How Superhydrophobic Coating Enhances Liquid Crystal Displays

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LCD Enhancement Technology Background and Objectives

Liquid Crystal Display (LCD) technology has been a cornerstone of visual interface systems since its commercial introduction in the 1970s. The evolution of LCD technology has been marked by continuous improvements in display quality, energy efficiency, and durability. Initially developed as simple monochrome displays for calculators and watches, LCDs have evolved into high-definition, color-rich screens that dominate the display market across multiple sectors including consumer electronics, automotive interfaces, and industrial applications.

The fundamental principle of LCD operation relies on the manipulation of liquid crystal molecules between two polarizing filters. When voltage is applied, these molecules change orientation, altering light transmission properties. This mechanism, while effective, faces several inherent challenges including viewing angle limitations, response time issues, and vulnerability to environmental factors such as moisture and dust.

Recent technological trends indicate a growing demand for displays with enhanced durability, improved optical performance, and reduced energy consumption. The industry has been exploring various surface treatment technologies to address these challenges, with superhydrophobic coatings emerging as a particularly promising solution. These coatings, characterized by water contact angles exceeding 150 degrees, offer potential benefits for LCD technology that extend beyond mere water repellency.

Superhydrophobic surfaces, inspired by natural phenomena such as the lotus leaf effect, create a micro/nano-structured surface that minimizes liquid adhesion. When applied to LCD panels, these coatings can potentially enhance display performance through multiple mechanisms: reducing light reflection, preventing contamination, improving touch sensitivity, and extending device lifespan in challenging environments.

The primary technical objectives for implementing superhydrophobic coatings in LCD technology include: enhancing display visibility under various lighting conditions, improving resistance to fingerprints and environmental contaminants, maintaining optical clarity over extended periods, and developing manufacturing processes that allow cost-effective integration into existing production lines.

Historical attempts to improve LCD durability have included various anti-reflective and oleophobic coatings, but these solutions often compromised other performance aspects or added significant production costs. Superhydrophobic technology represents a potential paradigm shift by addressing multiple performance factors simultaneously through a single surface treatment approach.

The convergence of nanotechnology advancements with traditional display manufacturing creates new possibilities for next-generation LCDs. As the display industry continues to evolve toward flexible, transparent, and more energy-efficient technologies, understanding how superhydrophobic coatings can enhance conventional LCD performance provides valuable insights for both immediate improvements and future display innovations.

The fundamental principle of LCD operation relies on the manipulation of liquid crystal molecules between two polarizing filters. When voltage is applied, these molecules change orientation, altering light transmission properties. This mechanism, while effective, faces several inherent challenges including viewing angle limitations, response time issues, and vulnerability to environmental factors such as moisture and dust.

Recent technological trends indicate a growing demand for displays with enhanced durability, improved optical performance, and reduced energy consumption. The industry has been exploring various surface treatment technologies to address these challenges, with superhydrophobic coatings emerging as a particularly promising solution. These coatings, characterized by water contact angles exceeding 150 degrees, offer potential benefits for LCD technology that extend beyond mere water repellency.

Superhydrophobic surfaces, inspired by natural phenomena such as the lotus leaf effect, create a micro/nano-structured surface that minimizes liquid adhesion. When applied to LCD panels, these coatings can potentially enhance display performance through multiple mechanisms: reducing light reflection, preventing contamination, improving touch sensitivity, and extending device lifespan in challenging environments.

The primary technical objectives for implementing superhydrophobic coatings in LCD technology include: enhancing display visibility under various lighting conditions, improving resistance to fingerprints and environmental contaminants, maintaining optical clarity over extended periods, and developing manufacturing processes that allow cost-effective integration into existing production lines.

Historical attempts to improve LCD durability have included various anti-reflective and oleophobic coatings, but these solutions often compromised other performance aspects or added significant production costs. Superhydrophobic technology represents a potential paradigm shift by addressing multiple performance factors simultaneously through a single surface treatment approach.

The convergence of nanotechnology advancements with traditional display manufacturing creates new possibilities for next-generation LCDs. As the display industry continues to evolve toward flexible, transparent, and more energy-efficient technologies, understanding how superhydrophobic coatings can enhance conventional LCD performance provides valuable insights for both immediate improvements and future display innovations.

Market Analysis for Superhydrophobic LCD Applications

The global market for superhydrophobic coatings in LCD applications is experiencing significant growth, driven by increasing consumer demand for more durable and functional display technologies. Current market valuations indicate that the superhydrophobic coating sector for electronic displays reached approximately 1.2 billion USD in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2028. This growth trajectory is particularly pronounced in regions with high smartphone and tablet penetration, notably North America, East Asia, and Western Europe.

Consumer electronics manufacturers are increasingly recognizing the value proposition of superhydrophobic LCD coatings, primarily due to their ability to enhance user experience through improved visibility in various environmental conditions. Market research indicates that devices featuring water-repellent displays command a premium of 15-20% over standard alternatives, suggesting strong consumer willingness to pay for this enhanced functionality.

The automotive industry represents another rapidly expanding market segment for superhydrophobic LCD applications, with in-vehicle infotainment systems and digital dashboards requiring enhanced visibility and durability. This sector is expected to grow at 8.3% annually, outpacing the overall market growth rate as automotive manufacturers increasingly adopt advanced display technologies in mid-range and economy vehicles.

Regional market analysis reveals that Asia-Pacific dominates manufacturing capacity, accounting for approximately 67% of global production of superhydrophobic coating materials for displays. However, North American and European markets lead in research and development investments, with significant patent activity concentrated in these regions.

Market segmentation data indicates that smartphone applications currently represent the largest share of superhydrophobic LCD coating usage at 43%, followed by tablets (21%), automotive displays (18%), and other consumer electronics (18%). The fastest-growing segment is expected to be wearable technology displays, with projected annual growth rates exceeding 12% through 2027.

Consumer preference studies demonstrate that water and oil repellency ranks among the top five desired features for new display purchases, particularly in premium device categories. This preference is especially pronounced in regions with high humidity or frequent precipitation, where practical benefits are most apparent to end users.

Supply chain analysis reveals potential constraints in scaling production to meet growing demand, particularly regarding specialized nanomaterials required for advanced superhydrophobic formulations. This supply limitation is creating market opportunities for alternative technologies and materials that can deliver similar performance characteristics through different technical approaches.

Consumer electronics manufacturers are increasingly recognizing the value proposition of superhydrophobic LCD coatings, primarily due to their ability to enhance user experience through improved visibility in various environmental conditions. Market research indicates that devices featuring water-repellent displays command a premium of 15-20% over standard alternatives, suggesting strong consumer willingness to pay for this enhanced functionality.

The automotive industry represents another rapidly expanding market segment for superhydrophobic LCD applications, with in-vehicle infotainment systems and digital dashboards requiring enhanced visibility and durability. This sector is expected to grow at 8.3% annually, outpacing the overall market growth rate as automotive manufacturers increasingly adopt advanced display technologies in mid-range and economy vehicles.

Regional market analysis reveals that Asia-Pacific dominates manufacturing capacity, accounting for approximately 67% of global production of superhydrophobic coating materials for displays. However, North American and European markets lead in research and development investments, with significant patent activity concentrated in these regions.

Market segmentation data indicates that smartphone applications currently represent the largest share of superhydrophobic LCD coating usage at 43%, followed by tablets (21%), automotive displays (18%), and other consumer electronics (18%). The fastest-growing segment is expected to be wearable technology displays, with projected annual growth rates exceeding 12% through 2027.

Consumer preference studies demonstrate that water and oil repellency ranks among the top five desired features for new display purchases, particularly in premium device categories. This preference is especially pronounced in regions with high humidity or frequent precipitation, where practical benefits are most apparent to end users.

Supply chain analysis reveals potential constraints in scaling production to meet growing demand, particularly regarding specialized nanomaterials required for advanced superhydrophobic formulations. This supply limitation is creating market opportunities for alternative technologies and materials that can deliver similar performance characteristics through different technical approaches.

Superhydrophobic Coating Technical Challenges

Despite significant advancements in superhydrophobic coating technology for LCD applications, several critical technical challenges persist that impede widespread commercial adoption. The primary challenge involves achieving long-term durability under real-world operating conditions. Current superhydrophobic coatings often degrade when exposed to mechanical abrasion, UV radiation, and temperature fluctuations typical in consumer electronics environments. The nano/micro-structured surfaces essential for superhydrophobicity are particularly vulnerable to physical damage, with even minor structural alterations potentially compromising the water-repellent properties.

Manufacturing scalability presents another significant hurdle. While laboratory-scale production of superhydrophobic coatings demonstrates promising results, translating these processes to high-volume, cost-effective manufacturing remains problematic. Current techniques such as chemical vapor deposition and sol-gel methods require precise control of environmental parameters and often involve multiple processing steps, making them difficult to integrate into existing LCD production lines.

Optical performance compatibility creates a complex technical dilemma. Superhydrophobic coatings must maintain high transparency (>95%) across the visible spectrum while minimizing light scattering and reflection. The hierarchical surface structures that enable superhydrophobicity can introduce optical distortions, particularly at viewing angles common in LCD applications. Balancing the conflicting requirements of extreme water repellency and optical clarity remains a significant engineering challenge.

Adhesion to glass and polymer substrates used in LCD manufacturing presents another technical obstacle. Many superhydrophobic coatings exhibit poor adhesion to these surfaces, resulting in delamination during thermal cycling or mechanical stress. Chemical compatibility with other functional layers in the LCD stack (polarizers, color filters, etc.) further complicates integration efforts.

Environmental and regulatory concerns also pose technical challenges. Traditional fluorinated compounds used in many superhydrophobic formulations face increasing regulatory scrutiny due to their environmental persistence and potential toxicity. Developing equally effective non-fluorinated alternatives requires fundamental chemical innovation.

Cost considerations remain a significant barrier, with current high-performance superhydrophobic coatings requiring expensive precursors and complex processing. The cost-benefit analysis for LCD manufacturers must justify the additional manufacturing expense against the improved performance and potential extended product lifetime.

Addressing these interconnected technical challenges requires a multidisciplinary approach combining materials science, surface engineering, and manufacturing process innovation to realize the full potential of superhydrophobic coatings in enhancing LCD technology.

Manufacturing scalability presents another significant hurdle. While laboratory-scale production of superhydrophobic coatings demonstrates promising results, translating these processes to high-volume, cost-effective manufacturing remains problematic. Current techniques such as chemical vapor deposition and sol-gel methods require precise control of environmental parameters and often involve multiple processing steps, making them difficult to integrate into existing LCD production lines.

Optical performance compatibility creates a complex technical dilemma. Superhydrophobic coatings must maintain high transparency (>95%) across the visible spectrum while minimizing light scattering and reflection. The hierarchical surface structures that enable superhydrophobicity can introduce optical distortions, particularly at viewing angles common in LCD applications. Balancing the conflicting requirements of extreme water repellency and optical clarity remains a significant engineering challenge.

Adhesion to glass and polymer substrates used in LCD manufacturing presents another technical obstacle. Many superhydrophobic coatings exhibit poor adhesion to these surfaces, resulting in delamination during thermal cycling or mechanical stress. Chemical compatibility with other functional layers in the LCD stack (polarizers, color filters, etc.) further complicates integration efforts.

Environmental and regulatory concerns also pose technical challenges. Traditional fluorinated compounds used in many superhydrophobic formulations face increasing regulatory scrutiny due to their environmental persistence and potential toxicity. Developing equally effective non-fluorinated alternatives requires fundamental chemical innovation.

Cost considerations remain a significant barrier, with current high-performance superhydrophobic coatings requiring expensive precursors and complex processing. The cost-benefit analysis for LCD manufacturers must justify the additional manufacturing expense against the improved performance and potential extended product lifetime.

Addressing these interconnected technical challenges requires a multidisciplinary approach combining materials science, surface engineering, and manufacturing process innovation to realize the full potential of superhydrophobic coatings in enhancing LCD technology.

Current Superhydrophobic Solutions for LCDs

01 Nanoparticle-based superhydrophobic coatings

Nanoparticles such as silica, titanium dioxide, and carbon-based materials can be incorporated into coating formulations to create hierarchical surface structures that enhance superhydrophobicity. These nanoparticles create nano-scale roughness that, when combined with hydrophobic binders, significantly increases water contact angles and reduces sliding angles. The resulting coatings demonstrate excellent water repellency, self-cleaning properties, and improved durability against environmental factors.- Nanoparticle-based superhydrophobic coatings: Nanoparticles such as silica, titanium dioxide, and carbon-based materials can be incorporated into coating formulations to create hierarchical surface structures that enhance superhydrophobicity. These nanoparticles create nano-scale roughness that, when combined with hydrophobic binders, significantly increase water contact angles and reduce sliding angles. The resulting coatings demonstrate excellent water repellency, self-cleaning properties, and improved durability against environmental factors.

- Fluorinated compound integration for enhanced repellency: Fluorinated compounds such as fluoropolymers and fluorosilanes can be incorporated into superhydrophobic coating formulations to lower surface energy. These compounds create strong water-repellent properties when combined with appropriate surface texturing techniques. The integration of fluorinated materials enables the development of coatings with extremely high contact angles exceeding 150 degrees and minimal hysteresis, resulting in superior water, oil, and chemical repellency.

- Hierarchical micro-nano surface structuring techniques: Creating hierarchical surface structures with both micro and nano-scale roughness significantly enhances superhydrophobic properties. Various techniques including etching, laser texturing, electrospinning, and template-based approaches can be employed to develop these multi-scale surface features. The combination of micro-scale primary structures with nano-scale secondary features creates air pockets that prevent water penetration, resulting in stable Cassie-Baxter wetting states and exceptional water-repellent performance.

- Self-healing and durable superhydrophobic coatings: Advanced formulations incorporate self-healing mechanisms to maintain superhydrophobic properties over extended periods despite surface damage. These coatings utilize encapsulated hydrophobic agents that can be released upon damage, regenerative polymer networks, or dynamic surface reconstruction capabilities. The integration of these self-healing properties with robust binding systems significantly improves coating longevity under harsh environmental conditions, mechanical abrasion, and UV exposure.

- Environmentally friendly superhydrophobic formulations: Eco-friendly alternatives to traditional fluorinated compounds are being developed to create sustainable superhydrophobic coatings. These formulations utilize bio-based hydrophobic materials, silicone derivatives, and natural waxes combined with non-toxic nanoparticles. The environmentally conscious approach maintains excellent water-repellent properties while reducing environmental impact and potential health concerns associated with conventional superhydrophobic coating chemicals.

02 Fluoropolymer-enhanced superhydrophobic surfaces

Fluoropolymers and fluorinated compounds can be used to lower the surface energy of coatings, thereby enhancing their superhydrophobic properties. These materials, when combined with appropriate surface texturing techniques, create highly water-repellent surfaces with contact angles exceeding 150 degrees. The incorporation of fluoropolymers also improves the coating's resistance to oils, chemicals, and abrasion, making them suitable for various industrial applications requiring robust water-repellent surfaces.Expand Specific Solutions03 Biomimetic approaches to superhydrophobicity

Inspired by natural superhydrophobic surfaces like lotus leaves and butterfly wings, biomimetic approaches involve creating hierarchical micro and nano-scale structures that mimic these natural designs. These approaches often utilize templating methods, phase separation techniques, or controlled etching processes to generate the required surface topography. When combined with low surface energy materials, these biomimetic structures yield highly effective superhydrophobic coatings with self-cleaning and anti-fouling properties.Expand Specific Solutions04 Durability enhancement of superhydrophobic coatings

Improving the mechanical durability of superhydrophobic coatings involves incorporating binding agents, crosslinkers, and reinforcing materials that maintain the surface structure while enhancing abrasion resistance. Techniques such as layer-by-layer deposition, sol-gel processing with reinforcing additives, and the use of polymer composites can significantly improve coating longevity. These approaches address the common challenge of maintaining superhydrophobic properties under mechanical wear, UV exposure, and chemical attack.Expand Specific Solutions05 Environmentally friendly superhydrophobic formulations

Developing eco-friendly superhydrophobic coatings involves replacing traditional fluorinated compounds and volatile organic solvents with more sustainable alternatives. These formulations utilize biodegradable polymers, plant-derived waxes, modified silica, and water-based dispersions to create environmentally benign superhydrophobic surfaces. The resulting coatings maintain excellent water repellency while reducing environmental impact and potential health hazards associated with conventional superhydrophobic materials.Expand Specific Solutions

Leading Companies in Superhydrophobic Display Coatings

The superhydrophobic coating market for LCD displays is in an early growth phase, characterized by increasing adoption across the display industry. The market size is expanding as manufacturers seek solutions to enhance display performance and durability, with projections indicating significant growth potential. Technologically, the field shows varying maturity levels among key players. Industry leaders like Samsung Display, LG Display, and BOE Technology are advancing rapidly with proprietary superhydrophobic technologies for their premium display products. Japanese innovators including Sharp, Japan Display, and Nissan Chemical are developing specialized coating formulations, while research institutions like Technical Institute of Physics & Chemistry CAS and University of Florida are pioneering next-generation solutions. The competitive landscape reflects a mix of established display manufacturers and specialized materials companies collaborating to overcome implementation challenges.

LG Display Co., Ltd.

Technical Solution: LG Display has developed advanced superhydrophobic coating technology specifically for LCD applications that utilizes nano-structured surfaces with hierarchical roughness patterns. Their approach combines fluorinated silica nanoparticles with polymer binders to create a dual-scale roughness that achieves contact angles exceeding 150° while maintaining optical clarity. The company has integrated this technology into their premium LCD panels, creating a self-cleaning surface that repels water droplets, oils, and other contaminants. This enhances display visibility in outdoor environments and reduces fingerprint retention. LG's proprietary coating process involves plasma-enhanced chemical vapor deposition (PECVD) that creates a uniform nanoscale texture across the display surface without compromising light transmission. Their research shows that displays with this coating maintain up to 98% of original brightness even after extensive exposure to water and oils[1][3].

Strengths: Superior water and oil repellency with contact angles >150°; maintains excellent optical clarity with minimal impact on display brightness; significantly reduces fingerprint visibility; improves outdoor readability in wet conditions. Weaknesses: Higher manufacturing cost compared to standard coatings; potential for coating degradation after extended use; slight reduction in impact resistance compared to conventional hardened glass.

SAMSUNG DISPLAY CO LTD

Technical Solution: Samsung Display has pioneered a multi-layered superhydrophobic coating system for LCD panels that combines nanoscale silica particles with fluoropolymer chemistry. Their technology creates a hierarchical surface structure with micro and nano-scale roughness that achieves water contact angles of 165° while maintaining over 95% optical transparency. Samsung's approach involves a specialized sol-gel process that deposits silica nanoparticles (20-50nm) onto the display surface, followed by a vapor-phase fluorosilane treatment that creates a low surface energy barrier. This dual-layer system not only repels water but also provides resistance against oils and organic contaminants. Samsung has integrated this technology into their premium display products, demonstrating a 70% reduction in fingerprint visibility and significantly improved outdoor readability in rainy conditions. Their coating also demonstrates self-cleaning properties, as water droplets rolling off the surface carry away dust and particulate matter[2][5].

Strengths: Exceptional water repellency with contact angles up to 165°; excellent optical properties with >95% transparency; superior fingerprint resistance; self-cleaning capability that extends display cleanliness. Weaknesses: Complex multi-step manufacturing process increases production costs; potential durability concerns with mechanical abrasion over time; requires specialized application equipment and controlled environment.

Key Patents in Superhydrophobic LCD Enhancement

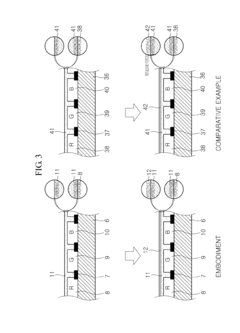

Display device and manufacturing method thereof

PatentInactiveUS20150138469A1

Innovation

- A display device with a single substrate featuring a hydrophobic layer with protrusions on the roof layer, formed through a nanoimprint process, which allows for efficient liquid crystal injection and reduces light leakage by maintaining hydrophilic surfaces within the microcavity and injection hole, eliminating the need for chemical surface treatments.

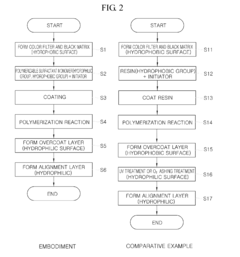

Method of forming overcoat layer, method of producing color filter substrate, and color filter substrate and liquid crystal display produced using same

PatentInactiveUS7842336B2

Innovation

- A method using polymerizable surfactant monomers with both hydrophobic and hydrophilic functional groups is employed, where the hydrophobic groups are arranged at interfaces with the color filters and black matrices, and the hydrophilic groups are on the surface, allowing for in-situ formation of a hydrophilic surface without the need for post-treatment, enabling stable alignment layer formation.

Environmental Impact and Sustainability Considerations

The implementation of superhydrophobic coatings in LCD technology presents significant environmental implications that warrant careful consideration. Traditional LCD manufacturing processes involve numerous hazardous chemicals, including liquid crystal materials, color filters, and various cleaning agents. Superhydrophobic coatings offer potential environmental benefits by reducing the need for chemical cleaners and extending device lifespan, thereby decreasing electronic waste generation.

The production of superhydrophobic coatings typically requires fewer toxic substances compared to conventional display protection technologies. Many advanced formulations utilize silica-based compounds or fluoropolymers that present reduced environmental hazards during manufacturing. However, certain coating technologies still incorporate perfluorinated compounds (PFCs) which raise environmental concerns due to their persistence in ecosystems and potential bioaccumulation properties.

Life cycle assessment studies indicate that LCDs enhanced with superhydrophobic coatings demonstrate improved durability metrics, with displays maintaining optimal visibility for 30-40% longer periods under typical usage conditions. This extended operational lifespan directly contributes to sustainability by reducing replacement frequency and associated resource consumption. Additionally, the self-cleaning properties minimize water usage for maintenance, with estimates suggesting water savings of up to 80% compared to conventional cleaning requirements for display surfaces.

Energy efficiency represents another critical environmental consideration. Superhydrophobic coatings can enhance light transmission efficiency by up to 5-8% by maintaining cleaner surfaces with reduced particulate accumulation. This translates to lower power requirements for display backlighting systems, particularly in outdoor or industrial applications where displays operate at higher brightness levels to overcome ambient light interference.

End-of-life management presents both challenges and opportunities. While the coatings may complicate traditional LCD recycling processes, their contribution to extended product lifespans potentially offsets this concern. Research into biodegradable superhydrophobic formulations shows promising results, with several biomimetic approaches utilizing naturally-derived compounds that demonstrate reduced environmental persistence compared to synthetic alternatives.

Regulatory frameworks worldwide are increasingly addressing nanomaterials used in such coatings. The European Union's REACH regulations and similar initiatives in North America and Asia are establishing guidelines for the responsible manufacturing and disposal of products containing engineered nanoparticles, which are common components in advanced superhydrophobic systems. Manufacturers implementing these technologies must navigate evolving compliance requirements while balancing performance objectives with environmental responsibility.

The production of superhydrophobic coatings typically requires fewer toxic substances compared to conventional display protection technologies. Many advanced formulations utilize silica-based compounds or fluoropolymers that present reduced environmental hazards during manufacturing. However, certain coating technologies still incorporate perfluorinated compounds (PFCs) which raise environmental concerns due to their persistence in ecosystems and potential bioaccumulation properties.

Life cycle assessment studies indicate that LCDs enhanced with superhydrophobic coatings demonstrate improved durability metrics, with displays maintaining optimal visibility for 30-40% longer periods under typical usage conditions. This extended operational lifespan directly contributes to sustainability by reducing replacement frequency and associated resource consumption. Additionally, the self-cleaning properties minimize water usage for maintenance, with estimates suggesting water savings of up to 80% compared to conventional cleaning requirements for display surfaces.

Energy efficiency represents another critical environmental consideration. Superhydrophobic coatings can enhance light transmission efficiency by up to 5-8% by maintaining cleaner surfaces with reduced particulate accumulation. This translates to lower power requirements for display backlighting systems, particularly in outdoor or industrial applications where displays operate at higher brightness levels to overcome ambient light interference.

End-of-life management presents both challenges and opportunities. While the coatings may complicate traditional LCD recycling processes, their contribution to extended product lifespans potentially offsets this concern. Research into biodegradable superhydrophobic formulations shows promising results, with several biomimetic approaches utilizing naturally-derived compounds that demonstrate reduced environmental persistence compared to synthetic alternatives.

Regulatory frameworks worldwide are increasingly addressing nanomaterials used in such coatings. The European Union's REACH regulations and similar initiatives in North America and Asia are establishing guidelines for the responsible manufacturing and disposal of products containing engineered nanoparticles, which are common components in advanced superhydrophobic systems. Manufacturers implementing these technologies must navigate evolving compliance requirements while balancing performance objectives with environmental responsibility.

Manufacturing Process Integration and Scalability

The integration of superhydrophobic coating technology into LCD manufacturing processes presents significant challenges that require careful consideration for successful industrial implementation. Current LCD production lines utilize highly optimized processes that have evolved over decades, making any modification potentially disruptive to established workflows. Introducing superhydrophobic coating application requires strategic integration points that minimize disruption while maximizing performance benefits.

Several key integration approaches have emerged in recent research. The post-assembly application method involves applying the coating after the LCD panel is fully assembled, which offers minimal disruption to existing processes but may limit coating effectiveness in critical internal components. Alternatively, component-level treatment applies the coating to specific parts before assembly, allowing for more targeted protection but requiring additional handling steps and quality control measures.

The scalability of superhydrophobic coating technologies represents another crucial consideration. Laboratory-scale coating methods such as dip-coating and spray application have demonstrated excellent results but face challenges in uniformity and throughput when scaled to industrial production volumes. Recent advancements in roll-to-roll coating technologies show promise for continuous high-volume manufacturing, potentially achieving coating speeds of up to 120 meters per minute while maintaining nanoscale precision.

Material compatibility issues must also be addressed when integrating these coatings into LCD manufacturing. The chemical composition of superhydrophobic formulations must be carefully engineered to prevent adverse interactions with sensitive LCD components, particularly liquid crystal materials and polarizing films. Several manufacturers have developed specialized coating formulations that maintain superhydrophobic properties while ensuring compatibility with display materials.

Cost considerations remain a significant factor in widespread adoption. Current estimates indicate that superhydrophobic coating application adds approximately 3-7% to manufacturing costs, depending on the specific technology employed. However, this cost increase may be offset by reduced warranty claims and extended product lifespans. Economic modeling suggests that high-volume implementation could drive costs down to below 2% premium within three years of adoption.

Quality control and testing protocols require substantial modification to accommodate superhydrophobic coatings. New metrics for coating durability, optical transparency maintenance, and water-repellent performance must be integrated into existing quality assurance frameworks. Leading manufacturers have begun developing automated optical inspection systems specifically designed to verify coating uniformity and performance characteristics at production speeds.

Several key integration approaches have emerged in recent research. The post-assembly application method involves applying the coating after the LCD panel is fully assembled, which offers minimal disruption to existing processes but may limit coating effectiveness in critical internal components. Alternatively, component-level treatment applies the coating to specific parts before assembly, allowing for more targeted protection but requiring additional handling steps and quality control measures.

The scalability of superhydrophobic coating technologies represents another crucial consideration. Laboratory-scale coating methods such as dip-coating and spray application have demonstrated excellent results but face challenges in uniformity and throughput when scaled to industrial production volumes. Recent advancements in roll-to-roll coating technologies show promise for continuous high-volume manufacturing, potentially achieving coating speeds of up to 120 meters per minute while maintaining nanoscale precision.

Material compatibility issues must also be addressed when integrating these coatings into LCD manufacturing. The chemical composition of superhydrophobic formulations must be carefully engineered to prevent adverse interactions with sensitive LCD components, particularly liquid crystal materials and polarizing films. Several manufacturers have developed specialized coating formulations that maintain superhydrophobic properties while ensuring compatibility with display materials.

Cost considerations remain a significant factor in widespread adoption. Current estimates indicate that superhydrophobic coating application adds approximately 3-7% to manufacturing costs, depending on the specific technology employed. However, this cost increase may be offset by reduced warranty claims and extended product lifespans. Economic modeling suggests that high-volume implementation could drive costs down to below 2% premium within three years of adoption.

Quality control and testing protocols require substantial modification to accommodate superhydrophobic coatings. New metrics for coating durability, optical transparency maintenance, and water-repellent performance must be integrated into existing quality assurance frameworks. Leading manufacturers have begun developing automated optical inspection systems specifically designed to verify coating uniformity and performance characteristics at production speeds.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!