodegradable components, but comprehensive studies on their decomposition behavior in various disposal environments are still limited.

Regulatory frameworks worldwide are increasingly restricting the use of environmentally harmful water-repellent compounds, driving innovation toward greener alternatives. The European Union's REACH regulations and similar initiatives in other regions have accelerated the transition away from persistent fluorinated compounds, creating market opportunities for sustainable superhydrophobic technologies that can deliver performance without environmental compromise.

Durability and Washing Resistance of Superhydrophobic Textiles

The durability and washing resistance of superhydrophobic textiles represent critical challenges in the commercial viability of these advanced materials. Conventional superhydrophobic coatings often demonstrate impressive water repellency initially but deteriorate rapidly under mechanical abrasion, repeated washing cycles, and exposure to environmental factors such as UV radiation and chemical contaminants.

Current research indicates that most superhydrophobic textiles lose their functionality after 5-10 standard washing cycles, significantly limiting their practical applications in everyday garments and industrial textiles. This degradation primarily occurs through the physical removal of the hierarchical micro/nano structures that create the superhydrophobic effect, as well as chemical degradation of the low surface energy compounds.

Several approaches have emerged to enhance durability. Cross-linking mechanisms that form covalent bonds between the coating and textile fibers show promising results, with some formulations maintaining water contact angles above 150° after 20 washing cycles. These systems typically employ silane coupling agents or polymer grafting techniques to create robust interfaces between the textile substrate and the hydrophobic coating.

Nanoparticle incorporation represents another effective strategy, with silica, titanium dioxide, and zinc oxide nanoparticles being particularly effective. These particles not only reinforce the coating structure but also contribute to the creation of the hierarchical roughness necessary for superhydrophobicity. Recent studies demonstrate that textiles treated with nanocomposite coatings can withstand up to 30 washing cycles while maintaining water contact angles above 140°.

Multi-layer coating systems have also shown enhanced durability by creating redundancy in the protective layers. When the outermost layer becomes damaged, underlying layers continue to provide hydrophobic protection. Some commercial systems utilizing this approach have achieved resistance to 50+ washing cycles, though often with some gradual reduction in performance.

Self-healing superhydrophobic coatings represent the cutting edge of durability enhancement. These systems incorporate microcapsules containing hydrophobic agents that release upon mechanical damage, automatically restoring the superhydrophobic properties. While still primarily in laboratory development, early prototypes have demonstrated the ability to recover superhydrophobicity after multiple abrasion cycles.

Standardization remains a significant challenge in evaluating durability, as testing protocols vary widely across research groups. The industry is moving toward adopting standardized testing methods such as AATCC Test Method 61 for accelerated laundering and ISO 105-C06 for color fastness to domestic and commercial laundering, adapted specifically for evaluating superhydrophobic performance retention.

Current research indicates that most superhydrophobic textiles lose their functionality after 5-10 standard washing cycles, significantly limiting their practical applications in everyday garments and industrial textiles. This degradation primarily occurs through the physical removal of the hierarchical micro/nano structures that create the superhydrophobic effect, as well as chemical degradation of the low surface energy compounds.

Several approaches have emerged to enhance durability. Cross-linking mechanisms that form covalent bonds between the coating and textile fibers show promising results, with some formulations maintaining water contact angles above 150° after 20 washing cycles. These systems typically employ silane coupling agents or polymer grafting techniques to create robust interfaces between the textile substrate and the hydrophobic coating.

Nanoparticle incorporation represents another effective strategy, with silica, titanium dioxide, and zinc oxide nanoparticles being particularly effective. These particles not only reinforce the coating structure but also contribute to the creation of the hierarchical roughness necessary for superhydrophobicity. Recent studies demonstrate that textiles treated with nanocomposite coatings can withstand up to 30 washing cycles while maintaining water contact angles above 140°.

Multi-layer coating systems have also shown enhanced durability by creating redundancy in the protective layers. When the outermost layer becomes damaged, underlying layers continue to provide hydrophobic protection. Some commercial systems utilizing this approach have achieved resistance to 50+ washing cycles, though often with some gradual reduction in performance.

Self-healing superhydrophobic coatings represent the cutting edge of durability enhancement. These systems incorporate microcapsules containing hydrophobic agents that release upon mechanical damage, automatically restoring the superhydrophobic properties. While still primarily in laboratory development, early prototypes have demonstrated the ability to recover superhydrophobicity after multiple abrasion cycles.

Standardization remains a significant challenge in evaluating durability, as testing protocols vary widely across research groups. The industry is moving toward adopting standardized testing methods such as AATCC Test Method 61 for accelerated laundering and ISO 105-C06 for color fastness to domestic and commercial laundering, adapted specifically for evaluating superhydrophobic performance retention.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!