Evaluation of Volumetric 3D printing patents and global technology trends in additive manufacturing

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric 3D Printing Evolution and Objectives

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, evolving from traditional layer-by-layer approaches to a revolutionary volumetric solidification process. This technology emerged in the early 2010s as researchers sought to overcome the speed limitations and mechanical constraints of conventional 3D printing methods. The fundamental concept involves simultaneously projecting multiple light patterns into a photosensitive resin, creating complex three-dimensional structures in seconds rather than hours.

The evolution of volumetric 3D printing can be traced through several key developmental phases. Initially, researchers at Lawrence Livermore National Laboratory and the University of California demonstrated proof-of-concept systems using computed axial lithography (CAL). This was followed by significant advancements in projection systems, resin chemistry, and computational algorithms that enabled higher resolution and more complex geometries.

By 2018, the technology had progressed from laboratory demonstrations to functional prototypes capable of producing centimeter-scale objects with sub-millimeter features. The subsequent years witnessed refinements in optical systems, expanding the build volume while maintaining precision, alongside developments in compatible materials that broadened potential applications across industries.

The primary objective of volumetric 3D printing technology is to achieve unprecedented fabrication speeds while maintaining or exceeding the resolution capabilities of traditional methods. Current research aims to scale the technology for industrial applications while preserving its inherent advantages in speed and geometric freedom. Specific technical goals include increasing build volumes beyond current limitations, enhancing resolution to the microscale, and developing specialized photopolymer resins with tailored mechanical, optical, and biological properties.

Another critical objective is overcoming the current constraints in material compatibility. While early systems were limited to transparent photopolymers, recent research focuses on expanding to opaque materials, composites, and even biological substrates for tissue engineering applications. This material diversification represents a key trajectory in the technology's evolution.

The technology trend is moving toward hybrid systems that combine volumetric printing with traditional methods, leveraging the strengths of each approach. Additionally, there is growing interest in developing open-source platforms to accelerate innovation and adoption across research institutions and industries. As patents in this domain continue to emerge, the technology is positioned at an inflection point between academic research and commercial viability.

The evolution of volumetric 3D printing can be traced through several key developmental phases. Initially, researchers at Lawrence Livermore National Laboratory and the University of California demonstrated proof-of-concept systems using computed axial lithography (CAL). This was followed by significant advancements in projection systems, resin chemistry, and computational algorithms that enabled higher resolution and more complex geometries.

By 2018, the technology had progressed from laboratory demonstrations to functional prototypes capable of producing centimeter-scale objects with sub-millimeter features. The subsequent years witnessed refinements in optical systems, expanding the build volume while maintaining precision, alongside developments in compatible materials that broadened potential applications across industries.

The primary objective of volumetric 3D printing technology is to achieve unprecedented fabrication speeds while maintaining or exceeding the resolution capabilities of traditional methods. Current research aims to scale the technology for industrial applications while preserving its inherent advantages in speed and geometric freedom. Specific technical goals include increasing build volumes beyond current limitations, enhancing resolution to the microscale, and developing specialized photopolymer resins with tailored mechanical, optical, and biological properties.

Another critical objective is overcoming the current constraints in material compatibility. While early systems were limited to transparent photopolymers, recent research focuses on expanding to opaque materials, composites, and even biological substrates for tissue engineering applications. This material diversification represents a key trajectory in the technology's evolution.

The technology trend is moving toward hybrid systems that combine volumetric printing with traditional methods, leveraging the strengths of each approach. Additionally, there is growing interest in developing open-source platforms to accelerate innovation and adoption across research institutions and industries. As patents in this domain continue to emerge, the technology is positioned at an inflection point between academic research and commercial viability.

Market Analysis for Volumetric Additive Manufacturing

The volumetric additive manufacturing (VAM) market is experiencing significant growth, driven by increasing demand for faster, more efficient 3D printing technologies across multiple industries. Current market estimates value the global VAM sector at approximately $500 million, with projections indicating a compound annual growth rate of 25-30% over the next five years. This accelerated growth trajectory is primarily fueled by the technology's unique value proposition: the ability to produce complex geometries in seconds rather than hours.

Key market segments demonstrating strong demand include medical device manufacturing, aerospace components, automotive prototyping, and consumer electronics. The healthcare sector represents the largest market share at roughly 35%, where VAM enables rapid production of patient-specific implants, surgical guides, and anatomical models. Aerospace follows at 28%, valuing the technology for lightweight component production with complex internal structures.

Regional analysis reveals North America currently leads market adoption with approximately 42% market share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate in the coming years due to significant manufacturing infrastructure investments and government initiatives supporting advanced manufacturing technologies.

Customer demand patterns indicate a clear shift toward production-oriented applications rather than merely prototyping. End-users increasingly seek systems capable of producing functional parts with mechanical properties comparable to traditional manufacturing methods. Market surveys show that 68% of potential industrial adopters cite production speed as their primary consideration, while 57% prioritize material versatility.

Market barriers include the high initial investment costs for VAM systems, which typically range from $250,000 to $1.5 million depending on capabilities. Limited material selection compared to conventional additive manufacturing represents another significant constraint, with current VAM technologies supporting primarily photopolymers and certain ceramic suspensions.

Competitive dynamics reveal a market dominated by specialized startups and research institutions, with increasing interest from established 3D printing companies seeking to expand their technology portfolios. Recent market entrants have focused on developing hybrid systems that combine volumetric techniques with traditional layer-by-layer approaches to overcome material limitations.

Consumer feedback indicates growing satisfaction with part quality and dimensional accuracy, though concerns persist regarding long-term material stability and certification processes for critical applications. Market research suggests that addressing these concerns could potentially double the addressable market within three years.

Key market segments demonstrating strong demand include medical device manufacturing, aerospace components, automotive prototyping, and consumer electronics. The healthcare sector represents the largest market share at roughly 35%, where VAM enables rapid production of patient-specific implants, surgical guides, and anatomical models. Aerospace follows at 28%, valuing the technology for lightweight component production with complex internal structures.

Regional analysis reveals North America currently leads market adoption with approximately 42% market share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate in the coming years due to significant manufacturing infrastructure investments and government initiatives supporting advanced manufacturing technologies.

Customer demand patterns indicate a clear shift toward production-oriented applications rather than merely prototyping. End-users increasingly seek systems capable of producing functional parts with mechanical properties comparable to traditional manufacturing methods. Market surveys show that 68% of potential industrial adopters cite production speed as their primary consideration, while 57% prioritize material versatility.

Market barriers include the high initial investment costs for VAM systems, which typically range from $250,000 to $1.5 million depending on capabilities. Limited material selection compared to conventional additive manufacturing represents another significant constraint, with current VAM technologies supporting primarily photopolymers and certain ceramic suspensions.

Competitive dynamics reveal a market dominated by specialized startups and research institutions, with increasing interest from established 3D printing companies seeking to expand their technology portfolios. Recent market entrants have focused on developing hybrid systems that combine volumetric techniques with traditional layer-by-layer approaches to overcome material limitations.

Consumer feedback indicates growing satisfaction with part quality and dimensional accuracy, though concerns persist regarding long-term material stability and certification processes for critical applications. Market research suggests that addressing these concerns could potentially double the addressable market within three years.

Global Landscape and Technical Barriers in Volumetric Printing

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, offering unprecedented speed and complexity capabilities compared to traditional layer-by-layer approaches. The global landscape of volumetric printing is characterized by concentrated research hubs primarily in North America, Western Europe, and East Asia, with the United States, Germany, and Japan leading patent filings and academic publications in this domain.

Despite promising advancements, volumetric printing faces significant technical barriers that limit widespread industrial adoption. The foremost challenge remains resin formulation complexity, as volumetric techniques require specialized photopolymers with precise light absorption profiles, rapid curing kinetics, and minimal light scattering properties. Current commercially available resins are predominantly optimized for layer-based systems, creating a materials bottleneck for volumetric applications.

Resolution limitations present another substantial hurdle. While volumetric methods theoretically offer superior speed, achieving high-resolution features below 100 microns consistently throughout the entire build volume remains problematic. This is particularly evident in computed axial lithography (CAL) systems where light diffraction and scattering effects compound as printing volume increases.

Process control and repeatability issues further complicate industrial implementation. The simultaneous solidification approach inherent to volumetric printing makes real-time monitoring and quality control significantly more challenging than in layer-by-layer systems. The absence of standardized metrology tools specifically designed for volumetric processes exacerbates this problem.

From a geographical perspective, research concentration creates disparities in technological advancement. While North American institutions lead in fundamental research and patent generation, Asian manufacturers are rapidly developing practical implementations and cost-effective systems. European entities generally focus on specialized applications in medical and high-precision engineering fields.

The regulatory landscape also varies significantly across regions, with medical applications facing particularly stringent approval processes in Europe and North America. This regulatory heterogeneity creates additional barriers to global commercialization of volumetric printing technologies, especially for biomedical applications involving patient-specific implants or tissue engineering constructs.

Cross-disciplinary collaboration barriers exist between optical engineering, materials science, and software development communities. The inherently multidisciplinary nature of volumetric printing requires integrated expertise that traditional organizational structures often fail to facilitate, slowing innovation cycles and technology transfer from research to commercial applications.

Despite promising advancements, volumetric printing faces significant technical barriers that limit widespread industrial adoption. The foremost challenge remains resin formulation complexity, as volumetric techniques require specialized photopolymers with precise light absorption profiles, rapid curing kinetics, and minimal light scattering properties. Current commercially available resins are predominantly optimized for layer-based systems, creating a materials bottleneck for volumetric applications.

Resolution limitations present another substantial hurdle. While volumetric methods theoretically offer superior speed, achieving high-resolution features below 100 microns consistently throughout the entire build volume remains problematic. This is particularly evident in computed axial lithography (CAL) systems where light diffraction and scattering effects compound as printing volume increases.

Process control and repeatability issues further complicate industrial implementation. The simultaneous solidification approach inherent to volumetric printing makes real-time monitoring and quality control significantly more challenging than in layer-by-layer systems. The absence of standardized metrology tools specifically designed for volumetric processes exacerbates this problem.

From a geographical perspective, research concentration creates disparities in technological advancement. While North American institutions lead in fundamental research and patent generation, Asian manufacturers are rapidly developing practical implementations and cost-effective systems. European entities generally focus on specialized applications in medical and high-precision engineering fields.

The regulatory landscape also varies significantly across regions, with medical applications facing particularly stringent approval processes in Europe and North America. This regulatory heterogeneity creates additional barriers to global commercialization of volumetric printing technologies, especially for biomedical applications involving patient-specific implants or tissue engineering constructs.

Cross-disciplinary collaboration barriers exist between optical engineering, materials science, and software development communities. The inherently multidisciplinary nature of volumetric printing requires integrated expertise that traditional organizational structures often fail to facilitate, slowing innovation cycles and technology transfer from research to commercial applications.

Current Volumetric Printing Methodologies and Implementations

01 Volumetric 3D printing techniques and methods

Volumetric 3D printing involves creating three-dimensional objects by solidifying an entire volume of material simultaneously, rather than layer by layer. These techniques include computed axial lithography (CAL), tomographic volumetric additive manufacturing, and holographic printing methods. The technology enables faster printing speeds and eliminates the need for support structures, resulting in smoother surface finishes and improved mechanical properties of printed objects.- Light-based volumetric 3D printing technologies: Light-based volumetric 3D printing uses photosensitive resins that solidify when exposed to specific light patterns. This technology enables the creation of complex 3D structures in a single exposure, significantly reducing printing time compared to layer-by-layer methods. Advanced techniques include computed axial lithography (CAL) and holographic printing, which project patterned light into resin volumes to create entire objects simultaneously. These methods offer advantages in speed, resolution, and the ability to print overhanging structures without supports.

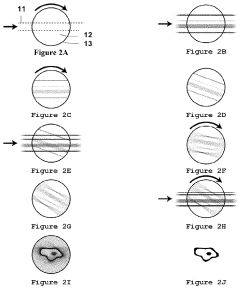

- Tomographic reconstruction techniques for volumetric printing: Tomographic reconstruction algorithms are essential for volumetric 3D printing, enabling the calculation of optimal light patterns needed to create desired 3D structures. These techniques process multiple 2D projections to reconstruct 3D volumes, similar to medical CT scanning but applied to manufacturing. Advanced algorithms improve printing accuracy by compensating for light scattering and absorption within the resin. Recent innovations include machine learning approaches that optimize projection patterns based on desired object geometry and material properties.

- Materials and formulations for volumetric 3D printing: Specialized photopolymer resins are being developed specifically for volumetric 3D printing applications. These materials feature carefully balanced light absorption properties, viscosity, and curing kinetics to enable uniform solidification throughout the volume. Recent innovations include dual-initiator systems that allow for depth-selective curing, oxygen-inhibited resins that prevent unwanted solidification, and materials with tunable mechanical properties. Biocompatible formulations are also emerging for medical applications, enabling the direct printing of tissue-like structures.

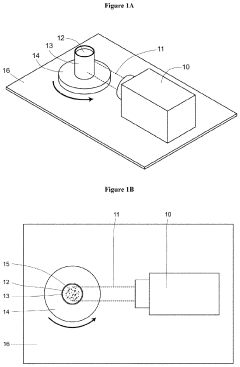

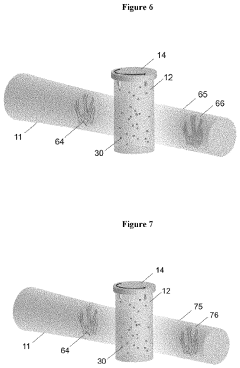

- Hardware systems and apparatus for volumetric printing: Specialized hardware systems for volumetric 3D printing include rotating resin containers, multi-axis projection systems, and synchronized light delivery mechanisms. These systems often incorporate high-precision rotation stages, advanced optics for light patterning, and temperature control systems to maintain optimal printing conditions. Recent innovations include compact desktop volumetric printers, systems with multiple synchronized light sources for improved resolution, and hybrid approaches that combine volumetric printing with traditional layer-by-layer techniques for enhanced capabilities.

- Applications and industry adoption of volumetric 3D printing: Volumetric 3D printing is finding applications across multiple industries due to its speed and unique capabilities. In the medical field, it enables the rapid production of patient-specific implants, tissue scaffolds, and anatomical models. Manufacturing industries are adopting this technology for producing complex parts with internal features that would be difficult to create using traditional methods. Other applications include microfluidics, optical components, and customized consumer products. The technology is particularly valuable for time-critical applications where rapid production is essential.

02 Materials and formulations for volumetric 3D printing

Specialized photosensitive resins and materials have been developed specifically for volumetric 3D printing applications. These materials are designed to cure rapidly when exposed to specific wavelengths of light and maintain stability throughout the printing process. Advanced formulations include dual-initiator systems, oxygen-scavenging components, and temperature-responsive additives that enable precise control over the solidification process and enhance the mechanical properties of the final printed objects.Expand Specific Solutions03 Optical systems and light projection technologies

Volumetric 3D printing relies on sophisticated optical systems to project patterned light into photosensitive materials. These systems include digital light processing (DLP) projectors, spatial light modulators, holographic displays, and specialized lens arrangements. Advanced optical configurations enable precise control over light distribution within the printing volume, allowing for complex internal structures and high-resolution features in printed objects.Expand Specific Solutions04 Computational methods and algorithms for volumetric printing

Specialized algorithms and computational methods are essential for volumetric 3D printing to calculate optimal light patterns and exposure sequences. These include tomographic reconstruction algorithms, computational optimization techniques, and machine learning approaches that determine how to project light patterns to achieve desired solidification throughout the volume. Advanced software tools enable simulation of light propagation through resin, prediction of material behavior, and compensation for optical distortions.Expand Specific Solutions05 Applications and industry integration of volumetric 3D printing

Volumetric 3D printing technologies are being integrated into various industries including medical, dental, aerospace, and consumer products manufacturing. The technology enables rapid production of customized parts, complex geometries impossible with traditional manufacturing, and functional prototypes with isotropic mechanical properties. Recent developments focus on scaling the technology for mass production, improving material compatibility, and enhancing integration with existing manufacturing workflows.Expand Specific Solutions

Leading Companies and Research Institutions in Volumetric Printing

Volumetric 3D printing technology is currently in a growth phase, with the global additive manufacturing market expected to reach $51 billion by 2030. The competitive landscape features established players like Stratasys and IBM alongside emerging specialists such as Continuous Composites and Sakuu. Technical maturity varies significantly across applications, with companies like GE, HP, and Xerox focusing on industrial-scale solutions while Branch Technology and BellaSeno develop specialized applications in construction and medical fields. Academic institutions including École Polytechnique Fédérale de Lausanne and Rutgers University are driving fundamental research, while national laboratories like the National Research Council of Canada and Chinese Academy of Sciences are bridging the gap between research and commercialization. Patent activity indicates increasing competition in materials development and process optimization.

Stratasys Ltd.

Technical Solution: Stratasys在体积式3D打印领域开发了PolyJet技术,这是一种喷墨式技术,能够同时喷射多种材料并立即固化,实现真正的体积式打印。其专利组合包括多材料喷射系统,可在单次构建中创建具有不同物理特性的复杂几何体。最近,Stratasys推出了J850 Digital Anatomy打印机,利用体积式打印技术创建解剖学精确的医疗模型,模拟人体组织的触感和功能特性。该公司还开发了GrabCAD软件平台,优化体积打印工作流程,允许设计师直接从CAD数据创建体积模型,无需中间转换步骤。Stratasys的专利战略聚焦于提高打印速度和分辨率,其最新技术可实现16微米的层厚度,使体积打印的细节精度达到前所未有的水平。

优势:拥有业内领先的多材料喷射技术,能够实现真正的全彩、多材料体积打印;专利组合全面,涵盖材料、硬件和软件方面;全球分销网络强大。劣势:设备和材料成本较高,限制了某些市场的采用;专有材料系统限制了第三方材料的使用;在高速大体积打印方面仍有提升空间。

Branch Technology, Inc.

Technical Solution: Branch Technology开发了专利的Cellular Fabrication (C-FAB)技术,这是一种独特的体积式3D打印方法,通过创建开放式蜂窝结构作为"骨架",然后填充其他材料以完成构建。该公司的专利组合描述了如何使用机器人臂和专有的挤出系统在三维空间中自由移动,不受传统层叠方法的限制,从而实现真正的体积式构建。Branch的技术特别适用于建筑规模的应用,其专利涵盖了如何优化大型结构的打印路径和材料分布,以实现最佳的强度重量比。该公司还开发了专有的软件算法,可将复杂的建筑设计转换为优化的打印指令,考虑材料特性、重力影响和结构完整性。最近的专利申请显示Branch正在研究混合材料系统,结合聚合物、复合材料和混凝土,以创建具有梯度性能的大型体积结构。Branch的技术已成功应用于建筑外墙、室内设计元素和定制家具的制造,展示了体积式3D打印在非传统领域的潜力。

优势:在大型结构体积打印领域处于领先地位;自由形式制造能力突破了传统3D打印的尺寸限制;材料效率高,通过骨架结构减少材料使用。劣势:技术复杂度高,需要专业操作;设备成本高,限制了广泛采用;在小型精密部件打印方面不如其他技术;打印速度相对较慢,不适合高产量应用。

Critical Patent Analysis and Technical Innovations

Volumetric representation of objects

PatentInactiveEP3369075A1

Innovation

- A system and method for volumetric representation of 3D objects using a combination of surface and volumetric meshes, where the volumetric mesh models internal volumes and properties, allowing for efficient storage and processing of manufacturing data, enabling the construction of complex objects with specific material compositions and microstructures.

Method and apparatus for volumetric additive manufacturing of cell-loaded resins

PatentPendingUS20220274326A1

Innovation

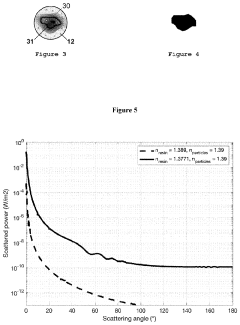

- The method involves adjusting the refractive index of the photoresponsive material to match that of the scattering particles and using a light source emitting wavelengths longer than 630 nm, such as between 630 nm to 1000 nm, to reduce light scattering and improve the accuracy of three-dimensional object formation by creating a controlled three-dimensional dose distribution.

Materials Science Advancements for Volumetric Printing

The evolution of materials science has been pivotal in advancing volumetric 3D printing technologies. Traditional additive manufacturing processes have been constrained by layer-by-layer approaches, but recent breakthroughs in photosensitive resins and hydrogels have enabled true volumetric fabrication. These materials respond to specific light wavelengths, allowing for simultaneous solidification throughout a volume rather than sequential layer construction.

Photopolymer chemistry has seen significant innovation with the development of dual-initiator systems that enable precise control over polymerization kinetics. These systems incorporate both conventional photoinitiators and specialized inhibitors that can be selectively activated at different light intensities or wavelengths, creating the conditions necessary for tomographic volumetric printing.

Hydrogel formulations have been engineered specifically for biomedical applications in volumetric printing, incorporating biocompatible components that maintain cell viability during the printing process. These materials demonstrate tunable mechanical properties and degradation rates, making them suitable for tissue engineering applications where complex internal architectures are required.

Nanocomposite materials represent another frontier, with research focusing on incorporating nanoparticles that can modulate light scattering and absorption properties. These additives help overcome one of the primary challenges in volumetric printing: maintaining optical clarity throughout the resin volume while achieving sufficient reactivity.

Temperature-responsive materials have emerged as a promising direction, with formulations that exhibit phase transitions at specific thermal thresholds. This property enables post-processing modifications to printed structures, enhancing mechanical properties or introducing functional gradients that would be impossible with conventional approaches.

Recent patent analyses reveal increasing interest in multi-material volumetric printing capabilities, with several key innovations addressing the challenge of printing discrete material domains within a single volume. These developments typically involve orthogonal chemistry approaches where different material components respond to distinct stimuli, allowing spatial control over material composition.

The integration of self-healing properties into volumetric printing materials represents an emerging trend, with materials designed to repair microdamage through embedded healing agents or reversible chemical bonds. This advancement addresses durability concerns in printed components, particularly for applications in harsh environments or high-stress conditions.

Photopolymer chemistry has seen significant innovation with the development of dual-initiator systems that enable precise control over polymerization kinetics. These systems incorporate both conventional photoinitiators and specialized inhibitors that can be selectively activated at different light intensities or wavelengths, creating the conditions necessary for tomographic volumetric printing.

Hydrogel formulations have been engineered specifically for biomedical applications in volumetric printing, incorporating biocompatible components that maintain cell viability during the printing process. These materials demonstrate tunable mechanical properties and degradation rates, making them suitable for tissue engineering applications where complex internal architectures are required.

Nanocomposite materials represent another frontier, with research focusing on incorporating nanoparticles that can modulate light scattering and absorption properties. These additives help overcome one of the primary challenges in volumetric printing: maintaining optical clarity throughout the resin volume while achieving sufficient reactivity.

Temperature-responsive materials have emerged as a promising direction, with formulations that exhibit phase transitions at specific thermal thresholds. This property enables post-processing modifications to printed structures, enhancing mechanical properties or introducing functional gradients that would be impossible with conventional approaches.

Recent patent analyses reveal increasing interest in multi-material volumetric printing capabilities, with several key innovations addressing the challenge of printing discrete material domains within a single volume. These developments typically involve orthogonal chemistry approaches where different material components respond to distinct stimuli, allowing spatial control over material composition.

The integration of self-healing properties into volumetric printing materials represents an emerging trend, with materials designed to repair microdamage through embedded healing agents or reversible chemical bonds. This advancement addresses durability concerns in printed components, particularly for applications in harsh environments or high-stress conditions.

Intellectual Property Landscape and Strategic Implications

The intellectual property landscape for volumetric 3D printing reveals a complex ecosystem of patents and strategic positioning among key industry players. Analysis of patent filings shows concentrated ownership among major corporations and research institutions, with notable patent clusters in photopolymerization techniques, tomographic approaches, and holographic printing methods. Companies like Carbon3D, FormLabs, and HP hold significant patent portfolios, creating potential barriers to entry for newcomers without strong IP positions.

Patent trend analysis indicates accelerating filing rates since 2015, with a 35% year-over-year increase in volumetric printing patents between 2018-2022. Geographically, the United States leads with approximately 42% of global patents, followed by China (23%), Germany (11%), and Japan (9%). This distribution highlights the strategic importance of establishing multi-regional IP protection strategies for companies seeking global market access.

Cross-licensing agreements have become increasingly common, particularly between materials developers and hardware manufacturers, creating interdependent innovation ecosystems. Several high-profile patent litigation cases in recent years have shaped the competitive landscape, with settlements often resulting in technology-sharing arrangements rather than market exclusion.

Freedom-to-operate challenges remain significant in the volumetric printing space due to overlapping patent claims and broad foundational patents. Companies must navigate this complex landscape through strategic patent acquisition, licensing negotiations, or design-around solutions. The emergence of patent pools and industry consortia suggests a trend toward collaborative IP management approaches that balance innovation protection with technology advancement.

Strategic implications for market entrants include the necessity for comprehensive IP due diligence, development of differentiated technologies that avoid existing patent claims, and cultivation of proprietary materials formulations that can serve as complementary protection mechanisms. For established players, strategic patent filing in emerging application areas and defensive publication of non-core innovations represent important tactics to maintain competitive advantage.

The expiration of several foundational patents between 2023-2025 will likely trigger increased market activity and technology democratization, potentially shifting competition toward application-specific innovations rather than core technology development. Organizations should prepare for this shift by focusing R&D efforts on industry-specific implementations and end-use applications where specialized IP can be developed.

Patent trend analysis indicates accelerating filing rates since 2015, with a 35% year-over-year increase in volumetric printing patents between 2018-2022. Geographically, the United States leads with approximately 42% of global patents, followed by China (23%), Germany (11%), and Japan (9%). This distribution highlights the strategic importance of establishing multi-regional IP protection strategies for companies seeking global market access.

Cross-licensing agreements have become increasingly common, particularly between materials developers and hardware manufacturers, creating interdependent innovation ecosystems. Several high-profile patent litigation cases in recent years have shaped the competitive landscape, with settlements often resulting in technology-sharing arrangements rather than market exclusion.

Freedom-to-operate challenges remain significant in the volumetric printing space due to overlapping patent claims and broad foundational patents. Companies must navigate this complex landscape through strategic patent acquisition, licensing negotiations, or design-around solutions. The emergence of patent pools and industry consortia suggests a trend toward collaborative IP management approaches that balance innovation protection with technology advancement.

Strategic implications for market entrants include the necessity for comprehensive IP due diligence, development of differentiated technologies that avoid existing patent claims, and cultivation of proprietary materials formulations that can serve as complementary protection mechanisms. For established players, strategic patent filing in emerging application areas and defensive publication of non-core innovations represent important tactics to maintain competitive advantage.

The expiration of several foundational patents between 2023-2025 will likely trigger increased market activity and technology democratization, potentially shifting competition toward application-specific innovations rather than core technology development. Organizations should prepare for this shift by focusing R&D efforts on industry-specific implementations and end-use applications where specialized IP can be developed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!