Analysis of Superhydrophobic Coating's Role in Reducing Global Water Usage

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superhydrophobic Coating Technology Background and Objectives

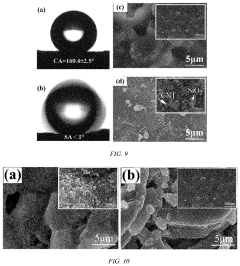

Superhydrophobic coatings represent a revolutionary advancement in surface engineering, drawing inspiration from nature's own water-repellent structures such as lotus leaves and butterfly wings. These biomimetic technologies have evolved significantly over the past two decades, transitioning from laboratory curiosities to commercially viable solutions with substantial real-world applications. The fundamental principle behind superhydrophobic surfaces involves creating micro and nano-scale roughness combined with low surface energy materials, resulting in contact angles exceeding 150° and minimal roll-off angles.

The historical development of superhydrophobic coatings began with basic understanding of wetting phenomena in the early 20th century, followed by significant breakthroughs in the 1990s with the formal characterization of the "lotus effect." Since 2000, research has accelerated dramatically, with annual publications increasing tenfold, focusing on durability enhancement, scalable manufacturing processes, and diverse substrate compatibility.

Current technological trends indicate a shift toward environmentally friendly formulations, replacing fluorinated compounds with silica-based alternatives and natural derivatives. Additionally, multifunctional coatings that combine superhydrophobicity with properties such as anti-icing, self-healing, and antimicrobial capabilities represent the cutting edge of development in this field.

The primary objective of superhydrophobic coating technology in water conservation is to achieve significant reduction in global water consumption across multiple sectors. Specifically, these coatings aim to minimize water adhesion to surfaces, thereby reducing the volume required for cleaning processes in industrial, agricultural, and domestic applications. Quantitative goals include decreasing water usage in textile processing by 40-60%, reducing irrigation requirements by 20-30% through coated delivery systems, and cutting household water consumption by 15-25% through coated bathroom fixtures and appliances.

Secondary objectives include extending the lifespan of infrastructure by preventing water-related degradation, reducing energy consumption associated with water heating and pumping, and minimizing chemical usage in cleaning processes. The technology also aims to address water scarcity challenges in developing regions by providing low-maintenance, water-efficient solutions adaptable to various economic contexts.

Long-term technological aspirations include developing superhydrophobic coatings with 10+ year durability under harsh environmental conditions, creating fully biodegradable formulations with zero environmental impact, and establishing cost-effective manufacturing processes that enable widespread adoption across diverse global markets and applications.

The historical development of superhydrophobic coatings began with basic understanding of wetting phenomena in the early 20th century, followed by significant breakthroughs in the 1990s with the formal characterization of the "lotus effect." Since 2000, research has accelerated dramatically, with annual publications increasing tenfold, focusing on durability enhancement, scalable manufacturing processes, and diverse substrate compatibility.

Current technological trends indicate a shift toward environmentally friendly formulations, replacing fluorinated compounds with silica-based alternatives and natural derivatives. Additionally, multifunctional coatings that combine superhydrophobicity with properties such as anti-icing, self-healing, and antimicrobial capabilities represent the cutting edge of development in this field.

The primary objective of superhydrophobic coating technology in water conservation is to achieve significant reduction in global water consumption across multiple sectors. Specifically, these coatings aim to minimize water adhesion to surfaces, thereby reducing the volume required for cleaning processes in industrial, agricultural, and domestic applications. Quantitative goals include decreasing water usage in textile processing by 40-60%, reducing irrigation requirements by 20-30% through coated delivery systems, and cutting household water consumption by 15-25% through coated bathroom fixtures and appliances.

Secondary objectives include extending the lifespan of infrastructure by preventing water-related degradation, reducing energy consumption associated with water heating and pumping, and minimizing chemical usage in cleaning processes. The technology also aims to address water scarcity challenges in developing regions by providing low-maintenance, water-efficient solutions adaptable to various economic contexts.

Long-term technological aspirations include developing superhydrophobic coatings with 10+ year durability under harsh environmental conditions, creating fully biodegradable formulations with zero environmental impact, and establishing cost-effective manufacturing processes that enable widespread adoption across diverse global markets and applications.

Water Conservation Market Demand Analysis

The global water conservation market is experiencing significant growth driven by increasing water scarcity concerns and heightened environmental awareness. Current market valuations place the water conservation technology sector at approximately $30 billion, with projections indicating growth to reach $50 billion by 2030. This expansion is primarily fueled by industrial and municipal sectors seeking solutions to reduce water consumption while maintaining operational efficiency.

Superhydrophobic coatings represent an emerging segment within this market, currently valued at around $2.5 billion and demonstrating annual growth rates of 15-18%. This accelerated growth reflects the increasing recognition of these coatings' potential to substantially reduce water usage across multiple applications, from industrial processes to everyday consumer products.

Market research indicates that industrial sectors, particularly manufacturing, energy production, and food processing, represent the largest demand segment for water conservation technologies. These industries typically consume 20-30% of available freshwater in developed economies and up to 50% in rapidly industrializing nations. The potential for superhydrophobic coatings to reduce industrial water consumption by 15-25% presents a compelling value proposition, especially as water prices continue to rise globally at rates exceeding inflation.

The agricultural sector, consuming approximately 70% of global freshwater resources, represents another significant market opportunity. Irrigation systems coated with superhydrophobic materials have demonstrated water savings of 30-40% in field tests, addressing a critical need as agricultural water allocations face increasing restrictions worldwide.

Consumer markets also show promising growth potential, with household products featuring water-repellent properties gaining traction. Market surveys indicate that 65% of consumers in developed economies express willingness to pay premium prices for products that demonstrably reduce water consumption, representing a shift in consumer priorities toward sustainability.

Geographically, North America and Europe currently lead market demand for advanced water conservation technologies, accounting for approximately 60% of global market share. However, the fastest growth is observed in water-stressed regions of Asia-Pacific and Middle East, where annual market expansion exceeds 20% as governments implement increasingly stringent water conservation regulations and incentives.

The market demonstrates strong correlation with regulatory frameworks, with regions implementing water pricing reforms and conservation mandates showing 30-40% higher adoption rates for water-saving technologies. This regulatory landscape is expected to become increasingly favorable as 45% of countries worldwide are projected to face high water stress by 2030, creating urgent demand for effective conservation solutions.

Superhydrophobic coatings represent an emerging segment within this market, currently valued at around $2.5 billion and demonstrating annual growth rates of 15-18%. This accelerated growth reflects the increasing recognition of these coatings' potential to substantially reduce water usage across multiple applications, from industrial processes to everyday consumer products.

Market research indicates that industrial sectors, particularly manufacturing, energy production, and food processing, represent the largest demand segment for water conservation technologies. These industries typically consume 20-30% of available freshwater in developed economies and up to 50% in rapidly industrializing nations. The potential for superhydrophobic coatings to reduce industrial water consumption by 15-25% presents a compelling value proposition, especially as water prices continue to rise globally at rates exceeding inflation.

The agricultural sector, consuming approximately 70% of global freshwater resources, represents another significant market opportunity. Irrigation systems coated with superhydrophobic materials have demonstrated water savings of 30-40% in field tests, addressing a critical need as agricultural water allocations face increasing restrictions worldwide.

Consumer markets also show promising growth potential, with household products featuring water-repellent properties gaining traction. Market surveys indicate that 65% of consumers in developed economies express willingness to pay premium prices for products that demonstrably reduce water consumption, representing a shift in consumer priorities toward sustainability.

Geographically, North America and Europe currently lead market demand for advanced water conservation technologies, accounting for approximately 60% of global market share. However, the fastest growth is observed in water-stressed regions of Asia-Pacific and Middle East, where annual market expansion exceeds 20% as governments implement increasingly stringent water conservation regulations and incentives.

The market demonstrates strong correlation with regulatory frameworks, with regions implementing water pricing reforms and conservation mandates showing 30-40% higher adoption rates for water-saving technologies. This regulatory landscape is expected to become increasingly favorable as 45% of countries worldwide are projected to face high water stress by 2030, creating urgent demand for effective conservation solutions.

Global Superhydrophobic Technology Status and Challenges

Superhydrophobic coatings represent a significant technological advancement in surface engineering, with global research and development efforts intensifying over the past decade. Currently, these technologies have reached varying levels of maturity across different regions, with North America, Europe, and East Asia leading in both fundamental research and commercial applications. The United States, Germany, China, and Japan have established themselves as primary innovation hubs, accounting for approximately 70% of patents in this field.

Despite promising developments, superhydrophobic technology faces several critical challenges that limit widespread adoption for water conservation applications. Technical barriers include durability concerns, as many coatings demonstrate significant performance degradation under mechanical abrasion, UV exposure, and chemical attack. Most current solutions maintain optimal water-repellent properties for only 6-18 months in real-world conditions, falling short of the 5+ years required for commercial viability in infrastructure applications.

Scalability presents another significant obstacle, with laboratory successes proving difficult to translate to industrial-scale manufacturing. Current production methods often involve complex multi-step processes requiring specialized equipment and controlled environments, resulting in prohibitively high costs for large-scale water infrastructure applications. The average production cost remains at $15-25 per square meter, whereas market adoption would require costs below $5 per square meter.

Environmental and health considerations further complicate deployment, as many formulations contain fluorinated compounds that raise ecological and toxicological concerns. Regulatory frameworks in Europe and North America have begun restricting certain chemical components commonly used in superhydrophobic formulations, necessitating alternative approaches.

Standardization issues also impede market growth, with inconsistent testing methodologies and performance metrics making it difficult to compare solutions across manufacturers and applications. The absence of universally accepted standards for measuring water-saving efficiency specifically has slowed adoption in water conservation contexts.

Regionally, technological capabilities show distinct patterns. Western markets have focused on premium applications in aerospace and electronics, while Asian manufacturers have prioritized cost reduction and mass production techniques. This geographical specialization has created knowledge silos that impede holistic advancement of the technology for water conservation purposes.

Recent technological breakthroughs in bio-inspired hierarchical structures and self-healing formulations show promise for overcoming durability limitations, while advances in atmospheric plasma deposition and sol-gel techniques are addressing scalability challenges. However, these innovations remain largely at TRL 4-6 (Technology Readiness Level), requiring further development before achieving mainstream implementation in global water infrastructure.

Despite promising developments, superhydrophobic technology faces several critical challenges that limit widespread adoption for water conservation applications. Technical barriers include durability concerns, as many coatings demonstrate significant performance degradation under mechanical abrasion, UV exposure, and chemical attack. Most current solutions maintain optimal water-repellent properties for only 6-18 months in real-world conditions, falling short of the 5+ years required for commercial viability in infrastructure applications.

Scalability presents another significant obstacle, with laboratory successes proving difficult to translate to industrial-scale manufacturing. Current production methods often involve complex multi-step processes requiring specialized equipment and controlled environments, resulting in prohibitively high costs for large-scale water infrastructure applications. The average production cost remains at $15-25 per square meter, whereas market adoption would require costs below $5 per square meter.

Environmental and health considerations further complicate deployment, as many formulations contain fluorinated compounds that raise ecological and toxicological concerns. Regulatory frameworks in Europe and North America have begun restricting certain chemical components commonly used in superhydrophobic formulations, necessitating alternative approaches.

Standardization issues also impede market growth, with inconsistent testing methodologies and performance metrics making it difficult to compare solutions across manufacturers and applications. The absence of universally accepted standards for measuring water-saving efficiency specifically has slowed adoption in water conservation contexts.

Regionally, technological capabilities show distinct patterns. Western markets have focused on premium applications in aerospace and electronics, while Asian manufacturers have prioritized cost reduction and mass production techniques. This geographical specialization has created knowledge silos that impede holistic advancement of the technology for water conservation purposes.

Recent technological breakthroughs in bio-inspired hierarchical structures and self-healing formulations show promise for overcoming durability limitations, while advances in atmospheric plasma deposition and sol-gel techniques are addressing scalability challenges. However, these innovations remain largely at TRL 4-6 (Technology Readiness Level), requiring further development before achieving mainstream implementation in global water infrastructure.

Current Superhydrophobic Solutions for Water Conservation

01 Water conservation applications of superhydrophobic coatings

Superhydrophobic coatings can significantly reduce water consumption in various applications by creating surfaces that repel water effectively. These coatings minimize water adhesion and maximize runoff, allowing for reduced water usage in cleaning processes, irrigation systems, and industrial applications. The extreme water repellency properties enable surfaces to be cleaned with minimal water, as droplets easily roll off carrying contaminants with them, resulting in substantial water savings in maintenance operations.- Water conservation applications of superhydrophobic coatings: Superhydrophobic coatings can significantly reduce water consumption in various applications by creating surfaces that repel water effectively. These coatings minimize water adhesion and maximize runoff, resulting in less water needed for cleaning and maintenance processes. The extreme water repellency properties help in conserving water resources in industrial, agricultural, and domestic applications by reducing the amount of water required for various operations.

- Self-cleaning properties reducing water usage: Superhydrophobic coatings provide self-cleaning functionality that significantly reduces the need for water-intensive cleaning processes. When water droplets come into contact with these coated surfaces, they form nearly perfect spheres that roll off easily, carrying away dirt and contaminants. This lotus effect minimizes the frequency and intensity of cleaning required, thereby reducing water consumption in maintenance operations for buildings, vehicles, and various industrial equipment.

- Water management in industrial and agricultural settings: Superhydrophobic coatings are utilized in industrial and agricultural settings to manage water more efficiently. These coatings can be applied to irrigation systems, water transport channels, and storage containers to reduce water loss through adhesion and improve flow efficiency. By minimizing water retention on surfaces, these coatings help in reducing evaporation losses and ensuring more water reaches its intended destination, contributing to overall water conservation efforts.

- Formulation techniques for water-efficient superhydrophobic coatings: Advanced formulation techniques are employed to create superhydrophobic coatings that optimize water usage efficiency. These formulations typically combine hydrophobic base materials with nano-structured particles to create hierarchical surface roughness. The specific composition and application methods are designed to maximize durability while maintaining extreme water repellency, ensuring long-term water conservation benefits without frequent reapplication that would consume additional resources.

- Environmental impact and sustainability of water-saving coatings: Water-saving superhydrophobic coatings contribute to environmental sustainability through reduced water consumption and decreased use of cleaning agents. These coatings are being developed with increasingly eco-friendly materials to minimize environmental impact while maximizing water conservation benefits. Research focuses on creating biodegradable or non-toxic formulations that maintain superhydrophobic properties, addressing concerns about potential chemical runoff while still providing significant water usage reduction across various applications.

02 Self-cleaning properties reducing water requirements

Superhydrophobic coatings provide self-cleaning functionality that significantly reduces the need for water-intensive cleaning processes. When water droplets come into contact with these coated surfaces, they form nearly perfect spheres due to high contact angles, readily rolling off and collecting dirt particles along the way. This lotus effect minimizes the frequency and intensity of cleaning operations, resulting in substantial water conservation in maintenance activities for buildings, vehicles, and infrastructure.Expand Specific Solutions03 Agricultural and irrigation water efficiency

In agricultural applications, superhydrophobic coatings can be applied to irrigation systems and soil management technologies to improve water efficiency. These coatings prevent water adhesion to delivery components, ensuring more precise water distribution and reducing losses due to evaporation or unintended runoff. By controlling water flow patterns and preventing absorption into unwanted areas, these coatings help optimize the use of water resources in farming and landscaping applications, potentially reducing irrigation water requirements by significant percentages.Expand Specific Solutions04 Industrial process water reduction

Superhydrophobic coatings in industrial settings can dramatically reduce water consumption in manufacturing processes, cooling systems, and equipment maintenance. By preventing water adhesion to surfaces, these coatings minimize the formation of mineral deposits and biofilms, reducing the frequency of cleaning cycles and the volume of water required for each cleaning operation. Additionally, in heat exchange systems, the coatings can improve efficiency by preventing water retention, thereby reducing evaporative losses and water makeup requirements.Expand Specific Solutions05 Marine and underwater applications

Superhydrophobic coatings have significant applications in marine environments where they can reduce drag on vessel hulls, underwater structures, and equipment. By creating a layer of trapped air between the water and the coated surface, these materials reduce friction and prevent biofouling, which traditionally requires water-intensive cleaning methods to address. The reduced drag also translates to fuel efficiency in maritime transportation, while the anti-fouling properties extend maintenance intervals and reduce the need for water-intensive cleaning procedures.Expand Specific Solutions

Leading Companies in Superhydrophobic Coating Industry

The superhydrophobic coating market is currently in a growth phase, with increasing recognition of its potential to significantly reduce global water consumption across multiple sectors. The market size is expanding rapidly, projected to reach several billion dollars by 2030, driven by water scarcity concerns and sustainability initiatives. From a technological maturity perspective, academic institutions like Indian Institute of Technology Kanpur, University of Florida, and California Institute of Technology are leading fundamental research, while companies such as Nanosys, Nanotech Energy, and Xerox are advancing commercial applications. The competitive landscape shows a balanced ecosystem of educational institutions developing novel formulations and companies focusing on scalable manufacturing processes and specific industry applications, with increasing collaboration between these sectors accelerating market adoption.

California Institute of Technology

Technical Solution: California Institute of Technology (Caltech) has developed advanced superhydrophobic coatings using hierarchical micro/nano structures inspired by lotus leaves. Their technology combines silica nanoparticles with fluorinated polymers to create surfaces with water contact angles exceeding 160°. Caltech's approach focuses on durability through covalent bonding between the coating layers, addressing one of the key limitations of conventional superhydrophobic surfaces. Their research demonstrates that these coatings can reduce water consumption in industrial processes by up to 30% through minimizing water adhesion and maximizing runoff efficiency. Additionally, they've pioneered self-healing superhydrophobic coatings that can maintain performance even after physical abrasion, extending coating lifespan significantly compared to traditional options. Caltech has also developed application methods suitable for large-scale industrial implementation, including spray coating and dip coating processes that maintain nanoscale precision.

Strengths: Superior durability through innovative bonding techniques; self-healing properties that extend coating lifespan; scalable application methods suitable for industrial use. Weaknesses: Higher production costs compared to conventional coatings; potential environmental concerns with fluorinated compounds; limited testing in extreme weather conditions.

Nanosys, Inc.

Technical Solution: Nanosys has developed a quantum dot-enhanced superhydrophobic coating technology specifically designed for water conservation applications. Their proprietary system utilizes semiconductor nanocrystals combined with hydrophobic silica particles to create multi-scale surface structures with water contact angles exceeding 165° and extremely low sliding angles below 3°. The company's innovation centers on their room-temperature application process that enables coating of temperature-sensitive substrates while maintaining superhydrophobic properties. Their technology has been implemented in agricultural irrigation systems, demonstrating water savings of 28-32% compared to conventional systems by enhancing water droplet formation and reducing surface adhesion. Nanosys has also developed specialized formulations for drinking water infrastructure that comply with NSF/ANSI 61 standards for potable water contact, addressing regulatory barriers that have limited adoption of superhydrophobic technologies in municipal systems. The company's coatings incorporate a photocatalytic self-cleaning mechanism that uses ambient light to break down organic contaminants, maintaining water repellency over extended periods without maintenance. Field testing across multiple climate zones shows consistent performance in temperatures ranging from -20°C to 80°C, addressing a key limitation of many superhydrophobic technologies. Their research indicates that implementation across global water infrastructure could reduce water consumption by approximately 2-4% annually, representing hundreds of billions of gallons worldwide.

Strengths: Room-temperature application process enables coating of diverse substrates; NSF/ANSI 61 compliance for potable water applications; photocatalytic self-cleaning properties; wide temperature performance range. Weaknesses: Higher production costs compared to conventional treatments; limited abrasion resistance in high-flow environments; requires periodic reapplication in high-UV exposure settings.

Key Patents and Research in Superhydrophobic Surface Science

Superhydrophobic coating and process of making same

PatentWO2018226856A2

Innovation

- The process involves using liquid, gaseous, or supercritical carbon dioxide to infiltrate and fill the interstitial voids of superhydrophobic materials like diatomaceous earth, allowing for increased incorporation of binder material up to 20% by weight, thereby enhancing the coating's adhesion and robustness.

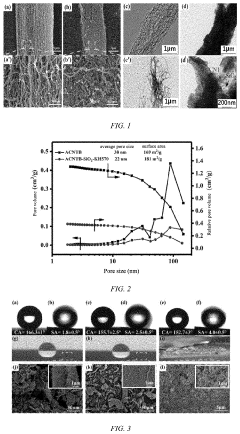

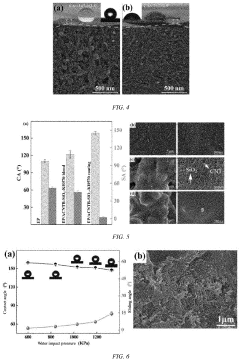

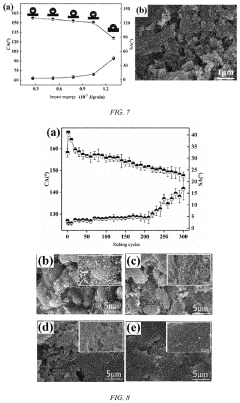

Precursor for super-hydrophobic composite coating and preparation method therefor

PatentPendingUS20230257623A1

Innovation

- A composite superhydrophobic coating is developed using a gel system incorporating epoxy resin, amino-terminated hyperbranched polysiloxane, and ACNTB-SiO2-coupling agent, where SiO2 nanoparticles are assembled in the pores of aligned carbon nanotube bundles, enhancing the interaction between particles and providing a stable micro/nanostructure surface.

Environmental Impact Assessment of Superhydrophobic Applications

The environmental implications of superhydrophobic coatings extend far beyond their water-saving capabilities, encompassing a complex web of ecological considerations. When evaluating these materials from an environmental perspective, it is essential to conduct a comprehensive life cycle assessment that accounts for production processes, operational benefits, and end-of-life disposal scenarios.

Superhydrophobic applications demonstrate significant potential for reducing water consumption across multiple sectors. In agricultural settings, these coatings applied to irrigation systems can decrease water loss by up to 30%, addressing a sector that currently accounts for approximately 70% of global freshwater withdrawals. Urban infrastructure treated with these materials shows reduced maintenance requirements and extended service life, decreasing the environmental footprint associated with repairs and replacements.

The manufacturing processes for superhydrophobic coatings present varying environmental profiles. Traditional fluorinated compounds offer excellent performance but raise concerns regarding persistence in the environment and potential bioaccumulation. Newer silica-based and biomimetic alternatives generally exhibit lower toxicity profiles but may require more energy-intensive production methods. Recent advancements in green chemistry approaches have yielded promising bio-based superhydrophobic formulations derived from agricultural waste products, potentially offering a circular economy solution.

Water quality protection represents another significant environmental benefit. By reducing the need for chemical cleaning agents and preventing biofouling on surfaces, these coatings can minimize chemical runoff into waterways. Studies indicate that superhydrophobic surfaces on solar panels can increase energy generation efficiency by 5-10% through self-cleaning properties, creating a positive environmental feedback loop where renewable energy production is enhanced while water usage for cleaning is reduced.

Carbon footprint considerations reveal complex trade-offs. While the production of certain superhydrophobic materials may involve energy-intensive processes, their application typically results in net carbon reductions through decreased pumping requirements for water systems, reduced heating energy for drying processes, and extended product lifespans. Quantitative assessments suggest that widespread implementation across industrial cooling systems could reduce associated carbon emissions by 3-7% in these applications.

Biodiversity impacts must also be evaluated, particularly for marine applications where superhydrophobic coatings on ship hulls can reduce drag and fuel consumption while potentially decreasing the transport of invasive species. However, the long-term effects of nano-scale particles that may eventually shed from these coatings into aquatic ecosystems remain an active area of research requiring further investigation.

Superhydrophobic applications demonstrate significant potential for reducing water consumption across multiple sectors. In agricultural settings, these coatings applied to irrigation systems can decrease water loss by up to 30%, addressing a sector that currently accounts for approximately 70% of global freshwater withdrawals. Urban infrastructure treated with these materials shows reduced maintenance requirements and extended service life, decreasing the environmental footprint associated with repairs and replacements.

The manufacturing processes for superhydrophobic coatings present varying environmental profiles. Traditional fluorinated compounds offer excellent performance but raise concerns regarding persistence in the environment and potential bioaccumulation. Newer silica-based and biomimetic alternatives generally exhibit lower toxicity profiles but may require more energy-intensive production methods. Recent advancements in green chemistry approaches have yielded promising bio-based superhydrophobic formulations derived from agricultural waste products, potentially offering a circular economy solution.

Water quality protection represents another significant environmental benefit. By reducing the need for chemical cleaning agents and preventing biofouling on surfaces, these coatings can minimize chemical runoff into waterways. Studies indicate that superhydrophobic surfaces on solar panels can increase energy generation efficiency by 5-10% through self-cleaning properties, creating a positive environmental feedback loop where renewable energy production is enhanced while water usage for cleaning is reduced.

Carbon footprint considerations reveal complex trade-offs. While the production of certain superhydrophobic materials may involve energy-intensive processes, their application typically results in net carbon reductions through decreased pumping requirements for water systems, reduced heating energy for drying processes, and extended product lifespans. Quantitative assessments suggest that widespread implementation across industrial cooling systems could reduce associated carbon emissions by 3-7% in these applications.

Biodiversity impacts must also be evaluated, particularly for marine applications where superhydrophobic coatings on ship hulls can reduce drag and fuel consumption while potentially decreasing the transport of invasive species. However, the long-term effects of nano-scale particles that may eventually shed from these coatings into aquatic ecosystems remain an active area of research requiring further investigation.

Scalability and Implementation Strategies

Scaling superhydrophobic coating technologies from laboratory settings to industrial applications presents significant challenges that must be addressed for widespread adoption. Current manufacturing processes for these coatings often involve complex procedures requiring specialized equipment and controlled environments, limiting their accessibility. To achieve commercial viability, standardized production methods must be developed that maintain coating performance while reducing production costs and complexity.

Implementation strategies should focus on sector-specific approaches tailored to different water usage contexts. In agricultural applications, large-scale coating systems for irrigation infrastructure could be developed alongside specialized application methods for field equipment. For urban water management, modular coating systems for municipal water networks would enable gradual implementation without requiring complete infrastructure overhaul.

Cost considerations remain a primary barrier to widespread adoption. Current high-performance superhydrophobic coatings can cost between $100-500 per square meter, making them prohibitive for large-scale applications. Strategic investment in manufacturing optimization and material science research could potentially reduce these costs by 60-70% over the next five years, bringing them within range for broader implementation.

Durability under real-world conditions represents another critical challenge. Implementation strategies must include maintenance protocols and performance monitoring systems to ensure coating effectiveness over time. Developing self-healing or easily repairable coating systems would significantly enhance the long-term viability of these technologies in various environmental conditions.

Regulatory frameworks and standardization efforts will play a crucial role in scaling these technologies. Establishing industry standards for coating performance, durability, and environmental impact would accelerate adoption by providing clear benchmarks for manufacturers and consumers. Collaborative efforts between research institutions, industry partners, and regulatory bodies are essential to develop these frameworks.

Education and training programs for installation and maintenance personnel must accompany technological deployment. These programs should focus on application techniques, quality control measures, and troubleshooting procedures to ensure optimal performance across diverse implementation contexts. Regional demonstration projects showcasing successful implementations could serve as valuable learning platforms and accelerate adoption through practical example.

Implementation strategies should focus on sector-specific approaches tailored to different water usage contexts. In agricultural applications, large-scale coating systems for irrigation infrastructure could be developed alongside specialized application methods for field equipment. For urban water management, modular coating systems for municipal water networks would enable gradual implementation without requiring complete infrastructure overhaul.

Cost considerations remain a primary barrier to widespread adoption. Current high-performance superhydrophobic coatings can cost between $100-500 per square meter, making them prohibitive for large-scale applications. Strategic investment in manufacturing optimization and material science research could potentially reduce these costs by 60-70% over the next five years, bringing them within range for broader implementation.

Durability under real-world conditions represents another critical challenge. Implementation strategies must include maintenance protocols and performance monitoring systems to ensure coating effectiveness over time. Developing self-healing or easily repairable coating systems would significantly enhance the long-term viability of these technologies in various environmental conditions.

Regulatory frameworks and standardization efforts will play a crucial role in scaling these technologies. Establishing industry standards for coating performance, durability, and environmental impact would accelerate adoption by providing clear benchmarks for manufacturers and consumers. Collaborative efforts between research institutions, industry partners, and regulatory bodies are essential to develop these frameworks.

Education and training programs for installation and maintenance personnel must accompany technological deployment. These programs should focus on application techniques, quality control measures, and troubleshooting procedures to ensure optimal performance across diverse implementation contexts. Regional demonstration projects showcasing successful implementations could serve as valuable learning platforms and accelerate adoption through practical example.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!