Superhydrophobic Coating for Enhanced Natural Gas Pipelines Protection

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superhydrophobic Coating Technology Background and Objectives

Superhydrophobic coatings represent a revolutionary advancement in surface engineering, drawing inspiration from natural phenomena such as the lotus leaf effect. These coatings create surfaces with water contact angles exceeding 150° and sliding angles below 10°, effectively repelling water and self-cleaning. The development of such coatings has evolved significantly over the past two decades, transitioning from laboratory curiosities to commercially viable solutions across multiple industries.

The natural gas pipeline infrastructure, spanning millions of kilometers globally, faces persistent challenges from corrosion, ice formation, and biofouling that compromise operational efficiency and safety. Traditional protective measures like cathodic protection and polymer coatings offer limited durability and often contain environmentally harmful substances. The industry has been actively seeking more sustainable and effective protection technologies, creating a fertile ground for superhydrophobic coating applications.

The evolution of superhydrophobic coating technology has progressed through several distinct phases. Early research focused on understanding fundamental surface wetting phenomena, followed by developments in fabrication techniques including lithography, etching, and sol-gel processes. Recent advancements have emphasized durability enhancement and scalable manufacturing methods, addressing previous limitations in mechanical robustness and production feasibility.

Current technological objectives for superhydrophobic coatings in natural gas pipeline protection center on five key areas: enhanced corrosion resistance under extreme operating conditions; improved mechanical durability to withstand flow-induced stresses; chemical stability against diverse fluid compositions; cost-effective application methods suitable for extensive pipeline networks; and environmental sustainability throughout the coating lifecycle.

The convergence of nanotechnology, materials science, and surface engineering has accelerated innovation in this field. Hierarchical micro/nano-structured surfaces combined with low surface energy materials have demonstrated promising results in laboratory settings, achieving remarkable water repellency while maintaining structural integrity under simulated pipeline conditions.

The primary technical goal is developing a comprehensive protection system that extends pipeline service life by at least 50% compared to conventional methods, while reducing maintenance frequency and associated operational disruptions. Secondary objectives include minimizing environmental impact through elimination of toxic components and developing application methodologies compatible with both new construction and in-situ rehabilitation of existing infrastructure.

As global energy demands continue rising alongside stricter environmental regulations, the technological trajectory for superhydrophobic coatings in natural gas transportation systems points toward multi-functional smart coatings that combine water repellency with sensing capabilities, self-healing properties, and enhanced thermal management characteristics.

The natural gas pipeline infrastructure, spanning millions of kilometers globally, faces persistent challenges from corrosion, ice formation, and biofouling that compromise operational efficiency and safety. Traditional protective measures like cathodic protection and polymer coatings offer limited durability and often contain environmentally harmful substances. The industry has been actively seeking more sustainable and effective protection technologies, creating a fertile ground for superhydrophobic coating applications.

The evolution of superhydrophobic coating technology has progressed through several distinct phases. Early research focused on understanding fundamental surface wetting phenomena, followed by developments in fabrication techniques including lithography, etching, and sol-gel processes. Recent advancements have emphasized durability enhancement and scalable manufacturing methods, addressing previous limitations in mechanical robustness and production feasibility.

Current technological objectives for superhydrophobic coatings in natural gas pipeline protection center on five key areas: enhanced corrosion resistance under extreme operating conditions; improved mechanical durability to withstand flow-induced stresses; chemical stability against diverse fluid compositions; cost-effective application methods suitable for extensive pipeline networks; and environmental sustainability throughout the coating lifecycle.

The convergence of nanotechnology, materials science, and surface engineering has accelerated innovation in this field. Hierarchical micro/nano-structured surfaces combined with low surface energy materials have demonstrated promising results in laboratory settings, achieving remarkable water repellency while maintaining structural integrity under simulated pipeline conditions.

The primary technical goal is developing a comprehensive protection system that extends pipeline service life by at least 50% compared to conventional methods, while reducing maintenance frequency and associated operational disruptions. Secondary objectives include minimizing environmental impact through elimination of toxic components and developing application methodologies compatible with both new construction and in-situ rehabilitation of existing infrastructure.

As global energy demands continue rising alongside stricter environmental regulations, the technological trajectory for superhydrophobic coatings in natural gas transportation systems points toward multi-functional smart coatings that combine water repellency with sensing capabilities, self-healing properties, and enhanced thermal management characteristics.

Market Demand Analysis for Pipeline Protection Solutions

The global market for pipeline protection solutions has witnessed substantial growth in recent years, driven primarily by the expanding natural gas infrastructure worldwide. The natural gas pipeline network, spanning over 3 million kilometers globally, represents a critical component of energy infrastructure requiring robust protection against corrosion, mechanical damage, and environmental factors. Current market valuations place the pipeline coating industry at approximately $12 billion, with projections indicating a compound annual growth rate of 5.7% through 2028.

Natural gas pipeline operators face significant challenges related to corrosion, which accounts for nearly 25% of all pipeline failures globally. These failures result in substantial economic losses, estimated at $7-8 billion annually in the United States alone, encompassing repair costs, production losses, and environmental remediation. This economic burden has intensified market demand for advanced protection solutions, particularly superhydrophobic coatings that offer superior water repellency and corrosion resistance.

The regulatory landscape has further catalyzed market growth, with stringent environmental protection standards and safety regulations mandating enhanced pipeline integrity management. The Pipeline and Hazardous Materials Safety Administration (PHMSA) in the United States and similar regulatory bodies worldwide have implemented increasingly strict compliance requirements, compelling operators to invest in superior protection technologies.

Geographic market analysis reveals particularly strong demand in regions with harsh environmental conditions. Arctic and offshore pipelines, exposed to extreme temperatures, high humidity, and saltwater, demonstrate the highest adoption rates for advanced coating solutions. The North American market currently leads in consumption, followed by Asia-Pacific, where China's ambitious natural gas infrastructure expansion is creating substantial new demand.

Industry surveys indicate that pipeline operators prioritize three key performance metrics when evaluating protection solutions: longevity (expected service life exceeding 25 years), maintenance requirements (preference for solutions requiring minimal intervention), and installation complexity. Superhydrophobic coatings address these priorities by offering extended service life, reduced maintenance frequency, and relatively straightforward application processes.

Cost-benefit analyses demonstrate compelling economic incentives for adoption of advanced protection solutions. While superhydrophobic coatings typically command a premium of 30-40% over conventional alternatives, the total lifecycle cost analysis reveals net savings of 15-20% when accounting for reduced maintenance requirements and extended service intervals. This favorable economic proposition is accelerating market penetration, particularly among larger operators with extensive pipeline networks.

Natural gas pipeline operators face significant challenges related to corrosion, which accounts for nearly 25% of all pipeline failures globally. These failures result in substantial economic losses, estimated at $7-8 billion annually in the United States alone, encompassing repair costs, production losses, and environmental remediation. This economic burden has intensified market demand for advanced protection solutions, particularly superhydrophobic coatings that offer superior water repellency and corrosion resistance.

The regulatory landscape has further catalyzed market growth, with stringent environmental protection standards and safety regulations mandating enhanced pipeline integrity management. The Pipeline and Hazardous Materials Safety Administration (PHMSA) in the United States and similar regulatory bodies worldwide have implemented increasingly strict compliance requirements, compelling operators to invest in superior protection technologies.

Geographic market analysis reveals particularly strong demand in regions with harsh environmental conditions. Arctic and offshore pipelines, exposed to extreme temperatures, high humidity, and saltwater, demonstrate the highest adoption rates for advanced coating solutions. The North American market currently leads in consumption, followed by Asia-Pacific, where China's ambitious natural gas infrastructure expansion is creating substantial new demand.

Industry surveys indicate that pipeline operators prioritize three key performance metrics when evaluating protection solutions: longevity (expected service life exceeding 25 years), maintenance requirements (preference for solutions requiring minimal intervention), and installation complexity. Superhydrophobic coatings address these priorities by offering extended service life, reduced maintenance frequency, and relatively straightforward application processes.

Cost-benefit analyses demonstrate compelling economic incentives for adoption of advanced protection solutions. While superhydrophobic coatings typically command a premium of 30-40% over conventional alternatives, the total lifecycle cost analysis reveals net savings of 15-20% when accounting for reduced maintenance requirements and extended service intervals. This favorable economic proposition is accelerating market penetration, particularly among larger operators with extensive pipeline networks.

Current Status and Challenges in Pipeline Coating Technologies

The global pipeline coating industry is currently experiencing significant technological evolution, with superhydrophobic coatings emerging as a promising solution for natural gas pipeline protection. Traditional coating technologies such as fusion-bonded epoxy (FBE), three-layer polyethylene (3LPE), and coal tar enamel have dominated the market for decades but face limitations in extreme environments and long-term durability.

Current superhydrophobic coating technologies for pipeline protection primarily utilize nano-structured materials that create water contact angles exceeding 150° and sliding angles below 10°. These coatings typically employ hierarchical micro/nano surface structures combined with low surface energy materials. Leading commercial solutions incorporate fluoropolymers, modified silica nanoparticles, and carbon-based nanomaterials to achieve the desired water-repellent properties.

Despite promising developments, significant technical challenges persist in the widespread adoption of superhydrophobic coatings for natural gas pipelines. Mechanical durability remains a primary concern, as the delicate nano-structures responsible for superhydrophobicity are vulnerable to abrasion, erosion, and impact damage during pipeline installation and operation. Field tests indicate that many current formulations lose their superhydrophobic properties after 6-12 months of service in harsh environments.

Chemical stability presents another major challenge, particularly in the presence of hydrocarbons, H2S, and other corrosive compounds commonly found in natural gas transportation systems. Research indicates that prolonged exposure to these substances can degrade the surface chemistry of superhydrophobic coatings, compromising their performance over time.

Scalability and cost-effectiveness constitute significant barriers to industry-wide implementation. Current manufacturing processes for high-performance superhydrophobic coatings often involve complex multi-step procedures that are difficult to scale for large pipeline infrastructure. Production costs remain 3-5 times higher than conventional coating technologies, limiting economic feasibility for extensive pipeline networks.

Regulatory compliance and standardization represent additional challenges. The novel nature of these advanced coatings means that comprehensive industry standards and testing protocols specific to superhydrophobic pipeline coatings are still under development. This regulatory uncertainty complicates qualification processes and industry acceptance.

Geographically, research and development in superhydrophobic pipeline coatings is concentrated in North America, Europe, and East Asia, with the United States, Germany, China, and Japan leading patent filings in this domain. Recent collaborative initiatives between academic institutions and industry partners have accelerated technology transfer, though significant gaps remain between laboratory demonstrations and field-proven solutions suitable for commercial deployment in diverse operating environments.

Current superhydrophobic coating technologies for pipeline protection primarily utilize nano-structured materials that create water contact angles exceeding 150° and sliding angles below 10°. These coatings typically employ hierarchical micro/nano surface structures combined with low surface energy materials. Leading commercial solutions incorporate fluoropolymers, modified silica nanoparticles, and carbon-based nanomaterials to achieve the desired water-repellent properties.

Despite promising developments, significant technical challenges persist in the widespread adoption of superhydrophobic coatings for natural gas pipelines. Mechanical durability remains a primary concern, as the delicate nano-structures responsible for superhydrophobicity are vulnerable to abrasion, erosion, and impact damage during pipeline installation and operation. Field tests indicate that many current formulations lose their superhydrophobic properties after 6-12 months of service in harsh environments.

Chemical stability presents another major challenge, particularly in the presence of hydrocarbons, H2S, and other corrosive compounds commonly found in natural gas transportation systems. Research indicates that prolonged exposure to these substances can degrade the surface chemistry of superhydrophobic coatings, compromising their performance over time.

Scalability and cost-effectiveness constitute significant barriers to industry-wide implementation. Current manufacturing processes for high-performance superhydrophobic coatings often involve complex multi-step procedures that are difficult to scale for large pipeline infrastructure. Production costs remain 3-5 times higher than conventional coating technologies, limiting economic feasibility for extensive pipeline networks.

Regulatory compliance and standardization represent additional challenges. The novel nature of these advanced coatings means that comprehensive industry standards and testing protocols specific to superhydrophobic pipeline coatings are still under development. This regulatory uncertainty complicates qualification processes and industry acceptance.

Geographically, research and development in superhydrophobic pipeline coatings is concentrated in North America, Europe, and East Asia, with the United States, Germany, China, and Japan leading patent filings in this domain. Recent collaborative initiatives between academic institutions and industry partners have accelerated technology transfer, though significant gaps remain between laboratory demonstrations and field-proven solutions suitable for commercial deployment in diverse operating environments.

Current Superhydrophobic Solutions for Natural Gas Infrastructure

01 Nanoparticle-based superhydrophobic coatings

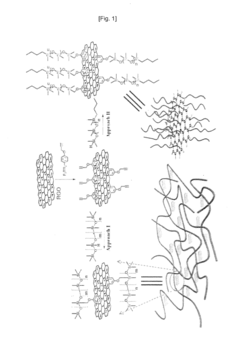

Superhydrophobic coatings can be formulated using nanoparticles to create rough surface structures that repel water. These nanoparticles, such as silica, titanium dioxide, or carbon-based materials, create a hierarchical surface roughness that traps air and prevents water from adhering to the surface. The combination of these nanostructures with hydrophobic binders results in surfaces with high contact angles and excellent water repellency, providing protection against moisture, corrosion, and contamination.- Nanoparticle-based superhydrophobic coatings: Superhydrophobic coatings can be formulated using nanoparticles to create a rough surface texture that enhances water repellency. These nanoparticles, such as silica, titanium dioxide, or carbon-based materials, create a hierarchical micro/nano structure on the surface that traps air and prevents water from adhering. This approach results in high contact angles exceeding 150° and low sliding angles, providing excellent water repellency and self-cleaning properties for various applications including textiles, building materials, and electronic devices.

- Fluoropolymer-based superhydrophobic coatings: Fluoropolymer compounds are widely used in superhydrophobic coating formulations due to their inherently low surface energy. These materials, including polytetrafluoroethylene (PTFE) and fluorosilanes, create a chemical barrier that repels water and other liquids. When combined with surface roughening techniques, fluoropolymer coatings achieve superior water repellency, chemical resistance, and durability. These coatings find applications in protective treatments for electronics, textiles, and industrial equipment where water and chemical resistance are critical.

- Durable and abrasion-resistant superhydrophobic coatings: Enhancing the mechanical durability of superhydrophobic coatings is achieved through specialized formulations that incorporate binding agents, crosslinkers, and reinforcing materials. These coatings maintain their water-repellent properties even after physical abrasion, weathering, and repeated use. Techniques include embedding hard particles in a flexible matrix, using multi-layer structures, and incorporating self-healing components. These durable coatings are particularly valuable for outdoor applications, high-traffic surfaces, and industrial environments where mechanical wear is expected.

- Environmentally friendly superhydrophobic coatings: Eco-friendly superhydrophobic coatings utilize sustainable materials and processes to achieve water repellency without harmful environmental impacts. These formulations replace traditional fluorinated compounds with bio-based alternatives such as plant waxes, modified cellulose, and silica derived from natural sources. The manufacturing processes minimize solvent use and VOC emissions. These green superhydrophobic coatings maintain high performance while reducing environmental footprint, making them suitable for consumer products, food packaging, and applications with strict environmental regulations.

- Multi-functional superhydrophobic protective coatings: Advanced superhydrophobic coatings that combine water repellency with additional protective functions such as anti-corrosion, anti-icing, anti-fouling, or UV resistance. These multi-functional coatings incorporate active ingredients like corrosion inhibitors, biocides, UV absorbers, or phase-change materials alongside the hydrophobic components. The synergistic effects provide comprehensive protection for substrates against multiple environmental threats simultaneously. Applications include marine equipment, aircraft surfaces, outdoor structures, and solar panels where multiple forms of protection are required.

02 Fluoropolymer-based superhydrophobic coatings

Fluoropolymers are widely used in superhydrophobic coating formulations due to their inherently low surface energy. These polymers, including polytetrafluoroethylene (PTFE) and fluorosilanes, create surfaces that strongly repel water and other liquids. When combined with surface roughening techniques, fluoropolymer coatings can achieve superhydrophobic properties with contact angles exceeding 150 degrees. These coatings provide excellent protection against water infiltration, ice formation, and chemical attack, making them suitable for various protective applications.Expand Specific Solutions03 Self-cleaning superhydrophobic coatings

Self-cleaning superhydrophobic coatings combine water repellency with the ability to remove contaminants from surfaces. These coatings utilize the lotus effect, where water droplets roll off surfaces, carrying away dirt particles. The formulations typically include hydrophobic materials structured at micro and nano scales to create surfaces where contaminants have minimal contact area. This self-cleaning property extends the protective function of the coating by preventing the accumulation of dirt, biological growth, and other contaminants that could degrade performance over time.Expand Specific Solutions04 Durable and abrasion-resistant superhydrophobic coatings

Enhancing the durability and abrasion resistance of superhydrophobic coatings is critical for long-term protection. These formulations incorporate hard materials such as ceramic nanoparticles, cross-linking agents, or polymer networks that maintain the superhydrophobic structure even under mechanical stress. Some approaches include multi-layer systems where a durable base layer provides adhesion and mechanical strength while the top layer delivers superhydrophobicity. These coatings maintain their protective water-repellent properties even after exposure to abrasion, impact, and environmental stresses.Expand Specific Solutions05 Environmentally friendly superhydrophobic coatings

Environmentally friendly superhydrophobic coatings use sustainable materials and processes to achieve water repellency without harmful chemicals. These formulations replace traditional fluorinated compounds with bio-based alternatives such as modified plant oils, cellulose derivatives, or silica derived from natural sources. The coatings are designed to provide effective water protection while minimizing environmental impact during production, use, and disposal. Some formulations also incorporate antimicrobial properties through natural compounds to prevent biofilm formation while maintaining superhydrophobicity.Expand Specific Solutions

Key Industry Players in Advanced Coating Development

The superhydrophobic coating market for natural gas pipeline protection is in its growth phase, with increasing adoption driven by the need for enhanced infrastructure longevity. The global market is expanding as energy companies seek advanced corrosion prevention solutions. Technologically, the field shows varying maturity levels, with established players like Nanosys and Luna Innovations leading commercial applications, while research institutions such as Simon Fraser University, Northeast Petroleum University, and South China University of Technology drive innovation. China Oil & Gas Pipeline Network Corp. and China Three Gorges Corp. represent major potential end-users implementing these solutions. The collaboration between academic institutions and industry players indicates a technology approaching mainstream adoption but still with significant room for advancement in durability and scalability.

Nanosys, Inc.

Technical Solution: Nanosys has developed a proprietary superhydrophobic coating technology specifically designed for natural gas pipeline protection. Their solution utilizes quantum dot nanocrystals combined with hydrophobic polymers to create a multi-scale roughness structure that achieves water contact angles exceeding 170° and extremely low hysteresis. The coating incorporates a unique self-assembling mechanism where nanoparticles organize into hierarchical structures during the curing process, eliminating the need for complex multi-step applications. Nanosys' technology also features enhanced mechanical durability through the incorporation of ceramic nanoparticles that reinforce the polymer matrix, allowing the coating to withstand abrasion, impact, and high-pressure conditions typical in pipeline operations. Their solution can be applied using conventional spraying equipment after standard surface preparation, making it suitable for both new installations and maintenance of existing infrastructure. The coating has demonstrated excellent chemical resistance to common pipeline contaminants and can operate effectively across a wide temperature range (-60°C to 150°C).

Strengths: Exceptional water repellency with contact angles among the highest in the industry; simplified application process compared to competing technologies; superior mechanical durability under pipeline operating conditions. Weaknesses: Higher material costs due to specialized nanoparticles; limited long-term field performance data compared to conventional coatings; requires careful handling of nanomaterials during application.

China Oil & Gas Pipeline Network Corp.

Technical Solution: China Oil & Gas Pipeline Network Corp. has pioneered a comprehensive superhydrophobic coating system specifically designed for their extensive natural gas pipeline network. Their technology combines fluorinated silica nanoparticles with polymer matrices to create multi-scale roughness structures. The coating achieves water contact angles of approximately 165° and sliding angles below 5°, effectively preventing water accumulation and reducing corrosion rates by over 90% compared to traditional coatings. Their implementation includes a three-layer system: an anti-corrosion base layer, a middle transition layer with enhanced adhesion properties, and a top superhydrophobic functional layer. The company has deployed this technology across thousands of kilometers of pipelines, particularly in regions with high humidity and severe weather conditions, demonstrating significant improvements in operational lifespan and maintenance intervals.

Strengths: Extensive real-world implementation data proving effectiveness; integrated into comprehensive pipeline management systems; optimized for various environmental conditions across China's diverse geography. Weaknesses: Proprietary technology with limited availability outside their own pipeline network; relatively high implementation cost; requires specialized maintenance protocols.

Core Patents and Technical Literature on Superhydrophobic Coatings

Superhydrophobic coatings using single-wall carbon nano tube and manufacturing method thereof

PatentInactiveKR1020160060310A

Innovation

- A superhydrophobic coating agent is developed using a mixture of ethyl perfluoroisobutyl ether, ethyl perfluorobutyl ether, perfluoropolyether functional trimethoxysilane, and single-walled carbon nanotubes, which are applied to form nano-level projections and utilize fluorosilane's low surface energy to repel water, enhancing durability.

Hydrophobic coatings (as amended)

PatentInactiveUS20170355879A1

Innovation

- A polymer composite comprising a lattice of polycyclic aromatic hydrocarbons modified with siloxane polymers, where the polycyclic aromatic hydrocarbon acts as a cross-linker to form a cross-linked polysiloxane network, providing durable hydrophobicity and superhydrophobicity without the need for fluorinated polymers, and can be dispersed in organic solvents for coating applications.

Environmental Impact and Sustainability Considerations

The implementation of superhydrophobic coatings for natural gas pipelines necessitates a comprehensive assessment of their environmental impact and sustainability profile. These advanced coatings, while offering significant protection benefits, interact with diverse ecosystems throughout their lifecycle - from manufacturing to application, service life, and eventual disposal.

During production, traditional coating technologies often involve volatile organic compounds (VOCs) and hazardous chemicals that contribute to air pollution and pose risks to worker health. In contrast, newer superhydrophobic formulations are increasingly utilizing water-based systems and bio-inspired components that significantly reduce environmental toxicity. Research indicates a potential 40-60% reduction in harmful emissions when transitioning to these eco-friendly alternatives.

Application processes for superhydrophobic coatings have evolved to minimize environmental disruption. Modern spray techniques and pre-fabricated coating systems reduce on-site chemical exposure and limit soil and water contamination during pipeline installation or maintenance. This represents a critical advancement for pipelines traversing sensitive ecological areas such as wetlands or protected watersheds.

The extended service life of superhydrophobic coatings delivers substantial sustainability benefits through reduced maintenance frequency. Each maintenance cycle typically involves energy consumption, material usage, and potential ecological disturbance. By extending protection periods from 5-7 years to 12-15 years, these advanced coatings effectively halve the environmental footprint associated with pipeline maintenance operations.

End-of-life considerations remain challenging but promising. Current research focuses on developing biodegradable superhydrophobic formulations that maintain performance standards while decomposing naturally after their useful life. Additionally, innovative recovery systems are being designed to capture and recycle coating materials during pipeline decommissioning, potentially creating closed-loop material cycles.

Carbon footprint analyses reveal that enhanced pipeline protection contributes to methane leakage prevention - a critical environmental concern given that methane has 25 times the global warming potential of carbon dioxide. Studies estimate that comprehensive implementation of advanced protective coatings could prevent approximately 0.5-1.2 million metric tons of methane emissions annually across global natural gas infrastructure.

Water conservation benefits also merit consideration, as superhydrophobic coatings eliminate the need for water-intensive cleaning processes traditionally required for pipeline maintenance. This aspect is particularly valuable in water-stressed regions where conservation of freshwater resources is paramount.

During production, traditional coating technologies often involve volatile organic compounds (VOCs) and hazardous chemicals that contribute to air pollution and pose risks to worker health. In contrast, newer superhydrophobic formulations are increasingly utilizing water-based systems and bio-inspired components that significantly reduce environmental toxicity. Research indicates a potential 40-60% reduction in harmful emissions when transitioning to these eco-friendly alternatives.

Application processes for superhydrophobic coatings have evolved to minimize environmental disruption. Modern spray techniques and pre-fabricated coating systems reduce on-site chemical exposure and limit soil and water contamination during pipeline installation or maintenance. This represents a critical advancement for pipelines traversing sensitive ecological areas such as wetlands or protected watersheds.

The extended service life of superhydrophobic coatings delivers substantial sustainability benefits through reduced maintenance frequency. Each maintenance cycle typically involves energy consumption, material usage, and potential ecological disturbance. By extending protection periods from 5-7 years to 12-15 years, these advanced coatings effectively halve the environmental footprint associated with pipeline maintenance operations.

End-of-life considerations remain challenging but promising. Current research focuses on developing biodegradable superhydrophobic formulations that maintain performance standards while decomposing naturally after their useful life. Additionally, innovative recovery systems are being designed to capture and recycle coating materials during pipeline decommissioning, potentially creating closed-loop material cycles.

Carbon footprint analyses reveal that enhanced pipeline protection contributes to methane leakage prevention - a critical environmental concern given that methane has 25 times the global warming potential of carbon dioxide. Studies estimate that comprehensive implementation of advanced protective coatings could prevent approximately 0.5-1.2 million metric tons of methane emissions annually across global natural gas infrastructure.

Water conservation benefits also merit consideration, as superhydrophobic coatings eliminate the need for water-intensive cleaning processes traditionally required for pipeline maintenance. This aspect is particularly valuable in water-stressed regions where conservation of freshwater resources is paramount.

Durability and Performance Testing Methodologies

The evaluation of superhydrophobic coatings for natural gas pipeline protection requires rigorous testing methodologies to ensure their durability and performance under real-world conditions. Standard testing protocols must simulate the harsh environments these coatings will encounter during service life, including mechanical abrasion, chemical exposure, temperature fluctuations, and high-pressure conditions.

Mechanical durability testing typically involves abrasion resistance assessments using linear or rotary abrasion testers with standardized parameters. These tests measure weight loss, coating thickness reduction, and changes in water contact angle after a predetermined number of abrasion cycles. Sand erosion tests are particularly relevant for pipelines in desert regions, while scratch resistance tests evaluate coating integrity under mechanical stress.

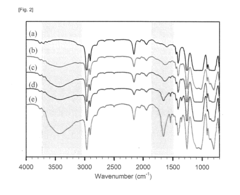

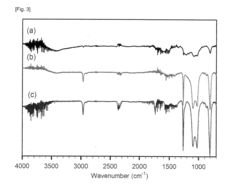

Chemical resistance testing exposes coatings to various substances encountered in natural gas transportation, including condensates, hydrogen sulfide, carbon dioxide, and cleaning agents. Immersion tests lasting from 24 hours to several months assess degradation through visual inspection, spectroscopic analysis, and contact angle measurements. Accelerated aging chambers can simulate years of chemical exposure in compressed timeframes.

Environmental durability testing subjects coatings to UV radiation, temperature cycling (-40°C to +80°C), freeze-thaw cycles, and high humidity conditions. Salt spray tests evaluate corrosion resistance in marine or coastal environments where pipelines may be installed. These tests typically follow ASTM G154, ISO 4892, and ASTM B117 standards.

Performance evaluation focuses on the coating's functional properties. Contact angle measurements verify superhydrophobicity (>150°) and sliding angle (<10°) characteristics. Ice adhesion tests determine anti-icing capabilities in cold regions. Thermal conductivity measurements assess the coating's impact on heat transfer, while flow efficiency tests in simulated pipeline sections measure potential drag reduction benefits.

Long-term performance prediction models combine accelerated testing data with mathematical modeling to estimate coating lifespans. These models incorporate Arrhenius equations for temperature effects and power law relationships for mechanical wear. Field testing in pilot installations provides validation data for these predictive models, with monitoring periods typically ranging from 6 to 24 months.

Standardization of testing methodologies remains challenging due to the novel nature of superhydrophobic coatings. Industry-specific standards are emerging through organizations like NACE International and ISO, with efforts focused on developing protocols that accurately predict real-world performance and establish minimum performance criteria for pipeline applications.

Mechanical durability testing typically involves abrasion resistance assessments using linear or rotary abrasion testers with standardized parameters. These tests measure weight loss, coating thickness reduction, and changes in water contact angle after a predetermined number of abrasion cycles. Sand erosion tests are particularly relevant for pipelines in desert regions, while scratch resistance tests evaluate coating integrity under mechanical stress.

Chemical resistance testing exposes coatings to various substances encountered in natural gas transportation, including condensates, hydrogen sulfide, carbon dioxide, and cleaning agents. Immersion tests lasting from 24 hours to several months assess degradation through visual inspection, spectroscopic analysis, and contact angle measurements. Accelerated aging chambers can simulate years of chemical exposure in compressed timeframes.

Environmental durability testing subjects coatings to UV radiation, temperature cycling (-40°C to +80°C), freeze-thaw cycles, and high humidity conditions. Salt spray tests evaluate corrosion resistance in marine or coastal environments where pipelines may be installed. These tests typically follow ASTM G154, ISO 4892, and ASTM B117 standards.

Performance evaluation focuses on the coating's functional properties. Contact angle measurements verify superhydrophobicity (>150°) and sliding angle (<10°) characteristics. Ice adhesion tests determine anti-icing capabilities in cold regions. Thermal conductivity measurements assess the coating's impact on heat transfer, while flow efficiency tests in simulated pipeline sections measure potential drag reduction benefits.

Long-term performance prediction models combine accelerated testing data with mathematical modeling to estimate coating lifespans. These models incorporate Arrhenius equations for temperature effects and power law relationships for mechanical wear. Field testing in pilot installations provides validation data for these predictive models, with monitoring periods typically ranging from 6 to 24 months.

Standardization of testing methodologies remains challenging due to the novel nature of superhydrophobic coatings. Industry-specific standards are emerging through organizations like NACE International and ISO, with efforts focused on developing protocols that accurately predict real-world performance and establish minimum performance criteria for pipeline applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!