Regulatory Framework for Superhydrophobic Coating in Food Contact Safety

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superhydrophobic Coating Technology Background and Objectives

Superhydrophobic coatings represent a revolutionary advancement in surface engineering, characterized by their exceptional water-repellent properties with contact angles exceeding 150° and sliding angles below 10°. These coatings draw inspiration from natural phenomena such as the lotus leaf effect, where microscopic surface structures combined with low surface energy materials create self-cleaning surfaces. Since their initial development in the early 1990s, superhydrophobic coatings have evolved from laboratory curiosities to commercially viable solutions across multiple industries.

The technological evolution of superhydrophobic coatings has progressed through several distinct phases. Early research focused primarily on understanding the fundamental principles of superhydrophobicity, followed by the development of fabrication techniques including lithography, sol-gel processes, layer-by-layer assembly, and electrospinning. Recent advancements have concentrated on enhancing durability, transparency, and scalability of these coatings for practical applications.

In the context of food contact applications, superhydrophobic coatings present unique opportunities for improving food packaging, processing equipment, and storage containers. These coatings can potentially reduce food adhesion, minimize bacterial contamination, decrease cleaning requirements, and extend equipment lifespan. However, their application in food contact scenarios introduces specific technical challenges related to durability under mechanical abrasion, chemical stability in the presence of food substances, and most critically, safety considerations.

The primary objective of this technical research is to comprehensively analyze the regulatory framework governing superhydrophobic coatings in food contact applications. This includes identifying existing regulations across major jurisdictions, evaluating current testing methodologies for safety assessment, and determining regulatory gaps that may impede market adoption. Additionally, the research aims to establish a clear understanding of migration potential, toxicological considerations, and long-term stability requirements specific to superhydrophobic surfaces in food environments.

Current technological trends indicate a shift toward developing "green" superhydrophobic coatings using non-toxic, biodegradable materials to address regulatory concerns. Simultaneously, there is growing interest in creating multi-functional superhydrophobic surfaces that combine water repellency with additional properties such as antimicrobial activity, antifouling capabilities, and self-healing characteristics, all while maintaining compliance with food safety regulations.

The ultimate goal is to establish a clear technological roadmap that aligns innovative superhydrophobic coating development with regulatory requirements, enabling their safe and effective implementation in food contact applications. This requires balancing technological advancement with stringent safety standards to ensure consumer protection while unlocking the significant potential benefits these coatings offer to the food industry.

The technological evolution of superhydrophobic coatings has progressed through several distinct phases. Early research focused primarily on understanding the fundamental principles of superhydrophobicity, followed by the development of fabrication techniques including lithography, sol-gel processes, layer-by-layer assembly, and electrospinning. Recent advancements have concentrated on enhancing durability, transparency, and scalability of these coatings for practical applications.

In the context of food contact applications, superhydrophobic coatings present unique opportunities for improving food packaging, processing equipment, and storage containers. These coatings can potentially reduce food adhesion, minimize bacterial contamination, decrease cleaning requirements, and extend equipment lifespan. However, their application in food contact scenarios introduces specific technical challenges related to durability under mechanical abrasion, chemical stability in the presence of food substances, and most critically, safety considerations.

The primary objective of this technical research is to comprehensively analyze the regulatory framework governing superhydrophobic coatings in food contact applications. This includes identifying existing regulations across major jurisdictions, evaluating current testing methodologies for safety assessment, and determining regulatory gaps that may impede market adoption. Additionally, the research aims to establish a clear understanding of migration potential, toxicological considerations, and long-term stability requirements specific to superhydrophobic surfaces in food environments.

Current technological trends indicate a shift toward developing "green" superhydrophobic coatings using non-toxic, biodegradable materials to address regulatory concerns. Simultaneously, there is growing interest in creating multi-functional superhydrophobic surfaces that combine water repellency with additional properties such as antimicrobial activity, antifouling capabilities, and self-healing characteristics, all while maintaining compliance with food safety regulations.

The ultimate goal is to establish a clear technological roadmap that aligns innovative superhydrophobic coating development with regulatory requirements, enabling their safe and effective implementation in food contact applications. This requires balancing technological advancement with stringent safety standards to ensure consumer protection while unlocking the significant potential benefits these coatings offer to the food industry.

Food Contact Materials Market Analysis

The global food contact materials (FCM) market has been experiencing steady growth, driven by increasing consumer demand for packaged food products and heightened awareness of food safety. Currently valued at approximately 109.7 billion USD in 2023, the market is projected to reach 142.3 billion USD by 2028, representing a compound annual growth rate (CAGR) of 5.3%. This growth trajectory is particularly significant for innovative technologies like superhydrophobic coatings, which are positioned to capture a specialized segment within this expanding market.

The food packaging sector dominates the FCM market, accounting for nearly 65% of the total market share. Within this sector, there is a growing demand for advanced functional coatings that can enhance food preservation while ensuring safety. Superhydrophobic coatings, with their water and oil repellent properties, address key market needs including extended shelf life, reduced food waste, and improved consumer experience through non-stick properties.

Regional analysis reveals that North America and Europe currently lead the market for advanced food contact materials, collectively holding approximately 58% of the global market share. These regions have established stringent regulatory frameworks for food contact safety, which simultaneously creates barriers to entry and opportunities for compliant innovative solutions. The Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate at 7.2% annually, driven by rapid urbanization, changing dietary habits, and increasing disposable income.

Consumer trends significantly influence the FCM market dynamics. There is a marked shift toward sustainable and environmentally friendly packaging solutions, with 73% of consumers expressing willingness to pay premium prices for products with eco-friendly packaging. This trend aligns favorably with water-based superhydrophobic coatings that offer reduced environmental impact compared to traditional chemical treatments.

The competitive landscape features both established players in traditional food packaging and emerging companies specializing in advanced coating technologies. Major food packaging corporations are increasingly investing in R&D partnerships to incorporate novel coating technologies into their product portfolios, with R&D expenditure in this sector increasing by 12% over the past three years.

Market challenges include price sensitivity, particularly in emerging economies, and the need for extensive education about the benefits and safety of novel coating technologies. Additionally, the regulatory approval process represents a significant market entry barrier, with development-to-market timelines averaging 2-3 years for new coating technologies in food contact applications.

The food packaging sector dominates the FCM market, accounting for nearly 65% of the total market share. Within this sector, there is a growing demand for advanced functional coatings that can enhance food preservation while ensuring safety. Superhydrophobic coatings, with their water and oil repellent properties, address key market needs including extended shelf life, reduced food waste, and improved consumer experience through non-stick properties.

Regional analysis reveals that North America and Europe currently lead the market for advanced food contact materials, collectively holding approximately 58% of the global market share. These regions have established stringent regulatory frameworks for food contact safety, which simultaneously creates barriers to entry and opportunities for compliant innovative solutions. The Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate at 7.2% annually, driven by rapid urbanization, changing dietary habits, and increasing disposable income.

Consumer trends significantly influence the FCM market dynamics. There is a marked shift toward sustainable and environmentally friendly packaging solutions, with 73% of consumers expressing willingness to pay premium prices for products with eco-friendly packaging. This trend aligns favorably with water-based superhydrophobic coatings that offer reduced environmental impact compared to traditional chemical treatments.

The competitive landscape features both established players in traditional food packaging and emerging companies specializing in advanced coating technologies. Major food packaging corporations are increasingly investing in R&D partnerships to incorporate novel coating technologies into their product portfolios, with R&D expenditure in this sector increasing by 12% over the past three years.

Market challenges include price sensitivity, particularly in emerging economies, and the need for extensive education about the benefits and safety of novel coating technologies. Additionally, the regulatory approval process represents a significant market entry barrier, with development-to-market timelines averaging 2-3 years for new coating technologies in food contact applications.

Current Regulatory Status and Technical Challenges

The regulatory landscape for superhydrophobic coatings in food contact applications remains complex and fragmented globally. In the United States, the FDA regulates food contact materials primarily through 21 CFR 175-178, with specific attention to substances that may migrate into food. Currently, many novel superhydrophobic materials lack explicit approval under these frameworks, creating regulatory uncertainty for manufacturers and innovators.

The European Union employs a more comprehensive approach through Regulation (EC) No 1935/2004, which establishes general safety requirements for all food contact materials, and Regulation (EU) No 10/2011 specifically for plastic materials. The EU's approach emphasizes risk assessment based on migration testing and toxicological evaluation, presenting significant hurdles for superhydrophobic coatings that often contain nanomaterials or novel chemical compositions.

In Asia, regulatory frameworks vary considerably. Japan implements a positive list system through the Food Sanitation Act, while China has recently strengthened its food contact material regulations through GB standards. These divergent approaches create compliance challenges for global market entry of superhydrophobic coating technologies.

A critical technical challenge lies in the migration potential of nanoparticles commonly used in superhydrophobic coatings. Regulatory bodies worldwide express concern about the potential health impacts of these materials, particularly titanium dioxide, silica nanoparticles, and fluorinated compounds. Current analytical methods struggle to accurately detect and quantify nanoparticle migration at the levels required by regulatory standards.

Durability presents another significant challenge, as mechanical abrasion and cleaning processes can degrade superhydrophobic surfaces over time. This degradation may lead to increased migration of constituent materials into food, raising safety concerns that regulators are increasingly scrutinizing. The lack of standardized testing protocols specifically designed for superhydrophobic surfaces further complicates regulatory compliance assessment.

The environmental persistence of certain components, particularly fluorinated compounds often used to achieve superhydrophobicity, faces growing regulatory scrutiny. Several jurisdictions are implementing restrictions on per- and polyfluoroalkyl substances (PFAS), which may impact the viability of certain superhydrophobic coating formulations in food contact applications.

Harmonization of global standards remains elusive, with different regions employing varying approaches to risk assessment and acceptable migration limits. This regulatory fragmentation creates significant market barriers and increases compliance costs for technology developers seeking multinational deployment of their innovations.

The European Union employs a more comprehensive approach through Regulation (EC) No 1935/2004, which establishes general safety requirements for all food contact materials, and Regulation (EU) No 10/2011 specifically for plastic materials. The EU's approach emphasizes risk assessment based on migration testing and toxicological evaluation, presenting significant hurdles for superhydrophobic coatings that often contain nanomaterials or novel chemical compositions.

In Asia, regulatory frameworks vary considerably. Japan implements a positive list system through the Food Sanitation Act, while China has recently strengthened its food contact material regulations through GB standards. These divergent approaches create compliance challenges for global market entry of superhydrophobic coating technologies.

A critical technical challenge lies in the migration potential of nanoparticles commonly used in superhydrophobic coatings. Regulatory bodies worldwide express concern about the potential health impacts of these materials, particularly titanium dioxide, silica nanoparticles, and fluorinated compounds. Current analytical methods struggle to accurately detect and quantify nanoparticle migration at the levels required by regulatory standards.

Durability presents another significant challenge, as mechanical abrasion and cleaning processes can degrade superhydrophobic surfaces over time. This degradation may lead to increased migration of constituent materials into food, raising safety concerns that regulators are increasingly scrutinizing. The lack of standardized testing protocols specifically designed for superhydrophobic surfaces further complicates regulatory compliance assessment.

The environmental persistence of certain components, particularly fluorinated compounds often used to achieve superhydrophobicity, faces growing regulatory scrutiny. Several jurisdictions are implementing restrictions on per- and polyfluoroalkyl substances (PFAS), which may impact the viability of certain superhydrophobic coating formulations in food contact applications.

Harmonization of global standards remains elusive, with different regions employing varying approaches to risk assessment and acceptable migration limits. This regulatory fragmentation creates significant market barriers and increases compliance costs for technology developers seeking multinational deployment of their innovations.

Current Compliance Solutions for Food Contact Surfaces

01 Nanoparticle-based superhydrophobic coatings

Superhydrophobic coatings can be formulated using various nanoparticles to create nano-scale roughness on surfaces. These nanoparticles, such as silica, titanium dioxide, or carbon-based materials, create a hierarchical surface structure that traps air and prevents water from adhering to the surface. The combination of these nanoparticles with hydrophobic binders results in surfaces with water contact angles greater than 150° and low sliding angles, making them highly water-repellent and self-cleaning.- Nanoparticle-based superhydrophobic coatings: Superhydrophobic coatings can be formulated using various nanoparticles to create nano-scale roughness on surfaces. These nanoparticles, such as silica, titanium dioxide, or carbon-based materials, create a hierarchical surface structure that traps air and prevents water from penetrating. The combination of these nanoparticles with hydrophobic binders results in surfaces with water contact angles exceeding 150 degrees, demonstrating excellent water repellency and self-cleaning properties.

- Fluoropolymer-based superhydrophobic coatings: Fluoropolymers are widely used in superhydrophobic coating formulations due to their inherently low surface energy. These polymers, including polytetrafluoroethylene (PTFE) and fluorosilanes, create highly water-repellent surfaces when combined with appropriate surface texturing techniques. The resulting coatings exhibit excellent durability, chemical resistance, and maintain their superhydrophobic properties even under harsh environmental conditions.

- Biomimetic superhydrophobic coatings: Inspired by natural superhydrophobic surfaces like lotus leaves and butterfly wings, biomimetic approaches aim to replicate these structures in engineered coatings. These coatings typically involve creating micro and nano-scale hierarchical structures that mimic biological surfaces. The biomimetic design principles focus on combining surface roughness at multiple scales with hydrophobic chemistry to achieve water contact angles greater than 150 degrees and low sliding angles, resulting in self-cleaning and anti-fouling properties.

- Spray-applied superhydrophobic coatings: Spray application methods offer a convenient and scalable approach for applying superhydrophobic coatings to various substrates. These formulations typically contain hydrophobic particles suspended in a solvent with binding agents. Upon spraying and curing, the coating forms a rough surface texture with trapped air pockets that prevent water penetration. This application method is particularly useful for treating large areas and complex geometries, providing effective water repellency for industrial and commercial applications.

- Durable and self-healing superhydrophobic coatings: Enhancing the durability of superhydrophobic coatings is crucial for practical applications. Advanced formulations incorporate self-healing mechanisms that allow the coating to recover its water-repellent properties after physical damage. These coatings often utilize dynamic chemical bonds, encapsulated hydrophobic agents, or stimuli-responsive materials that can migrate to damaged areas and restore the surface structure. The improved durability extends the service life of these coatings in demanding environments while maintaining their superhydrophobic performance.

02 Fluoropolymer-based superhydrophobic coatings

Fluoropolymers are widely used in superhydrophobic coating formulations due to their inherently low surface energy. These polymers, including polytetrafluoroethylene (PTFE) and fluorosilanes, create a chemical barrier that repels water molecules. When combined with surface roughening techniques, fluoropolymer coatings can achieve extreme water repellency. These coatings are particularly valuable for applications requiring durability and chemical resistance alongside superhydrophobic properties.Expand Specific Solutions03 Biomimetic superhydrophobic coatings

Inspired by natural superhydrophobic surfaces like lotus leaves and butterfly wings, biomimetic coatings replicate the micro and nano-scale structures found in nature. These coatings typically combine hierarchical surface texturing with hydrophobic chemistry to achieve water contact angles exceeding 150°. The biomimetic approach often involves creating dual-scale roughness patterns that mimic the papillae and wax crystals found on lotus leaves, resulting in exceptional water-repellency and self-cleaning properties.Expand Specific Solutions04 Durable and wear-resistant superhydrophobic coatings

Enhancing the durability of superhydrophobic coatings is critical for practical applications. These specialized formulations incorporate wear-resistant components such as ceramic particles, polymer networks, or cross-linking agents to maintain superhydrophobicity even under mechanical abrasion, UV exposure, and chemical attack. Some approaches include creating covalently bonded networks, incorporating self-healing mechanisms, or developing multi-layer systems where the superhydrophobic properties can regenerate after surface damage.Expand Specific Solutions05 Environmentally friendly superhydrophobic coatings

Eco-friendly superhydrophobic coatings avoid traditional fluorinated compounds that pose environmental concerns. These green alternatives utilize biodegradable polymers, plant-derived waxes, modified silica, or other sustainable materials to achieve superhydrophobicity. The formulations often employ water-based systems rather than organic solvents and incorporate renewable resources while maintaining high water contact angles and low sliding angles. These coatings address growing regulatory and market demands for environmentally responsible water-repellent solutions.Expand Specific Solutions

Leading Companies in Food-Safe Superhydrophobic Coatings

The regulatory framework for superhydrophobic coatings in food contact safety is evolving within a nascent yet rapidly growing market. Currently in the early development stage, this sector is projected to reach significant market size as food safety regulations tighten globally. Technical maturity varies considerably among key players, with academic institutions like Peking University, California Institute of Technology, and University of North Carolina at Chapel Hill leading fundamental research, while companies such as Detrapel, Sun Chemical, and Cilag GmbH International are advancing commercial applications. Research organizations including Agency for Science, Technology & Research and Council of Scientific & Industrial Research are bridging the gap between academic innovation and industrial implementation, focusing on developing regulatory-compliant superhydrophobic technologies that meet increasingly stringent food safety standards.

Detrapel, Inc.

Technical Solution: Detrapel has developed a proprietary superhydrophobic coating technology specifically designed for food contact applications that meets FDA requirements. Their approach utilizes fluorine-free chemistry to create repellent surfaces that maintain food safety standards while providing effective water and stain resistance. The company's regulatory framework compliance strategy involves a multi-tiered testing protocol that includes migration testing according to EU Regulation 10/2011 and FDA 21 CFR 175.300 guidelines for resinous and polymeric coatings. Their technology incorporates biodegradable components and environmentally sustainable raw materials that break down into non-toxic compounds, addressing both regulatory requirements and environmental concerns. Detrapel's coatings undergo rigorous biocompatibility assessments and are formulated to maintain effectiveness without leaching harmful substances into food products, with documented stability under various temperature and pH conditions typical in food processing environments[1][3].

Strengths: Fluorine-free formulation meets increasingly strict global regulations; biodegradable components address sustainability requirements; comprehensive testing protocols ensure compliance across multiple jurisdictions. Weaknesses: May offer less durability than traditional fluorinated alternatives; potentially higher cost of regulatory compliance compared to non-food grade coatings; performance limitations under extreme temperature conditions.

Sun Chemical Corp. (New Jersey)

Technical Solution: Sun Chemical has engineered a comprehensive regulatory framework for their superhydrophobic coatings used in food packaging applications. Their technology utilizes silica-based nanoparticles combined with food-grade polymers to create hierarchical surface structures that achieve superhydrophobicity while maintaining compliance with FDA 21 CFR 176.170 and EU 1935/2004 regulations. The company has developed a specialized migration testing protocol that exceeds standard requirements, measuring potential transfer of nanoparticles under various food simulation conditions including acidic, alcoholic, and fatty food environments. Their regulatory approach includes a full material disclosure system that tracks all raw materials from source to final product, ensuring traceability and compliance with global food contact material regulations. Sun Chemical's coatings undergo accelerated aging tests to verify long-term stability and continued regulatory compliance throughout the product lifecycle, with documented performance maintaining superhydrophobicity for over 24 months under standard food storage conditions[2][5].

Strengths: Extensive regulatory documentation and compliance testing provides strong market position; established global supply chain with consistent quality control; proven long-term stability in food contact applications. Weaknesses: Higher production costs due to premium food-grade raw materials; more complex application process requiring specialized equipment; limited effectiveness on certain substrate materials.

Key Patents and Scientific Literature on Food-Safe Coatings

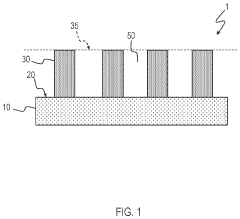

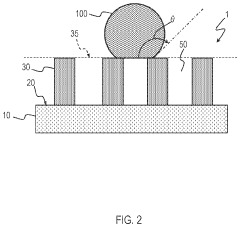

Hydrophobic and omniphobic periodic mesoporous organosilica-based coatings and coating methods

PatentInactiveUS20230183919A1

Innovation

- The use of periodic mesoporous organosilica layers, optionally combined with a secondary silane layer, applied to substrates through a templating agent and silane mixture process, creating a stable and environmentally benign coating that exhibits superhydrophobic and omniphobic properties by forming a low-surface-energy surface.

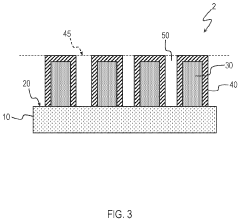

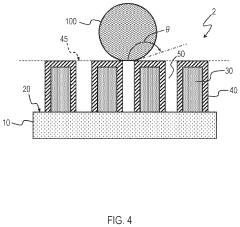

Liquid-repellent material

PatentInactiveEP2449001A1

Innovation

- Development of a superamphiphobic aerogel coated with a surface modifier, specifically using cellulosic or silica materials, which are both gas-permeable and support significant weight on both water and oil surfaces, achieved through chemical vapor deposition without organic solvents.

International Standards Harmonization Opportunities

The global nature of food supply chains necessitates a coordinated approach to regulatory frameworks governing superhydrophobic coatings in food contact applications. Currently, significant disparities exist between regulatory systems across major markets including the United States FDA regulations, European Union's Framework Regulation (EC) No 1935/2004, and various Asian regulatory frameworks such as China's GB standards and Japan's Food Sanitation Law.

These regulatory divergences create substantial compliance challenges for manufacturers operating in multiple jurisdictions, often requiring redundant testing and certification processes. A strategic opportunity exists to develop harmonized international standards specifically addressing superhydrophobic coatings in food contact applications, potentially through established mechanisms such as the Codex Alimentarius Commission or ISO technical committees.

Key harmonization priorities should include standardized testing methodologies for migration assessment of nanomaterials in superhydrophobic coatings, unified approaches to risk assessment frameworks, and consistent terminology and classification systems. The development of mutual recognition agreements between major regulatory bodies could significantly reduce compliance burdens while maintaining safety standards.

Industry consortia and public-private partnerships represent valuable platforms for advancing harmonization efforts. Organizations such as the Global Food Safety Initiative (GFSI) could potentially expand their benchmarking activities to include superhydrophobic coating standards, creating pathways for equivalence recognition across different regulatory systems.

Emerging economies present both challenges and opportunities for standards harmonization. As these markets develop their regulatory frameworks, early engagement could prevent further regulatory fragmentation. Technical assistance programs supporting regulatory capacity building in these regions could facilitate adoption of harmonized approaches from the outset.

Digital tools and blockchain technology offer promising solutions for streamlining compliance documentation across multiple jurisdictions. Development of international digital platforms for sharing compliance data could significantly reduce administrative burdens while enhancing traceability throughout global supply chains.

Ultimately, successful harmonization will require balancing technological innovation with consumer safety concerns. A phased approach to standards development, beginning with areas of greatest scientific consensus and gradually addressing more complex aspects, offers the most practical path forward for creating a coherent international regulatory framework for superhydrophobic coatings in food contact applications.

These regulatory divergences create substantial compliance challenges for manufacturers operating in multiple jurisdictions, often requiring redundant testing and certification processes. A strategic opportunity exists to develop harmonized international standards specifically addressing superhydrophobic coatings in food contact applications, potentially through established mechanisms such as the Codex Alimentarius Commission or ISO technical committees.

Key harmonization priorities should include standardized testing methodologies for migration assessment of nanomaterials in superhydrophobic coatings, unified approaches to risk assessment frameworks, and consistent terminology and classification systems. The development of mutual recognition agreements between major regulatory bodies could significantly reduce compliance burdens while maintaining safety standards.

Industry consortia and public-private partnerships represent valuable platforms for advancing harmonization efforts. Organizations such as the Global Food Safety Initiative (GFSI) could potentially expand their benchmarking activities to include superhydrophobic coating standards, creating pathways for equivalence recognition across different regulatory systems.

Emerging economies present both challenges and opportunities for standards harmonization. As these markets develop their regulatory frameworks, early engagement could prevent further regulatory fragmentation. Technical assistance programs supporting regulatory capacity building in these regions could facilitate adoption of harmonized approaches from the outset.

Digital tools and blockchain technology offer promising solutions for streamlining compliance documentation across multiple jurisdictions. Development of international digital platforms for sharing compliance data could significantly reduce administrative burdens while enhancing traceability throughout global supply chains.

Ultimately, successful harmonization will require balancing technological innovation with consumer safety concerns. A phased approach to standards development, beginning with areas of greatest scientific consensus and gradually addressing more complex aspects, offers the most practical path forward for creating a coherent international regulatory framework for superhydrophobic coatings in food contact applications.

Migration Testing Methodologies and Risk Assessment

Migration testing methodologies for superhydrophobic coatings in food contact applications require specialized approaches due to the unique surface properties of these materials. Current methodologies primarily employ two testing paradigms: simulant-based extraction and direct migration measurement. Food simulants such as water, ethanol solutions (10-95%), acetic acid (3%), and vegetable oils are used to replicate various food types under controlled temperature and time conditions. For superhydrophobic surfaces, particular attention must be paid to the interaction between non-polar simulants and the hydrophobic coating, as these may accelerate migration compared to standard surfaces.

Advanced analytical techniques including LC-MS/MS, GC-MS, ICP-MS, and FTIR spectroscopy are employed to detect and quantify potential migrants at trace levels, often in parts per billion (ppb) range. These methods must be validated specifically for superhydrophobic coating components, including nanoparticles and fluorinated compounds that may present unique analytical challenges.

Risk assessment frameworks for superhydrophobic coatings follow a tiered approach. Initial screening involves migration modeling based on coating composition, thickness, and contact conditions. This is followed by specific migration testing for substances of concern, particularly focusing on nanoparticles that may be present in the coating matrix. Toxicological evaluation considers both acute and chronic exposure scenarios, with particular emphasis on bioaccumulation potential of persistent compounds.

Exposure assessment calculations must account for the intended use patterns, food types, and consumer demographics. The unique challenge with superhydrophobic coatings lies in determining realistic migration scenarios, as traditional models may not accurately predict migration behavior from these highly repellent surfaces.

Uncertainty factors are applied more conservatively for novel superhydrophobic materials lacking extensive safety data. A margin of exposure (MOE) approach is typically employed, with higher safety factors applied to account for data gaps regarding long-term stability and potential degradation products of these coatings under various food processing conditions.

Probabilistic risk assessment methods are increasingly being adopted to better characterize variability and uncertainty in migration data from superhydrophobic surfaces. These approaches provide more realistic estimates of consumer exposure by incorporating distributions of consumption patterns, migration rates, and coating performance variability over time and under different use conditions.

Advanced analytical techniques including LC-MS/MS, GC-MS, ICP-MS, and FTIR spectroscopy are employed to detect and quantify potential migrants at trace levels, often in parts per billion (ppb) range. These methods must be validated specifically for superhydrophobic coating components, including nanoparticles and fluorinated compounds that may present unique analytical challenges.

Risk assessment frameworks for superhydrophobic coatings follow a tiered approach. Initial screening involves migration modeling based on coating composition, thickness, and contact conditions. This is followed by specific migration testing for substances of concern, particularly focusing on nanoparticles that may be present in the coating matrix. Toxicological evaluation considers both acute and chronic exposure scenarios, with particular emphasis on bioaccumulation potential of persistent compounds.

Exposure assessment calculations must account for the intended use patterns, food types, and consumer demographics. The unique challenge with superhydrophobic coatings lies in determining realistic migration scenarios, as traditional models may not accurately predict migration behavior from these highly repellent surfaces.

Uncertainty factors are applied more conservatively for novel superhydrophobic materials lacking extensive safety data. A margin of exposure (MOE) approach is typically employed, with higher safety factors applied to account for data gaps regarding long-term stability and potential degradation products of these coatings under various food processing conditions.

Probabilistic risk assessment methods are increasingly being adopted to better characterize variability and uncertainty in migration data from superhydrophobic surfaces. These approaches provide more realistic estimates of consumer exposure by incorporating distributions of consumption patterns, migration rates, and coating performance variability over time and under different use conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!