What material innovations improve Volumetric 3D printing speed and durability

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric 3D Printing Evolution and Objectives

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, evolving from traditional layer-by-layer approaches to a revolutionary technique that creates entire objects simultaneously. This technology emerged in the early 2010s as researchers sought to overcome the speed limitations inherent in conventional 3D printing methods. The fundamental concept involves projecting patterns of light into photosensitive resins, causing simultaneous solidification throughout the volume rather than sequentially building layers.

The evolution of volumetric 3D printing can be traced through several key developmental phases. Initially, researchers at Lawrence Livermore National Laboratory and UC Berkeley pioneered the Computed Axial Lithography (CAL) technique around 2017, demonstrating the first practical implementations of volumetric printing. This was followed by significant advancements in projection systems and material formulations between 2018-2020, enabling higher resolution and more complex geometries.

By 2021-2022, the technology witnessed substantial improvements in printing speed, with some systems achieving print times of mere seconds or minutes for objects that would require hours using traditional methods. This acceleration represented a critical inflection point in the technology's commercial viability. Concurrently, material scientists began developing specialized photopolymers specifically optimized for volumetric printing processes.

The primary objective of current research in volumetric 3D printing materials is to significantly enhance printing speed while maintaining or improving the durability of printed objects. This dual focus addresses the technology's most pressing limitations: the need for rapid production capabilities for industrial applications and the requirement for end-use parts with mechanical properties comparable to traditionally manufactured components.

Specific technical goals include developing photopolymer formulations with faster curing kinetics without sacrificing structural integrity, creating composite materials that incorporate reinforcement elements for enhanced mechanical properties, and engineering resins with improved thermal stability and chemical resistance. Additionally, researchers aim to expand the palette of available materials to include biocompatible options for medical applications and high-performance polymers for engineering applications.

The long-term trajectory for volumetric 3D printing technology points toward multi-material capabilities, enabling the creation of objects with regionally varied properties and functions. This evolution would potentially position volumetric printing as a transformative manufacturing technology across industries ranging from medical devices to automotive components, consumer electronics, and beyond.

The evolution of volumetric 3D printing can be traced through several key developmental phases. Initially, researchers at Lawrence Livermore National Laboratory and UC Berkeley pioneered the Computed Axial Lithography (CAL) technique around 2017, demonstrating the first practical implementations of volumetric printing. This was followed by significant advancements in projection systems and material formulations between 2018-2020, enabling higher resolution and more complex geometries.

By 2021-2022, the technology witnessed substantial improvements in printing speed, with some systems achieving print times of mere seconds or minutes for objects that would require hours using traditional methods. This acceleration represented a critical inflection point in the technology's commercial viability. Concurrently, material scientists began developing specialized photopolymers specifically optimized for volumetric printing processes.

The primary objective of current research in volumetric 3D printing materials is to significantly enhance printing speed while maintaining or improving the durability of printed objects. This dual focus addresses the technology's most pressing limitations: the need for rapid production capabilities for industrial applications and the requirement for end-use parts with mechanical properties comparable to traditionally manufactured components.

Specific technical goals include developing photopolymer formulations with faster curing kinetics without sacrificing structural integrity, creating composite materials that incorporate reinforcement elements for enhanced mechanical properties, and engineering resins with improved thermal stability and chemical resistance. Additionally, researchers aim to expand the palette of available materials to include biocompatible options for medical applications and high-performance polymers for engineering applications.

The long-term trajectory for volumetric 3D printing technology points toward multi-material capabilities, enabling the creation of objects with regionally varied properties and functions. This evolution would potentially position volumetric printing as a transformative manufacturing technology across industries ranging from medical devices to automotive components, consumer electronics, and beyond.

Market Analysis for High-Speed Volumetric 3D Printing

The volumetric 3D printing market is experiencing rapid growth, driven by increasing demand for faster, more efficient additive manufacturing solutions across multiple industries. Current market valuations place the global volumetric 3D printing sector at approximately $2.3 billion, with projections indicating a compound annual growth rate of 22% through 2028. This accelerated growth trajectory is primarily fueled by industrial manufacturing, healthcare, and aerospace sectors seeking advanced production capabilities.

Market demand for high-speed volumetric 3D printing is particularly strong in medical applications, where the technology enables rapid production of patient-specific implants, prosthetics, and anatomical models. The healthcare segment currently represents about 32% of the total market share, with surgical planning and medical device prototyping showing the strongest demand signals.

Industrial manufacturing constitutes another significant market segment, accounting for approximately 28% of current demand. Companies are increasingly adopting volumetric 3D printing to reduce production time and material waste while maintaining structural integrity in complex components. The automotive industry has emerged as a key adopter, utilizing the technology for rapid prototyping and small-batch production of specialized parts.

Consumer electronics manufacturers are also entering this market space, representing a growing segment with 15% market share. These companies leverage volumetric printing for creating intricate internal structures and custom housings that would be impossible to produce using traditional manufacturing methods.

Regional analysis reveals North America currently leads the market with 42% share, followed by Europe at 31% and Asia-Pacific at 22%. However, the Asia-Pacific region is demonstrating the fastest growth rate at 27% annually, driven by significant investments in manufacturing technology in China, Japan, and South Korea.

Market barriers include the high initial investment costs for volumetric printing systems, which typically range from $150,000 to $750,000 depending on capabilities. Material limitations also restrict wider adoption, as many industries require specific performance characteristics that current printable materials cannot consistently deliver.

Customer surveys indicate that print speed and material durability rank as the top two priorities for potential adopters, with 78% of respondents citing these factors as critical decision-making criteria. This clearly signals that material innovations addressing these specific pain points would unlock significant market potential and accelerate adoption across industries currently hesitant to invest in the technology.

Market demand for high-speed volumetric 3D printing is particularly strong in medical applications, where the technology enables rapid production of patient-specific implants, prosthetics, and anatomical models. The healthcare segment currently represents about 32% of the total market share, with surgical planning and medical device prototyping showing the strongest demand signals.

Industrial manufacturing constitutes another significant market segment, accounting for approximately 28% of current demand. Companies are increasingly adopting volumetric 3D printing to reduce production time and material waste while maintaining structural integrity in complex components. The automotive industry has emerged as a key adopter, utilizing the technology for rapid prototyping and small-batch production of specialized parts.

Consumer electronics manufacturers are also entering this market space, representing a growing segment with 15% market share. These companies leverage volumetric printing for creating intricate internal structures and custom housings that would be impossible to produce using traditional manufacturing methods.

Regional analysis reveals North America currently leads the market with 42% share, followed by Europe at 31% and Asia-Pacific at 22%. However, the Asia-Pacific region is demonstrating the fastest growth rate at 27% annually, driven by significant investments in manufacturing technology in China, Japan, and South Korea.

Market barriers include the high initial investment costs for volumetric printing systems, which typically range from $150,000 to $750,000 depending on capabilities. Material limitations also restrict wider adoption, as many industries require specific performance characteristics that current printable materials cannot consistently deliver.

Customer surveys indicate that print speed and material durability rank as the top two priorities for potential adopters, with 78% of respondents citing these factors as critical decision-making criteria. This clearly signals that material innovations addressing these specific pain points would unlock significant market potential and accelerate adoption across industries currently hesitant to invest in the technology.

Current Material Limitations and Technical Challenges

Volumetric 3D printing faces significant material limitations that currently restrict its widespread industrial adoption. Traditional photopolymer resins used in volumetric printing exhibit insufficient mechanical properties, particularly in terms of tensile strength and impact resistance. These materials often produce parts that are brittle and prone to fracture under stress, limiting their application in functional prototypes or end-use parts that require durability.

The viscosity of printable materials presents another critical challenge. Optimal volumetric printing requires materials with low viscosity to allow rapid light penetration and curing throughout the volume. However, low-viscosity resins typically result in weaker mechanical properties. This creates a fundamental trade-off between printing speed and part durability that has proven difficult to overcome with current material formulations.

Photoinitiator efficiency remains a significant bottleneck in volumetric printing processes. Current photoinitiators often exhibit limited quantum yield and absorption spectra that don't perfectly match the emission profiles of commonly used light sources. This mismatch reduces energy transfer efficiency, necessitating longer exposure times and consequently slower printing speeds.

The refractive index homogeneity across the printing volume presents additional complications. As light travels through the resin, scattering and absorption effects can create inconsistent curing patterns, leading to internal stresses and potential part failure. This issue becomes more pronounced when printing larger objects, where light must penetrate deeper into the material volume.

Temperature sensitivity of current materials further complicates the printing process. Many photopolymer resins exhibit significant property variations with temperature fluctuations, affecting both printing speed and final part characteristics. This sensitivity necessitates precise environmental control systems, adding complexity and cost to volumetric printing setups.

Oxygen inhibition represents another persistent challenge, particularly at material interfaces. Oxygen molecules can quench the free-radical polymerization process, creating uncured or partially cured regions that compromise structural integrity. While some volumetric techniques mitigate this through complete volume immersion, the problem persists at microscopic levels.

Material shrinkage during curing introduces dimensional accuracy issues and internal stresses. Current resins typically experience volumetric shrinkage of 5-15% during polymerization, which can lead to warping, cracking, and deviation from intended geometries. This shrinkage becomes particularly problematic for precision applications requiring tight tolerances.

The limited range of available materials also restricts application versatility. Unlike traditional manufacturing or even other 3D printing methods, volumetric printing currently offers a relatively narrow selection of compatible materials, predominantly photocurable resins with limited functional properties. The development of materials with enhanced mechanical properties, thermal stability, and functional characteristics remains a critical research priority.

The viscosity of printable materials presents another critical challenge. Optimal volumetric printing requires materials with low viscosity to allow rapid light penetration and curing throughout the volume. However, low-viscosity resins typically result in weaker mechanical properties. This creates a fundamental trade-off between printing speed and part durability that has proven difficult to overcome with current material formulations.

Photoinitiator efficiency remains a significant bottleneck in volumetric printing processes. Current photoinitiators often exhibit limited quantum yield and absorption spectra that don't perfectly match the emission profiles of commonly used light sources. This mismatch reduces energy transfer efficiency, necessitating longer exposure times and consequently slower printing speeds.

The refractive index homogeneity across the printing volume presents additional complications. As light travels through the resin, scattering and absorption effects can create inconsistent curing patterns, leading to internal stresses and potential part failure. This issue becomes more pronounced when printing larger objects, where light must penetrate deeper into the material volume.

Temperature sensitivity of current materials further complicates the printing process. Many photopolymer resins exhibit significant property variations with temperature fluctuations, affecting both printing speed and final part characteristics. This sensitivity necessitates precise environmental control systems, adding complexity and cost to volumetric printing setups.

Oxygen inhibition represents another persistent challenge, particularly at material interfaces. Oxygen molecules can quench the free-radical polymerization process, creating uncured or partially cured regions that compromise structural integrity. While some volumetric techniques mitigate this through complete volume immersion, the problem persists at microscopic levels.

Material shrinkage during curing introduces dimensional accuracy issues and internal stresses. Current resins typically experience volumetric shrinkage of 5-15% during polymerization, which can lead to warping, cracking, and deviation from intended geometries. This shrinkage becomes particularly problematic for precision applications requiring tight tolerances.

The limited range of available materials also restricts application versatility. Unlike traditional manufacturing or even other 3D printing methods, volumetric printing currently offers a relatively narrow selection of compatible materials, predominantly photocurable resins with limited functional properties. The development of materials with enhanced mechanical properties, thermal stability, and functional characteristics remains a critical research priority.

Current Material Formulations for Enhanced Print Speed

01 Photopolymer resins for high-speed volumetric printing

Advanced photopolymer resins specifically formulated for volumetric 3D printing enable significantly faster production speeds while maintaining structural integrity. These materials contain photoinitiators that respond rapidly to specific light wavelengths, allowing for simultaneous curing throughout the entire volume rather than layer-by-layer processing. The formulations balance cure speed with mechanical properties to achieve both rapid production and durable final parts.- High-speed volumetric 3D printing materials: Advanced materials specifically designed for high-speed volumetric 3D printing processes that enable rapid fabrication without compromising structural integrity. These materials are formulated to cure quickly under specific light conditions, allowing for faster printing speeds while maintaining dimensional accuracy. The formulations typically include photoinitiators that respond rapidly to light exposure, reducing the overall print time significantly compared to traditional layer-by-layer methods.

- Durable resin compositions for volumetric printing: Specialized resin compositions developed for volumetric 3D printing that offer enhanced mechanical properties and durability. These materials incorporate reinforcing agents, cross-linking additives, and stabilizers to improve tensile strength, impact resistance, and long-term stability. The resulting printed objects demonstrate superior durability under various environmental conditions and mechanical stresses, making them suitable for functional prototypes and end-use parts.

- Hybrid materials for balancing speed and durability: Innovative hybrid material systems that combine different polymer types or incorporate nanoparticles to achieve an optimal balance between printing speed and final part durability. These materials are engineered to maintain rapid curing characteristics while simultaneously enhancing mechanical properties such as flexibility, hardness, and wear resistance. The hybrid approach allows manufacturers to customize material properties based on specific application requirements without sacrificing production efficiency.

- Temperature-responsive materials for volumetric printing: Temperature-sensitive materials designed specifically for volumetric 3D printing that exhibit improved curing rates and mechanical properties through controlled thermal conditions. These materials incorporate thermally activated components that enhance cross-linking efficiency and structural integrity when exposed to specific temperature profiles during the printing process. By optimizing the thermal behavior of these materials, both printing speed and final part durability can be significantly improved.

- Post-processing techniques for enhanced durability: Methods and materials designed to improve the durability of volumetrically printed objects through specialized post-processing techniques. These approaches include secondary curing processes, thermal treatments, and surface modification methods that enhance the mechanical properties and environmental resistance of printed parts. The materials are formulated to respond favorably to these post-processing steps, resulting in significant improvements in strength, durability, and functional performance while maintaining the speed advantages of volumetric printing.

02 Composite materials for enhanced durability

Composite materials incorporating reinforcing elements such as nanoparticles, fibers, or ceramic additives significantly improve the mechanical properties of volumetrically printed objects. These additives enhance tensile strength, impact resistance, and overall durability while maintaining compatibility with high-speed volumetric printing processes. The strategic distribution of reinforcing elements throughout the printing material creates stronger internal structures that resist deformation and failure under stress.Expand Specific Solutions03 Temperature-responsive materials for process optimization

Temperature-responsive materials designed for volumetric 3D printing exhibit controlled viscosity and curing behavior at specific temperature ranges. These materials flow efficiently during the printing process and then rapidly solidify when exposed to the appropriate thermal conditions, enabling faster production cycles. The temperature-responsive properties also contribute to improved layer adhesion and reduced internal stresses, resulting in more durable printed objects with enhanced mechanical performance.Expand Specific Solutions04 Light-sensitive hydrogels for biomedical applications

Specialized light-sensitive hydrogels have been developed for volumetric bioprinting that combine rapid curing speeds with biocompatibility and controlled degradation properties. These materials respond quickly to specific light patterns while maintaining cell viability and providing appropriate mechanical support for tissue engineering applications. The hydrogels can be formulated with varying stiffness and porosity to match the requirements of different biological tissues, offering both speed in fabrication and durability appropriate for their intended medical use.Expand Specific Solutions05 Multi-material systems for optimized performance

Advanced multi-material volumetric printing systems utilize combinations of materials with complementary properties to achieve both high printing speeds and excellent durability. These systems strategically distribute rigid and flexible components throughout the printed object, creating structures with optimized mechanical performance. The precise spatial control of different materials enables the creation of gradient properties and functional interfaces that enhance overall durability while maintaining rapid production capabilities.Expand Specific Solutions

Leading Companies and Research Institutions in Volumetric Printing

Volumetric 3D printing technology is currently in a growth phase, with the market expected to reach significant expansion as material innovations address key limitations in speed and durability. The competitive landscape features established players like HP Development and Desktop Metal alongside specialized innovators such as dp polar GmbH (part of 3D Systems) and AIM3D GmbH. Academic institutions including Lawrence Livermore National Laboratory, Northwestern University, and EPFL are driving fundamental research advances. Industrial manufacturers like Siemens Energy and Hon Hai Precision are exploring applications in high-performance components. The technology is approaching commercial maturity for specific applications, with companies focusing on proprietary material formulations that balance rapid curing properties with mechanical strength and longevity, positioning volumetric 3D printing for broader industrial adoption.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Laboratory has pioneered volumetric 3D printing through their Computed Axial Lithography (CAL) technology, which creates objects simultaneously rather than layer-by-layer. Their approach uses projected light patterns from multiple angles into photosensitive resin, allowing for printing speeds 100-1000 times faster than conventional methods. They've developed specialized photopolymer formulations with tunable mechanical properties and enhanced durability through the incorporation of ceramic or metal nanoparticles. Their recent material innovations include self-healing resins that can repair microdamage and temperature-resistant formulations that maintain structural integrity under extreme conditions. The lab has also implemented machine learning algorithms to optimize light delivery patterns, further reducing print times while maintaining resolution quality. Their volumetric printing technology eliminates the need for support structures, enabling complex geometries impossible with traditional methods.

Strengths: Dramatically faster printing speeds compared to conventional methods; ability to create objects with complex internal structures without support materials; excellent surface finish quality due to absence of layer lines. Weaknesses: Currently limited to photopolymer materials; size constraints based on optical setup; requires specialized equipment not widely available in commercial settings.

École Polytechnique Fédérale de Lausanne

Technical Solution: EPFL researchers have developed a groundbreaking volumetric 3D printing technique called tomographic volumetric additive manufacturing. This approach uses tomographic projections to solidify an entire volume of photosensitive resin simultaneously, rather than layer-by-layer. Their system rotates a container of resin while projecting carefully calculated light patterns from multiple angles, achieving complete solidification in under 30 seconds for centimeter-scale objects - a process that would take hours with conventional methods. EPFL has focused on material innovations by developing specialized photoinitiators that respond to specific wavelengths, allowing for multi-material printing within the same volume. Their research includes nanocomposite resins incorporating silica nanoparticles that significantly improve mechanical properties, with tensile strength increases of up to 40% compared to standard resins. They've also pioneered bio-compatible formulations suitable for medical applications, with controlled degradation rates for tissue engineering scaffolds. Recent advancements include the development of thiol-ene chemistry-based resins that offer reduced oxygen inhibition and faster curing rates, further accelerating the printing process.

Strengths: Extremely fast printing speeds (seconds versus hours); excellent resolution capabilities down to 80 micrometers; ability to create objects with complex internal structures impossible with other methods. Weaknesses: Currently limited to relatively small build volumes; restricted to photopolymer materials; challenges with creating objects that have varying optical properties throughout the volume.

Key Patents and Research on Durable Volumetric Printing Materials

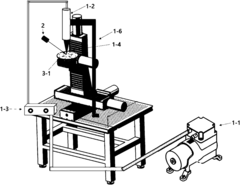

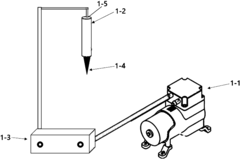

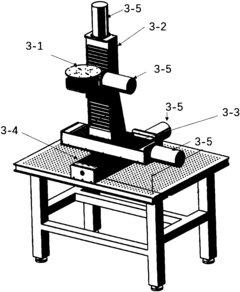

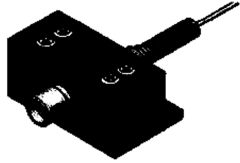

3D printing material and equipment for three-dimensional laser deposition molding

PatentActiveCN108264756A

Innovation

- Three-dimensional laser deposition modeling material composed of aluminum powder, silica, polyurethane acrylate, ethoxyethoxyethylacrylate and phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide , combined with the equipment of feeding device, light curing device and three-dimensional motion platform, to achieve fast and accurate printing.

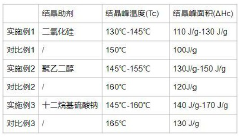

3D printing elastomer material capable of accelerating crystallization rate and preparation method of 3D printing elastomer material

PatentPendingCN116715950A

Innovation

- Using a combination of polyurethane, polylactic acid, polycaprolactone, inorganic fillers, stabilizers and crystallization aids, extruded through twin-screw blending equipment, adding crystallization aids such as nano-silica, polyethylene glycol and dodecane base sodium sulfate, adjust the temperature and screw speed to speed up the crystallization rate.

Sustainability Aspects of Advanced 3D Printing Materials

The sustainability implications of volumetric 3D printing materials represent a critical dimension in the advancement of additive manufacturing technologies. As industries increasingly adopt volumetric 3D printing methods, the environmental footprint of these processes demands thorough examination. Current photopolymer resins used in volumetric printing often contain petroleum-based components with significant ecological concerns regarding biodegradability and toxicity.

Recent innovations have focused on developing bio-based alternatives derived from renewable resources such as cellulose, lignin, and plant oils. These materials not only reduce dependency on fossil fuels but also demonstrate promising degradability characteristics. For instance, modified alginate-based resins have shown comparable mechanical properties to conventional options while offering enhanced end-of-life management possibilities.

Energy consumption represents another crucial sustainability factor. Traditional volumetric printing materials require substantial energy inputs during both production and curing processes. New formulations incorporating photo-initiators with higher quantum efficiency have demonstrated energy requirement reductions of up to 30%, significantly lowering the carbon footprint of printing operations.

Material waste reduction constitutes a fundamental advantage of volumetric printing compared to layer-by-layer approaches. However, innovations in material recyclability further enhance this benefit. Advanced recovery systems now enable the reclamation of uncured resins with minimal quality degradation, creating closed-loop material cycles within manufacturing environments.

Water usage and contamination concerns are being addressed through the development of water-soluble support materials that dissolve without harmful chemical additives. This approach eliminates the need for solvent-based cleaning processes that traditionally generate hazardous waste streams requiring specialized disposal.

Life cycle assessment (LCA) studies indicate that durability improvements in volumetric printing materials significantly enhance sustainability metrics. Materials exhibiting extended functional lifespans effectively amortize their environmental impact over longer periods, reducing replacement frequency and associated resource consumption.

Regulatory frameworks worldwide are increasingly emphasizing material sustainability, with the European Union's REACH regulations and similar initiatives driving research toward less hazardous photopolymer compositions. This regulatory landscape is accelerating the transition toward greener chemistry approaches in volumetric printing material development, creating market opportunities for environmentally responsible innovations.

Recent innovations have focused on developing bio-based alternatives derived from renewable resources such as cellulose, lignin, and plant oils. These materials not only reduce dependency on fossil fuels but also demonstrate promising degradability characteristics. For instance, modified alginate-based resins have shown comparable mechanical properties to conventional options while offering enhanced end-of-life management possibilities.

Energy consumption represents another crucial sustainability factor. Traditional volumetric printing materials require substantial energy inputs during both production and curing processes. New formulations incorporating photo-initiators with higher quantum efficiency have demonstrated energy requirement reductions of up to 30%, significantly lowering the carbon footprint of printing operations.

Material waste reduction constitutes a fundamental advantage of volumetric printing compared to layer-by-layer approaches. However, innovations in material recyclability further enhance this benefit. Advanced recovery systems now enable the reclamation of uncured resins with minimal quality degradation, creating closed-loop material cycles within manufacturing environments.

Water usage and contamination concerns are being addressed through the development of water-soluble support materials that dissolve without harmful chemical additives. This approach eliminates the need for solvent-based cleaning processes that traditionally generate hazardous waste streams requiring specialized disposal.

Life cycle assessment (LCA) studies indicate that durability improvements in volumetric printing materials significantly enhance sustainability metrics. Materials exhibiting extended functional lifespans effectively amortize their environmental impact over longer periods, reducing replacement frequency and associated resource consumption.

Regulatory frameworks worldwide are increasingly emphasizing material sustainability, with the European Union's REACH regulations and similar initiatives driving research toward less hazardous photopolymer compositions. This regulatory landscape is accelerating the transition toward greener chemistry approaches in volumetric printing material development, creating market opportunities for environmentally responsible innovations.

Manufacturing Scale-up Considerations for Novel Materials

Scaling up the production of novel materials for volumetric 3D printing presents significant challenges that must be addressed to transition from laboratory-scale demonstrations to industrial manufacturing. The primary consideration involves establishing consistent material synthesis protocols that can be replicated at larger scales without compromising the photosensitive properties essential for volumetric printing processes.

Material homogeneity becomes increasingly critical at industrial scales, as variations in resin composition can lead to inconsistent curing responses and structural defects in printed objects. Manufacturers must implement rigorous quality control measures, including spectroscopic analysis and rheological testing, to ensure batch-to-batch consistency of photopolymer formulations.

Supply chain resilience represents another key consideration, particularly for specialized photoinitiators and additives that enhance printing speed and durability. Many cutting-edge volumetric printing materials rely on components with limited commercial availability, necessitating strategic supplier relationships or in-house synthesis capabilities to prevent production bottlenecks.

Equipment modification for large-scale material production presents technical challenges distinct from those in conventional manufacturing. Specialized mixing equipment with precise temperature control and inert atmosphere capabilities is often required to maintain material integrity during scale-up. Additionally, filtration systems must be optimized to remove particulates that could interfere with light transmission during the volumetric printing process.

Cost optimization strategies become paramount when scaling novel materials production. While laboratory-scale materials may utilize expensive components to achieve proof-of-concept results, commercial viability demands reformulation with more economical alternatives without sacrificing performance characteristics. This often involves substituting proprietary additives with commercially available alternatives or developing synthetic pathways that reduce production complexity.

Environmental and safety considerations also influence manufacturing scale-up decisions. Many photopolymer components present handling hazards that become more significant at industrial scales. Manufacturers must implement appropriate engineering controls, including closed processing systems and solvent recovery technologies, to minimize worker exposure and environmental impact while complying with regulatory requirements.

Shelf-life stability represents a final critical consideration for scaled production of volumetric printing materials. Formulations that demonstrate adequate stability in laboratory settings may exhibit accelerated degradation when produced in larger batches or stored for extended periods. Manufacturers must conduct accelerated aging studies and develop appropriate stabilization strategies, such as antioxidant additives or modified packaging, to ensure consistent performance throughout the material's commercial lifecycle.

Material homogeneity becomes increasingly critical at industrial scales, as variations in resin composition can lead to inconsistent curing responses and structural defects in printed objects. Manufacturers must implement rigorous quality control measures, including spectroscopic analysis and rheological testing, to ensure batch-to-batch consistency of photopolymer formulations.

Supply chain resilience represents another key consideration, particularly for specialized photoinitiators and additives that enhance printing speed and durability. Many cutting-edge volumetric printing materials rely on components with limited commercial availability, necessitating strategic supplier relationships or in-house synthesis capabilities to prevent production bottlenecks.

Equipment modification for large-scale material production presents technical challenges distinct from those in conventional manufacturing. Specialized mixing equipment with precise temperature control and inert atmosphere capabilities is often required to maintain material integrity during scale-up. Additionally, filtration systems must be optimized to remove particulates that could interfere with light transmission during the volumetric printing process.

Cost optimization strategies become paramount when scaling novel materials production. While laboratory-scale materials may utilize expensive components to achieve proof-of-concept results, commercial viability demands reformulation with more economical alternatives without sacrificing performance characteristics. This often involves substituting proprietary additives with commercially available alternatives or developing synthetic pathways that reduce production complexity.

Environmental and safety considerations also influence manufacturing scale-up decisions. Many photopolymer components present handling hazards that become more significant at industrial scales. Manufacturers must implement appropriate engineering controls, including closed processing systems and solvent recovery technologies, to minimize worker exposure and environmental impact while complying with regulatory requirements.

Shelf-life stability represents a final critical consideration for scaled production of volumetric printing materials. Formulations that demonstrate adequate stability in laboratory settings may exhibit accelerated degradation when produced in larger batches or stored for extended periods. Manufacturers must conduct accelerated aging studies and develop appropriate stabilization strategies, such as antioxidant additives or modified packaging, to ensure consistent performance throughout the material's commercial lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!