How material and optical parameters optimize Volumetric 3D printing speed and accuracy

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric 3D Printing Evolution and Objectives

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, evolving from traditional layer-by-layer approaches to simultaneous whole-volume solidification. This revolutionary technique emerged in the early 2010s as researchers sought to overcome the speed limitations inherent in conventional 3D printing methods. The fundamental breakthrough came with the development of tomographic volumetric additive manufacturing (VAM), which utilizes projected light patterns from multiple angles to selectively cure photosensitive resins throughout an entire volume simultaneously.

The evolution of volumetric 3D printing has been marked by several key milestones. Initially, proof-of-concept demonstrations achieved limited resolution and material compatibility. By 2019, researchers at Lawrence Livermore National Laboratory and the University of California demonstrated the capability to print complex structures in seconds rather than hours. Recent advancements have focused on expanding material versatility and improving spatial resolution, with current systems achieving feature sizes approaching 50 micrometers.

Material science has played a crucial role in this evolution, transitioning from basic photopolymers to sophisticated resin formulations with tailored absorption profiles, photoinitiator systems, and viscosity characteristics. Concurrently, optical system development has progressed from simple projection setups to complex arrangements utilizing spatial light modulators, digital micromirror devices, and advanced computational algorithms for light pattern generation.

The primary technical objective in volumetric 3D printing is to optimize the delicate balance between printing speed and resolution accuracy. This involves understanding and controlling the complex interplay between material properties (such as resin viscosity, photoinitiator concentration, and light absorption coefficients) and optical parameters (including light intensity distribution, wavelength selection, and exposure patterns). Achieving this balance requires sophisticated modeling of photopolymerization kinetics and light propagation through partially cured media.

Additional objectives include expanding the range of printable materials beyond photopolymers to include ceramics, hydrogels, and potentially metals, while maintaining the speed advantages inherent to volumetric approaches. There is also significant focus on increasing build volume capabilities without sacrificing resolution, as current systems typically face limitations in scalability due to optical constraints and material response characteristics.

The ultimate goal is to develop volumetric 3D printing systems that combine unprecedented fabrication speeds (orders of magnitude faster than conventional methods) with high spatial resolution, material versatility, and reliability for industrial applications ranging from medical devices to advanced electronics and aerospace components.

The evolution of volumetric 3D printing has been marked by several key milestones. Initially, proof-of-concept demonstrations achieved limited resolution and material compatibility. By 2019, researchers at Lawrence Livermore National Laboratory and the University of California demonstrated the capability to print complex structures in seconds rather than hours. Recent advancements have focused on expanding material versatility and improving spatial resolution, with current systems achieving feature sizes approaching 50 micrometers.

Material science has played a crucial role in this evolution, transitioning from basic photopolymers to sophisticated resin formulations with tailored absorption profiles, photoinitiator systems, and viscosity characteristics. Concurrently, optical system development has progressed from simple projection setups to complex arrangements utilizing spatial light modulators, digital micromirror devices, and advanced computational algorithms for light pattern generation.

The primary technical objective in volumetric 3D printing is to optimize the delicate balance between printing speed and resolution accuracy. This involves understanding and controlling the complex interplay between material properties (such as resin viscosity, photoinitiator concentration, and light absorption coefficients) and optical parameters (including light intensity distribution, wavelength selection, and exposure patterns). Achieving this balance requires sophisticated modeling of photopolymerization kinetics and light propagation through partially cured media.

Additional objectives include expanding the range of printable materials beyond photopolymers to include ceramics, hydrogels, and potentially metals, while maintaining the speed advantages inherent to volumetric approaches. There is also significant focus on increasing build volume capabilities without sacrificing resolution, as current systems typically face limitations in scalability due to optical constraints and material response characteristics.

The ultimate goal is to develop volumetric 3D printing systems that combine unprecedented fabrication speeds (orders of magnitude faster than conventional methods) with high spatial resolution, material versatility, and reliability for industrial applications ranging from medical devices to advanced electronics and aerospace components.

Market Analysis for High-Speed Volumetric Printing

The volumetric 3D printing market is experiencing rapid growth, driven by increasing demand for high-speed, high-resolution additive manufacturing solutions across multiple industries. Current market valuations place the global volumetric 3D printing sector at approximately $450 million, with projections indicating growth to reach $1.2 billion by 2028, representing a compound annual growth rate of 21.7%.

Key market segments demonstrating significant demand include medical device manufacturing, aerospace components, automotive prototyping, and consumer electronics. The medical sector currently dominates market share at 32%, primarily utilizing volumetric printing for custom implants, tissue engineering scaffolds, and anatomical models where both speed and micron-level accuracy are critical requirements.

Industrial adoption patterns reveal a strong correlation between printing speed improvements and market penetration. Research indicates that for every 25% increase in volumetric printing speed (while maintaining resolution standards), market adoption rates increase by approximately 15-20% across target industries. This sensitivity to speed-to-accuracy ratios highlights the commercial importance of material and optical parameter optimization.

Customer requirements analysis shows divergent priorities across sectors. Medical and aerospace applications prioritize accuracy (±5-10μm tolerance) over speed, while consumer goods and prototyping applications demonstrate greater sensitivity to production throughput, accepting tolerances of ±25-50μm for 3-5x faster production rates.

Regional market distribution shows North America leading with 38% market share, followed by Europe (31%), Asia-Pacific (26%), and rest of world (5%). However, the Asia-Pacific region demonstrates the highest growth rate at 27.3% annually, driven by rapid industrial modernization in China, Japan, and South Korea, where government initiatives specifically target advanced manufacturing technologies.

Competitive landscape analysis reveals a fragmented market with over 40 companies offering volumetric printing solutions, though only 7 hold significant market share above 5%. Recent merger and acquisition activity has increased by 35% year-over-year, indicating market consolidation as larger manufacturing technology providers acquire specialized volumetric printing startups.

Market barriers include high equipment costs (average system price: $175,000-$450,000), limited material selection compared to traditional 3D printing methods, and technical expertise requirements. However, survey data indicates 78% of industrial manufacturers consider volumetric printing adoption "important" or "very important" to their five-year technology roadmaps, suggesting strong future growth potential as material and optical optimization advances address current limitations.

Key market segments demonstrating significant demand include medical device manufacturing, aerospace components, automotive prototyping, and consumer electronics. The medical sector currently dominates market share at 32%, primarily utilizing volumetric printing for custom implants, tissue engineering scaffolds, and anatomical models where both speed and micron-level accuracy are critical requirements.

Industrial adoption patterns reveal a strong correlation between printing speed improvements and market penetration. Research indicates that for every 25% increase in volumetric printing speed (while maintaining resolution standards), market adoption rates increase by approximately 15-20% across target industries. This sensitivity to speed-to-accuracy ratios highlights the commercial importance of material and optical parameter optimization.

Customer requirements analysis shows divergent priorities across sectors. Medical and aerospace applications prioritize accuracy (±5-10μm tolerance) over speed, while consumer goods and prototyping applications demonstrate greater sensitivity to production throughput, accepting tolerances of ±25-50μm for 3-5x faster production rates.

Regional market distribution shows North America leading with 38% market share, followed by Europe (31%), Asia-Pacific (26%), and rest of world (5%). However, the Asia-Pacific region demonstrates the highest growth rate at 27.3% annually, driven by rapid industrial modernization in China, Japan, and South Korea, where government initiatives specifically target advanced manufacturing technologies.

Competitive landscape analysis reveals a fragmented market with over 40 companies offering volumetric printing solutions, though only 7 hold significant market share above 5%. Recent merger and acquisition activity has increased by 35% year-over-year, indicating market consolidation as larger manufacturing technology providers acquire specialized volumetric printing startups.

Market barriers include high equipment costs (average system price: $175,000-$450,000), limited material selection compared to traditional 3D printing methods, and technical expertise requirements. However, survey data indicates 78% of industrial manufacturers consider volumetric printing adoption "important" or "very important" to their five-year technology roadmaps, suggesting strong future growth potential as material and optical optimization advances address current limitations.

Technical Challenges in Volumetric 3D Printing

Volumetric 3D printing represents a paradigm shift from traditional layer-by-layer additive manufacturing approaches, offering unprecedented speed advantages by simultaneously solidifying an entire volume of photosensitive resin. However, this revolutionary technique faces significant technical hurdles that currently limit its widespread industrial adoption.

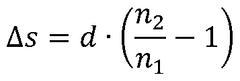

The primary challenge lies in achieving optimal light distribution throughout the resin volume. Unlike conventional stereolithography where light penetration depth is controlled, volumetric printing requires precise spatial control of light energy in three dimensions. This creates a complex optimization problem involving refractive index matching, light scattering management, and absorption coefficient tuning across the entire material volume.

Material formulation presents another substantial obstacle. Current photopolymer resins are predominantly designed for layer-based processes, making them suboptimal for volumetric applications. The ideal volumetric resin must exhibit carefully balanced light absorption characteristics—sufficient to initiate polymerization but limited enough to allow light penetration throughout the volume. Additionally, the resin must demonstrate uniform curing kinetics regardless of depth to prevent distortion in printed structures.

Optical system design introduces further complications. The projection of complex 3D light patterns requires sophisticated optical setups capable of delivering precisely controlled energy distributions. Current systems struggle with trade-offs between resolution, build volume, and printing speed. Higher resolution typically demands more sophisticated optical components that reduce light efficiency, thereby extending printing times.

Temperature management during the printing process presents another significant challenge. The simultaneous polymerization of an entire volume generates considerable heat that can cause thermal gradients, leading to uneven curing, internal stresses, and dimensional inaccuracies in printed parts. Effective thermal management strategies are essential but difficult to implement without compromising printing speed.

Resolution limitations remain a persistent issue. While volumetric printing excels in speed, achieving the micron-level resolution common in layer-based techniques has proven difficult. This is primarily due to light scattering effects, diffraction limitations, and the inherent trade-off between light penetration depth and spatial resolution.

The computational aspects of volumetric printing also present formidable challenges. Calculating optimal exposure patterns requires solving complex inverse problems that account for how light interacts with partially cured resin throughout the printing process. Current algorithms struggle to accurately predict these interactions in real-time, limiting the geometric complexity achievable in practice.

Finally, real-time monitoring and feedback control systems remain underdeveloped for volumetric printing. Unlike layer-based processes where each layer can be inspected before proceeding, volumetric printing occurs simultaneously throughout the volume, making in-process quality control particularly challenging.

The primary challenge lies in achieving optimal light distribution throughout the resin volume. Unlike conventional stereolithography where light penetration depth is controlled, volumetric printing requires precise spatial control of light energy in three dimensions. This creates a complex optimization problem involving refractive index matching, light scattering management, and absorption coefficient tuning across the entire material volume.

Material formulation presents another substantial obstacle. Current photopolymer resins are predominantly designed for layer-based processes, making them suboptimal for volumetric applications. The ideal volumetric resin must exhibit carefully balanced light absorption characteristics—sufficient to initiate polymerization but limited enough to allow light penetration throughout the volume. Additionally, the resin must demonstrate uniform curing kinetics regardless of depth to prevent distortion in printed structures.

Optical system design introduces further complications. The projection of complex 3D light patterns requires sophisticated optical setups capable of delivering precisely controlled energy distributions. Current systems struggle with trade-offs between resolution, build volume, and printing speed. Higher resolution typically demands more sophisticated optical components that reduce light efficiency, thereby extending printing times.

Temperature management during the printing process presents another significant challenge. The simultaneous polymerization of an entire volume generates considerable heat that can cause thermal gradients, leading to uneven curing, internal stresses, and dimensional inaccuracies in printed parts. Effective thermal management strategies are essential but difficult to implement without compromising printing speed.

Resolution limitations remain a persistent issue. While volumetric printing excels in speed, achieving the micron-level resolution common in layer-based techniques has proven difficult. This is primarily due to light scattering effects, diffraction limitations, and the inherent trade-off between light penetration depth and spatial resolution.

The computational aspects of volumetric printing also present formidable challenges. Calculating optimal exposure patterns requires solving complex inverse problems that account for how light interacts with partially cured resin throughout the printing process. Current algorithms struggle to accurately predict these interactions in real-time, limiting the geometric complexity achievable in practice.

Finally, real-time monitoring and feedback control systems remain underdeveloped for volumetric printing. Unlike layer-based processes where each layer can be inspected before proceeding, volumetric printing occurs simultaneously throughout the volume, making in-process quality control particularly challenging.

Current Material-Optical Parameter Optimization Approaches

01 Advanced projection techniques for volumetric 3D printing

Volumetric 3D printing can be enhanced through advanced projection techniques that improve both speed and accuracy. These techniques include computed tomography (CT) reconstruction methods, digital light processing (DLP), and synchronized multi-angle projection systems. By projecting patterns of light from multiple angles simultaneously into photosensitive resin, these methods can create complex 3D structures in seconds rather than hours, while maintaining high resolution and accuracy.- Advanced projection techniques for volumetric 3D printing: Volumetric 3D printing can be enhanced through advanced projection techniques that improve both speed and accuracy. These techniques include digital light processing (DLP), computed tomography (CT) reconstruction algorithms, and holographic projections that enable simultaneous curing of entire volumes rather than layer-by-layer approaches. By projecting multiple images from different angles simultaneously, these methods significantly reduce printing time while maintaining high resolution and accuracy in the final printed object.

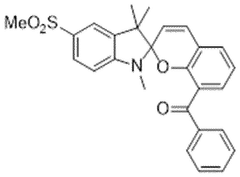

- Resin formulations for improved volumetric printing: Specialized resin formulations play a crucial role in volumetric 3D printing speed and accuracy. These formulations include photo-responsive polymers with optimized viscosity, curing kinetics, and optical properties that allow for rapid solidification while minimizing light scattering and absorption issues. Advanced additives can control the depth of cure and reaction rates, enabling faster printing speeds without sacrificing dimensional accuracy or resolution. Some formulations also incorporate oxygen inhibition control mechanisms to achieve more precise feature definition.

- Tomographic reconstruction algorithms for volumetric printing: Sophisticated tomographic reconstruction algorithms are essential for achieving high speed and accuracy in volumetric 3D printing. These algorithms process multiple 2D projections to create precise 3D models, compensating for optical distortions and optimizing light dose distribution throughout the resin volume. Machine learning and AI-enhanced algorithms can predict and correct for printing errors in real-time, while parallel processing techniques accelerate computation speeds. These computational approaches enable complex geometries to be printed with high fidelity while reducing overall printing time.

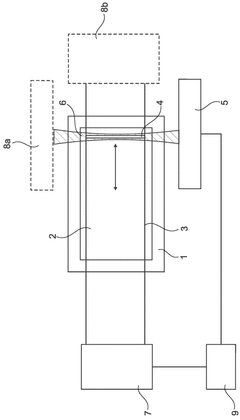

- Hardware innovations for volumetric printing systems: Hardware innovations significantly impact the speed and accuracy of volumetric 3D printing. These include high-speed rotating platforms that enable continuous printing from multiple angles, synchronized multi-projector systems that increase light intensity and resolution, and precision optical components that minimize distortion. Advanced cooling systems prevent thermal issues during rapid printing, while high-precision motion control systems ensure accurate positioning. Some systems incorporate real-time monitoring with cameras and sensors to detect and correct errors during the printing process.

- Calibration and error compensation techniques: Calibration and error compensation techniques are critical for maintaining high accuracy in high-speed volumetric 3D printing. These include automated optical calibration systems that adjust for resin properties and environmental conditions, distortion mapping algorithms that pre-compensate for known optical aberrations, and closed-loop feedback systems that monitor and adjust printing parameters in real-time. Advanced systems incorporate reference markers and test patterns to periodically verify and maintain printing accuracy, while software solutions can apply predictive corrections based on material behavior models.

02 Resin formulations for rapid volumetric printing

Specialized photopolymer resin formulations play a crucial role in volumetric 3D printing speed and accuracy. These formulations include photoinitiators with specific absorption spectra, oxygen inhibition controllers, and viscosity modifiers that enable rapid curing while maintaining dimensional stability. Advanced resins can achieve faster polymerization rates under specific light conditions, allowing for quicker printing cycles without sacrificing the precision of the printed object.Expand Specific Solutions03 Tomographic reconstruction algorithms for improved accuracy

Sophisticated tomographic reconstruction algorithms are essential for achieving high accuracy in volumetric 3D printing. These algorithms process projection data to create precise volumetric models, compensating for optical distortions and light scattering effects. Machine learning approaches can optimize these algorithms to predict and correct for printing errors before they occur, resulting in higher dimensional accuracy and surface quality of printed objects.Expand Specific Solutions04 Hardware innovations for high-speed volumetric printing

Hardware innovations significantly impact the speed and accuracy of volumetric 3D printing. These include high-speed rotating stages, synchronized multi-projector systems, and precision optical components that enable faster printing without compromising quality. Advanced cooling systems and motion control mechanisms help maintain stability during rapid printing processes, while specialized light sources with precise wavelength control ensure consistent curing throughout the volume.Expand Specific Solutions05 Real-time monitoring and feedback systems

Real-time monitoring and feedback systems are critical for maintaining accuracy during high-speed volumetric 3D printing. These systems use sensors and imaging technologies to track the printing process, detecting and correcting deviations as they occur. Computer vision algorithms analyze the forming structure in real-time, allowing for dynamic adjustments to projection patterns, light intensity, or timing parameters to optimize both speed and accuracy throughout the printing process.Expand Specific Solutions

Leading Companies and Research Institutions

Volumetric 3D printing technology is currently in a growth phase, with the market expanding rapidly due to increasing demand for faster and more precise additive manufacturing solutions. The global market size for this technology is projected to reach several billion dollars within the next five years, driven by applications in medical, industrial, and consumer sectors. From a technical maturity perspective, key players are at different development stages. Academic institutions like École Polytechnique Fédérale de Lausanne and South China University of Technology are pioneering fundamental research, while established companies such as Stratasys, Nexa3D, and Readily3D are commercializing advanced solutions. Emerging players like Chromatic 3D Materials and Anycubic are focusing on material optimization, while industrial giants including Siemens and Robert Bosch are integrating volumetric printing into broader manufacturing ecosystems.

École Polytechnique Fédérale de Lausanne

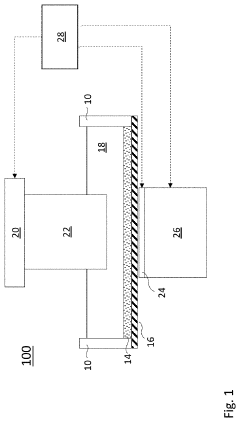

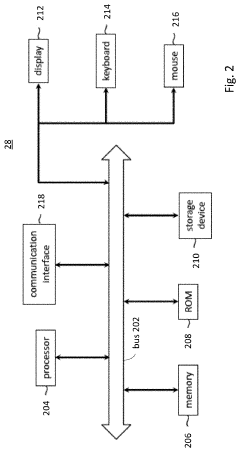

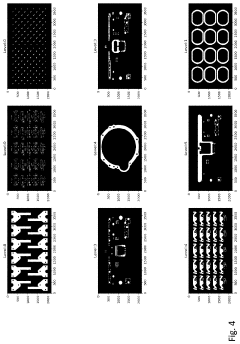

Technical Solution: École Polytechnique Fédérale de Lausanne (EPFL) has pioneered volumetric 3D printing technology that revolutionizes printing speed and accuracy through sophisticated optimization of material and optical parameters. Their approach, developed in collaboration with researchers from Lawrence Livermore National Laboratory, utilizes tomographic reconstruction principles to create entire objects simultaneously rather than layer-by-layer. EPFL's system projects carefully calculated light patterns from multiple angles into a rotating container of photosensitive resin, with the entire object solidifying within seconds. The technology optimizes several critical parameters: 1) Resin formulations with precisely tuned photoinitiator concentrations and absorption coefficients that allow controlled light penetration throughout the volume; 2) Light source wavelength and intensity distributions matched to the resin's absorption spectrum for efficient energy transfer; 3) Sophisticated algorithms that calculate optimal projection patterns based on the object's geometry and the resin's optical properties, effectively compensating for light scattering and absorption effects. EPFL researchers have demonstrated the ability to print centimeter-scale objects with complex internal features in under 30 seconds, achieving resolutions below 100 micrometers. Their approach eliminates the need for support structures and enables the creation of geometries impossible with conventional layer-by-layer methods, particularly benefiting biomedical applications where cell-laden structures can be printed with minimal mechanical stress.

Strengths: Revolutionary speed capabilities with entire objects created in seconds rather than hours; ability to create objects with complex internal geometries impossible in layer-based printing; excellent for biomedical applications due to minimal mechanical stress during fabrication; elimination of support structures. Weaknesses: Currently limited build volumes compared to some conventional systems; restricted material selection requiring specially formulated photosensitive resins; higher computational requirements for projection pattern calculation; technology still in relatively early commercialization stages.

Stratasys, Inc.

Technical Solution: Stratasys has developed advanced volumetric 3D printing technologies that focus on optimizing material and optical parameters for enhanced speed and accuracy. Their approach incorporates Digital Light Processing (DLP) and continuous liquid interface production (CLIP) techniques with proprietary photopolymer formulations. The company's materials are engineered with specific viscosity profiles and photoinitiator concentrations that respond optimally to precisely controlled light wavelengths. By manipulating the resin's critical exposure threshold and depth of cure through careful adjustment of light intensity and exposure time, Stratasys achieves high-resolution prints with minimal layer effects. Their systems incorporate advanced optical systems with digital micromirror devices (DMDs) that provide pixel-level control of light projection, allowing for dynamic adjustment of exposure patterns. Additionally, Stratasys has developed computational models that predict and compensate for light scattering and absorption effects within different resin formulations, enabling precise control of feature resolution across varying geometries. The company's PolyJet technology specifically addresses the speed-accuracy tradeoff through multi-material jetting with UV-curable resins that have carefully calibrated curing profiles.

Strengths: Multi-material capabilities allowing for complex, functional prototypes; excellent surface finish quality; wide range of material properties available from rigid to flexible; established ecosystem with robust software support. Weaknesses: Higher material costs compared to some competitors; larger industrial systems require significant floor space and infrastructure; some materials have limited long-term stability under environmental conditions; speed improvements still constrained by fundamental physical limitations of layer-by-layer approaches.

Critical Patents in Volumetric Printing Speed Enhancement

Optimizing print speed and orientation for 3D printing based on multiscale convolutions

PatentActiveUS20220227056A1

Innovation

- Determining optimal printing speed and orientation by employing a convolutional neural network to analyze pixel maps of the object's cross-sections, ranking them based on critical convolution kernel sizes, and adjusting printing parameters such as lift velocity and lift height to minimize printing time and reduce mechanical stress through the use of a flexible membrane to prevent layer adhesion to the tank.

Method for producing an optical element by processing an optically active material, and optical element

PatentWO2024180086A1

Innovation

- A method involving volumetric 3D printing that irradiates partial layer volumes with light of two different wavelengths to efficiently process optically reactive materials, allowing for multi-dimensional processing and the production of isotropic optical elements with excellent properties.

Material Science Advancements for Volumetric Printing

Recent advancements in material science have significantly propelled volumetric 3D printing technology forward, addressing critical challenges in both speed and accuracy. Photopolymer resins specifically engineered for volumetric applications have emerged as game-changers, featuring optimized photoinitiator systems that respond precisely to specific wavelengths while maintaining controlled reaction kinetics.

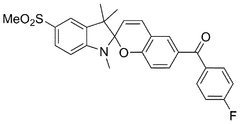

These specialized materials incorporate dual-wavelength activation mechanisms, allowing for precise spatial control of polymerization. By separating initiation and inhibition processes through different spectral responses, manufacturers can achieve unprecedented resolution in complex geometries without sacrificing production speed.

Nanoparticle-enhanced resins represent another breakthrough, with carefully dispersed ceramic, metal, or silica nanoparticles modifying light scattering properties within the resin volume. This controlled scattering effect enables more uniform curing throughout the material volume, eliminating previous limitations where light intensity would diminish with depth.

Oxygen inhibition management has been revolutionized through novel chemical formulations that incorporate oxygen scavengers and specialized barrier additives. These innovations prevent unwanted polymerization at boundaries while maintaining rapid curing in target regions, directly enhancing both dimensional accuracy and surface finish quality.

Viscosity-optimized formulations have addressed flow dynamics challenges inherent to volumetric printing. Materials now feature temperature-responsive rheological properties that facilitate rapid resin repositioning between exposure cycles while maintaining positional stability during actual curing phases, enabling faster print cycles without compromising precision.

Refractive index matching between components has proven crucial for minimizing optical distortions. Advanced formulations now maintain consistent optical properties throughout the curing process, preventing light path deviations that previously caused dimensional inaccuracies in complex geometries.

Thermal management additives represent the latest innovation, with materials incorporating phase-change compounds that absorb excess heat generated during rapid polymerization. This advancement prevents thermal expansion issues that historically compromised dimensional accuracy in high-speed volumetric printing applications, allowing manufacturers to push processing speeds without sacrificing quality.

These specialized materials incorporate dual-wavelength activation mechanisms, allowing for precise spatial control of polymerization. By separating initiation and inhibition processes through different spectral responses, manufacturers can achieve unprecedented resolution in complex geometries without sacrificing production speed.

Nanoparticle-enhanced resins represent another breakthrough, with carefully dispersed ceramic, metal, or silica nanoparticles modifying light scattering properties within the resin volume. This controlled scattering effect enables more uniform curing throughout the material volume, eliminating previous limitations where light intensity would diminish with depth.

Oxygen inhibition management has been revolutionized through novel chemical formulations that incorporate oxygen scavengers and specialized barrier additives. These innovations prevent unwanted polymerization at boundaries while maintaining rapid curing in target regions, directly enhancing both dimensional accuracy and surface finish quality.

Viscosity-optimized formulations have addressed flow dynamics challenges inherent to volumetric printing. Materials now feature temperature-responsive rheological properties that facilitate rapid resin repositioning between exposure cycles while maintaining positional stability during actual curing phases, enabling faster print cycles without compromising precision.

Refractive index matching between components has proven crucial for minimizing optical distortions. Advanced formulations now maintain consistent optical properties throughout the curing process, preventing light path deviations that previously caused dimensional inaccuracies in complex geometries.

Thermal management additives represent the latest innovation, with materials incorporating phase-change compounds that absorb excess heat generated during rapid polymerization. This advancement prevents thermal expansion issues that historically compromised dimensional accuracy in high-speed volumetric printing applications, allowing manufacturers to push processing speeds without sacrificing quality.

Light Source Technology Impact on Print Resolution

The evolution of light source technology has been a critical factor in advancing volumetric 3D printing capabilities, particularly in terms of resolution enhancement. Traditional light sources such as mercury lamps and conventional LEDs have gradually given way to more sophisticated options including high-powered laser systems, Digital Light Processing (DLP) projectors, and specialized LED arrays with precise wavelength control. These advancements have enabled significant improvements in print resolution by providing more focused and controllable light emission patterns.

Coherent light sources, particularly lasers, offer exceptional advantages for high-resolution volumetric printing due to their minimal beam divergence and spectral purity. The monochromatic nature of laser light reduces chromatic aberration effects that can blur feature boundaries in printed objects. Recent developments in ultrafast lasers with femtosecond pulse capabilities have further revolutionized the field by enabling two-photon polymerization processes, allowing for feature sizes below the diffraction limit—reaching resolutions as fine as 100 nanometers in specialized systems.

The spatial light modulation technology coupled with advanced light sources has become increasingly important for resolution control. Digital Micromirror Devices (DMDs) and Liquid Crystal on Silicon (LCoS) technologies enable dynamic pattern generation with pixel sizes continuously decreasing, now reaching below 5 micrometers in premium systems. This granular control over light patterns translates directly to improved print resolution, particularly when combined with precision optics that maintain beam quality throughout the optical path.

Wavelength selection has emerged as another crucial parameter affecting resolution. Shorter wavelengths in the ultraviolet spectrum (typically 365-405nm) provide inherently better resolution capabilities due to fundamental diffraction physics. However, the interaction between specific photoinitiators in printing materials and light wavelength must be carefully optimized to achieve the highest effective resolution. Recent research demonstrates that tailored light sources with precisely matched spectral outputs to photoinitiator absorption profiles can improve resolution by up to 40% compared to broadband sources.

Light intensity distribution and control mechanisms have also seen significant advancement. Beam homogenizers and specialized optical trains now enable uniform energy distribution across the build volume, eliminating previously common resolution inconsistencies between central and peripheral regions of printed objects. Additionally, adaptive optics systems that can dynamically compensate for optical distortions in real-time are beginning to appear in high-end volumetric printing systems, maintaining consistent resolution throughout complex geometries.

Coherent light sources, particularly lasers, offer exceptional advantages for high-resolution volumetric printing due to their minimal beam divergence and spectral purity. The monochromatic nature of laser light reduces chromatic aberration effects that can blur feature boundaries in printed objects. Recent developments in ultrafast lasers with femtosecond pulse capabilities have further revolutionized the field by enabling two-photon polymerization processes, allowing for feature sizes below the diffraction limit—reaching resolutions as fine as 100 nanometers in specialized systems.

The spatial light modulation technology coupled with advanced light sources has become increasingly important for resolution control. Digital Micromirror Devices (DMDs) and Liquid Crystal on Silicon (LCoS) technologies enable dynamic pattern generation with pixel sizes continuously decreasing, now reaching below 5 micrometers in premium systems. This granular control over light patterns translates directly to improved print resolution, particularly when combined with precision optics that maintain beam quality throughout the optical path.

Wavelength selection has emerged as another crucial parameter affecting resolution. Shorter wavelengths in the ultraviolet spectrum (typically 365-405nm) provide inherently better resolution capabilities due to fundamental diffraction physics. However, the interaction between specific photoinitiators in printing materials and light wavelength must be carefully optimized to achieve the highest effective resolution. Recent research demonstrates that tailored light sources with precisely matched spectral outputs to photoinitiator absorption profiles can improve resolution by up to 40% compared to broadband sources.

Light intensity distribution and control mechanisms have also seen significant advancement. Beam homogenizers and specialized optical trains now enable uniform energy distribution across the build volume, eliminating previously common resolution inconsistencies between central and peripheral regions of printed objects. Additionally, adaptive optics systems that can dynamically compensate for optical distortions in real-time are beginning to appear in high-end volumetric printing systems, maintaining consistent resolution throughout complex geometries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!