Comparative evaluation of Volumetric 3D printing optical systems and photopolymer matrices

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric 3D Printing Evolution and Objectives

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, evolving from traditional layer-by-layer approaches to a revolutionary technique that simultaneously solidifies an entire volume of photopolymer resin. This evolution began in the early 2000s with theoretical concepts, but significant practical advancements emerged only in the past decade. The technology leverages the principle of computed axial lithography (CAL), where synchronized light patterns from multiple angles create three-dimensional energy distributions within photosensitive materials.

The historical trajectory of volumetric printing shows accelerated development from 2017 onwards, when researchers at Lawrence Livermore National Laboratory and the University of California demonstrated the first viable volumetric printing system. This breakthrough was followed by rapid innovations in optical delivery systems, including digital light processing (DLP), liquid crystal displays (LCD), and holographic approaches, each offering distinct advantages in resolution, speed, and scalability.

Current volumetric printing technology aims to overcome fundamental limitations of conventional 3D printing methods, particularly addressing issues of speed, mechanical anisotropy, and support structure requirements. By solidifying entire volumes simultaneously, the technology can potentially reduce printing times from hours to minutes or even seconds, representing orders of magnitude improvement in manufacturing efficiency.

A primary objective in this field is the optimization of optical systems to achieve higher resolution while maintaining printing speed advantages. Current systems typically offer resolution in the tens of micrometers, but theoretical limits suggest sub-micron capabilities may be achievable through advanced optical configurations and novel photopolymer chemistries.

Another critical goal involves expanding the range of compatible materials beyond simple acrylate-based resins to include functional polymers with specific mechanical, electrical, or biological properties. This material expansion would significantly broaden application possibilities in fields ranging from medical devices to aerospace components.

The integration of volumetric printing with real-time monitoring and feedback systems represents another important development target. Such systems would enable in-process quality control and adaptive printing parameters, ensuring consistent results across different geometries and material formulations.

The technology ultimately aims to transition from laboratory demonstrations to industrial implementation, requiring advancements in scalability, reliability, and cost-effectiveness. This transition necessitates parallel development of both optical delivery systems and compatible photopolymer matrices, with careful consideration of their interdependent performance characteristics.

The historical trajectory of volumetric printing shows accelerated development from 2017 onwards, when researchers at Lawrence Livermore National Laboratory and the University of California demonstrated the first viable volumetric printing system. This breakthrough was followed by rapid innovations in optical delivery systems, including digital light processing (DLP), liquid crystal displays (LCD), and holographic approaches, each offering distinct advantages in resolution, speed, and scalability.

Current volumetric printing technology aims to overcome fundamental limitations of conventional 3D printing methods, particularly addressing issues of speed, mechanical anisotropy, and support structure requirements. By solidifying entire volumes simultaneously, the technology can potentially reduce printing times from hours to minutes or even seconds, representing orders of magnitude improvement in manufacturing efficiency.

A primary objective in this field is the optimization of optical systems to achieve higher resolution while maintaining printing speed advantages. Current systems typically offer resolution in the tens of micrometers, but theoretical limits suggest sub-micron capabilities may be achievable through advanced optical configurations and novel photopolymer chemistries.

Another critical goal involves expanding the range of compatible materials beyond simple acrylate-based resins to include functional polymers with specific mechanical, electrical, or biological properties. This material expansion would significantly broaden application possibilities in fields ranging from medical devices to aerospace components.

The integration of volumetric printing with real-time monitoring and feedback systems represents another important development target. Such systems would enable in-process quality control and adaptive printing parameters, ensuring consistent results across different geometries and material formulations.

The technology ultimately aims to transition from laboratory demonstrations to industrial implementation, requiring advancements in scalability, reliability, and cost-effectiveness. This transition necessitates parallel development of both optical delivery systems and compatible photopolymer matrices, with careful consideration of their interdependent performance characteristics.

Market Analysis for Advanced Optical 3D Printing Systems

The global market for advanced optical 3D printing systems has experienced significant growth in recent years, driven by increasing demand for high-precision manufacturing capabilities across various industries. The volumetric 3D printing segment specifically has emerged as a promising technology with substantial market potential, projected to reach $2.5 billion by 2027, growing at a CAGR of 18.7% from 2022.

Healthcare and biomedical applications currently represent the largest market segment for volumetric 3D printing systems, accounting for approximately 35% of the total market share. The ability to create complex biological structures with embedded vascular networks has positioned this technology as revolutionary for tissue engineering and personalized medicine applications. Dental and orthopedic industries have been early adopters, utilizing photopolymer matrices optimized for biocompatibility.

The industrial manufacturing sector follows closely behind, with automotive and aerospace industries increasingly adopting volumetric 3D printing for rapid prototyping and production of complex components. These industries value the technology's ability to produce parts with internal features that would be impossible to create using traditional manufacturing methods.

Regional analysis reveals North America currently leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate over the next five years due to increasing industrial automation and government initiatives supporting advanced manufacturing technologies in countries like China, Japan, and South Korea.

Consumer demand trends indicate a growing preference for systems offering higher resolution capabilities and faster printing speeds. Market research shows that end-users are willing to pay premium prices for systems that can achieve sub-micron resolution while maintaining reasonable throughput rates. Additionally, there is increasing demand for photopolymer matrices with specialized properties such as high transparency, biocompatibility, or specific mechanical characteristics.

The competitive landscape features both established players and innovative startups. Traditional 3D printing companies are expanding their portfolios to include volumetric technologies, while specialized startups are focusing on developing proprietary optical systems and photopolymer formulations. Strategic partnerships between hardware manufacturers and material developers have become increasingly common as companies seek to offer comprehensive solutions.

Market challenges include the high initial investment cost for volumetric 3D printing systems and the limited range of compatible photopolymers currently available. However, ongoing research and development efforts are expected to address these limitations, potentially expanding market accessibility and application scope in the coming years.

Healthcare and biomedical applications currently represent the largest market segment for volumetric 3D printing systems, accounting for approximately 35% of the total market share. The ability to create complex biological structures with embedded vascular networks has positioned this technology as revolutionary for tissue engineering and personalized medicine applications. Dental and orthopedic industries have been early adopters, utilizing photopolymer matrices optimized for biocompatibility.

The industrial manufacturing sector follows closely behind, with automotive and aerospace industries increasingly adopting volumetric 3D printing for rapid prototyping and production of complex components. These industries value the technology's ability to produce parts with internal features that would be impossible to create using traditional manufacturing methods.

Regional analysis reveals North America currently leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate over the next five years due to increasing industrial automation and government initiatives supporting advanced manufacturing technologies in countries like China, Japan, and South Korea.

Consumer demand trends indicate a growing preference for systems offering higher resolution capabilities and faster printing speeds. Market research shows that end-users are willing to pay premium prices for systems that can achieve sub-micron resolution while maintaining reasonable throughput rates. Additionally, there is increasing demand for photopolymer matrices with specialized properties such as high transparency, biocompatibility, or specific mechanical characteristics.

The competitive landscape features both established players and innovative startups. Traditional 3D printing companies are expanding their portfolios to include volumetric technologies, while specialized startups are focusing on developing proprietary optical systems and photopolymer formulations. Strategic partnerships between hardware manufacturers and material developers have become increasingly common as companies seek to offer comprehensive solutions.

Market challenges include the high initial investment cost for volumetric 3D printing systems and the limited range of compatible photopolymers currently available. However, ongoing research and development efforts are expected to address these limitations, potentially expanding market accessibility and application scope in the coming years.

Current Challenges in Volumetric Printing Technologies

Despite significant advancements in volumetric 3D printing technologies, several critical challenges persist that impede wider industrial adoption and application versatility. The optical systems employed in volumetric printing face fundamental limitations in resolution capabilities, with current systems struggling to achieve sub-micron precision consistently across the entire build volume. This resolution constraint is particularly problematic for applications requiring intricate microstructures or precise cellular scaffolds.

Energy distribution uniformity remains a significant hurdle, as light intensity often decreases with depth penetration, resulting in inconsistent curing throughout the volume. This non-uniform energy distribution leads to mechanical property variations within printed objects, compromising structural integrity and functional performance. Advanced optical designs incorporating spatial light modulators and precision optics are being explored, but they introduce additional system complexity and cost barriers.

Photopolymer matrices present their own set of challenges in volumetric printing. Current resin formulations exhibit inherent trade-offs between curing speed, mechanical properties, and optical clarity. Fast-curing resins often produce brittle structures with limited mechanical performance, while more durable formulations typically require longer exposure times, reducing overall printing efficiency. Additionally, the absorption and scattering characteristics of photopolymers can distort projected light patterns, further compromising printing accuracy.

The synchronization between optical projection systems and resin chemistry represents another significant technical obstacle. Achieving precise temporal and spatial control over the photopolymerization process requires sophisticated coordination between light delivery systems and resin reactivity profiles. This synchronization becomes increasingly complex when attempting to incorporate multiple materials or gradient properties within a single print.

Heat management during the printing process presents additional complications, as localized temperature increases from exothermic polymerization reactions can cause thermal distortion and internal stress accumulation. These thermal effects are particularly problematic for larger volume prints where heat dissipation is limited by the surrounding uncured resin.

Calibration and quality control systems for volumetric printing remain underdeveloped compared to traditional layer-by-layer approaches. The absence of standardized testing protocols and in-process monitoring tools makes it difficult to ensure consistent print quality and detect defects during fabrication. This lack of robust quality assurance mechanisms significantly limits the adoption of volumetric printing in critical applications such as medical devices or aerospace components.

Energy distribution uniformity remains a significant hurdle, as light intensity often decreases with depth penetration, resulting in inconsistent curing throughout the volume. This non-uniform energy distribution leads to mechanical property variations within printed objects, compromising structural integrity and functional performance. Advanced optical designs incorporating spatial light modulators and precision optics are being explored, but they introduce additional system complexity and cost barriers.

Photopolymer matrices present their own set of challenges in volumetric printing. Current resin formulations exhibit inherent trade-offs between curing speed, mechanical properties, and optical clarity. Fast-curing resins often produce brittle structures with limited mechanical performance, while more durable formulations typically require longer exposure times, reducing overall printing efficiency. Additionally, the absorption and scattering characteristics of photopolymers can distort projected light patterns, further compromising printing accuracy.

The synchronization between optical projection systems and resin chemistry represents another significant technical obstacle. Achieving precise temporal and spatial control over the photopolymerization process requires sophisticated coordination between light delivery systems and resin reactivity profiles. This synchronization becomes increasingly complex when attempting to incorporate multiple materials or gradient properties within a single print.

Heat management during the printing process presents additional complications, as localized temperature increases from exothermic polymerization reactions can cause thermal distortion and internal stress accumulation. These thermal effects are particularly problematic for larger volume prints where heat dissipation is limited by the surrounding uncured resin.

Calibration and quality control systems for volumetric printing remain underdeveloped compared to traditional layer-by-layer approaches. The absence of standardized testing protocols and in-process monitoring tools makes it difficult to ensure consistent print quality and detect defects during fabrication. This lack of robust quality assurance mechanisms significantly limits the adoption of volumetric printing in critical applications such as medical devices or aerospace components.

Comparative Analysis of Existing Volumetric Printing Solutions

01 Volumetric 3D printing techniques for optical systems

Volumetric 3D printing enables the fabrication of complex optical systems in a single process. This technique uses photopolymerization throughout the entire volume of resin simultaneously, rather than layer-by-layer, resulting in faster production times and smoother optical surfaces. The process involves projecting specific light patterns into photosensitive resin to create three-dimensional structures with optical properties suitable for various applications including lenses, waveguides, and other optical components.- Volumetric 3D printing techniques for optical systems: Volumetric 3D printing enables the fabrication of complex optical systems in a single process. This technique uses light projection from multiple angles to cure photopolymer resin throughout its volume simultaneously, rather than layer by layer. This approach allows for the creation of optical components with superior surface quality, reduced printing time, and elimination of layer lines that can affect optical performance. The technique is particularly valuable for creating lenses, waveguides, and other optical elements with precise geometrical features.

- Photopolymer matrices and formulations for optical applications: Specialized photopolymer matrices are developed specifically for optical applications in 3D printing. These formulations contain photoinitiators, monomers, and additives that determine the optical properties of the final product. Key characteristics include transparency, refractive index, optical clarity, and low shrinkage during curing. Advanced formulations may incorporate nanoparticles or other additives to enhance specific optical properties such as light transmission, dispersion, or absorption at particular wavelengths. The composition of these matrices significantly impacts the quality and performance of the printed optical components.

- Comparative evaluation methods for 3D printed optical systems: Various methods are employed to evaluate and compare the quality and performance of 3D printed optical systems. These include optical testing for parameters such as focal length, resolution, light transmission, and wavefront error. Surface metrology techniques assess surface roughness and form accuracy. Mechanical testing evaluates durability and dimensional stability over time. Comparative analyses between different printing technologies, materials, and post-processing methods help identify optimal approaches for specific optical applications. Standardized testing protocols enable objective comparison between different manufacturing methods.

- Post-processing techniques for 3D printed optical components: Post-processing is often essential to achieve optical-grade quality in 3D printed components. Techniques include surface polishing, coating application, thermal annealing, and UV post-curing. These processes help reduce surface roughness, enhance transparency, improve mechanical properties, and ensure dimensional stability. Advanced post-processing methods can significantly improve the optical performance of printed components by reducing scattering and improving clarity. The selection of appropriate post-processing techniques depends on the specific photopolymer matrix used and the intended optical application.

- Integration of 3D printed optics in functional systems: 3D printed optical components are increasingly being integrated into functional systems such as cameras, displays, sensors, and medical devices. This integration requires consideration of mounting interfaces, alignment features, and compatibility with other system components. Hybrid approaches combining 3D printed optics with conventional components can leverage the advantages of both manufacturing methods. Design considerations include thermal stability, environmental resistance, and long-term performance. The ability to create custom, complex optical geometries enables novel system designs that would be difficult or impossible to achieve with conventional manufacturing methods.

02 Photopolymer matrices for optical applications

Specialized photopolymer matrices are developed specifically for optical applications in 3D printing. These materials feature high transparency, controlled refractive indices, and minimal shrinkage during curing. The composition of these photopolymers typically includes monomers, photoinitiators, and additives that enhance optical clarity and stability. Advanced formulations allow for gradient refractive indices or other spatially varying optical properties within a single printed component.Expand Specific Solutions03 Comparative evaluation methodologies for 3D printed optics

Various methodologies are employed to evaluate the quality and performance of 3D printed optical components. These include optical transmission measurements, wavefront analysis, surface roughness characterization, and functional testing in application-specific environments. Comparative studies assess different printing technologies, materials, and post-processing techniques to determine optimal approaches for specific optical requirements. Standardized testing protocols help quantify optical performance metrics such as resolution, clarity, and durability.Expand Specific Solutions04 Post-processing techniques for 3D printed optical systems

After volumetric 3D printing, various post-processing techniques are applied to enhance the optical quality of printed components. These include thermal curing to complete polymerization, surface polishing to reduce roughness, coating applications to improve durability or add functionality, and precision machining for critical dimensions. Advanced post-processing methods can significantly improve optical performance by reducing scattering, enhancing transparency, and ensuring dimensional accuracy of the printed optical elements.Expand Specific Solutions05 Integration of 3D printed optics in complex systems

3D printed optical components are increasingly integrated into complex systems for various applications. This integration involves designing optical elements that can interface with electronic, mechanical, or biological systems. Approaches include printing optical components directly onto substrates, creating hybrid systems with conventional and printed optics, and developing modular designs for easy assembly. The integration capabilities enable novel applications in fields such as medical imaging, sensing, telecommunications, and augmented reality devices.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Volumetric 3D printing optical systems and photopolymer matrices are currently in an early growth phase, with the market expanding rapidly due to increasing industrial applications. The global market size is projected to reach significant scale as this technology bridges the gap between traditional manufacturing and advanced additive processes. Technologically, the field shows varying maturity levels across players: established companies like HP Development, Autodesk, and Siemens Healthineers bring substantial R&D capabilities, while specialized innovators such as Holo Inc., Mighty Buildings, and polySpectra are advancing novel approaches to volumetric printing. Academic institutions including EPFL, University of Maine, and Jiangnan University contribute fundamental research, while companies like Cubicure GmbH and Photosynthetic B.V. are developing proprietary photopolymer formulations that enhance printing speed and material properties.

Holo, Inc.

Technical Solution: Holo has pioneered a volumetric 3D printing approach called PureForm™ that combines holographic light projection with precisely engineered photopolymer resins. Their system utilizes spatial light modulators to generate complex 3D light patterns that cure entire volumes simultaneously rather than layer-by-layer[6]. The technology employs computational algorithms to calculate optimal light interference patterns that selectively solidify specific regions within the photopolymer volume. Holo's proprietary photopolymer matrices incorporate dual-wavelength photoinitiator systems that enable precise control over polymerization thresholds and reaction kinetics[7]. This allows for the creation of complex internal structures and gradient material properties within a single print. The system achieves volumetric printing speeds up to 50 times faster than conventional stereolithography while maintaining feature resolution down to 20 microns. Holo has also developed specialized optical correction systems that compensate for light refraction and scattering effects within the resin volume, ensuring geometric accuracy throughout the printed part.

Strengths: Exceptional speed for high-resolution prints; ability to create complex internal structures impossible with layer-based methods; minimal material waste; excellent surface finish quality without visible layer lines. Weaknesses: Limited build volume compared to some conventional systems; restricted material selection; higher material costs; challenges with very large solid structures due to light penetration limitations.

Mighty Buildings, Inc.

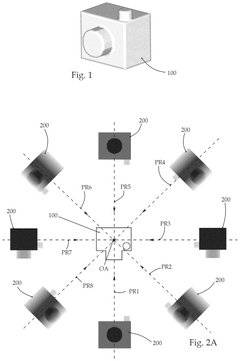

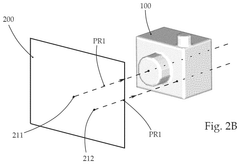

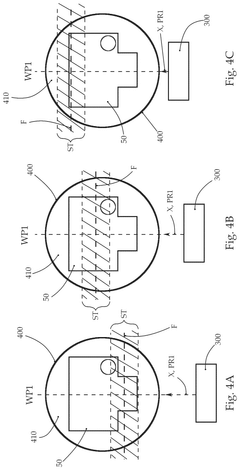

Technical Solution: Mighty Buildings has developed a hybrid volumetric 3D printing system that combines elements of Digital Light Processing (DLP) and computed tomography principles. Their technology, called Light Matrix Additive Manufacturing (LMAM), utilizes a rotating cylindrical vat of photopolymer resin illuminated by precisely synchronized light patterns from multiple projectors positioned around the perimeter[10]. This approach enables the creation of complex 3D structures without the need for layer-by-layer processing. Mighty Buildings has formulated proprietary photopolymer matrices specifically optimized for volumetric printing, featuring carefully balanced light absorption coefficients, photoinitiator systems, and viscosity profiles. Their materials incorporate specialized additives that enhance mechanical properties while maintaining optical clarity necessary for deep light penetration[11]. The system achieves print speeds up to 20 times faster than conventional stereolithography while maintaining feature resolution around 75 microns. Mighty Buildings has also developed advanced computational algorithms that correct for optical distortions and optimize light delivery patterns to ensure geometric accuracy throughout the printed volume.

Strengths: Significantly faster production speeds compared to layer-based methods; excellent structural integrity without layer boundaries; ability to create complex internal geometries; reduced material waste. Weaknesses: Limited build volume compared to some conventional systems; restricted material selection; challenges with very large solid structures due to light penetration limitations; complex calibration requirements for the multi-projector system.

Key Patents and Innovations in Photopolymer Matrices

3D printing method

PatentActiveUS12366843B2

Innovation

- The method involves displacing the focal plane relative to the container when the extension of the three-dimensional object along the irradiation direction is at least twice the depth of field range, ensuring that at least half of the object's extension is covered by the depth of field range, and using a Radon transform to create projection images with light intensity proportional to the summed virtual object material.

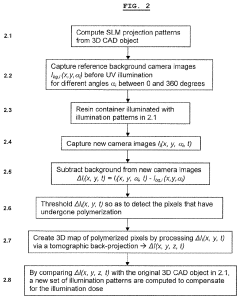

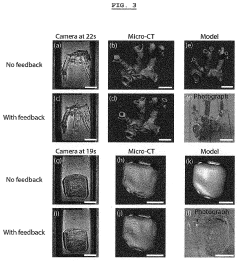

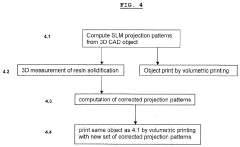

System and method of using feedback for correcting three dimensional objects in volumetric tomographic printers

PatentInactiveUS20220347929A1

Innovation

- A method involving real-time monitoring and feedback-enhanced tomographic reconstruction, where a 3D object being formed is imaged using an imaging system, and based on the images, new light patterns are generated to correct the photopolymerization process, allowing for higher resolution printing by adjusting the light dose distribution and stopping the process when complete.

Material Science Advancements for Photopolymer Formulations

Recent advancements in material science have significantly propelled the development of photopolymer formulations for volumetric 3D printing applications. These innovations have addressed critical challenges related to resin reactivity, optical clarity, and mechanical properties of printed objects. The evolution of photopolymer matrices has been particularly remarkable, with new formulations offering enhanced spatial resolution and reduced printing times.

Traditional photopolymer resins often suffered from limited light penetration and oxygen inhibition issues, resulting in inconsistent curing throughout the volume. Modern formulations now incorporate specialized photoinitiators that respond to specific wavelengths, allowing for precise control over the polymerization process. These photoinitiators demonstrate improved quantum efficiency and reduced oxygen sensitivity, enabling more uniform volumetric solidification.

The incorporation of thiol-ene and thiol-yne chemistry has revolutionized photopolymer matrices by providing rapid polymerization kinetics with minimal shrinkage. These systems form highly crosslinked networks through step-growth mechanisms rather than chain-growth, resulting in more homogeneous material properties throughout the printed structure. Additionally, the reduced oxygen inhibition in these systems makes them particularly suitable for volumetric printing techniques.

Nanocomposite photopolymers represent another significant advancement, where nanoparticles are dispersed within the resin matrix to enhance specific properties. Silica nanoparticles improve mechanical strength, while quantum dots can be utilized for wavelength-specific photoinitiation. These additives must be carefully selected to maintain optical transparency while providing the desired property enhancements.

Dual-cure systems have emerged as a promising approach for volumetric printing, combining photopolymerization with secondary curing mechanisms such as thermal or moisture-induced reactions. This approach allows for initial shape formation through light exposure, followed by post-processing to achieve superior mechanical properties and environmental stability.

Biocompatible photopolymers have also seen substantial development, with new formulations designed specifically for medical and dental applications. These materials incorporate non-toxic components and demonstrate reduced leaching of potentially harmful substances, making them suitable for direct contact with biological tissues. The integration of antimicrobial agents and growth factors into these matrices further expands their potential applications in tissue engineering and regenerative medicine.

The rheological properties of photopolymer formulations have been optimized to balance viscosity requirements for volumetric printing processes. Lower viscosity formulations facilitate faster recoating and reduced bubble formation, while carefully designed thixotropic behavior prevents settling of additives and improves print fidelity. These advancements collectively contribute to the expanding capabilities and applications of volumetric 3D printing technologies.

Traditional photopolymer resins often suffered from limited light penetration and oxygen inhibition issues, resulting in inconsistent curing throughout the volume. Modern formulations now incorporate specialized photoinitiators that respond to specific wavelengths, allowing for precise control over the polymerization process. These photoinitiators demonstrate improved quantum efficiency and reduced oxygen sensitivity, enabling more uniform volumetric solidification.

The incorporation of thiol-ene and thiol-yne chemistry has revolutionized photopolymer matrices by providing rapid polymerization kinetics with minimal shrinkage. These systems form highly crosslinked networks through step-growth mechanisms rather than chain-growth, resulting in more homogeneous material properties throughout the printed structure. Additionally, the reduced oxygen inhibition in these systems makes them particularly suitable for volumetric printing techniques.

Nanocomposite photopolymers represent another significant advancement, where nanoparticles are dispersed within the resin matrix to enhance specific properties. Silica nanoparticles improve mechanical strength, while quantum dots can be utilized for wavelength-specific photoinitiation. These additives must be carefully selected to maintain optical transparency while providing the desired property enhancements.

Dual-cure systems have emerged as a promising approach for volumetric printing, combining photopolymerization with secondary curing mechanisms such as thermal or moisture-induced reactions. This approach allows for initial shape formation through light exposure, followed by post-processing to achieve superior mechanical properties and environmental stability.

Biocompatible photopolymers have also seen substantial development, with new formulations designed specifically for medical and dental applications. These materials incorporate non-toxic components and demonstrate reduced leaching of potentially harmful substances, making them suitable for direct contact with biological tissues. The integration of antimicrobial agents and growth factors into these matrices further expands their potential applications in tissue engineering and regenerative medicine.

The rheological properties of photopolymer formulations have been optimized to balance viscosity requirements for volumetric printing processes. Lower viscosity formulations facilitate faster recoating and reduced bubble formation, while carefully designed thixotropic behavior prevents settling of additives and improves print fidelity. These advancements collectively contribute to the expanding capabilities and applications of volumetric 3D printing technologies.

Environmental Impact and Sustainability Considerations

Volumetric 3D printing technologies present significant environmental implications that warrant careful consideration in their development and deployment. The environmental footprint of these systems stems from multiple sources, including energy consumption during operation, raw material production, and end-of-life disposal considerations. Comparative analyses reveal that volumetric approaches generally demonstrate reduced energy requirements compared to traditional layer-by-layer methods, primarily due to shorter print times and elimination of mechanical movement systems.

The photopolymer matrices used in volumetric printing pose particular environmental challenges. Most commercial photopolymers are petroleum-derived and contain potentially harmful photoinitiators and additives. Recent research has focused on developing bio-based alternatives, with promising results from modified cellulose, lignin, and alginate-based resins that maintain comparable optical properties while reducing environmental impact. These bio-derived matrices have demonstrated up to 60% lower carbon footprint in lifecycle assessments compared to conventional options.

Waste generation represents another critical environmental consideration. Volumetric printing typically produces less material waste than traditional methods since it doesn't require support structures. However, uncured resin disposal remains problematic due to potential aquatic toxicity. Advanced filtration systems and closed-loop recycling protocols have been implemented by industry leaders to mitigate these concerns, with recovery rates reaching 85-90% for some materials.

Energy efficiency varies significantly between optical system designs. Comparative studies indicate that LED-based systems consume approximately 30-40% less energy than laser-based alternatives for equivalent print volumes. Additionally, the development of more photosensitive matrices has enabled lower power requirements, further reducing the carbon footprint of printing operations. Thermal management systems also impact overall energy consumption, with passive cooling designs offering sustainability advantages over active cooling approaches.

Lifecycle considerations extend to the durability and recyclability of printed objects. Recent innovations in photopolymer chemistry have yielded materials with improved biodegradability profiles without compromising mechanical properties. Some advanced formulations now achieve 90% degradation within 180 days under industrial composting conditions, addressing end-of-life concerns. Furthermore, the development of reversible photopolymerization mechanisms shows promise for creating truly circular material systems.

Regulatory frameworks are evolving to address these environmental considerations, with the European Union's REACH regulations and similar initiatives worldwide imposing stricter requirements on photopolymer composition and disposal. Industry certification programs like UL GREENGUARD and EPEAT are beginning to incorporate criteria specific to volumetric printing technologies, driving further sustainability innovations in this rapidly evolving field.

The photopolymer matrices used in volumetric printing pose particular environmental challenges. Most commercial photopolymers are petroleum-derived and contain potentially harmful photoinitiators and additives. Recent research has focused on developing bio-based alternatives, with promising results from modified cellulose, lignin, and alginate-based resins that maintain comparable optical properties while reducing environmental impact. These bio-derived matrices have demonstrated up to 60% lower carbon footprint in lifecycle assessments compared to conventional options.

Waste generation represents another critical environmental consideration. Volumetric printing typically produces less material waste than traditional methods since it doesn't require support structures. However, uncured resin disposal remains problematic due to potential aquatic toxicity. Advanced filtration systems and closed-loop recycling protocols have been implemented by industry leaders to mitigate these concerns, with recovery rates reaching 85-90% for some materials.

Energy efficiency varies significantly between optical system designs. Comparative studies indicate that LED-based systems consume approximately 30-40% less energy than laser-based alternatives for equivalent print volumes. Additionally, the development of more photosensitive matrices has enabled lower power requirements, further reducing the carbon footprint of printing operations. Thermal management systems also impact overall energy consumption, with passive cooling designs offering sustainability advantages over active cooling approaches.

Lifecycle considerations extend to the durability and recyclability of printed objects. Recent innovations in photopolymer chemistry have yielded materials with improved biodegradability profiles without compromising mechanical properties. Some advanced formulations now achieve 90% degradation within 180 days under industrial composting conditions, addressing end-of-life concerns. Furthermore, the development of reversible photopolymerization mechanisms shows promise for creating truly circular material systems.

Regulatory frameworks are evolving to address these environmental considerations, with the European Union's REACH regulations and similar initiatives worldwide imposing stricter requirements on photopolymer composition and disposal. Industry certification programs like UL GREENGUARD and EPEAT are beginning to incorporate criteria specific to volumetric printing technologies, driving further sustainability innovations in this rapidly evolving field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!