How light modulation strategies enhance Volumetric 3D printing resolution and throughput

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Light Modulation in Volumetric 3D Printing: Background & Objectives

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, offering unprecedented speed and geometric freedom compared to traditional layer-by-layer approaches. The evolution of this technology can be traced back to the early 2000s when researchers began exploring the concept of simultaneous solidification within a volume of photosensitive resin. However, significant breakthroughs only emerged in the last decade with the development of advanced light modulation techniques.

The technological trajectory has been characterized by a progressive refinement of light delivery methods, from basic projection systems to sophisticated spatial light modulators and holographic techniques. This evolution has been driven by the fundamental challenge of achieving precise control over photopolymerization in three-dimensional space, which requires both spatial and temporal modulation of light energy.

Current research focuses on overcoming the inherent trade-off between resolution and throughput that has historically limited volumetric printing applications. Traditional approaches often sacrifice one parameter to enhance the other, creating a significant barrier to industrial adoption. The primary technical objective is to develop light modulation strategies that can simultaneously improve both metrics without compromising structural integrity or material properties.

Recent advances in computational optics and photochemistry have opened new avenues for innovation in this domain. Techniques such as computed axial lithography (CAL), tomographic volumetric additive manufacturing (VAM), and holographic stereolithography represent different approaches to the same fundamental challenge: how to precisely control light distribution within a volume to achieve desired polymerization patterns.

The technical goals of current research include achieving sub-micron resolution across entire build volumes, reducing print times from hours to minutes or even seconds, expanding the range of compatible materials, and developing systems capable of multi-material printing with distinct properties. Additionally, there is growing interest in integrating real-time feedback mechanisms to monitor and adjust light modulation parameters during the printing process.

From an industry perspective, the development of advanced light modulation strategies aims to position volumetric 3D printing as a viable manufacturing technology for applications ranging from biomedical devices and microfluidics to optical components and consumer electronics. The ultimate objective is to create printing systems that combine the speed advantages of volumetric approaches with the precision of high-resolution techniques, thereby enabling new classes of products and manufacturing workflows.

As the field continues to mature, interdisciplinary collaboration between optics, materials science, and computational engineering becomes increasingly important for addressing the complex challenges associated with light modulation in volumetric printing environments.

The technological trajectory has been characterized by a progressive refinement of light delivery methods, from basic projection systems to sophisticated spatial light modulators and holographic techniques. This evolution has been driven by the fundamental challenge of achieving precise control over photopolymerization in three-dimensional space, which requires both spatial and temporal modulation of light energy.

Current research focuses on overcoming the inherent trade-off between resolution and throughput that has historically limited volumetric printing applications. Traditional approaches often sacrifice one parameter to enhance the other, creating a significant barrier to industrial adoption. The primary technical objective is to develop light modulation strategies that can simultaneously improve both metrics without compromising structural integrity or material properties.

Recent advances in computational optics and photochemistry have opened new avenues for innovation in this domain. Techniques such as computed axial lithography (CAL), tomographic volumetric additive manufacturing (VAM), and holographic stereolithography represent different approaches to the same fundamental challenge: how to precisely control light distribution within a volume to achieve desired polymerization patterns.

The technical goals of current research include achieving sub-micron resolution across entire build volumes, reducing print times from hours to minutes or even seconds, expanding the range of compatible materials, and developing systems capable of multi-material printing with distinct properties. Additionally, there is growing interest in integrating real-time feedback mechanisms to monitor and adjust light modulation parameters during the printing process.

From an industry perspective, the development of advanced light modulation strategies aims to position volumetric 3D printing as a viable manufacturing technology for applications ranging from biomedical devices and microfluidics to optical components and consumer electronics. The ultimate objective is to create printing systems that combine the speed advantages of volumetric approaches with the precision of high-resolution techniques, thereby enabling new classes of products and manufacturing workflows.

As the field continues to mature, interdisciplinary collaboration between optics, materials science, and computational engineering becomes increasingly important for addressing the complex challenges associated with light modulation in volumetric printing environments.

Market Analysis for High-Resolution Volumetric Printing

The volumetric 3D printing market is experiencing significant growth, driven by increasing demand for high-resolution, rapid prototyping solutions across multiple industries. Current market valuations place the global 3D printing market at approximately $13.7 billion in 2023, with volumetric printing technologies representing an emerging segment poised for accelerated adoption due to their superior speed and resolution capabilities.

Healthcare applications represent the largest market segment, accounting for nearly 28% of high-resolution volumetric printing demand. The ability to produce anatomically accurate medical models, customized implants, and potentially bioprinted tissues has created substantial market pull from medical device manufacturers, hospitals, and research institutions. This sector is projected to maintain double-digit growth rates through 2030.

Manufacturing industries constitute the second-largest market segment at 24%, where volumetric printing enables rapid prototyping of complex components with internal features that traditional manufacturing methods cannot achieve. Aerospace, automotive, and consumer electronics manufacturers are increasingly adopting these technologies to reduce development cycles and enable mass customization.

Research institutions and academic laboratories form a critical early-adopter market segment (18%), driving innovation and establishing new application areas. This segment has been instrumental in demonstrating proof-of-concept applications that later transition to commercial markets.

Geographically, North America leads market adoption (42%), followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is experiencing the fastest growth rate, particularly in China, Japan, and South Korea, where significant investments in advanced manufacturing technologies are occurring.

Market barriers include the high initial equipment costs, with advanced volumetric printing systems ranging from $100,000 to over $500,000, limiting adoption to larger enterprises and specialized service providers. Technical limitations in material compatibility also restrict market penetration in certain applications requiring specific mechanical or thermal properties.

Customer demand increasingly focuses on three key performance metrics: resolution capabilities (with sub-10 micron precision becoming a benchmark for high-end applications), throughput rates (measured in cm³/hour), and material versatility. Light modulation strategies directly impact these metrics, making them central to competitive differentiation in the marketplace.

Market forecasts indicate that as light modulation technologies advance, enabling higher resolution and faster throughput, the volumetric printing market segment could grow at a CAGR of 25-30% over the next five years, outpacing the broader 3D printing market's growth rate of 20%.

Healthcare applications represent the largest market segment, accounting for nearly 28% of high-resolution volumetric printing demand. The ability to produce anatomically accurate medical models, customized implants, and potentially bioprinted tissues has created substantial market pull from medical device manufacturers, hospitals, and research institutions. This sector is projected to maintain double-digit growth rates through 2030.

Manufacturing industries constitute the second-largest market segment at 24%, where volumetric printing enables rapid prototyping of complex components with internal features that traditional manufacturing methods cannot achieve. Aerospace, automotive, and consumer electronics manufacturers are increasingly adopting these technologies to reduce development cycles and enable mass customization.

Research institutions and academic laboratories form a critical early-adopter market segment (18%), driving innovation and establishing new application areas. This segment has been instrumental in demonstrating proof-of-concept applications that later transition to commercial markets.

Geographically, North America leads market adoption (42%), followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is experiencing the fastest growth rate, particularly in China, Japan, and South Korea, where significant investments in advanced manufacturing technologies are occurring.

Market barriers include the high initial equipment costs, with advanced volumetric printing systems ranging from $100,000 to over $500,000, limiting adoption to larger enterprises and specialized service providers. Technical limitations in material compatibility also restrict market penetration in certain applications requiring specific mechanical or thermal properties.

Customer demand increasingly focuses on three key performance metrics: resolution capabilities (with sub-10 micron precision becoming a benchmark for high-end applications), throughput rates (measured in cm³/hour), and material versatility. Light modulation strategies directly impact these metrics, making them central to competitive differentiation in the marketplace.

Market forecasts indicate that as light modulation technologies advance, enabling higher resolution and faster throughput, the volumetric printing market segment could grow at a CAGR of 25-30% over the next five years, outpacing the broader 3D printing market's growth rate of 20%.

Current Limitations in Light Modulation Technologies

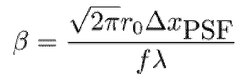

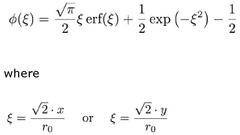

Despite significant advancements in volumetric 3D printing technologies, current light modulation strategies face several critical limitations that hinder optimal resolution and throughput performance. Conventional spatial light modulators (SLMs) typically operate with refresh rates between 60-240 Hz, creating a fundamental bottleneck in processing speed for high-resolution volumetric printing. This limitation becomes particularly problematic when attempting to project complex patterns requiring thousands of image frames for a single print job.

Resolution constraints represent another significant challenge, with most commercially available digital micromirror devices (DMDs) and liquid crystal displays (LCDs) offering pixel densities between 1080p and 4K. While seemingly adequate for many applications, these resolutions prove insufficient when printing microscale features with high precision across large build volumes. The physical pixel size and diffraction limits create a trade-off between field of view and achievable feature resolution.

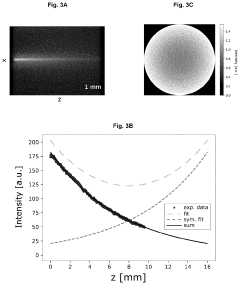

Light intensity distribution presents additional complications, as most current systems struggle with non-uniform illumination across the projection field. This results in inconsistent polymerization throughout the printing volume, leading to structural variations and potential print failures. The Gaussian distribution typical in many laser-based systems exacerbates this issue, creating stronger curing at the center compared to peripheral regions.

Wavelength limitations further restrict performance, with most systems designed around specific photoinitiator activation spectra. Single-wavelength approaches lack the flexibility to address multiple photochemical processes simultaneously, limiting material versatility. Additionally, chromatic aberration in multi-wavelength systems can degrade spatial resolution and pattern fidelity.

Dynamic range constraints in current light modulation technologies present challenges in controlling polymerization depth and feature definition. Most systems offer 8-bit or 10-bit intensity control (256-1024 levels), which proves inadequate for precise grayscale modulation needed to achieve smooth surface finishes and controlled material properties throughout complex geometries.

Heat management represents a persistent challenge, particularly in high-power applications necessary for rapid throughput. Thermal loading on optical components can cause pattern distortion, wavelength shifts, and reduced component lifespans. Current cooling solutions add bulk and complexity to systems while still falling short of optimal thermal stability requirements.

Finally, synchronization between light modulation and resin movement or stage positioning introduces timing challenges that impact print accuracy. Latency in signal processing, mechanical movements, and photoresponse creates alignment errors that compound throughout the printing process. These temporal limitations become increasingly problematic as print speeds increase, creating a fundamental barrier to simultaneous high-resolution and high-throughput performance.

Resolution constraints represent another significant challenge, with most commercially available digital micromirror devices (DMDs) and liquid crystal displays (LCDs) offering pixel densities between 1080p and 4K. While seemingly adequate for many applications, these resolutions prove insufficient when printing microscale features with high precision across large build volumes. The physical pixel size and diffraction limits create a trade-off between field of view and achievable feature resolution.

Light intensity distribution presents additional complications, as most current systems struggle with non-uniform illumination across the projection field. This results in inconsistent polymerization throughout the printing volume, leading to structural variations and potential print failures. The Gaussian distribution typical in many laser-based systems exacerbates this issue, creating stronger curing at the center compared to peripheral regions.

Wavelength limitations further restrict performance, with most systems designed around specific photoinitiator activation spectra. Single-wavelength approaches lack the flexibility to address multiple photochemical processes simultaneously, limiting material versatility. Additionally, chromatic aberration in multi-wavelength systems can degrade spatial resolution and pattern fidelity.

Dynamic range constraints in current light modulation technologies present challenges in controlling polymerization depth and feature definition. Most systems offer 8-bit or 10-bit intensity control (256-1024 levels), which proves inadequate for precise grayscale modulation needed to achieve smooth surface finishes and controlled material properties throughout complex geometries.

Heat management represents a persistent challenge, particularly in high-power applications necessary for rapid throughput. Thermal loading on optical components can cause pattern distortion, wavelength shifts, and reduced component lifespans. Current cooling solutions add bulk and complexity to systems while still falling short of optimal thermal stability requirements.

Finally, synchronization between light modulation and resin movement or stage positioning introduces timing challenges that impact print accuracy. Latency in signal processing, mechanical movements, and photoresponse creates alignment errors that compound throughout the printing process. These temporal limitations become increasingly problematic as print speeds increase, creating a fundamental barrier to simultaneous high-resolution and high-throughput performance.

State-of-the-Art Light Modulation Solutions

01 Spatial light modulation techniques for volumetric printing

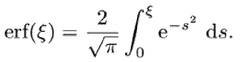

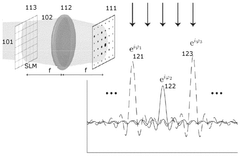

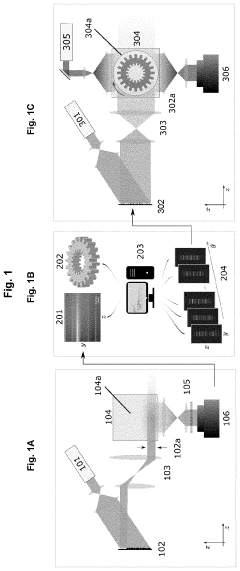

Spatial light modulators (SLMs) are used to control light patterns in volumetric 3D printing, enabling precise control over where photopolymerization occurs within the resin volume. These techniques include digital micromirror devices (DMDs) and liquid crystal displays (LCDs) that can shape light beams to create complex 3D structures. By dynamically modulating light patterns, these systems can achieve higher resolution and improved throughput in volumetric printing processes.- Spatial light modulation techniques for volumetric printing: Advanced spatial light modulation techniques are employed in volumetric 3D printing to control light distribution with high precision. These techniques utilize digital micromirror devices (DMDs) or spatial light modulators (SLMs) to selectively direct light patterns into photosensitive resin. By precisely controlling which areas receive light exposure, these systems can create complex 3D structures with improved resolution. The modulation strategies allow for dynamic adjustment of light intensity and pattern, enabling the creation of intricate features while maintaining high throughput.

- Temporal light modulation for improved resolution: Temporal light modulation strategies involve controlling the timing and duration of light exposure during the volumetric printing process. By synchronizing light pulses with the movement or rotation of the printing medium, these techniques can achieve higher resolution while maintaining throughput. The approach includes varying exposure times based on feature complexity, implementing sequential exposure patterns, and utilizing time-gated illumination to reduce light scattering effects. These temporal strategies help overcome the traditional trade-off between resolution and printing speed in volumetric 3D printing.

- Multi-wavelength and spectral light control: Multi-wavelength approaches utilize different light frequencies to achieve enhanced control over the printing process. By employing multiple wavelengths simultaneously or sequentially, these systems can initiate different photochemical reactions within the printing medium. This strategy enables selective curing at different depths and regions, improving both resolution and throughput. Spectral light control also allows for the creation of gradient properties within printed objects by varying the wavelength composition during the printing process, resulting in more sophisticated structures with region-specific mechanical or optical properties.

- Holographic and interference-based light patterning: Holographic and interference-based approaches create complex 3D light patterns within the printing volume using wave interference principles. These techniques generate precise light distributions throughout the entire volume simultaneously, rather than building layer by layer. By engineering constructive and destructive interference patterns, these systems can create intricate internal structures with high resolution. The holographic approach enables the printing of complex geometries in a single exposure, significantly increasing throughput while maintaining feature fidelity across the entire printed volume.

- Adaptive feedback and computational light control: Adaptive feedback systems incorporate real-time monitoring and adjustment of light patterns during the printing process. These systems use computational algorithms to predict and compensate for optical distortions, scattering effects, and material response variations. By continuously analyzing the printing progress and adjusting light modulation parameters accordingly, these approaches can optimize both resolution and throughput dynamically. The integration of machine learning algorithms further enhances the system's ability to adapt to different printing conditions and material properties, resulting in more consistent and precise volumetric printing outcomes.

02 Multi-beam projection systems for parallel processing

Multi-beam projection systems utilize multiple light sources or beam splitting techniques to simultaneously cure different regions of the printing volume. This parallel processing approach significantly increases throughput compared to single-beam methods. By coordinating multiple light paths with precise timing and positioning, these systems can create complex structures more rapidly while maintaining high resolution. Advanced algorithms control beam intensity and positioning to optimize the printing process.Expand Specific Solutions03 Temporal light modulation for improved resolution

Temporal modulation strategies involve controlling the timing, duration, and sequence of light exposure during the printing process. By precisely controlling when and for how long specific regions are exposed to light, these techniques can achieve finer feature resolution and reduce unwanted curing in adjacent areas. Methods include synchronized illumination patterns, pulsed light sources, and time-gated exposure systems that enhance both resolution and throughput in volumetric printing.Expand Specific Solutions04 Optical path optimization for volumetric printing

Optimizing the optical path in volumetric 3D printing systems involves designing specialized optics, beam shapers, and light delivery systems to enhance printing performance. These strategies include using beam homogenizers, custom lens arrays, and optical filters to control light distribution throughout the printing volume. By minimizing optical aberrations and ensuring uniform light intensity, these approaches improve both resolution and throughput while reducing printing artifacts.Expand Specific Solutions05 Computational approaches for light field optimization

Advanced computational methods are employed to optimize light field patterns for volumetric 3D printing. These approaches use algorithms to calculate optimal light distributions that maximize resolution and throughput simultaneously. Techniques include tomographic reconstruction, iterative optimization methods, and machine learning algorithms that predict and compensate for light scattering and absorption within the printing medium. These computational strategies enable more efficient use of light energy and improve overall printing quality.Expand Specific Solutions

Leading Companies and Research Institutions in Volumetric Printing

Volumetric 3D printing technology is currently in a growth phase, with the market expanding rapidly as light modulation strategies enhance resolution and throughput capabilities. The global market is projected to reach significant scale as industrial applications increase across manufacturing, healthcare, and consumer sectors. From a technical maturity perspective, research institutions like École Polytechnique Fédérale de Lausanne, MIT, and Lawrence Livermore National Laboratory are pioneering fundamental advances, while commercial players demonstrate varying levels of implementation. Companies including Nikon, Canon, and SCREEN Holdings are leveraging their optical expertise to develop advanced light modulation systems, while specialized firms like Structo, Upnano, and Prismlab are creating application-specific solutions. Asian manufacturers such as Shining 3D and OSSTEM IMPLANT are rapidly advancing practical implementations, particularly in industrial and medical applications.

École Polytechnique Fédérale de Lausanne

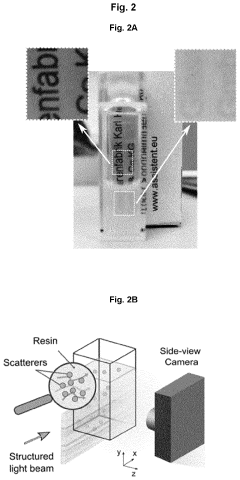

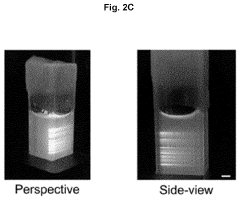

Technical Solution: EPFL has developed an advanced volumetric 3D printing approach utilizing tomographic principles and sophisticated light modulation strategies. Their system employs a Digital Light Processing (DLP) projector combined with a rotating cylindrical container of photosensitive resin. By synchronizing the projection of computed light patterns with the rotation of the container, EPFL researchers can create complex 3D structures in seconds rather than hours. Their technology incorporates advanced algorithms that calculate optimal light dose distributions from multiple angles, which when projected into the resin volume, selectively solidify the desired geometry. EPFL has enhanced resolution through the implementation of optical phase masks and specialized beam shaping techniques that compensate for light scattering and diffraction effects. Their recent innovations include multi-wavelength illumination strategies that enable gradient material properties and the integration of real-time feedback systems using optical coherence tomography to monitor and adjust the printing process dynamically. This approach has demonstrated the ability to create structures with features as small as 25 micrometers throughout volumes of several cubic centimeters.

Strengths: Exceptional printing speed (up to 100x faster than conventional methods); ability to create complex internal geometries without support structures; minimal mechanical stress during fabrication resulting in higher structural integrity and isotropic mechanical properties. Weaknesses: Resolution currently limited by optical diffraction effects; material compatibility restricted to specialized photopolymers; scaling to larger build volumes presents challenges related to light penetration and scattering in the resin.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Laboratory (LLNL) has developed a groundbreaking volumetric 3D printing technique called Computed Axial Lithography (CAL), which projects synchronized patterns of light into a rotating volume of photosensitive resin. This approach creates entire 3D objects simultaneously rather than layer-by-layer. LLNL's implementation uses Digital Light Processing (DLP) technology with specialized algorithms that calculate optimal light dose distributions from multiple angles. Their system achieves printing speeds of less than 30 seconds for complex structures that would take hours with conventional methods. LLNL has further enhanced resolution through multi-wavelength approaches and optical phase manipulation, achieving feature sizes down to 25 micrometers. Their recent advancements include the integration of oxygen inhibition control mechanisms and temperature-regulated printing environments to improve surface finish quality and dimensional accuracy. The technology has been demonstrated for biomedical applications requiring complex internal channels and aerospace components with intricate lattice structures.

Strengths: Exceptional printing speed (100x faster than conventional methods); ability to create objects with complex internal geometries impossible with layer-based approaches; minimal mechanical stress during fabrication resulting in higher structural integrity. Weaknesses: Resolution currently limited by optical diffraction effects; restricted to photopolymer materials compatible with volumetric curing; scaling to larger build volumes presents optical challenges related to light scattering and absorption.

Key Patents and Research in Volumetric Resolution Enhancement

Holographic volumetric additive manufacturing (holovam)

PatentWO2025088142A1

Innovation

- The method employs holographic volumetric additive manufacturing (HoloVAM) by generating a composite hologram that modulates a coherent input beam to create a pixelated projection in a reconstruction space, allowing for improved resolution, speed, and light efficiency through phase-only holographic projections.

High resolution and three-dimensional printing in complex photosensitive materials

PatentPendingUS20240239039A1

Innovation

- A method and apparatus that account for light scattering by characterizing and correcting light patterns using a 3-step protocol involving light scattering characterization, computation of optimized patterns, and implementation in a tomographic manufacturing system, incorporating a side-view camera and spatial light modulators to improve print fidelity and resolution in non-transparent materials.

Materials Compatibility with Advanced Light Modulation Techniques

The compatibility between photosensitive materials and advanced light modulation techniques represents a critical factor in volumetric 3D printing performance. Current photopolymer resins exhibit varying responses to different wavelengths and intensities of light, creating significant challenges for implementing sophisticated modulation strategies. Materials with high photosensitivity enable faster curing but may compromise resolution due to light scattering effects, while less sensitive materials require longer exposure times, reducing throughput.

Recent developments in dual-wavelength initiator systems have shown promising results, allowing for more precise control over the polymerization process. These systems utilize primary wavelengths for initial activation and secondary wavelengths for polymerization termination, enabling finer feature definition. However, the commercial availability of such specialized materials remains limited, constraining widespread adoption of advanced modulation techniques.

The viscosity characteristics of photopolymers also significantly impact compatibility with temporal focusing and multi-beam interference techniques. Lower viscosity materials facilitate faster recoating and reduced oxygen inhibition, but may suffer from decreased mechanical properties in the final printed parts. Conversely, higher viscosity materials offer improved structural integrity but present challenges for rapid volumetric fabrication processes that rely on quick material response times.

Oxygen inhibition effects vary considerably across material formulations, directly affecting the efficacy of oxygen-assisted light modulation strategies. Some advanced resins incorporate oxygen scavengers to minimize inhibition zones, while others deliberately leverage oxygen presence to enhance edge definition through controlled radical quenching mechanisms. This delicate balance requires careful material engineering to optimize for specific modulation approaches.

Nanoparticle-doped photopolymers represent an emerging material class with enhanced compatibility with spatial light modulation techniques. These materials incorporate specialized nanoparticles that can locally amplify or attenuate light effects, enabling higher contrast ratios and improved feature resolution. However, challenges remain in ensuring uniform dispersion of nanoparticles and preventing unwanted light scattering effects that could compromise printing precision.

The development of orthogonal chemistry systems presents another promising direction, where multiple independent photochemical reactions can be triggered selectively using different wavelengths or intensities. This approach enables multi-material volumetric printing with distinct material properties in different regions, though significant research is still needed to develop commercially viable formulations that maintain compatibility with high-throughput modulation strategies.

Recent developments in dual-wavelength initiator systems have shown promising results, allowing for more precise control over the polymerization process. These systems utilize primary wavelengths for initial activation and secondary wavelengths for polymerization termination, enabling finer feature definition. However, the commercial availability of such specialized materials remains limited, constraining widespread adoption of advanced modulation techniques.

The viscosity characteristics of photopolymers also significantly impact compatibility with temporal focusing and multi-beam interference techniques. Lower viscosity materials facilitate faster recoating and reduced oxygen inhibition, but may suffer from decreased mechanical properties in the final printed parts. Conversely, higher viscosity materials offer improved structural integrity but present challenges for rapid volumetric fabrication processes that rely on quick material response times.

Oxygen inhibition effects vary considerably across material formulations, directly affecting the efficacy of oxygen-assisted light modulation strategies. Some advanced resins incorporate oxygen scavengers to minimize inhibition zones, while others deliberately leverage oxygen presence to enhance edge definition through controlled radical quenching mechanisms. This delicate balance requires careful material engineering to optimize for specific modulation approaches.

Nanoparticle-doped photopolymers represent an emerging material class with enhanced compatibility with spatial light modulation techniques. These materials incorporate specialized nanoparticles that can locally amplify or attenuate light effects, enabling higher contrast ratios and improved feature resolution. However, challenges remain in ensuring uniform dispersion of nanoparticles and preventing unwanted light scattering effects that could compromise printing precision.

The development of orthogonal chemistry systems presents another promising direction, where multiple independent photochemical reactions can be triggered selectively using different wavelengths or intensities. This approach enables multi-material volumetric printing with distinct material properties in different regions, though significant research is still needed to develop commercially viable formulations that maintain compatibility with high-throughput modulation strategies.

Scalability Challenges for Industrial Implementation

The scaling of volumetric 3D printing technologies from laboratory demonstrations to industrial manufacturing environments presents significant challenges that must be addressed for widespread adoption. Current light modulation strategies, while promising for enhancing resolution and throughput, face substantial hurdles when implemented at industrial scales.

Primary among these challenges is the cost-effectiveness of scaling sophisticated optical systems. High-precision spatial light modulators, tunable optics, and advanced laser systems that enable superior resolution often come with prohibitive costs when scaled to industrial production volumes. The economic viability of these technologies requires either cost reduction through manufacturing optimization or demonstration of value that justifies the investment.

Energy consumption represents another critical barrier to industrial implementation. High-intensity light sources needed for rapid curing of larger volumes demand substantial power, particularly when maintaining the precision required for high-resolution outputs. This creates a complex balance between throughput, resolution, and energy efficiency that manufacturers must navigate.

Material compatibility issues also emerge at industrial scales. While laboratory demonstrations often utilize ideal photopolymers, industrial applications require materials with specific mechanical, thermal, and chemical properties. The interaction between advanced light modulation strategies and diverse material formulations can lead to unpredictable results, necessitating extensive testing and optimization for each material system.

Process reliability and repeatability become increasingly challenging as production volumes increase. Environmental factors such as temperature fluctuations, vibrations, and dust contamination can significantly impact the precision of light modulation systems. Industrial implementations require robust engineering solutions to maintain consistent performance under variable conditions.

Integration with existing manufacturing workflows presents additional complexity. Volumetric 3D printing systems must interface with established production lines, quality control systems, and digital workflows. This integration often requires substantial customization and may necessitate redesigning production processes to accommodate the unique requirements of volumetric fabrication techniques.

Regulatory compliance and quality assurance frameworks for volumetric 3D printing remain underdeveloped in many industries. Establishing standardized testing protocols and certification processes for parts produced using advanced light modulation strategies will be essential for adoption in regulated sectors such as aerospace, automotive, and medical device manufacturing.

Primary among these challenges is the cost-effectiveness of scaling sophisticated optical systems. High-precision spatial light modulators, tunable optics, and advanced laser systems that enable superior resolution often come with prohibitive costs when scaled to industrial production volumes. The economic viability of these technologies requires either cost reduction through manufacturing optimization or demonstration of value that justifies the investment.

Energy consumption represents another critical barrier to industrial implementation. High-intensity light sources needed for rapid curing of larger volumes demand substantial power, particularly when maintaining the precision required for high-resolution outputs. This creates a complex balance between throughput, resolution, and energy efficiency that manufacturers must navigate.

Material compatibility issues also emerge at industrial scales. While laboratory demonstrations often utilize ideal photopolymers, industrial applications require materials with specific mechanical, thermal, and chemical properties. The interaction between advanced light modulation strategies and diverse material formulations can lead to unpredictable results, necessitating extensive testing and optimization for each material system.

Process reliability and repeatability become increasingly challenging as production volumes increase. Environmental factors such as temperature fluctuations, vibrations, and dust contamination can significantly impact the precision of light modulation systems. Industrial implementations require robust engineering solutions to maintain consistent performance under variable conditions.

Integration with existing manufacturing workflows presents additional complexity. Volumetric 3D printing systems must interface with established production lines, quality control systems, and digital workflows. This integration often requires substantial customization and may necessitate redesigning production processes to accommodate the unique requirements of volumetric fabrication techniques.

Regulatory compliance and quality assurance frameworks for volumetric 3D printing remain underdeveloped in many industries. Establishing standardized testing protocols and certification processes for parts produced using advanced light modulation strategies will be essential for adoption in regulated sectors such as aerospace, automotive, and medical device manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!