What technical mechanisms govern Volumetric 3D printing part quality and surface finish

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric 3D Printing Evolution and Objectives

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, evolving from traditional layer-by-layer approaches to a revolutionary technique that simultaneously solidifies an entire volume of material. This evolution began in the early 2010s with theoretical concepts, followed by breakthrough demonstrations around 2017-2019 when researchers at Lawrence Livermore National Laboratory and UC Berkeley published seminal works on computed axial lithography (CAL).

The technology has progressed through several key developmental phases, starting with proof-of-concept demonstrations using simple photopolymer resins and basic optical setups. This was followed by refinements in projection systems, material formulations, and computational algorithms that have collectively enhanced print resolution, speed, and material compatibility. Recent advancements have focused on multi-material capabilities and integration with other manufacturing processes.

The primary objective of volumetric 3D printing research is to overcome fundamental limitations of conventional additive manufacturing, particularly regarding production speed, geometric constraints, and surface quality. By eliminating the layer-by-layer approach, volumetric techniques aim to produce parts with isotropic mechanical properties and superior surface finish while dramatically reducing production times from hours to minutes or even seconds.

Current research objectives center on several critical areas: increasing resolution beyond the current limitations (typically 100-200 microns), expanding the range of compatible materials beyond photopolymers to include ceramics, composites, and potentially metals, and developing more sophisticated computational models to predict and control solidification dynamics throughout the volume.

Another significant goal is to understand and optimize the relationship between processing parameters (light intensity, exposure time, resin formulation) and final part quality metrics such as dimensional accuracy, surface roughness, and mechanical properties. This understanding is essential for establishing volumetric printing as a reliable manufacturing technology rather than merely a laboratory curiosity.

The long-term vision for volumetric 3D printing extends beyond simply improving existing capabilities. Researchers aim to develop systems capable of producing functional end-use parts with embedded electronics, gradient material properties, and complex internal structures impossible to create with conventional manufacturing methods. This would enable entirely new classes of products across industries including medical devices, aerospace components, and consumer electronics.

The technology has progressed through several key developmental phases, starting with proof-of-concept demonstrations using simple photopolymer resins and basic optical setups. This was followed by refinements in projection systems, material formulations, and computational algorithms that have collectively enhanced print resolution, speed, and material compatibility. Recent advancements have focused on multi-material capabilities and integration with other manufacturing processes.

The primary objective of volumetric 3D printing research is to overcome fundamental limitations of conventional additive manufacturing, particularly regarding production speed, geometric constraints, and surface quality. By eliminating the layer-by-layer approach, volumetric techniques aim to produce parts with isotropic mechanical properties and superior surface finish while dramatically reducing production times from hours to minutes or even seconds.

Current research objectives center on several critical areas: increasing resolution beyond the current limitations (typically 100-200 microns), expanding the range of compatible materials beyond photopolymers to include ceramics, composites, and potentially metals, and developing more sophisticated computational models to predict and control solidification dynamics throughout the volume.

Another significant goal is to understand and optimize the relationship between processing parameters (light intensity, exposure time, resin formulation) and final part quality metrics such as dimensional accuracy, surface roughness, and mechanical properties. This understanding is essential for establishing volumetric printing as a reliable manufacturing technology rather than merely a laboratory curiosity.

The long-term vision for volumetric 3D printing extends beyond simply improving existing capabilities. Researchers aim to develop systems capable of producing functional end-use parts with embedded electronics, gradient material properties, and complex internal structures impossible to create with conventional manufacturing methods. This would enable entirely new classes of products across industries including medical devices, aerospace components, and consumer electronics.

Market Analysis for High-Quality 3D Printed Components

The global market for high-quality 3D printed components has experienced significant growth over the past decade, driven by increasing adoption across multiple industries. The market size for precision 3D printing was valued at approximately $12.6 billion in 2022 and is projected to reach $34.8 billion by 2028, with a compound annual growth rate of 18.4%. This growth trajectory is particularly evident in sectors requiring high-precision components with superior surface finish.

Healthcare represents the largest market segment, accounting for nearly 33% of the high-quality 3D printing market. The demand for patient-specific implants, prosthetics, and anatomical models with excellent surface quality has created a substantial market opportunity. Dental applications alone constitute a $2.5 billion segment, with growth rates exceeding 20% annually due to the requirement for smooth surface finishes and precise geometries.

Aerospace and automotive industries collectively represent approximately 28% of the market. These sectors demand components with exceptional mechanical properties, dimensional accuracy, and surface quality for functional prototypes and end-use parts. The aerospace industry specifically requires components that meet stringent certification standards, driving investment in volumetric 3D printing technologies that can deliver consistent surface finish and internal structure quality.

Consumer electronics manufacturers are increasingly adopting high-quality 3D printing for customized components, representing about 15% of the market. This sector values aesthetic surface finish alongside functional performance, particularly for visible consumer-facing parts.

Regionally, North America leads with approximately 42% market share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is experiencing the fastest growth rate at 22.3% annually, driven by rapid industrialization and significant government investments in advanced manufacturing technologies.

Market analysis indicates that customers are willing to pay premium prices for 3D printed components with superior surface finish, with price premiums ranging from 30-200% compared to standard quality prints. This price elasticity is particularly evident in medical and aerospace applications where surface quality directly impacts functionality.

Key market drivers include increasing demand for customization, reduced lead times compared to traditional manufacturing, and the ability to produce complex geometries impossible with conventional methods. The primary market restraint remains the high cost of equipment and materials capable of delivering superior surface finish, though these costs are decreasing as technology matures.

Future market growth will likely be fueled by advancements in volumetric printing technologies that can overcome current limitations in surface quality, particularly for overhanging features and internal structures. Industries requiring both aesthetic appeal and functional performance represent the most promising growth segments.

Healthcare represents the largest market segment, accounting for nearly 33% of the high-quality 3D printing market. The demand for patient-specific implants, prosthetics, and anatomical models with excellent surface quality has created a substantial market opportunity. Dental applications alone constitute a $2.5 billion segment, with growth rates exceeding 20% annually due to the requirement for smooth surface finishes and precise geometries.

Aerospace and automotive industries collectively represent approximately 28% of the market. These sectors demand components with exceptional mechanical properties, dimensional accuracy, and surface quality for functional prototypes and end-use parts. The aerospace industry specifically requires components that meet stringent certification standards, driving investment in volumetric 3D printing technologies that can deliver consistent surface finish and internal structure quality.

Consumer electronics manufacturers are increasingly adopting high-quality 3D printing for customized components, representing about 15% of the market. This sector values aesthetic surface finish alongside functional performance, particularly for visible consumer-facing parts.

Regionally, North America leads with approximately 42% market share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is experiencing the fastest growth rate at 22.3% annually, driven by rapid industrialization and significant government investments in advanced manufacturing technologies.

Market analysis indicates that customers are willing to pay premium prices for 3D printed components with superior surface finish, with price premiums ranging from 30-200% compared to standard quality prints. This price elasticity is particularly evident in medical and aerospace applications where surface quality directly impacts functionality.

Key market drivers include increasing demand for customization, reduced lead times compared to traditional manufacturing, and the ability to produce complex geometries impossible with conventional methods. The primary market restraint remains the high cost of equipment and materials capable of delivering superior surface finish, though these costs are decreasing as technology matures.

Future market growth will likely be fueled by advancements in volumetric printing technologies that can overcome current limitations in surface quality, particularly for overhanging features and internal structures. Industries requiring both aesthetic appeal and functional performance represent the most promising growth segments.

Current Challenges in Volumetric 3D Printing Technology

Despite significant advancements in volumetric 3D printing technology, several critical challenges continue to impede optimal part quality and surface finish. One fundamental limitation stems from the inherent trade-off between resolution and build volume. Current systems struggle to maintain high-resolution features when scaling up object dimensions, resulting in diminished surface quality for larger prints. This resolution constraint is particularly evident in tomographic volumetric printing, where light scattering and diffraction effects become more pronounced as build volumes increase.

Material constraints represent another significant hurdle. The photopolymer resins used in volumetric printing must simultaneously satisfy contradictory requirements: rapid curing kinetics for efficient printing while maintaining sufficient transparency to allow light penetration throughout the volume. These competing properties often result in compromised mechanical characteristics and surface quality, with many commercially available resins exhibiting post-cure shrinkage that introduces dimensional inaccuracies and surface defects.

Optical aberrations and light distribution non-uniformities present substantial technical barriers. The complex optical paths in volumetric systems frequently introduce distortions that manifest as surface irregularities. Particularly challenging is the "threshold effect" where regions receiving borderline exposure levels exhibit inconsistent polymerization, creating surface roughness and dimensional variability that proves difficult to predict or control systematically.

Thermal management during the curing process remains problematic. The exothermic nature of photopolymerization reactions generates localized heating that can cause material expansion, internal stress, and subsequent warping upon cooling. These thermal gradients are especially pronounced in larger builds, resulting in non-uniform surface characteristics and potential part deformation that compromises both aesthetic quality and functional performance.

Data processing limitations further complicate quality control efforts. The computational requirements for processing volumetric data at resolutions necessary for smooth surfaces exceed the capabilities of many current systems. This computational bottleneck often forces compromises in model fidelity, resulting in faceted surfaces and stair-stepping artifacts that diminish surface quality, particularly on curved or organic geometries.

Post-processing dependencies represent a final significant challenge. Unlike traditional manufacturing methods, volumetric printing currently requires extensive post-processing to achieve commercially acceptable surface finishes. This dependency on secondary operations increases production complexity, extends manufacturing timelines, and introduces variability that undermines the repeatability and standardization necessary for industrial adoption.

Material constraints represent another significant hurdle. The photopolymer resins used in volumetric printing must simultaneously satisfy contradictory requirements: rapid curing kinetics for efficient printing while maintaining sufficient transparency to allow light penetration throughout the volume. These competing properties often result in compromised mechanical characteristics and surface quality, with many commercially available resins exhibiting post-cure shrinkage that introduces dimensional inaccuracies and surface defects.

Optical aberrations and light distribution non-uniformities present substantial technical barriers. The complex optical paths in volumetric systems frequently introduce distortions that manifest as surface irregularities. Particularly challenging is the "threshold effect" where regions receiving borderline exposure levels exhibit inconsistent polymerization, creating surface roughness and dimensional variability that proves difficult to predict or control systematically.

Thermal management during the curing process remains problematic. The exothermic nature of photopolymerization reactions generates localized heating that can cause material expansion, internal stress, and subsequent warping upon cooling. These thermal gradients are especially pronounced in larger builds, resulting in non-uniform surface characteristics and potential part deformation that compromises both aesthetic quality and functional performance.

Data processing limitations further complicate quality control efforts. The computational requirements for processing volumetric data at resolutions necessary for smooth surfaces exceed the capabilities of many current systems. This computational bottleneck often forces compromises in model fidelity, resulting in faceted surfaces and stair-stepping artifacts that diminish surface quality, particularly on curved or organic geometries.

Post-processing dependencies represent a final significant challenge. Unlike traditional manufacturing methods, volumetric printing currently requires extensive post-processing to achieve commercially acceptable surface finishes. This dependency on secondary operations increases production complexity, extends manufacturing timelines, and introduces variability that undermines the repeatability and standardization necessary for industrial adoption.

Contemporary Solutions for Surface Finish Optimization

01 Surface finishing techniques for volumetric 3D printed parts

Various post-processing techniques can be applied to improve the surface finish of volumetric 3D printed parts. These techniques include mechanical polishing, chemical treatments, and thermal smoothing processes that can reduce surface roughness and enhance the aesthetic appearance of printed objects. The surface finishing methods are particularly important for parts requiring high precision and smooth surfaces for functional or visual purposes.- Surface finishing techniques for volumetric 3D printed parts: Various post-processing techniques can be applied to improve the surface finish of volumetric 3D printed parts. These include mechanical polishing, chemical treatments, and thermal smoothing processes that can reduce surface roughness and enhance the aesthetic appearance of printed objects. These finishing methods can effectively address layer lines and surface imperfections that are common in volumetric 3D printing, resulting in parts with smoother surfaces and improved visual quality.

- Optimization of printing parameters for improved part quality: The quality of volumetric 3D printed parts can be significantly enhanced by optimizing various printing parameters. These include light intensity, exposure time, resin composition, and curing strategies. By carefully controlling these parameters, issues such as over-curing, under-curing, and internal stress can be minimized, resulting in parts with better dimensional accuracy, mechanical properties, and surface finish. Advanced algorithms can be used to determine the optimal printing parameters for specific geometries and materials.

- Advanced resin formulations for enhanced surface quality: Specialized resin formulations can significantly improve the surface quality of volumetric 3D printed parts. These formulations may include additives that reduce shrinkage, minimize oxygen inhibition, and enhance light scattering properties. Some resins incorporate self-leveling components that help to smooth out surface imperfections during the curing process. Additionally, certain formulations are designed to achieve specific surface characteristics such as glossiness, matte finish, or textured appearances.

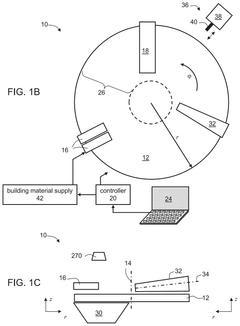

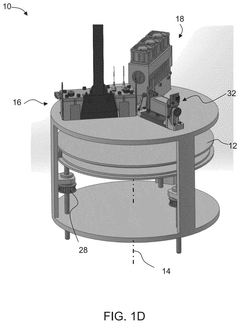

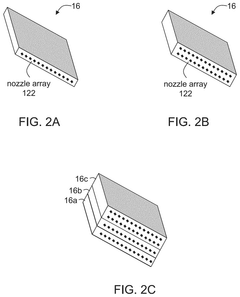

- Light projection and control systems for volumetric printing: Advanced light projection and control systems play a crucial role in achieving high-quality surface finish in volumetric 3D printing. These systems utilize precise spatial light modulators, sophisticated optics, and dynamic light patterns to control the curing process with high resolution. By implementing techniques such as grayscale projection, dynamic focusing, and synchronized multi-angle illumination, these systems can produce parts with smoother surfaces and finer details compared to conventional layer-by-layer printing approaches.

- Computational modeling for predicting and improving part quality: Computational modeling and simulation techniques are employed to predict and improve the quality of volumetric 3D printed parts. These models account for light propagation, resin curing kinetics, and material behavior during the printing process. By simulating the printing process before actual fabrication, potential issues such as internal stress, shrinkage, and surface defects can be identified and mitigated. Machine learning algorithms can also be used to analyze printing data and automatically adjust parameters to optimize surface finish and overall part quality.

02 Optimization of printing parameters for improved part quality

The quality of volumetric 3D printed parts can be significantly enhanced by optimizing various printing parameters. These parameters include light intensity, exposure time, resin composition, and curing conditions. By carefully controlling these variables, manufacturers can achieve better dimensional accuracy, reduced layer lines, and improved mechanical properties in the final printed parts.Expand Specific Solutions03 Advanced resin formulations for enhanced surface quality

Specialized resin formulations play a crucial role in determining the surface finish of volumetric 3D printed parts. Advanced resins containing specific additives, such as flow improvers, anti-aliasing agents, and nanoparticles, can significantly reduce surface roughness and minimize visible layer lines. These formulations are designed to achieve optimal viscosity and curing characteristics that result in smoother surfaces directly from the printing process.Expand Specific Solutions04 Multi-angle projection systems for improved part resolution

Multi-angle projection systems utilize multiple light sources or projectors positioned at different angles to cure resin from various directions simultaneously. This approach reduces the occurrence of shadowing effects and improves the resolution of complex geometries in volumetric 3D printing. By distributing the curing energy more evenly throughout the volume, these systems can achieve better feature definition and smoother surfaces on printed parts.Expand Specific Solutions05 Real-time monitoring and correction systems for print quality

Advanced monitoring systems can track the printing process in real-time and make dynamic adjustments to ensure optimal part quality. These systems use cameras, sensors, and machine learning algorithms to detect defects or irregularities during printing and automatically implement corrective measures. By continuously analyzing and adjusting the printing parameters, these systems can significantly improve surface finish and dimensional accuracy of volumetric 3D printed parts.Expand Specific Solutions

Leading Manufacturers and Research Institutions in the Field

Volumetric 3D printing technology is currently in a growth phase, with the market expanding rapidly due to increasing demand for high-quality, complex parts with superior surface finish. The global market is projected to reach significant scale as industries recognize the advantages of this technology over traditional layer-by-layer approaches. Technologically, the field shows varying maturity levels among key players. Stratasys and HP Development lead with advanced solutions for controlling part quality and surface finish, while newer entrants like Peridot Print and Quadratic 3D are introducing innovative approaches. Academic institutions including École Polytechnique Fédérale de Lausanne and Sichuan University are contributing fundamental research. Industrial giants such as Siemens, IBM, and Autodesk are developing supporting software and integration solutions, indicating the technology's transition toward industrial maturity and standardization.

Stratasys Ltd.

Technical Solution: Stratasys has developed advanced volumetric 3D printing technologies focusing on part quality and surface finish through their PolyJet technology. This system utilizes photopolymer jetting with UV curing to achieve micron-level precision. Their approach incorporates multi-material capabilities with simultaneous deposition of support structures that can be easily removed. Stratasys has implemented dynamic droplet size control that adjusts in real-time based on geometry requirements, allowing for smoother surfaces in critical areas. Their systems incorporate closed-loop feedback mechanisms that monitor curing parameters, material viscosity, and environmental conditions to maintain consistent part quality. Recent advancements include their GrabCAD Print software that optimizes tool paths specifically to enhance surface finish by calculating optimal deposition angles and layer transitions to minimize visible layer lines and artifacts.

Strengths: Superior multi-material capabilities allowing for complex geometries with excellent surface finish; proprietary software algorithms for optimizing surface quality; extensive material portfolio specifically engineered for surface finish. Weaknesses: Higher cost compared to conventional 3D printing technologies; requires specialized post-processing for certain applications; system complexity requires significant technical expertise.

AUTODESK INC

Technical Solution: Autodesk has developed comprehensive software solutions specifically addressing volumetric 3D printing quality and surface finish challenges. Their Netfabb software incorporates advanced algorithms for mesh optimization that identify and correct potential issues before printing begins. The platform includes specialized toolsets for lattice structure generation and optimization that maintain structural integrity while achieving desired surface characteristics. Autodesk's approach includes simulation capabilities that predict how material deposition, curing parameters, and support structures will affect final surface quality. Their software implements adaptive slicing algorithms that automatically vary layer thickness based on geometry complexity, allocating finer layers to areas requiring better surface finish. Autodesk has also pioneered generative design approaches that optimize part geometry for both functional requirements and manufacturability, including surface quality considerations. Their latest developments include AI-driven print preparation that learns from previous print outcomes to suggest optimal orientation, support structures, and process parameters for superior surface finish.

Strengths: Comprehensive software ecosystem that integrates with multiple hardware platforms; sophisticated simulation capabilities that predict surface quality issues before printing; powerful optimization algorithms. Weaknesses: Requires significant computing resources for complex simulations; steep learning curve for advanced features; primarily focused on software rather than hardware solutions.

Critical Patents and Research on Part Quality Enhancement

3D printing to obtain a predefined surface quality

PatentPendingUS20240342980A1

Innovation

- The method involves selecting a base surface with predefined qualities to print the 3D object, minimizing capillary forces of the jetted material, and integrating electronic components, ensuring that the surface quality is imparted to the object during the printing process, using substances like glass, polyimide, and polycarbonate to achieve desired textures such as glassiness, smoothness, or roughness.

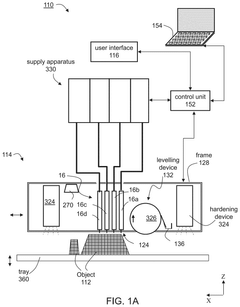

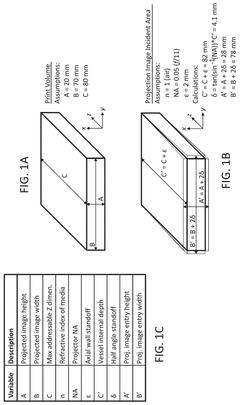

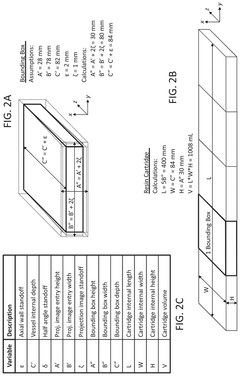

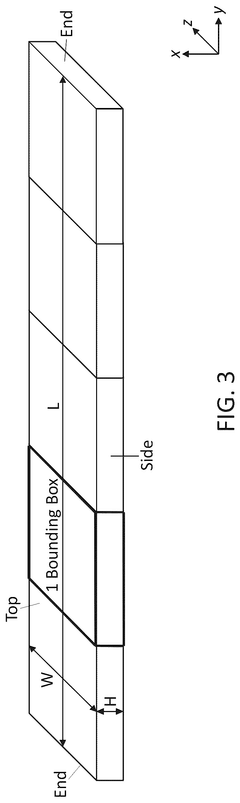

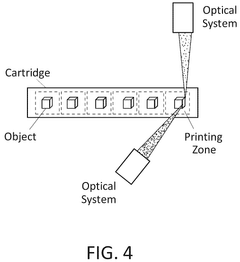

Cartridge, system, and method for volumetric 3D printing

PatentPendingUS20250073997A1

Innovation

- A cartridge system for volumetric 3D printing that uses a photopolymerizable composition with non-Newtonian rheological behavior, allowing for the formation of three-dimensional objects without support structures by irradiating the composition with multiple excitation light projections.

Material Science Advancements for Volumetric Printing

Recent advancements in material science have significantly propelled the evolution of volumetric 3D printing technologies, directly influencing part quality and surface finish outcomes. Photopolymer chemistry has undergone substantial refinement, with researchers developing specialized resins featuring optimized photoinitiators that respond precisely to specific wavelengths of light. These advanced formulations demonstrate improved reaction kinetics, enabling more controlled solidification processes and resulting in enhanced resolution capabilities down to the microscale.

The incorporation of nanoparticles and composite materials represents another breakthrough area. By integrating ceramic, metallic, or carbon-based nanoparticles into photosensitive resins, researchers have created materials with superior mechanical properties while maintaining excellent optical characteristics necessary for volumetric printing. These hybrid materials exhibit reduced shrinkage during curing, minimizing internal stresses that traditionally compromise dimensional accuracy and surface quality.

Rheological property optimization has emerged as a critical focus area, with scientists developing materials that maintain ideal viscosity profiles throughout the printing process. This advancement addresses one of the fundamental challenges in volumetric printing: ensuring uniform light penetration while preventing unwanted material flow during solidification. Materials with carefully engineered thixotropic properties allow for stable pattern formation during exposure while facilitating post-print material evacuation from uncured regions.

Cross-linking chemistry innovations have led to materials capable of forming more uniform polymer networks during curing. These advanced cross-linking mechanisms produce parts with isotropic mechanical properties and significantly improved surface smoothness. The development of dual-cure systems, combining photo and thermal curing mechanisms, has further enhanced material versatility, allowing for post-processing treatments that can refine surface characteristics without compromising structural integrity.

Biocompatible and functional materials represent the frontier of volumetric printing material science. Researchers have successfully developed hydrogel formulations with precisely controlled degradation profiles for biomedical applications, as well as stimuli-responsive materials that can change properties post-printing in response to environmental triggers. These advanced materials open new possibilities for creating complex functional structures with tailored surface properties.

The integration of machine learning approaches in material formulation has accelerated development cycles, with algorithms predicting optimal compositions based on desired mechanical and optical properties. This data-driven approach has led to the creation of material libraries specifically optimized for volumetric printing processes, each formulation designed to achieve specific quality metrics and surface finish characteristics under predetermined printing parameters.

The incorporation of nanoparticles and composite materials represents another breakthrough area. By integrating ceramic, metallic, or carbon-based nanoparticles into photosensitive resins, researchers have created materials with superior mechanical properties while maintaining excellent optical characteristics necessary for volumetric printing. These hybrid materials exhibit reduced shrinkage during curing, minimizing internal stresses that traditionally compromise dimensional accuracy and surface quality.

Rheological property optimization has emerged as a critical focus area, with scientists developing materials that maintain ideal viscosity profiles throughout the printing process. This advancement addresses one of the fundamental challenges in volumetric printing: ensuring uniform light penetration while preventing unwanted material flow during solidification. Materials with carefully engineered thixotropic properties allow for stable pattern formation during exposure while facilitating post-print material evacuation from uncured regions.

Cross-linking chemistry innovations have led to materials capable of forming more uniform polymer networks during curing. These advanced cross-linking mechanisms produce parts with isotropic mechanical properties and significantly improved surface smoothness. The development of dual-cure systems, combining photo and thermal curing mechanisms, has further enhanced material versatility, allowing for post-processing treatments that can refine surface characteristics without compromising structural integrity.

Biocompatible and functional materials represent the frontier of volumetric printing material science. Researchers have successfully developed hydrogel formulations with precisely controlled degradation profiles for biomedical applications, as well as stimuli-responsive materials that can change properties post-printing in response to environmental triggers. These advanced materials open new possibilities for creating complex functional structures with tailored surface properties.

The integration of machine learning approaches in material formulation has accelerated development cycles, with algorithms predicting optimal compositions based on desired mechanical and optical properties. This data-driven approach has led to the creation of material libraries specifically optimized for volumetric printing processes, each formulation designed to achieve specific quality metrics and surface finish characteristics under predetermined printing parameters.

Quality Control Systems and Standards for 3D Printed Parts

Quality control systems for volumetric 3D printing have evolved significantly to address the unique challenges presented by this advanced manufacturing technique. Current industry standards primarily focus on dimensional accuracy, surface finish quality, and material integrity. Organizations such as ASTM International and ISO have developed specific guidelines (ASTM F3091 and ISO/ASTM 52900) that establish measurement protocols and acceptance criteria for volumetric printed parts.

The implementation of in-situ monitoring systems represents a critical advancement in quality control for volumetric 3D printing. These systems utilize high-resolution cameras, spectroscopic sensors, and machine learning algorithms to detect anomalies during the printing process. Real-time data analysis enables immediate adjustments to printing parameters, significantly reducing defect rates and improving surface finish consistency.

Non-destructive testing (NDT) methodologies have been adapted specifically for volumetric printed components. Techniques such as computed tomography (CT) scanning, ultrasonic testing, and laser interferometry provide comprehensive assessment of internal structures without compromising part integrity. These methods are particularly valuable for detecting subsurface defects that may affect mechanical properties while maintaining pristine surface finish.

Statistical process control (SPC) frameworks tailored to volumetric 3D printing environments establish baseline performance metrics and control limits. By monitoring key process variables such as resin viscosity, light intensity distribution, and temperature gradients, manufacturers can maintain consistent part quality and surface characteristics across production runs. Advanced SPC implementations incorporate digital twins that simulate the printing process and predict potential quality issues before they manifest.

Certification pathways for volumetric 3D printed components have emerged in critical industries such as aerospace, medical devices, and automotive applications. These certification protocols typically require comprehensive documentation of process parameters, material traceability, and post-processing treatments that influence surface finish. Organizations like America Makes and the National Institute of Standards and Technology (NIST) continue to develop reference materials and calibration standards specifically for volumetric printing technologies.

Emerging quality control trends include the integration of artificial intelligence for predictive quality assurance and the development of standardized test artifacts designed to validate volumetric printing capabilities across different systems and materials. These innovations aim to establish universal benchmarks for surface finish quality and dimensional accuracy, facilitating broader industrial adoption of volumetric 3D printing technologies.

The implementation of in-situ monitoring systems represents a critical advancement in quality control for volumetric 3D printing. These systems utilize high-resolution cameras, spectroscopic sensors, and machine learning algorithms to detect anomalies during the printing process. Real-time data analysis enables immediate adjustments to printing parameters, significantly reducing defect rates and improving surface finish consistency.

Non-destructive testing (NDT) methodologies have been adapted specifically for volumetric printed components. Techniques such as computed tomography (CT) scanning, ultrasonic testing, and laser interferometry provide comprehensive assessment of internal structures without compromising part integrity. These methods are particularly valuable for detecting subsurface defects that may affect mechanical properties while maintaining pristine surface finish.

Statistical process control (SPC) frameworks tailored to volumetric 3D printing environments establish baseline performance metrics and control limits. By monitoring key process variables such as resin viscosity, light intensity distribution, and temperature gradients, manufacturers can maintain consistent part quality and surface characteristics across production runs. Advanced SPC implementations incorporate digital twins that simulate the printing process and predict potential quality issues before they manifest.

Certification pathways for volumetric 3D printed components have emerged in critical industries such as aerospace, medical devices, and automotive applications. These certification protocols typically require comprehensive documentation of process parameters, material traceability, and post-processing treatments that influence surface finish. Organizations like America Makes and the National Institute of Standards and Technology (NIST) continue to develop reference materials and calibration standards specifically for volumetric printing technologies.

Emerging quality control trends include the integration of artificial intelligence for predictive quality assurance and the development of standardized test artifacts designed to validate volumetric printing capabilities across different systems and materials. These innovations aim to establish universal benchmarks for surface finish quality and dimensional accuracy, facilitating broader industrial adoption of volumetric 3D printing technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!