Comparative analysis of Volumetric 3D printing curing methods and resin performance

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric 3D Printing Evolution and Objectives

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, evolving from traditional layer-by-layer approaches to a more holistic volumetric solidification process. The journey began in the early 2000s with theoretical concepts of simultaneous multi-beam curing, but practical implementations only emerged around 2017 when researchers at Lawrence Livermore National Laboratory demonstrated the first functional volumetric additive manufacturing system. This breakthrough utilized computed axial lithography (CAL), enabling the simultaneous curing of an entire volume of photosensitive resin.

The evolution of volumetric printing has been driven by limitations in conventional stereolithography (SLA) and digital light processing (DLP) techniques, particularly regarding production speed, mechanical anisotropy, and support structure requirements. Traditional methods face inherent constraints due to their sequential layer processing nature, creating a technological ceiling that volumetric approaches aim to transcend.

Key evolutionary milestones include the development of tomographic reconstruction algorithms specifically optimized for volumetric printing, advancements in high-speed spatial light modulators, and the formulation of specialized resins with tuned absorption and scattering properties. The convergence of these technologies has enabled printing speeds orders of magnitude faster than conventional methods, with complete objects materialized in seconds rather than hours.

Current volumetric printing technologies encompass several distinct approaches, including computed tomography-based techniques, holographic volumetric printing, and two-photon polymerization methods. Each variant offers unique advantages in terms of resolution, speed, and material compatibility, contributing to the diversification of the technology landscape.

The primary objectives of volumetric 3D printing research center on overcoming existing limitations while expanding application possibilities. These include achieving sub-micron resolution across entire printed volumes, expanding the range of compatible materials beyond photopolymers to include ceramics and multi-material printing, and developing real-time monitoring and feedback systems for quality control.

Industry adoption objectives focus on scaling production capabilities while maintaining precision, reducing system costs to enable broader accessibility, and establishing standardized protocols for material characterization and process validation. The ultimate goal is to position volumetric printing as a viable manufacturing technology for applications ranging from biomedical devices to complex mechanical components.

Academic research aims to deepen understanding of photochemical reaction kinetics in volumetric contexts, explore novel light patterning techniques, and develop predictive models for resin performance under various curing conditions. These fundamental investigations are essential for pushing the boundaries of what volumetric printing can achieve in terms of speed, resolution, and material versatility.

The evolution of volumetric printing has been driven by limitations in conventional stereolithography (SLA) and digital light processing (DLP) techniques, particularly regarding production speed, mechanical anisotropy, and support structure requirements. Traditional methods face inherent constraints due to their sequential layer processing nature, creating a technological ceiling that volumetric approaches aim to transcend.

Key evolutionary milestones include the development of tomographic reconstruction algorithms specifically optimized for volumetric printing, advancements in high-speed spatial light modulators, and the formulation of specialized resins with tuned absorption and scattering properties. The convergence of these technologies has enabled printing speeds orders of magnitude faster than conventional methods, with complete objects materialized in seconds rather than hours.

Current volumetric printing technologies encompass several distinct approaches, including computed tomography-based techniques, holographic volumetric printing, and two-photon polymerization methods. Each variant offers unique advantages in terms of resolution, speed, and material compatibility, contributing to the diversification of the technology landscape.

The primary objectives of volumetric 3D printing research center on overcoming existing limitations while expanding application possibilities. These include achieving sub-micron resolution across entire printed volumes, expanding the range of compatible materials beyond photopolymers to include ceramics and multi-material printing, and developing real-time monitoring and feedback systems for quality control.

Industry adoption objectives focus on scaling production capabilities while maintaining precision, reducing system costs to enable broader accessibility, and establishing standardized protocols for material characterization and process validation. The ultimate goal is to position volumetric printing as a viable manufacturing technology for applications ranging from biomedical devices to complex mechanical components.

Academic research aims to deepen understanding of photochemical reaction kinetics in volumetric contexts, explore novel light patterning techniques, and develop predictive models for resin performance under various curing conditions. These fundamental investigations are essential for pushing the boundaries of what volumetric printing can achieve in terms of speed, resolution, and material versatility.

Market Analysis for Advanced 3D Printing Technologies

The global 3D printing market has experienced significant growth in recent years, with volumetric 3D printing emerging as a revolutionary technology within this space. The market for advanced 3D printing technologies reached approximately $13.7 billion in 2021 and is projected to grow at a CAGR of 20.8% through 2028, potentially reaching $51.5 billion by the end of the forecast period.

Volumetric 3D printing, particularly focusing on different curing methods and resin performance, represents a high-growth segment within this broader market. The demand for faster, more precise, and material-efficient 3D printing solutions is driving innovation in volumetric techniques such as computed axial lithography (CAL), tomographic volumetric additive manufacturing (VAM), and holographic printing methods.

The healthcare sector currently dominates the application landscape for advanced volumetric printing, accounting for approximately 32% of the market share. Medical device manufacturing, custom implants, and bioprinting applications are experiencing particularly strong demand growth due to the ability of volumetric techniques to produce complex geometries with biocompatible resins.

Aerospace and automotive industries collectively represent about 28% of the market, where the demand for lightweight, high-performance components with complex internal structures is accelerating adoption. These sectors particularly value the superior mechanical properties and isotropic characteristics that advanced resin formulations can deliver through volumetric curing methods.

Consumer electronics manufacturers are increasingly exploring volumetric printing for prototyping and small-batch production, contributing approximately 15% to the current market. The ability to produce optically clear components with minimal post-processing is a significant driver in this segment.

Regional analysis indicates North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 24.3% annually, driven by rapid industrialization and significant government investments in advanced manufacturing technologies in countries like China, Japan, and South Korea.

The market for specialized photopolymer resins optimized for volumetric printing is experiencing particularly strong growth, with premium formulations commanding price points 3-5 times higher than conventional stereolithography resins. This premium pricing reflects the enhanced performance characteristics including faster cure rates, improved mechanical properties, and reduced shrinkage that these materials offer.

Customer demand trends indicate growing interest in environmentally sustainable resin formulations, with 67% of industrial users expressing preference for bio-based or recyclable materials when performance parameters can be maintained. This represents a significant market opportunity for developers of next-generation, eco-friendly volumetric printing materials.

Volumetric 3D printing, particularly focusing on different curing methods and resin performance, represents a high-growth segment within this broader market. The demand for faster, more precise, and material-efficient 3D printing solutions is driving innovation in volumetric techniques such as computed axial lithography (CAL), tomographic volumetric additive manufacturing (VAM), and holographic printing methods.

The healthcare sector currently dominates the application landscape for advanced volumetric printing, accounting for approximately 32% of the market share. Medical device manufacturing, custom implants, and bioprinting applications are experiencing particularly strong demand growth due to the ability of volumetric techniques to produce complex geometries with biocompatible resins.

Aerospace and automotive industries collectively represent about 28% of the market, where the demand for lightweight, high-performance components with complex internal structures is accelerating adoption. These sectors particularly value the superior mechanical properties and isotropic characteristics that advanced resin formulations can deliver through volumetric curing methods.

Consumer electronics manufacturers are increasingly exploring volumetric printing for prototyping and small-batch production, contributing approximately 15% to the current market. The ability to produce optically clear components with minimal post-processing is a significant driver in this segment.

Regional analysis indicates North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 24.3% annually, driven by rapid industrialization and significant government investments in advanced manufacturing technologies in countries like China, Japan, and South Korea.

The market for specialized photopolymer resins optimized for volumetric printing is experiencing particularly strong growth, with premium formulations commanding price points 3-5 times higher than conventional stereolithography resins. This premium pricing reflects the enhanced performance characteristics including faster cure rates, improved mechanical properties, and reduced shrinkage that these materials offer.

Customer demand trends indicate growing interest in environmentally sustainable resin formulations, with 67% of industrial users expressing preference for bio-based or recyclable materials when performance parameters can be maintained. This represents a significant market opportunity for developers of next-generation, eco-friendly volumetric printing materials.

Current Curing Methods and Technical Barriers

Volumetric 3D printing currently employs several distinct curing methods, each with specific technical characteristics and limitations. The most established approach is Digital Light Processing (DLP), which utilizes a digital micromirror device to project entire layer patterns simultaneously onto photosensitive resin. While DLP offers faster build speeds compared to point-by-point methods, it faces resolution constraints determined by the projector's pixel size and optical system quality.

Stereolithography (SLA) represents another widely adopted technique, using either laser or LED light sources to cure resin. Traditional SLA systems employ galvanometer-controlled mirrors to direct laser beams, achieving high precision but at the cost of slower processing speeds. More recent masked SLA variants have emerged, offering improved throughput but with potential compromises in resolution uniformity across the build area.

Continuous Liquid Interface Production (CLIP) has emerged as a significant advancement, utilizing oxygen-permeable windows to create a "dead zone" that prevents adhesion to the build platform. This enables continuous printing without mechanical separation steps between layers, dramatically increasing production speeds. However, CLIP technology faces challenges in material compatibility and requires specialized resins formulated to work with the oxygen inhibition mechanism.

Two-photon polymerization (2PP) stands at the cutting edge of resolution capabilities, employing femtosecond lasers to achieve sub-micron feature sizes. The technique relies on non-linear optical absorption, where polymerization occurs only at the focal point where photon density is sufficient. While 2PP delivers exceptional resolution, it suffers from extremely slow build speeds and high equipment costs, limiting its industrial applicability primarily to specialized applications like microfluidics and photonics.

The primary technical barriers across all volumetric curing methods include light penetration depth limitations, which restrict part thickness and dimensional accuracy. Resin shrinkage during polymerization introduces internal stresses that can cause warping and dimensional inaccuracies, particularly in larger components. Heat management presents another significant challenge, as exothermic polymerization reactions can create thermal gradients leading to uneven curing and potential part failure.

Resolution consistency across the build volume remains problematic, with edge areas often exhibiting different curing characteristics than central regions due to optical distortions and light intensity variations. Additionally, the limited range of compatible materials restricts application versatility, as most commercial resins are proprietary formulations optimized for specific printing systems rather than end-use requirements.

Stereolithography (SLA) represents another widely adopted technique, using either laser or LED light sources to cure resin. Traditional SLA systems employ galvanometer-controlled mirrors to direct laser beams, achieving high precision but at the cost of slower processing speeds. More recent masked SLA variants have emerged, offering improved throughput but with potential compromises in resolution uniformity across the build area.

Continuous Liquid Interface Production (CLIP) has emerged as a significant advancement, utilizing oxygen-permeable windows to create a "dead zone" that prevents adhesion to the build platform. This enables continuous printing without mechanical separation steps between layers, dramatically increasing production speeds. However, CLIP technology faces challenges in material compatibility and requires specialized resins formulated to work with the oxygen inhibition mechanism.

Two-photon polymerization (2PP) stands at the cutting edge of resolution capabilities, employing femtosecond lasers to achieve sub-micron feature sizes. The technique relies on non-linear optical absorption, where polymerization occurs only at the focal point where photon density is sufficient. While 2PP delivers exceptional resolution, it suffers from extremely slow build speeds and high equipment costs, limiting its industrial applicability primarily to specialized applications like microfluidics and photonics.

The primary technical barriers across all volumetric curing methods include light penetration depth limitations, which restrict part thickness and dimensional accuracy. Resin shrinkage during polymerization introduces internal stresses that can cause warping and dimensional inaccuracies, particularly in larger components. Heat management presents another significant challenge, as exothermic polymerization reactions can create thermal gradients leading to uneven curing and potential part failure.

Resolution consistency across the build volume remains problematic, with edge areas often exhibiting different curing characteristics than central regions due to optical distortions and light intensity variations. Additionally, the limited range of compatible materials restricts application versatility, as most commercial resins are proprietary formulations optimized for specific printing systems rather than end-use requirements.

Comparative Analysis of Current Curing Solutions

01 Light-based curing methods for volumetric 3D printing

Various light-based curing methods are employed in volumetric 3D printing to solidify photosensitive resins. These include techniques such as digital light processing (DLP), stereolithography (SLA), and computed axial lithography (CAL) where specific wavelengths of light are used to selectively cure resin in a controlled manner. The curing process can be optimized by adjusting light intensity, exposure time, and wavelength to achieve desired mechanical properties and printing resolution.- Light-based curing methods for volumetric 3D printing: Various light-based curing methods are employed in volumetric 3D printing to solidify photosensitive resins. These include techniques such as digital light processing (DLP), stereolithography (SLA), and computed axial lithography (CAL). These methods use controlled light exposure to cure specific volumes of resin simultaneously, allowing for faster printing speeds compared to layer-by-layer approaches. The curing process can be optimized by controlling light intensity, wavelength, and exposure time to achieve desired mechanical properties in the printed objects.

- Resin formulations for improved mechanical properties: Advanced resin formulations are critical for achieving optimal mechanical properties in volumetrically printed objects. These formulations typically include photoinitiators, monomers, oligomers, and various additives that influence curing behavior and final material characteristics. By adjusting the composition, manufacturers can create resins with enhanced strength, flexibility, durability, or heat resistance. Some formulations also incorporate reinforcing materials such as nanoparticles or fibers to further improve mechanical performance while maintaining compatibility with volumetric printing processes.

- Dual-curing and hybrid curing systems: Dual-curing and hybrid curing systems combine different curing mechanisms to enhance resin performance in volumetric 3D printing. These systems may utilize a combination of photo-curing, thermal curing, or chemical curing processes. The initial light-based curing provides shape definition, while secondary curing methods (such as heat treatment or chemical reactions) complete the polymerization process and improve mechanical properties. This approach allows for better control over the curing process and can result in printed objects with superior dimensional stability and mechanical characteristics.

- Oxygen inhibition control and curing atmosphere optimization: Oxygen inhibition significantly affects the curing process in volumetric 3D printing. Various techniques are employed to control oxygen levels during printing, including inert gas environments, oxygen scavengers in resin formulations, and specialized printing chamber designs. By minimizing oxygen inhibition, more efficient and uniform curing can be achieved, resulting in improved surface finish and mechanical properties. Some advanced systems actively manage the curing atmosphere to optimize the polymerization reaction and enhance overall print quality.

- Real-time monitoring and adaptive curing control: Advanced volumetric 3D printing systems incorporate real-time monitoring and adaptive control of the curing process. These systems use sensors to track resin viscosity, temperature, and curing progression, allowing for dynamic adjustments to light intensity, exposure patterns, or other parameters during printing. Machine learning algorithms can analyze this data to optimize curing parameters for specific geometries or resin formulations. This feedback-based approach improves print consistency, reduces defects, and enables more precise control over material properties in the final printed object.

02 Resin formulations for improved mechanical properties

Advanced resin formulations are designed to enhance the mechanical properties of 3D printed objects. These formulations may include various combinations of monomers, oligomers, photoinitiators, and additives that influence characteristics such as tensile strength, flexibility, and durability. By carefully balancing the composition of these components, resins can be tailored for specific applications requiring particular mechanical performance profiles, such as high strength, elasticity, or impact resistance.Expand Specific Solutions03 Thermal and dual-curing systems

Thermal and dual-curing systems combine different curing mechanisms to enhance resin performance in volumetric 3D printing. These systems may utilize both light and heat to initiate polymerization reactions, resulting in improved cross-linking density and mechanical properties. The dual-curing approach allows for better control over the curing process, reduced shrinkage, and enhanced overall performance of the printed parts, particularly for applications requiring high dimensional accuracy and stability.Expand Specific Solutions04 Oxygen inhibition control techniques

Oxygen inhibition control techniques are crucial for successful volumetric 3D printing as oxygen can interfere with the photopolymerization process. Various methods are employed to mitigate oxygen inhibition, including the use of oxygen scavengers, creating inert atmospheres, or incorporating specialized additives in the resin formulation. By effectively controlling oxygen inhibition, these techniques enable more efficient curing, improved surface finish, and enhanced mechanical properties of the printed objects.Expand Specific Solutions05 Real-time monitoring and adaptive curing systems

Real-time monitoring and adaptive curing systems utilize sensors and feedback mechanisms to optimize the curing process during volumetric 3D printing. These systems continuously analyze parameters such as light intensity, temperature, and resin viscosity, making dynamic adjustments to ensure consistent curing throughout the printing process. By implementing closed-loop control algorithms, these adaptive systems can compensate for variations in resin properties, environmental conditions, and other factors that might affect print quality and performance.Expand Specific Solutions

Leading Companies and Research Institutions in Volumetric Printing

Volumetric 3D printing technology is currently in a transitional phase from early development to commercial adoption, with the market expected to grow significantly as the technology matures. The global market for volumetric 3D printing is projected to expand as industries recognize its advantages in speed and complex geometry fabrication. Leading companies like Azul 3D, Carima, and 3M Innovative Properties are advancing curing methods, while materials specialists including Arkema, LG Chem, Covestro, and DSM IP Assets are developing high-performance resins with enhanced mechanical properties and cure kinetics. Research institutions such as MIT, EPFL, and Lawrence Livermore National Laboratory are contributing breakthrough innovations in light-based curing technologies and resin formulations, accelerating the technology toward broader industrial applications.

Lawrence Livermore National Security LLC

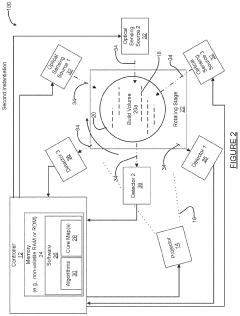

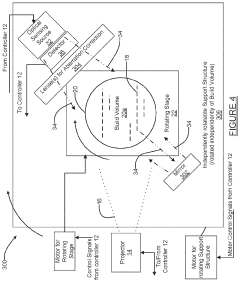

Technical Solution: Lawrence Livermore National Laboratory (LLNL) has developed Computed Axial Lithography (CAL), a revolutionary volumetric 3D printing technique that creates entire objects simultaneously rather than layer-by-layer. This approach projects computed tomographic images into a rotating volume of photosensitive resin, where the accumulated light energy selectively solidifies the material to form the desired object. LLNL has engineered specialized resin formulations with precisely tuned photoinitiator concentrations and light absorption characteristics to enable controlled volumetric curing. Their research has demonstrated the ability to print complex structures with internal features in under 30 seconds that would take hours with conventional methods. The laboratory has also developed advanced computational algorithms that determine optimal projection sequences to achieve desired geometries while minimizing light exposure to surrounding areas. LLNL's work extends to multi-material printing capabilities through selective wavelength activation of different photoinitiators within the same resin volume, allowing for gradient properties within a single print. Their research includes detailed characterization of mechanical properties, showing that volumetrically cured parts exhibit more isotropic behavior compared to layer-by-layer approaches.

Strengths: Dramatically faster production times (30-120 seconds for complete objects); elimination of layer lines and support structures; ability to create truly isotropic parts; excellent for producing optical-quality transparent components; capability to print around pre-existing embedded objects. Weaknesses: Currently limited to smaller build volumes (typically under 100mm diameter); restricted material selection due to specific optical requirements; higher complexity in system calibration; technology still transitioning from research to commercial applications.

Azul 3D, Inc.

Technical Solution: Azul 3D has developed a proprietary High Area Rapid Printing (HARP) technology that represents a significant advancement in volumetric 3D printing curing methods. Their approach uses a continuously flowing oil interface between the curing resin and the light source, which eliminates adhesion to the print window and enables continuous printing at high speeds. The HARP technology employs a specialized UV-curable resin system that can be rapidly polymerized while maintaining excellent mechanical properties. This method achieves print speeds exceeding 430 mm/hour vertically with minimal heat buildup, addressing one of the major limitations in traditional vat polymerization techniques. Azul 3D's technology also incorporates advanced oxygen inhibition control mechanisms that allow for precise curing depth management and improved resolution in complex geometries. Their resin formulations are engineered to provide isotropic mechanical properties regardless of build orientation, with tensile strengths comparable to injection-molded parts.

Strengths: Exceptionally high print speeds (up to 100x faster than traditional SLA/DLP); large build volumes without sacrificing resolution; minimal heat generation allowing continuous operation; excellent mechanical properties in printed parts. Weaknesses: Proprietary resin systems may limit material options; higher initial equipment investment compared to conventional systems; technology is relatively new to market with limited long-term performance data.

Critical Patents and Innovations in Resin Formulations

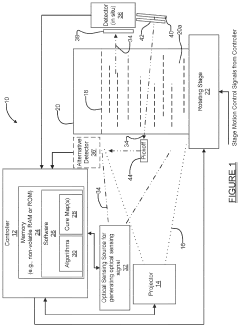

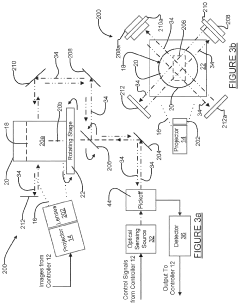

System and method for in situ volumetric sensing of 3D cure state of resin being used in an additive manufacturing system

PatentActiveUS11919244B2

Innovation

- Incorporating an in situ cure monitoring control system that uses optical Computed Tomographic (CT) images to generate real-time feedback on the curing state of the resist, allowing for adjustments to the curing beam to optimize the curing process.

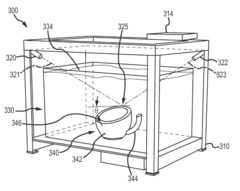

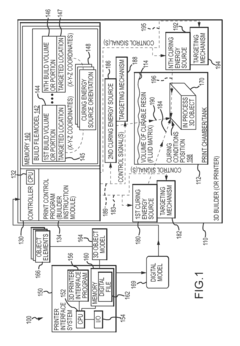

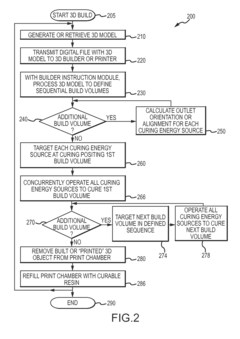

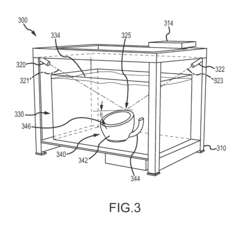

Three dimensional (3D) printing by volumetric addition through selective curing of a fluid matrix

PatentInactiveUS20160067922A1

Innovation

- A 3D printer that uses a tank of curable fluid to selectively and sequentially add volume to the object, eliminating the need for support structures by curing small volumes of resin at targeted locations using multiple curing energy sources, such as lasers or UV radiation, allowing for volumetric addition of the 3D object.

Material Science Advancements for Photopolymer Resins

Recent advancements in photopolymer resin technology have significantly expanded the capabilities and applications of volumetric 3D printing. The evolution of these materials has been driven by the need for faster curing times, improved mechanical properties, and enhanced biocompatibility for specialized applications. Traditional photopolymer resins were limited by their brittleness and narrow range of functional properties, but contemporary formulations have overcome many of these limitations.

The chemical composition of modern photopolymer resins has become increasingly sophisticated, incorporating various monomers, oligomers, photoinitiators, and additives that respond differently to specific curing methods. Acrylate-based resins remain popular for their rapid curing properties, while epoxy-based formulations offer superior dimensional stability and mechanical strength. Hybrid systems combining both chemistries have emerged to leverage the advantages of each.

Photoinitiator development has been particularly crucial in advancing volumetric printing capabilities. Two-photon initiators enable precise spatial control of the polymerization process, while wavelength-specific initiators allow for selective curing using different light sources. These innovations have directly impacted the resolution and speed achievable in various volumetric printing techniques.

The mechanical properties of cured resins have also seen remarkable improvements. High-performance formulations now achieve tensile strengths exceeding 80 MPa and elongation at break values of over 200% for elastomeric variants. Temperature resistance has improved significantly, with some specialized resins maintaining structural integrity at temperatures above 200°C, expanding applications into more demanding environments.

Biocompatible and biodegradable photopolymer resins represent another frontier in material science advancement. These formulations utilize naturally derived monomers and non-toxic photoinitiators to create structures suitable for medical applications. The development of resins that can be safely used in direct contact with human tissues has opened new possibilities in personalized medicine and implantable devices.

Functional additives have transformed photopolymers from purely structural materials to active components. Conductive fillers enable the printing of electronic circuits, while magnetic particles allow for the creation of responsive structures. Thermochromic and photochromic additives provide sensing capabilities, and the incorporation of ceramic or metal particles significantly enhances mechanical and thermal properties.

The relationship between resin composition and curing method compatibility has become a critical area of research. Optimization of resin formulations for specific volumetric techniques—whether computed axial lithography, holographic printing, or tomographic approaches—has led to specialized materials that maximize resolution, speed, and part quality for each method.

The chemical composition of modern photopolymer resins has become increasingly sophisticated, incorporating various monomers, oligomers, photoinitiators, and additives that respond differently to specific curing methods. Acrylate-based resins remain popular for their rapid curing properties, while epoxy-based formulations offer superior dimensional stability and mechanical strength. Hybrid systems combining both chemistries have emerged to leverage the advantages of each.

Photoinitiator development has been particularly crucial in advancing volumetric printing capabilities. Two-photon initiators enable precise spatial control of the polymerization process, while wavelength-specific initiators allow for selective curing using different light sources. These innovations have directly impacted the resolution and speed achievable in various volumetric printing techniques.

The mechanical properties of cured resins have also seen remarkable improvements. High-performance formulations now achieve tensile strengths exceeding 80 MPa and elongation at break values of over 200% for elastomeric variants. Temperature resistance has improved significantly, with some specialized resins maintaining structural integrity at temperatures above 200°C, expanding applications into more demanding environments.

Biocompatible and biodegradable photopolymer resins represent another frontier in material science advancement. These formulations utilize naturally derived monomers and non-toxic photoinitiators to create structures suitable for medical applications. The development of resins that can be safely used in direct contact with human tissues has opened new possibilities in personalized medicine and implantable devices.

Functional additives have transformed photopolymers from purely structural materials to active components. Conductive fillers enable the printing of electronic circuits, while magnetic particles allow for the creation of responsive structures. Thermochromic and photochromic additives provide sensing capabilities, and the incorporation of ceramic or metal particles significantly enhances mechanical and thermal properties.

The relationship between resin composition and curing method compatibility has become a critical area of research. Optimization of resin formulations for specific volumetric techniques—whether computed axial lithography, holographic printing, or tomographic approaches—has led to specialized materials that maximize resolution, speed, and part quality for each method.

Environmental Impact and Sustainability Considerations

Volumetric 3D printing technologies present significant environmental implications that warrant careful consideration in their development and application. The environmental footprint of these processes extends across multiple dimensions, from raw material sourcing to end-of-life disposal. Traditional photopolymer resins used in volumetric printing often contain potentially harmful chemicals, including photoinitiators, monomers, and additives that may pose ecological risks if improperly handled or disposed of.

The curing methods employed in volumetric printing demonstrate varying degrees of energy efficiency, directly impacting the carbon footprint of manufacturing operations. Computed Axial Lithography (CAL) systems typically require less energy than multi-projector approaches due to their simplified optical setup, though this advantage may be offset by longer processing times. Conversely, tomographic volumetric printing methods utilizing multiple light sources consume more electricity but achieve faster production cycles, presenting a sustainability trade-off that manufacturers must navigate.

Waste generation represents another critical environmental concern. The development of bio-based and biodegradable resins has gained momentum as a response to sustainability challenges, with several research groups reporting promising formulations derived from renewable resources such as cellulose derivatives and plant oils. These alternative materials demonstrate comparable mechanical properties while offering improved end-of-life scenarios compared to petroleum-based counterparts.

Material efficiency in volumetric printing surpasses many traditional additive manufacturing techniques, as the entire volume is cured simultaneously without the need for support structures. This advantage translates to reduced material waste and potentially lower environmental impact per manufactured unit. Additionally, the absence of layer-by-layer processing eliminates the need for mechanical movements between layers, further enhancing energy efficiency during production.

Lifecycle assessment studies indicate that the environmental impact of volumetric printing technologies extends beyond the manufacturing phase. The durability and recyclability of printed components significantly influence their overall sustainability profile. Recent advances in photopolymer chemistry have yielded resins designed for disassembly, where specific wavelengths or chemical treatments can trigger controlled degradation, facilitating material recovery and recycling.

Regulatory frameworks governing the environmental aspects of volumetric printing remain in development across many jurisdictions. Industry stakeholders are increasingly adopting voluntary standards and certification programs to demonstrate environmental responsibility. These initiatives encompass aspects such as VOC emissions during printing, energy consumption metrics, and end-of-life management protocols, collectively driving the sector toward more sustainable practices.

The curing methods employed in volumetric printing demonstrate varying degrees of energy efficiency, directly impacting the carbon footprint of manufacturing operations. Computed Axial Lithography (CAL) systems typically require less energy than multi-projector approaches due to their simplified optical setup, though this advantage may be offset by longer processing times. Conversely, tomographic volumetric printing methods utilizing multiple light sources consume more electricity but achieve faster production cycles, presenting a sustainability trade-off that manufacturers must navigate.

Waste generation represents another critical environmental concern. The development of bio-based and biodegradable resins has gained momentum as a response to sustainability challenges, with several research groups reporting promising formulations derived from renewable resources such as cellulose derivatives and plant oils. These alternative materials demonstrate comparable mechanical properties while offering improved end-of-life scenarios compared to petroleum-based counterparts.

Material efficiency in volumetric printing surpasses many traditional additive manufacturing techniques, as the entire volume is cured simultaneously without the need for support structures. This advantage translates to reduced material waste and potentially lower environmental impact per manufactured unit. Additionally, the absence of layer-by-layer processing eliminates the need for mechanical movements between layers, further enhancing energy efficiency during production.

Lifecycle assessment studies indicate that the environmental impact of volumetric printing technologies extends beyond the manufacturing phase. The durability and recyclability of printed components significantly influence their overall sustainability profile. Recent advances in photopolymer chemistry have yielded resins designed for disassembly, where specific wavelengths or chemical treatments can trigger controlled degradation, facilitating material recovery and recycling.

Regulatory frameworks governing the environmental aspects of volumetric printing remain in development across many jurisdictions. Industry stakeholders are increasingly adopting voluntary standards and certification programs to demonstrate environmental responsibility. These initiatives encompass aspects such as VOC emissions during printing, energy consumption metrics, and end-of-life management protocols, collectively driving the sector toward more sustainable practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!