Comparative evaluation of Volumetric 3D printing photopolymer versus hybrid resin systems

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

3D Printing Photopolymer Evolution and Objectives

The evolution of 3D printing photopolymers represents one of the most significant technological advancements in additive manufacturing over the past three decades. Initially developed in the 1980s through stereolithography (SLA), photopolymer-based 3D printing has undergone remarkable transformation from simple prototyping applications to advanced manufacturing solutions capable of producing functional end-use parts with increasingly complex geometries and material properties.

Traditional photopolymer systems relied primarily on acrylate and methacrylate chemistries, offering limited mechanical properties and suffering from significant shrinkage and warping issues. The technological trajectory shifted dramatically in the early 2000s with the introduction of hybrid resin systems that combined different polymerization mechanisms to overcome these limitations. This evolution has been driven by the growing demand for higher performance materials across industries including aerospace, automotive, medical, and consumer products.

Volumetric 3D printing represents the latest paradigm shift in photopolymer technology, enabling the simultaneous curing of entire volumes rather than layer-by-layer fabrication. This approach, first demonstrated commercially around 2019, promises dramatic improvements in production speed—reducing print times from hours to minutes or even seconds—while potentially eliminating surface defects associated with layer interfaces.

The fundamental distinction between traditional photopolymers and hybrid resin systems lies in their polymerization mechanisms and resulting material properties. While conventional photopolymers typically rely on free-radical polymerization, hybrid systems incorporate multiple reaction pathways, often combining free-radical with cationic polymerization or incorporating urethane, epoxy, or siloxane components to enhance mechanical properties, thermal stability, and chemical resistance.

The current technological objective centers on developing photopolymer systems that can match or exceed the performance characteristics of traditional manufacturing materials while maintaining the geometric freedom inherent to additive manufacturing. Specifically, researchers aim to overcome the historical trade-off between reaction speed and mechanical properties that has limited photopolymer applications.

Looking forward, the industry is pursuing several key objectives: reducing the environmental impact of photopolymer materials through bio-based precursors and improved recyclability; expanding the functional properties to include electrical conductivity, thermal management capabilities, and stimuli-responsive behaviors; and developing specialized formulations optimized for emerging volumetric printing technologies that can achieve sub-micron resolution while maintaining production speeds orders of magnitude faster than current systems.

The comparative evaluation of volumetric 3D printing photopolymers versus hybrid resin systems thus represents a critical investigation at the frontier of additive manufacturing, with significant implications for the future direction of the industry and its ability to address increasingly demanding applications across multiple sectors.

Traditional photopolymer systems relied primarily on acrylate and methacrylate chemistries, offering limited mechanical properties and suffering from significant shrinkage and warping issues. The technological trajectory shifted dramatically in the early 2000s with the introduction of hybrid resin systems that combined different polymerization mechanisms to overcome these limitations. This evolution has been driven by the growing demand for higher performance materials across industries including aerospace, automotive, medical, and consumer products.

Volumetric 3D printing represents the latest paradigm shift in photopolymer technology, enabling the simultaneous curing of entire volumes rather than layer-by-layer fabrication. This approach, first demonstrated commercially around 2019, promises dramatic improvements in production speed—reducing print times from hours to minutes or even seconds—while potentially eliminating surface defects associated with layer interfaces.

The fundamental distinction between traditional photopolymers and hybrid resin systems lies in their polymerization mechanisms and resulting material properties. While conventional photopolymers typically rely on free-radical polymerization, hybrid systems incorporate multiple reaction pathways, often combining free-radical with cationic polymerization or incorporating urethane, epoxy, or siloxane components to enhance mechanical properties, thermal stability, and chemical resistance.

The current technological objective centers on developing photopolymer systems that can match or exceed the performance characteristics of traditional manufacturing materials while maintaining the geometric freedom inherent to additive manufacturing. Specifically, researchers aim to overcome the historical trade-off between reaction speed and mechanical properties that has limited photopolymer applications.

Looking forward, the industry is pursuing several key objectives: reducing the environmental impact of photopolymer materials through bio-based precursors and improved recyclability; expanding the functional properties to include electrical conductivity, thermal management capabilities, and stimuli-responsive behaviors; and developing specialized formulations optimized for emerging volumetric printing technologies that can achieve sub-micron resolution while maintaining production speeds orders of magnitude faster than current systems.

The comparative evaluation of volumetric 3D printing photopolymers versus hybrid resin systems thus represents a critical investigation at the frontier of additive manufacturing, with significant implications for the future direction of the industry and its ability to address increasingly demanding applications across multiple sectors.

Market Analysis for Volumetric vs Hybrid Resin Systems

The global market for 3D printing photopolymers is experiencing significant growth, with the overall 3D printing materials market projected to reach $9.5 billion by 2025, growing at a CAGR of approximately 23%. Within this expanding market, volumetric 3D printing photopolymers and hybrid resin systems represent two distinct technological approaches that are gaining traction among different industry segments.

Volumetric 3D printing photopolymer systems are capturing attention in high-precision industries such as medical device manufacturing, dental applications, and microfluidics. This market segment is valued at approximately $1.2 billion currently, with projections indicating growth to $3.7 billion by 2027. The primary market drivers include the superior resolution capabilities, reduced print times, and elimination of layer lines that volumetric techniques offer.

Hybrid resin systems, combining different chemical components to achieve enhanced mechanical properties, are dominating in industrial prototyping, automotive parts manufacturing, and consumer goods production. This segment currently holds about $2.1 billion of the market share, with expected growth to $5.3 billion by 2027. The demand is primarily driven by the versatility of mechanical properties achievable through hybrid formulations.

Regional analysis reveals that North America leads in volumetric technology adoption with approximately 42% market share, followed by Europe at 31% and Asia-Pacific at 22%. For hybrid resin systems, the distribution is more balanced with Asia-Pacific leading at 38%, followed by North America at 34% and Europe at 25%.

End-user segmentation shows that healthcare applications account for 37% of volumetric photopolymer demand, while industrial manufacturing represents 45% of hybrid resin system consumption. The aerospace and automotive sectors together constitute about 28% of the market for both technologies, with different preferences based on specific application requirements.

Price sensitivity analysis indicates that volumetric systems command a premium of 30-40% over traditional photopolymers due to their specialized formulations and enhanced capabilities. Hybrid systems typically carry a 15-25% premium, justified by their improved mechanical performance profiles.

Market penetration barriers differ significantly between the two technologies. Volumetric systems face challenges related to material compatibility limitations and higher initial investment costs, while hybrid systems struggle with standardization issues and batch-to-batch consistency in production environments.

Volumetric 3D printing photopolymer systems are capturing attention in high-precision industries such as medical device manufacturing, dental applications, and microfluidics. This market segment is valued at approximately $1.2 billion currently, with projections indicating growth to $3.7 billion by 2027. The primary market drivers include the superior resolution capabilities, reduced print times, and elimination of layer lines that volumetric techniques offer.

Hybrid resin systems, combining different chemical components to achieve enhanced mechanical properties, are dominating in industrial prototyping, automotive parts manufacturing, and consumer goods production. This segment currently holds about $2.1 billion of the market share, with expected growth to $5.3 billion by 2027. The demand is primarily driven by the versatility of mechanical properties achievable through hybrid formulations.

Regional analysis reveals that North America leads in volumetric technology adoption with approximately 42% market share, followed by Europe at 31% and Asia-Pacific at 22%. For hybrid resin systems, the distribution is more balanced with Asia-Pacific leading at 38%, followed by North America at 34% and Europe at 25%.

End-user segmentation shows that healthcare applications account for 37% of volumetric photopolymer demand, while industrial manufacturing represents 45% of hybrid resin system consumption. The aerospace and automotive sectors together constitute about 28% of the market for both technologies, with different preferences based on specific application requirements.

Price sensitivity analysis indicates that volumetric systems command a premium of 30-40% over traditional photopolymers due to their specialized formulations and enhanced capabilities. Hybrid systems typically carry a 15-25% premium, justified by their improved mechanical performance profiles.

Market penetration barriers differ significantly between the two technologies. Volumetric systems face challenges related to material compatibility limitations and higher initial investment costs, while hybrid systems struggle with standardization issues and batch-to-batch consistency in production environments.

Technical Challenges in Photopolymer Development

The development of photopolymers for volumetric 3D printing faces several significant technical challenges compared to hybrid resin systems. One primary obstacle is achieving uniform curing throughout the volume. Unlike layer-by-layer approaches, volumetric printing requires simultaneous polymerization across the entire volume, which demands exceptional control over light penetration and reaction kinetics. Current photopolymer formulations often struggle with depth-dependent curing rates, leading to inconsistent mechanical properties throughout printed objects.

Oxygen inhibition presents another substantial challenge, particularly affecting volumetric printing processes. When oxygen molecules interact with free radicals generated during photopolymerization, they form peroxide species that terminate the polymerization reaction. This inhibition is more pronounced in volumetric printing where the entire volume is exposed simultaneously, compared to hybrid systems where exposure occurs in controlled environments.

Refractive index matching between components poses a critical challenge for volumetric photopolymers. Any mismatch causes light scattering and refraction, distorting the projected pattern and reducing printing accuracy. Hybrid resin systems typically face fewer challenges in this regard as they utilize layer-by-layer approaches where light penetration depth is less critical.

Heat management during curing represents a significant technical hurdle. The exothermic nature of photopolymerization reactions can cause thermal gradients within the printing volume, leading to internal stresses, warping, and dimensional inaccuracies. Volumetric printing, with its simultaneous curing approach, generates heat throughout the entire volume at once, making thermal management considerably more complex than in hybrid systems.

Achieving appropriate viscosity profiles presents another challenge. Volumetric photopolymers must maintain low viscosity during the printing process while rapidly transitioning to solid form upon light exposure. This balance is difficult to achieve without compromising other properties such as mechanical strength or optical clarity.

Photoinitiator efficiency and concentration optimization remain problematic areas. Volumetric printing requires photoinitiators that can generate sufficient radicals throughout the entire volume while maintaining optical transparency. Finding compounds that balance absorption characteristics, quantum yield, and solubility without introducing unwanted color or reducing light penetration continues to challenge researchers.

Finally, shrinkage control during polymerization represents perhaps the most persistent challenge. As monomers convert to polymers, molecular spacing decreases, causing volumetric contraction. This shrinkage occurs throughout the entire printed object simultaneously in volumetric printing, creating significant internal stresses that can lead to cracking, warping, or dimensional inaccuracies that are more difficult to predict and control than in layer-by-layer hybrid approaches.

Oxygen inhibition presents another substantial challenge, particularly affecting volumetric printing processes. When oxygen molecules interact with free radicals generated during photopolymerization, they form peroxide species that terminate the polymerization reaction. This inhibition is more pronounced in volumetric printing where the entire volume is exposed simultaneously, compared to hybrid systems where exposure occurs in controlled environments.

Refractive index matching between components poses a critical challenge for volumetric photopolymers. Any mismatch causes light scattering and refraction, distorting the projected pattern and reducing printing accuracy. Hybrid resin systems typically face fewer challenges in this regard as they utilize layer-by-layer approaches where light penetration depth is less critical.

Heat management during curing represents a significant technical hurdle. The exothermic nature of photopolymerization reactions can cause thermal gradients within the printing volume, leading to internal stresses, warping, and dimensional inaccuracies. Volumetric printing, with its simultaneous curing approach, generates heat throughout the entire volume at once, making thermal management considerably more complex than in hybrid systems.

Achieving appropriate viscosity profiles presents another challenge. Volumetric photopolymers must maintain low viscosity during the printing process while rapidly transitioning to solid form upon light exposure. This balance is difficult to achieve without compromising other properties such as mechanical strength or optical clarity.

Photoinitiator efficiency and concentration optimization remain problematic areas. Volumetric printing requires photoinitiators that can generate sufficient radicals throughout the entire volume while maintaining optical transparency. Finding compounds that balance absorption characteristics, quantum yield, and solubility without introducing unwanted color or reducing light penetration continues to challenge researchers.

Finally, shrinkage control during polymerization represents perhaps the most persistent challenge. As monomers convert to polymers, molecular spacing decreases, causing volumetric contraction. This shrinkage occurs throughout the entire printed object simultaneously in volumetric printing, creating significant internal stresses that can lead to cracking, warping, or dimensional inaccuracies that are more difficult to predict and control than in layer-by-layer hybrid approaches.

Current Volumetric and Hybrid Resin Solutions

01 Photopolymer compositions for volumetric 3D printing

Specialized photopolymer formulations designed specifically for volumetric 3D printing applications. These compositions typically include photoinitiators, monomers, and oligomers that can be rapidly cured through volumetric light projection. The formulations are engineered to achieve optimal curing speeds, resolution, and mechanical properties when exposed to specific wavelengths of light in volumetric printing processes.- Photopolymer compositions for volumetric 3D printing: Specialized photopolymer formulations designed specifically for volumetric 3D printing applications. These compositions typically include photoinitiators, monomers, and oligomers that can be rapidly cured through volumetric light projection. The formulations are optimized for properties such as cure depth, resolution, and mechanical strength when exposed to specific wavelengths of light in volumetric printing processes.

- Hybrid resin systems combining multiple materials: Hybrid resin systems that incorporate multiple material types to achieve enhanced properties in volumetric 3D printed parts. These systems often combine different classes of photopolymers, such as acrylates and epoxies, or incorporate inorganic components like ceramic or metal particles into organic photopolymer matrices. The resulting hybrid materials offer improved mechanical properties, thermal stability, or functional characteristics compared to single-component systems.

- Light projection and curing technologies for volumetric printing: Advanced light projection and curing technologies specifically designed for volumetric 3D printing with photopolymers. These systems utilize specialized light sources, optical arrangements, and control mechanisms to achieve precise spatial control of photopolymerization throughout a volume of resin. Technologies include computed axial lithography, holographic projection, and multi-beam interference patterns that enable simultaneous curing throughout the entire volume rather than layer-by-layer approaches.

- Oxygen inhibition control in volumetric photopolymerization: Methods and compositions for controlling oxygen inhibition during volumetric photopolymerization processes. Oxygen can inhibit free-radical polymerization, affecting cure rates and final properties of printed parts. These innovations include oxygen scavenging additives, specialized photoinitiator systems that overcome oxygen inhibition, and process modifications that control the oxygen environment during printing to achieve consistent curing throughout the volume of resin.

- Resin viscosity and diffusion control for volumetric printing: Formulation approaches that optimize resin viscosity and control diffusion phenomena during volumetric 3D printing. These innovations address challenges related to material movement during the printing process, which can affect resolution and feature definition. Techniques include thixotropic additives that provide shear-thinning behavior, viscosity modifiers that respond to temperature or light exposure, and diffusion-limiting components that maintain spatial fidelity during the curing process.

02 Hybrid resin systems combining multiple materials

Hybrid resin systems that incorporate multiple materials to enhance the properties of 3D printed objects. These systems often combine different types of monomers, oligomers, or additives to achieve specific performance characteristics such as improved strength, flexibility, or thermal stability. The hybrid approach allows for customization of material properties to suit various applications while maintaining compatibility with volumetric printing techniques.Expand Specific Solutions03 Light projection and curing technologies for volumetric printing

Advanced light projection and curing technologies specifically designed for volumetric 3D printing with photopolymers. These technologies include computed tomography-based approaches, holographic projection systems, and synchronized multi-angle illumination methods that enable the simultaneous curing of entire volumes of resin. The systems are optimized to work with specific photopolymer formulations to achieve rapid fabrication with high resolution.Expand Specific Solutions04 Additives and modifiers for enhanced resin performance

Specialized additives and modifiers incorporated into photopolymer and hybrid resin systems to enhance performance characteristics. These include light absorbers to control curing depth, nanoparticles for mechanical reinforcement, reactive diluents to adjust viscosity, and various functional additives that improve print quality, resolution, and final part properties. The careful selection and concentration of these additives is critical for optimizing volumetric printing outcomes.Expand Specific Solutions05 Post-processing methods for volumetrically printed objects

Post-processing techniques specifically developed for objects created using volumetric 3D printing with photopolymers and hybrid resins. These methods include specialized washing procedures to remove uncured resin, controlled post-curing processes to enhance mechanical properties, and surface treatment techniques to improve finish quality. The post-processing approaches are tailored to the unique characteristics of volumetrically printed parts and their specific resin chemistry.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The volumetric 3D printing photopolymer market is currently in a growth phase, with increasing adoption across industries due to superior production speeds compared to traditional layer-by-layer approaches. The global market is expanding rapidly, projected to reach significant value as companies like Cubicure, polySpectra, and SprintRay develop specialized formulations. Technical maturity varies significantly between hybrid and pure photopolymer systems, with established players like BASF, Corning, and Toray Industries focusing on material science innovations. Research institutions including Northwestern University, EPFL, and Chinese Academy of Science are advancing fundamental technologies, while specialized manufacturers such as Holo, Mighty Buildings, and Quadratic 3D are commercializing novel applications, creating a competitive landscape balanced between material suppliers and equipment manufacturers.

Mighty Buildings, Inc.

Technical Solution: Mighty Buildings has developed a proprietary Light-Activated Building Material (LABM) technology that combines volumetric 3D printing principles with construction-grade materials. Their system utilizes a specialized photopolymer composite that incorporates mineral fillers and structural reinforcements to create building components with exceptional strength-to-weight ratios. The company's printing process employs a novel approach to volumetric solidification where multiple light sources simultaneously cure large volumes of material without requiring traditional layer-by-layer deposition. Their proprietary resin system features a unique dual-hardening mechanism that combines photo-curing with a secondary chemical reaction to achieve final mechanical properties suitable for construction applications[5]. The technology enables the production of large-scale, structurally sound components with complex geometries that would be challenging to produce using conventional construction methods or traditional 3D printing approaches.

Strengths: Ability to produce construction-grade components with excellent thermal insulation properties (R-value >20 per inch reported); significantly reduced material waste compared to traditional construction (up to 95% less waste claimed); and faster production cycles enabling rapid deployment of housing units. Weaknesses: Higher initial material costs compared to traditional construction materials; limited color options and surface finishes; and regulatory challenges associated with novel construction materials in some jurisdictions.

Cubicure GmbH

Technical Solution: Cubicure has pioneered Hot Lithography technology, a specialized approach to volumetric 3D printing that processes high-performance photopolymers at elevated temperatures. Their proprietary system combines precise thermal control with advanced light projection techniques to enable volumetric printing of highly viscous resins that would be incompatible with conventional room-temperature processes. The company's Cubicure Evolution printer features a patented heating system that maintains photopolymer resins at optimal processing temperatures between 60-120°C, significantly expanding the range of usable materials[2]. Their Cubicure Precision Optics system delivers controlled light energy throughout the entire build volume, enabling true volumetric solidification rather than layer-by-layer processing. Cubicure's hybrid resin systems incorporate both acrylate and epoxy chemistries, offering a balance of rapid curing and excellent mechanical properties.

Strengths: Ability to process high-viscosity, high-performance materials that conventional systems cannot handle; excellent dimensional accuracy (±0.1% reported); and superior surface quality without visible layer lines. Weaknesses: Higher energy consumption due to heating requirements; more complex system maintenance; and longer processing times compared to some competing volumetric technologies.

Key Patents and Innovations in Photopolymer Chemistry

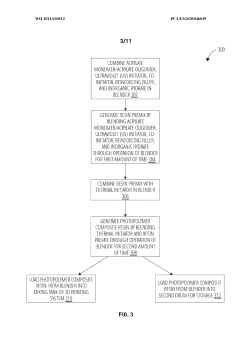

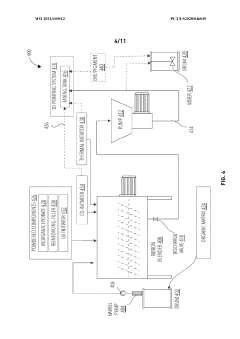

3D printing of a composite material via sequential dual-curing polymerization

PatentWO2021030512A1

Innovation

- A dual-cure 3D printing method using a photopolymer composite resin comprising acrylate monomers, inorganic hydrates, reinforcing fillers, UV initiators, and thermal initiators, which undergoes sequential photo- and thermal-polymerization, allowing for stable, rapid, and uniform curing with reduced stress and improved mechanical properties.

Photopolymerizable compositions including urea/acrylamide functional component, articles and methods

PatentWO2025057020A1

Innovation

- A photopolymerizable composition comprising 30-60 wt.% of a (meth)acrylate reactive diluent, a photoinitiator, and 30-60 wt.% of a polymerization reaction product including a urea or acrylamide functional component, which exhibits a dynamic viscosity of less than 5000 centipoises, suitable for 3D printing and forming resilient articles.

Environmental Impact and Sustainability Considerations

The environmental impact of 3D printing technologies has become increasingly important as the industry grows. When comparing volumetric 3D printing photopolymer systems with hybrid resin systems, several key sustainability factors emerge that warrant careful consideration by manufacturers and end-users alike.

Volumetric 3D printing typically demonstrates superior material efficiency compared to traditional layer-by-layer approaches. The one-shot curing process eliminates the need for support structures in many cases, reducing material waste by up to 35% according to recent industry analyses. Additionally, the energy consumption profile of volumetric systems shows potential advantages, with some studies indicating 20-40% lower electricity usage due to shorter production times and more efficient light utilization.

Hybrid resin systems, while offering enhanced mechanical properties through their composite nature, present more complex environmental challenges. The incorporation of multiple components often results in materials that are more difficult to recycle or biodegrade. However, recent developments in bio-based hybrid resins show promising advancements, with some formulations incorporating up to 30% renewable content derived from agricultural waste streams.

Chemical safety represents another critical environmental dimension. Volumetric photopolymers typically contain higher photoinitiator concentrations to enable rapid solidification throughout the volume, potentially increasing toxicity concerns. Conversely, hybrid systems may contain lower concentrations of individual harmful components but introduce a wider variety of chemicals into the manufacturing ecosystem. Recent toxicological assessments indicate that leaching of unreacted monomers remains a concern for both technologies, though advanced post-curing techniques have reduced this risk significantly.

End-of-life considerations reveal further distinctions between these technologies. Volumetric photopolymers, being more homogeneous in composition, may offer more straightforward recycling pathways. Several research groups have demonstrated successful depolymerization processes that can recover up to 75% of the original materials for reuse. Hybrid systems, while more challenging to recycle completely, often demonstrate longer service lifespans due to their enhanced durability, potentially offsetting their initial environmental impact through extended product lifecycles.

Water usage patterns also differ significantly between these technologies. Volumetric systems typically require more intensive cleaning processes to remove uncured resin from complex internal geometries, potentially increasing wastewater generation. Hybrid systems may require less post-processing water but often demand more extensive pre-processing of raw materials, creating a different water footprint profile that varies by specific application and implementation.

Volumetric 3D printing typically demonstrates superior material efficiency compared to traditional layer-by-layer approaches. The one-shot curing process eliminates the need for support structures in many cases, reducing material waste by up to 35% according to recent industry analyses. Additionally, the energy consumption profile of volumetric systems shows potential advantages, with some studies indicating 20-40% lower electricity usage due to shorter production times and more efficient light utilization.

Hybrid resin systems, while offering enhanced mechanical properties through their composite nature, present more complex environmental challenges. The incorporation of multiple components often results in materials that are more difficult to recycle or biodegrade. However, recent developments in bio-based hybrid resins show promising advancements, with some formulations incorporating up to 30% renewable content derived from agricultural waste streams.

Chemical safety represents another critical environmental dimension. Volumetric photopolymers typically contain higher photoinitiator concentrations to enable rapid solidification throughout the volume, potentially increasing toxicity concerns. Conversely, hybrid systems may contain lower concentrations of individual harmful components but introduce a wider variety of chemicals into the manufacturing ecosystem. Recent toxicological assessments indicate that leaching of unreacted monomers remains a concern for both technologies, though advanced post-curing techniques have reduced this risk significantly.

End-of-life considerations reveal further distinctions between these technologies. Volumetric photopolymers, being more homogeneous in composition, may offer more straightforward recycling pathways. Several research groups have demonstrated successful depolymerization processes that can recover up to 75% of the original materials for reuse. Hybrid systems, while more challenging to recycle completely, often demonstrate longer service lifespans due to their enhanced durability, potentially offsetting their initial environmental impact through extended product lifecycles.

Water usage patterns also differ significantly between these technologies. Volumetric systems typically require more intensive cleaning processes to remove uncured resin from complex internal geometries, potentially increasing wastewater generation. Hybrid systems may require less post-processing water but often demand more extensive pre-processing of raw materials, creating a different water footprint profile that varies by specific application and implementation.

Material Performance Benchmarking Methodologies

Effective benchmarking methodologies are essential for comparative evaluation of volumetric 3D printing photopolymers versus hybrid resin systems. The standardization of testing protocols ensures reliable and reproducible results across different material systems, enabling objective performance comparisons.

Mechanical property assessment forms the foundation of material benchmarking, typically including tensile strength, elongation at break, Young's modulus, and impact resistance. ASTM D638 and ISO 527 standards provide established frameworks for tensile testing, while ASTM D256 guides impact resistance evaluation. For volumetric 3D printing materials specifically, additional considerations must address the unique stress distributions resulting from simultaneous curing processes.

Photopolymerization kinetics benchmarking requires specialized methodologies to evaluate cure depth, cure time, and conversion efficiency. Real-time FTIR spectroscopy enables monitoring of functional group conversion rates, while photo-DSC (Differential Scanning Calorimetry) quantifies curing exotherms. For volumetric systems, light penetration depth and absorption coefficients must be carefully characterized using spectrophotometric techniques across relevant wavelengths.

Resolution and dimensional accuracy testing employs standardized test artifacts containing features of varying sizes and geometries. Optical microscopy and profilometry measurements quantify minimum feature size, surface roughness, and dimensional fidelity. The ISO 12836 standard provides guidelines for dental applications, while NIST has developed specialized test artifacts for additive manufacturing evaluation.

Long-term stability assessment involves accelerated aging protocols under controlled temperature, humidity, and UV exposure conditions. Changes in mechanical properties, color stability, and dimensional accuracy are monitored at regular intervals. ISO 4892 and ASTM G154 standards guide weathering resistance testing, while ASTM D6990 addresses creep and stress relaxation behaviors.

Biocompatibility testing follows ISO 10993 guidelines for materials intended for medical applications. Cytotoxicity (ISO 10993-5), sensitization (ISO 10993-10), and genotoxicity (ISO 10993-3) evaluations provide critical safety data. For dental applications, additional testing per ISO 7405 may be required to assess pulp and dentine compatibility.

Process parameter optimization benchmarking evaluates material performance across different printing conditions. Design of Experiments (DOE) methodologies identify critical parameters affecting material properties, establishing optimal processing windows. Statistical analysis techniques such as response surface methodology enable systematic exploration of parameter interactions and their effects on final part quality.

Mechanical property assessment forms the foundation of material benchmarking, typically including tensile strength, elongation at break, Young's modulus, and impact resistance. ASTM D638 and ISO 527 standards provide established frameworks for tensile testing, while ASTM D256 guides impact resistance evaluation. For volumetric 3D printing materials specifically, additional considerations must address the unique stress distributions resulting from simultaneous curing processes.

Photopolymerization kinetics benchmarking requires specialized methodologies to evaluate cure depth, cure time, and conversion efficiency. Real-time FTIR spectroscopy enables monitoring of functional group conversion rates, while photo-DSC (Differential Scanning Calorimetry) quantifies curing exotherms. For volumetric systems, light penetration depth and absorption coefficients must be carefully characterized using spectrophotometric techniques across relevant wavelengths.

Resolution and dimensional accuracy testing employs standardized test artifacts containing features of varying sizes and geometries. Optical microscopy and profilometry measurements quantify minimum feature size, surface roughness, and dimensional fidelity. The ISO 12836 standard provides guidelines for dental applications, while NIST has developed specialized test artifacts for additive manufacturing evaluation.

Long-term stability assessment involves accelerated aging protocols under controlled temperature, humidity, and UV exposure conditions. Changes in mechanical properties, color stability, and dimensional accuracy are monitored at regular intervals. ISO 4892 and ASTM G154 standards guide weathering resistance testing, while ASTM D6990 addresses creep and stress relaxation behaviors.

Biocompatibility testing follows ISO 10993 guidelines for materials intended for medical applications. Cytotoxicity (ISO 10993-5), sensitization (ISO 10993-10), and genotoxicity (ISO 10993-3) evaluations provide critical safety data. For dental applications, additional testing per ISO 7405 may be required to assess pulp and dentine compatibility.

Process parameter optimization benchmarking evaluates material performance across different printing conditions. Design of Experiments (DOE) methodologies identify critical parameters affecting material properties, establishing optimal processing windows. Statistical analysis techniques such as response surface methodology enable systematic exploration of parameter interactions and their effects on final part quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!