Analysis of Volumetric 3D printing for aerospace lightweight and high strength components

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace 3D Printing Evolution and Objectives

Volumetric 3D printing represents a significant technological advancement in additive manufacturing, evolving from traditional layer-by-layer approaches to a more sophisticated process that creates entire components simultaneously. This evolution began in the early 2000s with basic stereolithography techniques and has progressed to today's advanced volumetric methods utilizing computed axial lithography and holographic techniques. The aerospace industry has been particularly receptive to these developments due to the critical need for components that combine lightweight properties with exceptional strength.

The historical trajectory of aerospace 3D printing shows a clear progression from prototyping applications to functional end-use parts. Early implementations focused primarily on visual models and fit testing, while contemporary applications include critical flight components and structural elements. This shift has been enabled by significant improvements in material science, computational capabilities, and printing technologies that allow for precise control of material properties at the microscopic level.

Current objectives in volumetric 3D printing for aerospace applications center on several key areas. First, there is a push toward multi-material printing capabilities that can integrate different materials within a single component to optimize both weight and strength characteristics. Second, researchers are working to increase the build volume while maintaining or improving resolution, allowing for larger aerospace components to be manufactured in a single print operation. Third, there is significant focus on developing materials specifically engineered for aerospace requirements, including heat resistance, fatigue strength, and radiation shielding properties.

The industry is also targeting improvements in print speed and efficiency, as volumetric techniques already offer substantial time advantages over traditional layer-by-layer methods. Reducing production time while maintaining quality is essential for economic viability in aerospace manufacturing. Additionally, there are ongoing efforts to enhance the precision and repeatability of volumetric printing processes to meet the stringent certification requirements of the aerospace sector.

Looking forward, the technology roadmap for volumetric 3D printing in aerospace applications includes the development of in-situ monitoring and quality control systems, integration with digital twin technologies for predictive performance modeling, and the establishment of comprehensive material databases specific to aerospace applications. These advancements aim to position volumetric 3D printing as a cornerstone technology for next-generation aerospace manufacturing, enabling designs that were previously impossible and performance characteristics that exceed current capabilities.

The historical trajectory of aerospace 3D printing shows a clear progression from prototyping applications to functional end-use parts. Early implementations focused primarily on visual models and fit testing, while contemporary applications include critical flight components and structural elements. This shift has been enabled by significant improvements in material science, computational capabilities, and printing technologies that allow for precise control of material properties at the microscopic level.

Current objectives in volumetric 3D printing for aerospace applications center on several key areas. First, there is a push toward multi-material printing capabilities that can integrate different materials within a single component to optimize both weight and strength characteristics. Second, researchers are working to increase the build volume while maintaining or improving resolution, allowing for larger aerospace components to be manufactured in a single print operation. Third, there is significant focus on developing materials specifically engineered for aerospace requirements, including heat resistance, fatigue strength, and radiation shielding properties.

The industry is also targeting improvements in print speed and efficiency, as volumetric techniques already offer substantial time advantages over traditional layer-by-layer methods. Reducing production time while maintaining quality is essential for economic viability in aerospace manufacturing. Additionally, there are ongoing efforts to enhance the precision and repeatability of volumetric printing processes to meet the stringent certification requirements of the aerospace sector.

Looking forward, the technology roadmap for volumetric 3D printing in aerospace applications includes the development of in-situ monitoring and quality control systems, integration with digital twin technologies for predictive performance modeling, and the establishment of comprehensive material databases specific to aerospace applications. These advancements aim to position volumetric 3D printing as a cornerstone technology for next-generation aerospace manufacturing, enabling designs that were previously impossible and performance characteristics that exceed current capabilities.

Market Analysis for Aerospace Additive Manufacturing

The aerospace additive manufacturing market is experiencing robust growth, projected to reach $5.2 billion by 2026, with a compound annual growth rate of approximately 15.7%. This significant expansion is driven primarily by the aerospace industry's increasing demand for lightweight components that maintain or enhance structural integrity while reducing overall aircraft weight. For every kilogram reduced in aircraft weight, airlines can save approximately 3,000 liters of fuel annually per aircraft, translating to substantial operational cost reductions and environmental benefits.

The market segmentation reveals distinct application areas within aerospace additive manufacturing. Engine components represent the largest segment at 32% of market share, followed by structural components (28%), cabin interiors (18%), and other applications including specialized tooling and repair parts (22%). Volumetric 3D printing technology is particularly gaining traction in the engine and structural components segments due to its ability to produce complex geometries with internal lattice structures that optimize strength-to-weight ratios.

Geographically, North America dominates the aerospace additive manufacturing market with 42% share, followed by Europe (31%), Asia-Pacific (21%), and rest of the world (6%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 18.9% annually, driven by expanding aerospace manufacturing capabilities in China, Japan, and Singapore.

Customer demand analysis indicates that major aerospace OEMs including Boeing, Airbus, GE Aviation, and Rolls-Royce are increasingly incorporating additively manufactured components into their production lines. These companies are specifically seeking solutions that can reduce component weight by 40-60% while maintaining or improving mechanical properties, particularly fatigue resistance and thermal stability. Volumetric 3D printing addresses these requirements through its ability to create optimized internal structures that would be impossible to manufacture using traditional methods.

Market barriers include certification challenges, with regulatory bodies like FAA and EASA requiring extensive testing and validation of additively manufactured components. Material costs remain high, with specialized aerospace-grade powders costing 5-10 times more than conventional materials. Additionally, production speed limitations currently restrict volumetric 3D printing to low-volume, high-value applications rather than mass production scenarios.

The market forecast indicates that volumetric 3D printing for aerospace applications will initially focus on non-critical components before gradually expanding to primary structures as the technology matures and certification pathways become established. By 2030, industry analysts predict that up to 25% of all aerospace components could be manufactured using advanced additive manufacturing techniques, with volumetric 3D printing capturing a significant portion of this growing market.

The market segmentation reveals distinct application areas within aerospace additive manufacturing. Engine components represent the largest segment at 32% of market share, followed by structural components (28%), cabin interiors (18%), and other applications including specialized tooling and repair parts (22%). Volumetric 3D printing technology is particularly gaining traction in the engine and structural components segments due to its ability to produce complex geometries with internal lattice structures that optimize strength-to-weight ratios.

Geographically, North America dominates the aerospace additive manufacturing market with 42% share, followed by Europe (31%), Asia-Pacific (21%), and rest of the world (6%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 18.9% annually, driven by expanding aerospace manufacturing capabilities in China, Japan, and Singapore.

Customer demand analysis indicates that major aerospace OEMs including Boeing, Airbus, GE Aviation, and Rolls-Royce are increasingly incorporating additively manufactured components into their production lines. These companies are specifically seeking solutions that can reduce component weight by 40-60% while maintaining or improving mechanical properties, particularly fatigue resistance and thermal stability. Volumetric 3D printing addresses these requirements through its ability to create optimized internal structures that would be impossible to manufacture using traditional methods.

Market barriers include certification challenges, with regulatory bodies like FAA and EASA requiring extensive testing and validation of additively manufactured components. Material costs remain high, with specialized aerospace-grade powders costing 5-10 times more than conventional materials. Additionally, production speed limitations currently restrict volumetric 3D printing to low-volume, high-value applications rather than mass production scenarios.

The market forecast indicates that volumetric 3D printing for aerospace applications will initially focus on non-critical components before gradually expanding to primary structures as the technology matures and certification pathways become established. By 2030, industry analysts predict that up to 25% of all aerospace components could be manufactured using advanced additive manufacturing techniques, with volumetric 3D printing capturing a significant portion of this growing market.

Volumetric 3D Printing Technology Assessment

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, particularly for aerospace applications where weight reduction and structural integrity are paramount. Unlike traditional layer-by-layer 3D printing methods, volumetric techniques simultaneously solidify an entire volume of material, offering significant advantages in production speed, isotropy of mechanical properties, and geometric complexity.

The aerospace industry has increasingly adopted advanced manufacturing technologies to meet demands for lightweight components that maintain or exceed strength requirements. Volumetric 3D printing addresses this need through its ability to create complex internal lattice structures and topologically optimized geometries that would be impossible with conventional manufacturing methods. These structures can significantly reduce component weight while maintaining structural integrity under the extreme conditions encountered in aerospace applications.

Current volumetric printing technologies include computed axial lithography (CAL), holographic stereolithography, and tomographic volumetric additive manufacturing. Each offers unique capabilities for creating aerospace components with tailored mechanical properties. CAL, for instance, uses synchronized projections from multiple angles to solidify photopolymer resins in patterns that can be precisely engineered for specific stress distributions common in aerospace applications.

Material development has been crucial to the advancement of this technology. Recent innovations include high-performance photopolymers reinforced with carbon fibers, ceramic particles, and metallic powders that can withstand extreme temperatures and mechanical stresses. These composite materials enable the production of components with strength-to-weight ratios exceeding those of traditional aerospace alloys in certain applications.

The integration of computational design tools with volumetric printing has enabled unprecedented optimization capabilities. Advanced algorithms can now generate structures that distribute material precisely where needed for load-bearing, while minimizing it elsewhere. This approach has demonstrated weight reductions of 30-50% compared to traditionally manufactured components, while maintaining or improving mechanical performance.

Challenges remain in scaling volumetric techniques to larger aerospace components and ensuring consistent material properties throughout complex geometries. Current build volumes are typically limited to dimensions under 30cm, restricting applications to smaller components or necessitating assembly of multiple printed parts.

Quality assurance and certification represent significant hurdles for aerospace implementation, as regulatory frameworks are still adapting to these novel manufacturing methods. Non-destructive testing protocols are being developed specifically for volumetrically printed components to verify internal structural integrity without compromising the benefits of the manufacturing process.

The aerospace industry has increasingly adopted advanced manufacturing technologies to meet demands for lightweight components that maintain or exceed strength requirements. Volumetric 3D printing addresses this need through its ability to create complex internal lattice structures and topologically optimized geometries that would be impossible with conventional manufacturing methods. These structures can significantly reduce component weight while maintaining structural integrity under the extreme conditions encountered in aerospace applications.

Current volumetric printing technologies include computed axial lithography (CAL), holographic stereolithography, and tomographic volumetric additive manufacturing. Each offers unique capabilities for creating aerospace components with tailored mechanical properties. CAL, for instance, uses synchronized projections from multiple angles to solidify photopolymer resins in patterns that can be precisely engineered for specific stress distributions common in aerospace applications.

Material development has been crucial to the advancement of this technology. Recent innovations include high-performance photopolymers reinforced with carbon fibers, ceramic particles, and metallic powders that can withstand extreme temperatures and mechanical stresses. These composite materials enable the production of components with strength-to-weight ratios exceeding those of traditional aerospace alloys in certain applications.

The integration of computational design tools with volumetric printing has enabled unprecedented optimization capabilities. Advanced algorithms can now generate structures that distribute material precisely where needed for load-bearing, while minimizing it elsewhere. This approach has demonstrated weight reductions of 30-50% compared to traditionally manufactured components, while maintaining or improving mechanical performance.

Challenges remain in scaling volumetric techniques to larger aerospace components and ensuring consistent material properties throughout complex geometries. Current build volumes are typically limited to dimensions under 30cm, restricting applications to smaller components or necessitating assembly of multiple printed parts.

Quality assurance and certification represent significant hurdles for aerospace implementation, as regulatory frameworks are still adapting to these novel manufacturing methods. Non-destructive testing protocols are being developed specifically for volumetrically printed components to verify internal structural integrity without compromising the benefits of the manufacturing process.

Current Volumetric Printing Solutions for Aerospace Components

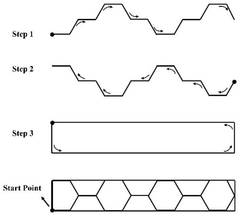

01 Lattice structures for lightweight and high-strength 3D printing

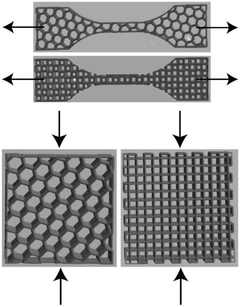

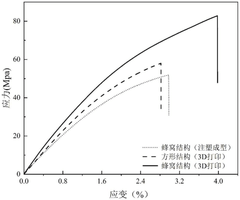

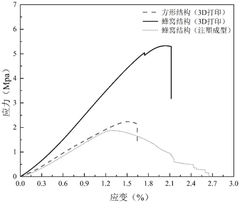

Volumetric 3D printing can create complex lattice structures that provide high strength-to-weight ratios. These structures feature interconnected struts or cells that distribute loads efficiently while minimizing material usage. By optimizing the geometry and arrangement of these lattices, manufacturers can produce components that combine lightweight properties with exceptional mechanical strength, making them ideal for aerospace, automotive, and medical applications.- Lattice structures for lightweight and high-strength 3D printing: Volumetric 3D printing can create complex lattice structures that provide high strength-to-weight ratios. These lattice designs distribute material efficiently, creating lightweight components that maintain structural integrity. The internal geometry can be optimized to provide strength in specific directions while minimizing material usage, making them ideal for applications requiring both lightweight properties and mechanical strength.

- Advanced materials for volumetric 3D printing: Specialized materials have been developed specifically for volumetric 3D printing that offer both lightweight characteristics and high strength. These include composite materials, reinforced polymers, and novel alloys that can be processed using volumetric printing techniques. The materials are engineered to cure or solidify rapidly during the printing process while maintaining structural properties that balance weight reduction with mechanical performance.

- Multi-material volumetric printing techniques: Volumetric 3D printing systems capable of processing multiple materials simultaneously allow for strategic placement of different materials within a single component. This enables the creation of parts with lightweight cores and high-strength outer shells or reinforced stress points. The combination of materials with complementary properties results in components that achieve optimal weight-to-strength ratios not possible with single-material approaches.

- Tomographic volumetric printing for complex geometries: Tomographic volumetric printing techniques enable the creation of complex internal and external geometries that would be difficult or impossible to achieve with traditional layer-by-layer printing. By projecting patterns of light into photosensitive resin from multiple angles simultaneously, these systems can create intricate structures with optimized weight distribution and reinforcement in critical areas, resulting in lightweight yet strong components.

- Computational design optimization for volumetric printing: Advanced computational methods are used to optimize designs for volumetric 3D printing, focusing on achieving the ideal balance between weight reduction and structural strength. These algorithms analyze stress patterns, material distribution, and performance requirements to generate designs that minimize material usage while maintaining or enhancing mechanical properties. The resulting optimized structures take full advantage of the volumetric printing process to create lightweight, high-strength components.

02 Advanced materials for volumetric 3D printing

The development of specialized materials plays a crucial role in achieving lightweight yet strong 3D printed parts. Composite materials, reinforced polymers, and novel alloys can be formulated specifically for volumetric 3D printing processes. These materials often incorporate reinforcing elements such as carbon fibers, ceramic particles, or nanomaterials to enhance mechanical properties while maintaining low density, resulting in components that offer superior strength-to-weight ratios compared to traditional manufacturing materials.Expand Specific Solutions03 Tomographic volumetric 3D printing techniques

Tomographic volumetric 3D printing represents an advanced approach that creates objects by projecting light patterns into photosensitive resin from multiple angles simultaneously. This technique allows for the rapid production of complex geometries without the need for layer-by-layer building, resulting in stronger parts with fewer structural weaknesses. The process enables the creation of lightweight, high-strength components with isotropic properties, overcoming many limitations of traditional additive manufacturing methods.Expand Specific Solutions04 Topology optimization for strength-to-weight ratio

Topology optimization algorithms are employed in volumetric 3D printing to design structures that maximize strength while minimizing weight. These computational methods analyze load paths and stress distributions to determine the optimal material placement, removing unnecessary material from areas with low stress. The resulting optimized designs feature organic, biomimetic structures that efficiently distribute forces throughout the component, achieving superior mechanical performance with minimal material usage.Expand Specific Solutions05 Multi-material volumetric printing for functional gradients

Multi-material volumetric 3D printing enables the creation of components with functionally graded properties, where material composition varies throughout the part. This approach allows engineers to design lightweight structures with reinforced high-stress regions, creating parts that are both lightweight overall and strong where needed. By strategically combining rigid and flexible materials or varying material densities within a single print, manufacturers can produce components with optimized mechanical properties tailored to specific loading conditions.Expand Specific Solutions

Leading Aerospace 3D Printing Industry Players

Volumetric 3D printing for aerospace lightweight components is in an early growth phase, with the market expected to reach significant expansion due to increasing demand for fuel-efficient aircraft. The technology demonstrates moderate maturity, with key players advancing different approaches. Academic institutions (University of Maine, Northwestern Polytechnical University, EPFL) are driving fundamental research, while aerospace manufacturers (Airbus, Kawasaki Heavy Industries, Safran Aircraft Engines) are integrating these technologies into production workflows. Specialized companies like Divergent Technologies and AIM3D are developing proprietary systems, while materials suppliers such as Wacker Chemie and ZEON Corp provide specialized feedstocks. The competitive landscape shows a balance between established aerospace giants and innovative startups, with collaboration between industry and academia accelerating commercialization efforts.

Airbus Operations GmbH

Technical Solution: Airbus has developed advanced volumetric 3D printing technologies specifically for aerospace applications, focusing on lightweight and high-strength components. Their approach combines Digital Light Processing (DLP) with specialized aerospace-grade photopolymers to create complex internal lattice structures that significantly reduce weight while maintaining structural integrity. Airbus's volumetric printing technology enables the production of components with variable density throughout the part, allowing engineers to optimize material placement only where structural requirements demand it. Their process incorporates continuous liquid interface production techniques that can produce parts up to 100 times faster than traditional layer-by-layer methods, while achieving superior surface finish quality. Airbus has successfully implemented this technology for producing non-critical components such as cabin interior parts and ducting systems, with plans to expand to more structurally critical components as the technology matures.

Strengths: Superior weight-to-strength ratio optimization through variable density structures; significantly faster production speeds compared to traditional additive manufacturing; excellent surface finish reducing post-processing requirements. Weaknesses: Limited to certain material types; certification challenges for critical aerospace components; higher initial investment costs compared to conventional manufacturing methods.

HP Development Co. LP

Technical Solution: HP has developed Multi Jet Fusion (MJF) technology that represents a significant advancement in volumetric 3D printing for aerospace applications. While not strictly volumetric in the holographic sense, HP's approach achieves similar benefits through its unique voxel-level control system. The technology enables precise material property manipulation at the microscopic level, allowing for the creation of aerospace components with variable mechanical properties throughout a single part. HP's system utilizes specialized high-performance thermoplastics and composites that meet aerospace flame, smoke, and toxicity requirements while delivering exceptional strength-to-weight ratios. The process incorporates HP's proprietary binding agents and detailing agents that are precisely deposited across each layer, followed by uniform energy application that ensures consistent material properties throughout the component. This approach enables the production of complex internal structures like lattices and honeycombs that significantly reduce weight while maintaining structural integrity. HP has demonstrated the ability to produce aerospace components with up to 60% weight reduction compared to traditionally manufactured parts while meeting or exceeding strength requirements.

Strengths: Exceptional dimensional accuracy and surface finish; ability to create parts with variable mechanical properties; high production speed compared to other additive manufacturing technologies; established quality control systems. Weaknesses: Limited material selection compared to some competing technologies; size constraints for larger aerospace components; higher material costs compared to conventional manufacturing.

Critical Patents in Aerospace Volumetric Printing

Honeycomb structure composite material and preparation method and application thereof

PatentPendingCN119682200A

Innovation

- The short carbon fiber reinforced honeycomb composite is manufactured using direct-write 3D printing technology, and the ink paste is prepared by mixing and stirring, and printed and cured in the 3D printer according to preset parameters, simplifying the process flow and reducing costs.

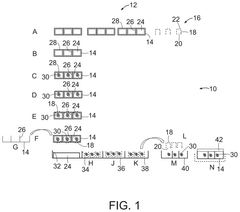

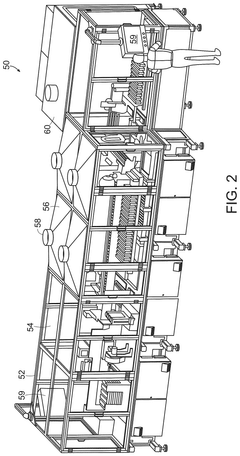

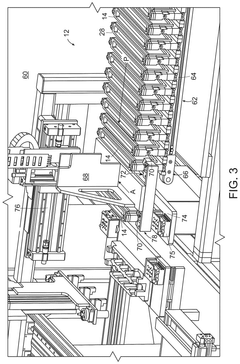

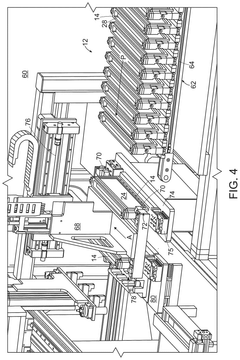

Volumetric three-dimensional (3D) printing system

PatentPendingUS20250074001A1

Innovation

- A high-throughput, automated system that uses cartridges filled with photohardenable resin, where 3D objects are formed by exposing the resin to excitation light sources, and then undergo automated post-processing steps without human intervention.

Material Science Advancements for Aerospace Applications

The aerospace industry's pursuit of lightweight yet high-strength components has driven significant advancements in material science. Recent developments in aerospace materials have focused on creating structures that maintain exceptional mechanical properties while reducing overall weight, directly addressing the industry's need for fuel efficiency and enhanced performance.

Composite materials have emerged as frontrunners in this domain, with carbon fiber reinforced polymers (CFRPs) demonstrating superior strength-to-weight ratios compared to traditional aluminum alloys. These materials exhibit tensile strengths exceeding 3,500 MPa while maintaining densities around 1.6 g/cm³, representing a revolutionary improvement over conventional aerospace metals.

Advanced metal alloys have also undergone substantial evolution, particularly aluminum-lithium alloys that offer 10-15% weight reduction while improving fatigue resistance. Similarly, titanium aluminides have gained prominence for high-temperature applications, maintaining structural integrity at temperatures up to 800°C while being approximately 50% lighter than nickel-based superalloys traditionally used in these environments.

Nanomaterial integration represents another frontier in aerospace material science. Carbon nanotubes and graphene, when incorporated into composite matrices, have demonstrated the ability to enhance mechanical properties by up to 30% while adding minimal weight. These nanomaterials also contribute to improved electrical conductivity, addressing lightning strike protection requirements for modern aircraft.

Metamaterials engineered at the microscopic level have enabled unprecedented combinations of properties, including structures that become stronger under stress or exhibit negative thermal expansion coefficients. These materials are particularly valuable for components subjected to extreme thermal cycling in aerospace applications.

Ceramic matrix composites (CMCs) have revolutionized high-temperature applications, particularly in propulsion systems. These materials maintain structural integrity at temperatures exceeding 1200°C while offering 30-40% weight savings compared to traditional superalloys, enabling more efficient engine designs with higher operating temperatures and reduced cooling requirements.

The integration of these advanced materials with volumetric 3D printing technologies has created new possibilities for aerospace component design, allowing for complex internal structures that optimize strength-to-weight ratios through biomimetic designs that would be impossible to manufacture using conventional methods.

Composite materials have emerged as frontrunners in this domain, with carbon fiber reinforced polymers (CFRPs) demonstrating superior strength-to-weight ratios compared to traditional aluminum alloys. These materials exhibit tensile strengths exceeding 3,500 MPa while maintaining densities around 1.6 g/cm³, representing a revolutionary improvement over conventional aerospace metals.

Advanced metal alloys have also undergone substantial evolution, particularly aluminum-lithium alloys that offer 10-15% weight reduction while improving fatigue resistance. Similarly, titanium aluminides have gained prominence for high-temperature applications, maintaining structural integrity at temperatures up to 800°C while being approximately 50% lighter than nickel-based superalloys traditionally used in these environments.

Nanomaterial integration represents another frontier in aerospace material science. Carbon nanotubes and graphene, when incorporated into composite matrices, have demonstrated the ability to enhance mechanical properties by up to 30% while adding minimal weight. These nanomaterials also contribute to improved electrical conductivity, addressing lightning strike protection requirements for modern aircraft.

Metamaterials engineered at the microscopic level have enabled unprecedented combinations of properties, including structures that become stronger under stress or exhibit negative thermal expansion coefficients. These materials are particularly valuable for components subjected to extreme thermal cycling in aerospace applications.

Ceramic matrix composites (CMCs) have revolutionized high-temperature applications, particularly in propulsion systems. These materials maintain structural integrity at temperatures exceeding 1200°C while offering 30-40% weight savings compared to traditional superalloys, enabling more efficient engine designs with higher operating temperatures and reduced cooling requirements.

The integration of these advanced materials with volumetric 3D printing technologies has created new possibilities for aerospace component design, allowing for complex internal structures that optimize strength-to-weight ratios through biomimetic designs that would be impossible to manufacture using conventional methods.

Certification Standards for Aerospace Printed Components

The aerospace industry maintains rigorous certification standards for components used in aircraft and spacecraft, with additive manufacturing introducing new challenges to this established framework. For volumetric 3D printed aerospace components, certification must address the unique material properties and manufacturing processes involved while ensuring compliance with existing regulatory requirements.

The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have developed specific guidelines for additively manufactured parts. These include the FAA's Advisory Circular 21.50-1 and EASA's Certification Memorandum CM-S-008, which outline the certification pathway for 3D printed components. For volumetric 3D printing specifically, these standards are being adapted to address the distinctive layer-less production method and its implications for material integrity.

ASTM International and SAE have established key standards that apply to volumetric 3D printed aerospace components. ASTM F3055 covers additive manufacturing process characterization, while SAE AMS7000 series addresses material and process specifications. The recently developed ASTM F42 committee works specifically on standards for additive manufacturing technologies, including volumetric techniques.

Certification for volumetric 3D printed aerospace components requires extensive material testing and process validation. This includes mechanical property testing (tensile strength, fatigue resistance, fracture toughness), microstructural analysis, and non-destructive evaluation methods. The unique aspect of volumetric printing—creating parts through photopolymerization throughout an entire volume simultaneously—necessitates specialized testing protocols to verify internal structural integrity.

Quality assurance systems for volumetric 3D printed components must include comprehensive process monitoring and control. This involves real-time monitoring of resin properties, light source calibration, and post-processing validation. AS9100 quality management standards have been adapted specifically for additive manufacturing processes in aerospace applications, with additional requirements for volumetric techniques under development.

Digital thread documentation is increasingly important for certification, requiring manufacturers to maintain complete records from design to production. This includes material batch data, process parameters, and post-processing treatments. For volumetric printing, this documentation must address the specific optical parameters and resin formulations that influence final part properties.

Emerging certification approaches include qualification by similarity and part family certification, which allow manufacturers to certify groups of similar components based on shared characteristics. These approaches are particularly valuable for volumetric 3D printing, where the process parameters may remain consistent across multiple component geometries while achieving the lightweight, high-strength properties required for aerospace applications.

The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have developed specific guidelines for additively manufactured parts. These include the FAA's Advisory Circular 21.50-1 and EASA's Certification Memorandum CM-S-008, which outline the certification pathway for 3D printed components. For volumetric 3D printing specifically, these standards are being adapted to address the distinctive layer-less production method and its implications for material integrity.

ASTM International and SAE have established key standards that apply to volumetric 3D printed aerospace components. ASTM F3055 covers additive manufacturing process characterization, while SAE AMS7000 series addresses material and process specifications. The recently developed ASTM F42 committee works specifically on standards for additive manufacturing technologies, including volumetric techniques.

Certification for volumetric 3D printed aerospace components requires extensive material testing and process validation. This includes mechanical property testing (tensile strength, fatigue resistance, fracture toughness), microstructural analysis, and non-destructive evaluation methods. The unique aspect of volumetric printing—creating parts through photopolymerization throughout an entire volume simultaneously—necessitates specialized testing protocols to verify internal structural integrity.

Quality assurance systems for volumetric 3D printed components must include comprehensive process monitoring and control. This involves real-time monitoring of resin properties, light source calibration, and post-processing validation. AS9100 quality management standards have been adapted specifically for additive manufacturing processes in aerospace applications, with additional requirements for volumetric techniques under development.

Digital thread documentation is increasingly important for certification, requiring manufacturers to maintain complete records from design to production. This includes material batch data, process parameters, and post-processing treatments. For volumetric printing, this documentation must address the specific optical parameters and resin formulations that influence final part properties.

Emerging certification approaches include qualification by similarity and part family certification, which allow manufacturers to certify groups of similar components based on shared characteristics. These approaches are particularly valuable for volumetric 3D printing, where the process parameters may remain consistent across multiple component geometries while achieving the lightweight, high-strength properties required for aerospace applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!