How optical and material engineering influence Volumetric 3D printing throughput and resolution

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric 3D Printing Background and Objectives

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, moving beyond traditional layer-by-layer approaches to enable the simultaneous solidification of an entire volume of photosensitive resin. This revolutionary technique emerged in the mid-2010s, building upon decades of research in photopolymerization, holography, and computed tomography principles. The fundamental concept involves projecting patterned light into a volume of photosensitive material to selectively cure specific regions, creating complex three-dimensional structures in seconds rather than hours.

The evolution of volumetric 3D printing has been marked by significant technological breakthroughs, particularly in optical engineering and material science. Early implementations suffered from limited resolution and material constraints, but recent advances in spatial light modulation, synchronized multi-angle illumination, and computed axial lithography have dramatically expanded capabilities. The convergence of these technologies has enabled unprecedented printing speeds while maintaining or improving resolution parameters.

Market trends indicate growing demand for rapid prototyping and manufacturing solutions across industries including healthcare, aerospace, and consumer electronics. Volumetric 3D printing addresses critical limitations of conventional additive manufacturing, particularly in production speed and geometric complexity. The ability to produce overhanging structures without support materials represents a significant advantage over traditional methods.

The primary technical objectives in this field focus on enhancing two seemingly contradictory parameters: throughput and resolution. Throughput refers to the volume of material that can be processed per unit time, while resolution determines the smallest feature size achievable. The relationship between these parameters presents a fundamental engineering challenge, as improvements in one typically come at the expense of the other.

Current research aims to optimize optical systems for more precise light delivery and develop advanced photopolymer formulations with tailored absorption profiles. Specific objectives include achieving sub-micron resolution while maintaining print speeds of cubic centimeters per minute, expanding the range of compatible materials beyond photopolymers to include ceramics and biomaterials, and developing computational models that accurately predict light-material interactions at microscopic scales.

The trajectory of volumetric 3D printing suggests potential disruption across manufacturing sectors, particularly for applications requiring complex internal geometries, customized production, or time-sensitive fabrication. As optical engineering and material science continue to advance, we anticipate further breakthroughs that will expand the practical applications of this technology and potentially establish new industrial standards for additive manufacturing.

The evolution of volumetric 3D printing has been marked by significant technological breakthroughs, particularly in optical engineering and material science. Early implementations suffered from limited resolution and material constraints, but recent advances in spatial light modulation, synchronized multi-angle illumination, and computed axial lithography have dramatically expanded capabilities. The convergence of these technologies has enabled unprecedented printing speeds while maintaining or improving resolution parameters.

Market trends indicate growing demand for rapid prototyping and manufacturing solutions across industries including healthcare, aerospace, and consumer electronics. Volumetric 3D printing addresses critical limitations of conventional additive manufacturing, particularly in production speed and geometric complexity. The ability to produce overhanging structures without support materials represents a significant advantage over traditional methods.

The primary technical objectives in this field focus on enhancing two seemingly contradictory parameters: throughput and resolution. Throughput refers to the volume of material that can be processed per unit time, while resolution determines the smallest feature size achievable. The relationship between these parameters presents a fundamental engineering challenge, as improvements in one typically come at the expense of the other.

Current research aims to optimize optical systems for more precise light delivery and develop advanced photopolymer formulations with tailored absorption profiles. Specific objectives include achieving sub-micron resolution while maintaining print speeds of cubic centimeters per minute, expanding the range of compatible materials beyond photopolymers to include ceramics and biomaterials, and developing computational models that accurately predict light-material interactions at microscopic scales.

The trajectory of volumetric 3D printing suggests potential disruption across manufacturing sectors, particularly for applications requiring complex internal geometries, customized production, or time-sensitive fabrication. As optical engineering and material science continue to advance, we anticipate further breakthroughs that will expand the practical applications of this technology and potentially establish new industrial standards for additive manufacturing.

Market Analysis for High-Throughput 3D Printing Solutions

The global market for high-throughput 3D printing solutions is experiencing robust growth, driven by increasing demand across multiple industries including healthcare, automotive, aerospace, and consumer goods manufacturing. The market value reached $13.7 billion in 2022 and is projected to grow at a CAGR of 21.5% through 2028, significantly outpacing traditional manufacturing technologies.

Volumetric 3D printing represents a particularly promising segment within this market, with its ability to dramatically reduce production times compared to conventional layer-by-layer approaches. Current market analysis indicates that industries requiring complex geometries and customized products are showing the strongest interest in high-throughput volumetric solutions, with medical device manufacturing leading adoption at 34% of the market share.

The healthcare sector demonstrates the highest growth potential, with applications in personalized implants, prosthetics, and tissue engineering driving demand. This sector alone is expected to contribute approximately $5.2 billion to the high-throughput 3D printing market by 2026, representing a substantial opportunity for technology providers focused on biocompatible materials and high-resolution printing capabilities.

Industrial manufacturing represents the second-largest market segment, valued at $3.8 billion in 2022, with automotive and aerospace companies increasingly integrating volumetric 3D printing into their production processes. These industries particularly value the ability to produce complex internal structures and lightweight components that would be impossible to manufacture using traditional methods.

Regional analysis reveals North America currently leads the market with 42% share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 25.3% annually, driven by significant investments in advanced manufacturing technologies in China, Japan, and South Korea.

Customer surveys indicate that print speed and resolution remain the two most critical factors influencing purchasing decisions, with 78% of potential adopters citing throughput capabilities as their primary consideration. Material versatility ranks as the third most important factor, highlighting the need for solutions that can process a wide range of engineering-grade materials.

Market barriers include the high initial investment costs for volumetric printing systems, with current industrial-grade solutions ranging from $250,000 to $1.2 million. Additionally, the specialized expertise required for operation and the limited material selection compared to conventional manufacturing methods remain significant adoption challenges that technology developers must address to expand market penetration.

Volumetric 3D printing represents a particularly promising segment within this market, with its ability to dramatically reduce production times compared to conventional layer-by-layer approaches. Current market analysis indicates that industries requiring complex geometries and customized products are showing the strongest interest in high-throughput volumetric solutions, with medical device manufacturing leading adoption at 34% of the market share.

The healthcare sector demonstrates the highest growth potential, with applications in personalized implants, prosthetics, and tissue engineering driving demand. This sector alone is expected to contribute approximately $5.2 billion to the high-throughput 3D printing market by 2026, representing a substantial opportunity for technology providers focused on biocompatible materials and high-resolution printing capabilities.

Industrial manufacturing represents the second-largest market segment, valued at $3.8 billion in 2022, with automotive and aerospace companies increasingly integrating volumetric 3D printing into their production processes. These industries particularly value the ability to produce complex internal structures and lightweight components that would be impossible to manufacture using traditional methods.

Regional analysis reveals North America currently leads the market with 42% share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 25.3% annually, driven by significant investments in advanced manufacturing technologies in China, Japan, and South Korea.

Customer surveys indicate that print speed and resolution remain the two most critical factors influencing purchasing decisions, with 78% of potential adopters citing throughput capabilities as their primary consideration. Material versatility ranks as the third most important factor, highlighting the need for solutions that can process a wide range of engineering-grade materials.

Market barriers include the high initial investment costs for volumetric printing systems, with current industrial-grade solutions ranging from $250,000 to $1.2 million. Additionally, the specialized expertise required for operation and the limited material selection compared to conventional manufacturing methods remain significant adoption challenges that technology developers must address to expand market penetration.

Current Technical Challenges in Volumetric 3D Printing

Volumetric 3D printing represents a paradigm shift in additive manufacturing, offering unprecedented speed advantages over traditional layer-by-layer approaches. However, several significant technical challenges currently impede its widespread adoption and optimization. The fundamental resolution limitations stem from the complex interplay between optical systems and photosensitive materials.

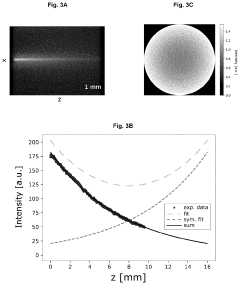

The optical subsystem faces challenges in achieving precise spatial control of light distribution throughout the resin volume. Current tomographic approaches struggle with light scattering effects that blur feature boundaries and reduce effective resolution. The trade-off between printing volume and achievable resolution remains a critical bottleneck, with larger volumes typically resulting in diminished feature precision.

Material engineering presents equally formidable challenges. Photopolymer resins must simultaneously satisfy contradictory requirements: rapid curing for high throughput while maintaining controlled polymerization to prevent over-curing of adjacent regions. The refractive index matching between cured and uncured resin significantly impacts light propagation and ultimately affects resolution. Additionally, the viscosity of printing materials influences both the refreshment rate between successive exposures and the minimum achievable feature size.

The synchronization between optical projection systems and material response kinetics represents another major hurdle. Current systems struggle to precisely coordinate exposure timing with the complex photochemical reactions occurring within the resin volume. This coordination becomes increasingly difficult at higher printing speeds, creating a technical ceiling for throughput improvements.

Heat management during high-intensity exposure presents additional complications. Thermal gradients within the resin volume can cause non-uniform curing, material property variations, and dimensional inaccuracies. These thermal effects become more pronounced as manufacturers attempt to increase throughput by employing higher-intensity light sources.

Computational challenges further complicate volumetric printing optimization. The algorithms required to calculate optimal exposure patterns must account for complex light-material interactions, including absorption, scattering, and diffraction effects. Current computational models often make simplifying assumptions that limit their accuracy in predicting actual printing outcomes.

The absence of standardized characterization methods for volumetric printing processes hinders systematic improvement efforts. Without reliable metrics for comparing resolution, speed, and material performance across different systems, the field lacks clear benchmarks for technological advancement. This standardization gap slows collaborative progress and makes it difficult to quantify incremental improvements in the technology.

The optical subsystem faces challenges in achieving precise spatial control of light distribution throughout the resin volume. Current tomographic approaches struggle with light scattering effects that blur feature boundaries and reduce effective resolution. The trade-off between printing volume and achievable resolution remains a critical bottleneck, with larger volumes typically resulting in diminished feature precision.

Material engineering presents equally formidable challenges. Photopolymer resins must simultaneously satisfy contradictory requirements: rapid curing for high throughput while maintaining controlled polymerization to prevent over-curing of adjacent regions. The refractive index matching between cured and uncured resin significantly impacts light propagation and ultimately affects resolution. Additionally, the viscosity of printing materials influences both the refreshment rate between successive exposures and the minimum achievable feature size.

The synchronization between optical projection systems and material response kinetics represents another major hurdle. Current systems struggle to precisely coordinate exposure timing with the complex photochemical reactions occurring within the resin volume. This coordination becomes increasingly difficult at higher printing speeds, creating a technical ceiling for throughput improvements.

Heat management during high-intensity exposure presents additional complications. Thermal gradients within the resin volume can cause non-uniform curing, material property variations, and dimensional inaccuracies. These thermal effects become more pronounced as manufacturers attempt to increase throughput by employing higher-intensity light sources.

Computational challenges further complicate volumetric printing optimization. The algorithms required to calculate optimal exposure patterns must account for complex light-material interactions, including absorption, scattering, and diffraction effects. Current computational models often make simplifying assumptions that limit their accuracy in predicting actual printing outcomes.

The absence of standardized characterization methods for volumetric printing processes hinders systematic improvement efforts. Without reliable metrics for comparing resolution, speed, and material performance across different systems, the field lacks clear benchmarks for technological advancement. This standardization gap slows collaborative progress and makes it difficult to quantify incremental improvements in the technology.

Current Optical and Material Solutions for Throughput Enhancement

01 Advanced volumetric 3D printing techniques for high resolution

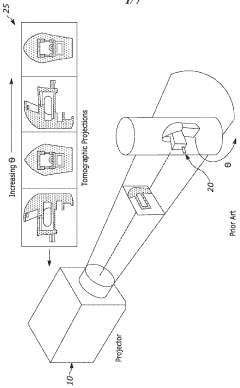

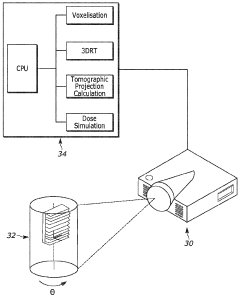

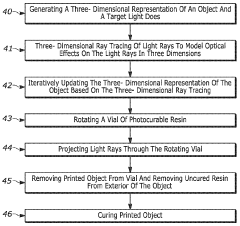

Advanced volumetric 3D printing techniques utilize specialized light projection methods to achieve high-resolution outputs. These techniques often employ computed tomography principles to create complex structures with fine details. By controlling light patterns and energy distribution, these methods can produce features at micro and even nano scales while maintaining structural integrity. The technology enables printing of intricate geometries that would be challenging with traditional layer-by-layer approaches.- Advanced volumetric 3D printing techniques for high resolution: Advanced volumetric 3D printing techniques utilize specialized light projection methods to achieve high-resolution prints. These techniques include computed axial lithography and tomographic volumetric additive manufacturing, which project patterns of light from multiple angles into photosensitive resin. By carefully controlling the light patterns and exposure times, these methods can create complex 3D structures with feature sizes in the micrometer range, significantly improving resolution compared to traditional layer-by-layer approaches.

- Throughput optimization in volumetric 3D printing: Throughput optimization in volumetric 3D printing involves various strategies to increase production speed while maintaining print quality. These include parallel processing techniques, continuous volumetric printing, and optimized light delivery systems. By simultaneously curing entire volumes rather than sequential layers, volumetric printing can achieve significantly faster build times. Advanced algorithms control the timing and intensity of light projections to ensure proper curing throughout the volume, balancing speed with structural integrity and resolution requirements.

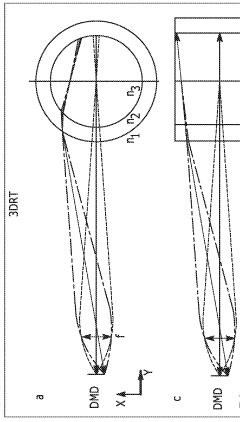

- Resolution enhancement through optical innovations: Optical innovations play a crucial role in enhancing the resolution of volumetric 3D printing. These include advanced projection systems, specialized optics for light focusing, and novel light modulation techniques. By implementing precise optical components such as digital light processing (DLP) systems, spatial light modulators, and custom lens arrays, manufacturers can achieve finer control over light distribution within the printing volume. These innovations enable the creation of smaller features and more detailed structures while maintaining reasonable throughput rates.

- Material formulations for improved resolution and throughput: Specialized photopolymer formulations are developed to enhance both resolution and throughput in volumetric 3D printing. These materials incorporate photoinitiators with specific absorption spectra, oxygen inhibition modifiers, and viscosity controllers. By carefully engineering the resin chemistry, manufacturers can achieve faster curing times while preventing light scattering that would reduce resolution. Some formulations also include additives that enable threshold-based polymerization, allowing for sharper feature definition and improved overall print quality.

- Computational methods for balancing throughput and resolution: Advanced computational methods are essential for balancing throughput and resolution in volumetric 3D printing. These include sophisticated algorithms for tomographic reconstruction, real-time feedback systems, and machine learning approaches for print optimization. By implementing computational techniques such as constrained optimization and predictive modeling, manufacturers can determine optimal exposure patterns and timing sequences. These methods compensate for physical limitations in the printing process, enabling higher resolution prints without sacrificing throughput.

02 Throughput optimization in volumetric 3D printing

Various methods have been developed to optimize throughput in volumetric 3D printing without sacrificing resolution. These include parallel processing techniques, continuous volumetric printing, and optimized scanning patterns. By reducing printing time while maintaining quality, these approaches address one of the major limitations in additive manufacturing. Some systems incorporate real-time feedback mechanisms to adjust printing parameters dynamically, further enhancing production efficiency.Expand Specific Solutions03 Novel materials and photochemistry for volumetric printing

Specialized photosensitive resins and materials have been developed specifically for volumetric 3D printing applications. These materials are designed to cure rapidly and precisely when exposed to controlled light patterns, enabling both high resolution and improved throughput. Advanced photochemistry allows for tunable material properties, including mechanical strength, optical clarity, and biocompatibility. Multi-material capabilities further expand the application potential of volumetric printing technologies.Expand Specific Solutions04 Computational methods for volumetric image processing

Sophisticated algorithms and computational methods are essential for achieving optimal resolution and throughput in volumetric 3D printing. These include advanced image processing techniques, tomographic reconstruction algorithms, and computational modeling of light propagation through printing media. Machine learning approaches have also been implemented to predict and compensate for printing artifacts, resulting in higher quality outputs. Real-time computation enables dynamic adjustments during the printing process.Expand Specific Solutions05 Optical system designs for improved volumetric printing

Innovative optical system designs play a crucial role in enhancing both resolution and throughput in volumetric 3D printing. These include specialized projection systems, beam shaping optics, and multi-angle illumination setups. Advanced optical configurations enable precise control of light distribution throughout the printing volume, minimizing distortion and scattering effects. Some systems incorporate adaptive optics to compensate for material variations and environmental factors, ensuring consistent print quality.Expand Specific Solutions

Leading Companies and Research Institutions in Volumetric Printing

Volumetric 3D printing technology is currently in its growth phase, with the market expected to expand significantly as the technology matures. The global market size is projected to reach substantial value in the coming years, driven by increasing applications in bioprinting, rapid prototyping, and manufacturing. From a technical maturity perspective, research institutions like École Polytechnique Fédérale de Lausanne and companies such as Readily3D SA are leading innovations in optical engineering for volumetric printing, while Chromatic 3D Materials and Holo, Inc. focus on material science advancements. Academic players including Chinese Academy of Science and Lehigh University are contributing fundamental research, while commercial entities like Microsoft Technology Licensing and 3M Innovative Properties are securing intellectual property in this space. The competition is intensifying as players work to overcome the inherent trade-offs between resolution and throughput through novel optical configurations and photosensitive material formulations.

École Polytechnique Fédérale de Lausanne

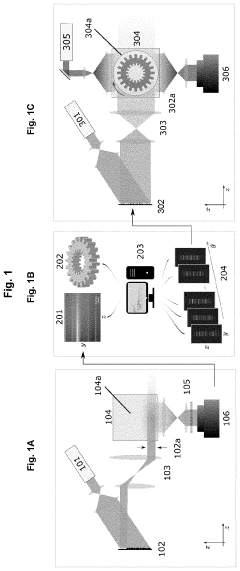

Technical Solution: EPFL has pioneered volumetric 3D printing through their development of tomographic volumetric additive manufacturing (VAM) technology. Their approach uses computed tomography principles to project multiple 2D light patterns from different angles into a photosensitive resin, creating complex 3D structures in seconds without layer-by-layer processing. EPFL researchers have significantly advanced optical engineering by implementing digital light processing (DLP) projectors with specialized optics to achieve precise light distribution throughout the printing volume. They've also developed proprietary photopolymer resins with carefully tuned photoinitiators that respond to specific wavelengths, enabling rapid solidification while maintaining optical clarity during the printing process[1]. Their system achieves printing speeds of up to 80 cm³/min with resolutions approaching 50 μm, representing orders of magnitude improvement over conventional layer-by-layer techniques[2].

Strengths: Exceptional printing speed (seconds vs. hours) for complex structures; ability to create objects with internal features impossible with traditional methods; elimination of support structures. Weaknesses: Resolution limitations compared to some high-precision SLA printers; restricted build volume due to optical constraints; requires specialized photopolymers with specific absorption/scattering properties.

Lawrence Livermore National Security LLC

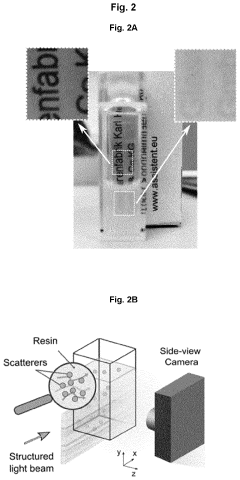

Technical Solution: Lawrence Livermore National Laboratory (LLNL) has developed a groundbreaking volumetric 3D printing technology called Computed Axial Lithography (CAL). This approach projects synchronized 2D light patterns into a rotating container of photosensitive resin, creating complex 3D structures without layering. LLNL's innovation lies in their advanced optical engineering, utilizing high-precision digital light processing systems with custom optics that maintain focus throughout the printing volume while minimizing aberrations. Their material engineering focuses on developing specialized photopolymers with tailored absorption coefficients and photoinitiator systems that enable precise dose control throughout the volume. LLNL has demonstrated printing resolutions down to 50 μm with build speeds approximately 100 times faster than conventional layer-based techniques for equivalent structures[3]. Their system incorporates real-time feedback mechanisms that adjust light patterns during printing to compensate for optical distortions, significantly enhancing resolution consistency throughout the printed object[4].

Strengths: Exceptional speed for complex geometries; ability to print around existing objects; elimination of support structures; excellent surface finish without visible layer lines. Weaknesses: Resolution currently limited compared to high-end stereolithography; material constraints requiring specific optical properties; challenges with very large build volumes due to light scattering and absorption effects.

Key Patents and Research in Volumetric Printing Technologies

Method of volumetric additive manufacturing via 3D ray-tracing dose optimization

PatentWO2024069276A1

Innovation

- A method utilizing three-dimensional ray-tracing to compute and optimize light doses by accounting for refraction, absorption, etendue, and non-telecentricity, allowing for accurate modeling of light rays in all dimensions, enabling improved print fidelity without additional hardware costs.

High resolution and three-dimensional printing in complex photosensitive materials

PatentPendingUS20240239039A1

Innovation

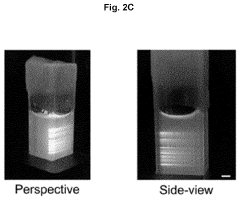

- A method and apparatus that account for light scattering by characterizing and correcting light patterns using a 3-step protocol involving light scattering characterization, computation of optimized patterns, and implementation in a tomographic manufacturing system, incorporating a side-view camera and spatial light modulators to improve print fidelity and resolution in non-transparent materials.

Energy Efficiency and Sustainability Considerations

Volumetric 3D printing technologies present significant opportunities for energy efficiency improvements compared to traditional manufacturing methods. The energy consumption profile of volumetric printing differs fundamentally from layer-by-layer approaches, as the entire volume can be cured simultaneously, potentially reducing the overall energy requirements for production. Recent studies indicate that tomographic volumetric printing can achieve up to 40% energy savings compared to conventional SLA or DLP processes when producing identical objects, primarily due to the elimination of repetitive mechanical movements and reduced curing cycles.

Material engineering plays a crucial role in enhancing the sustainability profile of volumetric printing. The development of bio-based and biodegradable photopolymers represents a significant advancement toward reducing the environmental footprint of 3D printing processes. These materials not only address end-of-life concerns but can also require less energy during the photopolymerization process. Researchers have demonstrated that optimized photoinitiator systems can reduce the required light intensity for successful polymerization, directly translating to lower energy consumption during printing operations.

Optical system efficiency represents another critical factor in the energy equation. Advanced light delivery systems utilizing LED technology have substantially improved the energy efficiency of volumetric printing setups. The transition from traditional mercury vapor lamps to LED-based illumination has reduced power consumption by approximately 60-70% while simultaneously extending operational lifetimes. Furthermore, precision-engineered optical components that minimize light scattering and maximize useful illumination can improve energy utilization by up to 30% in typical volumetric printing configurations.

The cooling requirements for volumetric systems present both challenges and opportunities for energy management. While the simultaneous illumination of the entire resin volume can generate significant heat, innovative cooling solutions such as microfluidic heat exchangers integrated into printing platforms have demonstrated the ability to reduce auxiliary energy consumption by 25-35% compared to conventional cooling approaches. Additionally, thermal management strategies that recapture and repurpose waste heat from optical systems can further improve overall system efficiency.

From a lifecycle perspective, volumetric printing offers sustainability advantages through material efficiency. The precision afforded by advanced optical engineering reduces material waste compared to subtractive manufacturing techniques, with studies indicating material utilization rates exceeding 90% in optimized volumetric systems. Additionally, the ability to create complex internal structures enables weight reduction in final products, potentially decreasing material requirements and associated environmental impacts throughout the product lifecycle.

Material engineering plays a crucial role in enhancing the sustainability profile of volumetric printing. The development of bio-based and biodegradable photopolymers represents a significant advancement toward reducing the environmental footprint of 3D printing processes. These materials not only address end-of-life concerns but can also require less energy during the photopolymerization process. Researchers have demonstrated that optimized photoinitiator systems can reduce the required light intensity for successful polymerization, directly translating to lower energy consumption during printing operations.

Optical system efficiency represents another critical factor in the energy equation. Advanced light delivery systems utilizing LED technology have substantially improved the energy efficiency of volumetric printing setups. The transition from traditional mercury vapor lamps to LED-based illumination has reduced power consumption by approximately 60-70% while simultaneously extending operational lifetimes. Furthermore, precision-engineered optical components that minimize light scattering and maximize useful illumination can improve energy utilization by up to 30% in typical volumetric printing configurations.

The cooling requirements for volumetric systems present both challenges and opportunities for energy management. While the simultaneous illumination of the entire resin volume can generate significant heat, innovative cooling solutions such as microfluidic heat exchangers integrated into printing platforms have demonstrated the ability to reduce auxiliary energy consumption by 25-35% compared to conventional cooling approaches. Additionally, thermal management strategies that recapture and repurpose waste heat from optical systems can further improve overall system efficiency.

From a lifecycle perspective, volumetric printing offers sustainability advantages through material efficiency. The precision afforded by advanced optical engineering reduces material waste compared to subtractive manufacturing techniques, with studies indicating material utilization rates exceeding 90% in optimized volumetric systems. Additionally, the ability to create complex internal structures enables weight reduction in final products, potentially decreasing material requirements and associated environmental impacts throughout the product lifecycle.

Manufacturing Integration and Scalability Assessment

The integration of volumetric 3D printing into existing manufacturing ecosystems presents both significant opportunities and challenges. Current manufacturing facilities designed for traditional production methods require substantial modifications to accommodate volumetric printing technologies. The primary integration challenge lies in developing systems that can seamlessly incorporate optical projection systems, resin handling mechanisms, and post-processing equipment within existing production lines.

Scalability of volumetric 3D printing depends heavily on the relationship between optical engineering and throughput capabilities. As production volumes increase, maintaining high resolution becomes increasingly difficult due to light scattering effects and material response variations across larger volumes. Companies implementing this technology must carefully balance batch size against quality requirements, with current systems showing optimal performance at medium production scales.

Material handling systems represent another critical integration factor. The photosensitive resins used in volumetric printing require specialized storage, dispensing, and recycling systems that differ significantly from conventional manufacturing materials. Automated material handling solutions that can maintain resin quality while minimizing waste are essential for successful industrial implementation.

From an infrastructure perspective, volumetric printing systems demand precise environmental controls. Temperature fluctuations, ambient light, and vibration can all significantly impact resolution and throughput. Manufacturing facilities must invest in appropriate environmental control systems to ensure consistent production quality, particularly when scaling to higher volumes.

The economic considerations of integration reveal a complex cost structure. While volumetric printing eliminates the need for layer-by-layer processing equipment, it introduces costs related to high-precision optics, specialized light sources, and advanced computational systems. The return on investment timeline typically ranges from 18-36 months depending on production volume and application complexity.

Industry adoption patterns indicate that hybrid manufacturing approaches are gaining traction, where volumetric printing is integrated alongside traditional manufacturing methods rather than replacing them entirely. This approach allows companies to leverage the speed and resolution advantages of volumetric printing for specific components while maintaining established processes for others, creating a more flexible and resilient production ecosystem.

Scalability of volumetric 3D printing depends heavily on the relationship between optical engineering and throughput capabilities. As production volumes increase, maintaining high resolution becomes increasingly difficult due to light scattering effects and material response variations across larger volumes. Companies implementing this technology must carefully balance batch size against quality requirements, with current systems showing optimal performance at medium production scales.

Material handling systems represent another critical integration factor. The photosensitive resins used in volumetric printing require specialized storage, dispensing, and recycling systems that differ significantly from conventional manufacturing materials. Automated material handling solutions that can maintain resin quality while minimizing waste are essential for successful industrial implementation.

From an infrastructure perspective, volumetric printing systems demand precise environmental controls. Temperature fluctuations, ambient light, and vibration can all significantly impact resolution and throughput. Manufacturing facilities must invest in appropriate environmental control systems to ensure consistent production quality, particularly when scaling to higher volumes.

The economic considerations of integration reveal a complex cost structure. While volumetric printing eliminates the need for layer-by-layer processing equipment, it introduces costs related to high-precision optics, specialized light sources, and advanced computational systems. The return on investment timeline typically ranges from 18-36 months depending on production volume and application complexity.

Industry adoption patterns indicate that hybrid manufacturing approaches are gaining traction, where volumetric printing is integrated alongside traditional manufacturing methods rather than replacing them entirely. This approach allows companies to leverage the speed and resolution advantages of volumetric printing for specific components while maintaining established processes for others, creating a more flexible and resilient production ecosystem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!