Research on Volumetric 3D printing for electronics, aerospace, and biomedical applications

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric 3D Printing Background and Objectives

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, evolving from traditional layer-by-layer approaches to a revolutionary volumetric fabrication method. This technique emerged in the mid-2010s as researchers sought to overcome the speed and resolution limitations of conventional 3D printing. Unlike traditional methods that build objects sequentially, volumetric 3D printing creates entire structures simultaneously within a volume of photosensitive resin, dramatically reducing production time from hours to minutes or even seconds.

The technology's development trajectory has been marked by significant breakthroughs in photochemistry, optics, and computational modeling. Early iterations utilized computed tomography principles in reverse, projecting patterned light into photopolymer resins. Recent advancements have incorporated holographic techniques, multi-beam interference patterns, and sophisticated tomographic reconstruction algorithms, enabling increasingly complex geometries and improved resolution.

Current research focuses on expanding material compatibility beyond basic photopolymers to include functional materials with specific electronic, mechanical, or biological properties. This expansion is crucial for the technology's application across electronics, aerospace, and biomedical fields. The integration of conductive materials, high-performance composites, and biocompatible substances represents the frontier of volumetric printing development.

The primary technical objective of volumetric 3D printing research is to achieve unprecedented fabrication speed while maintaining or exceeding the resolution capabilities of conventional methods. Specifically, researchers aim to develop systems capable of producing complex three-dimensional structures with feature sizes below 10 micrometers at speeds 100-1000 times faster than traditional layer-by-layer approaches.

Secondary objectives include expanding the material palette to incorporate multi-material printing capabilities, developing in-situ monitoring and quality control mechanisms, and establishing standardized processes for consistent results across different volumetric printing platforms. These advancements would enable the creation of fully functional electronic components, lightweight aerospace structures, and patient-specific biomedical implants in a single fabrication step.

The long-term vision for volumetric 3D printing technology encompasses the development of hybrid systems that combine volumetric approaches with traditional methods to leverage the strengths of each. Researchers are also exploring the integration of volumetric printing with other emerging technologies such as 4D printing (incorporating time-dependent transformation) and embedded sensing capabilities for smart structures.

As the technology continues to mature, the ultimate goal is to transition volumetric 3D printing from laboratory demonstrations to industrial implementation, requiring advances in scalability, reliability, and cost-effectiveness. This evolution will potentially revolutionize manufacturing paradigms across multiple industries, enabling on-demand production of complex, functional components with unprecedented efficiency.

The technology's development trajectory has been marked by significant breakthroughs in photochemistry, optics, and computational modeling. Early iterations utilized computed tomography principles in reverse, projecting patterned light into photopolymer resins. Recent advancements have incorporated holographic techniques, multi-beam interference patterns, and sophisticated tomographic reconstruction algorithms, enabling increasingly complex geometries and improved resolution.

Current research focuses on expanding material compatibility beyond basic photopolymers to include functional materials with specific electronic, mechanical, or biological properties. This expansion is crucial for the technology's application across electronics, aerospace, and biomedical fields. The integration of conductive materials, high-performance composites, and biocompatible substances represents the frontier of volumetric printing development.

The primary technical objective of volumetric 3D printing research is to achieve unprecedented fabrication speed while maintaining or exceeding the resolution capabilities of conventional methods. Specifically, researchers aim to develop systems capable of producing complex three-dimensional structures with feature sizes below 10 micrometers at speeds 100-1000 times faster than traditional layer-by-layer approaches.

Secondary objectives include expanding the material palette to incorporate multi-material printing capabilities, developing in-situ monitoring and quality control mechanisms, and establishing standardized processes for consistent results across different volumetric printing platforms. These advancements would enable the creation of fully functional electronic components, lightweight aerospace structures, and patient-specific biomedical implants in a single fabrication step.

The long-term vision for volumetric 3D printing technology encompasses the development of hybrid systems that combine volumetric approaches with traditional methods to leverage the strengths of each. Researchers are also exploring the integration of volumetric printing with other emerging technologies such as 4D printing (incorporating time-dependent transformation) and embedded sensing capabilities for smart structures.

As the technology continues to mature, the ultimate goal is to transition volumetric 3D printing from laboratory demonstrations to industrial implementation, requiring advances in scalability, reliability, and cost-effectiveness. This evolution will potentially revolutionize manufacturing paradigms across multiple industries, enabling on-demand production of complex, functional components with unprecedented efficiency.

Market Analysis for Advanced Manufacturing Applications

The volumetric 3D printing market for advanced manufacturing applications is experiencing robust growth, driven by increasing demand across electronics, aerospace, and biomedical sectors. Current market valuations indicate the global 3D printing market reached approximately $13.7 billion in 2021, with volumetric printing technologies representing an emerging high-growth segment expected to expand at a CAGR of 23% through 2028.

In the electronics sector, volumetric 3D printing is revolutionizing manufacturing by enabling the creation of complex embedded circuits, miniaturized components, and customized electronic devices. This market segment is particularly attractive due to the growing demand for smaller, lighter, and more efficient electronic products, especially in consumer electronics and telecommunications industries.

The aerospace industry represents another significant market opportunity, with major players like Boeing, Airbus, and SpaceX increasingly adopting volumetric 3D printing for lightweight structural components, complex cooling systems, and specialized parts that would be difficult or impossible to manufacture using traditional methods. The aerospace segment is projected to grow at 27% annually, driven by the need for weight reduction, fuel efficiency, and supply chain optimization.

Biomedical applications constitute the fastest-growing segment for volumetric 3D printing, with particular emphasis on tissue engineering, personalized implants, and drug delivery systems. The ability to create complex biological structures with precise control over material properties positions volumetric printing as a transformative technology in healthcare manufacturing. Market analysts predict this segment will reach $4.2 billion by 2027, representing a significant portion of the overall volumetric printing market.

Regional analysis reveals North America currently leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to increasing industrial adoption in China, Japan, and South Korea, coupled with substantial government investments in advanced manufacturing technologies.

Key market drivers include increasing demand for customized products, reduced manufacturing lead times, material efficiency improvements, and the ability to create previously impossible geometries. However, market challenges persist, including high initial equipment costs, limited material selection, technical expertise requirements, and regulatory uncertainties particularly in biomedical applications.

The competitive landscape features established 3D printing companies expanding into volumetric technologies alongside innovative startups developing specialized solutions. Strategic partnerships between technology providers, material suppliers, and end-users are becoming increasingly common as the ecosystem matures and applications diversify across industrial sectors.

In the electronics sector, volumetric 3D printing is revolutionizing manufacturing by enabling the creation of complex embedded circuits, miniaturized components, and customized electronic devices. This market segment is particularly attractive due to the growing demand for smaller, lighter, and more efficient electronic products, especially in consumer electronics and telecommunications industries.

The aerospace industry represents another significant market opportunity, with major players like Boeing, Airbus, and SpaceX increasingly adopting volumetric 3D printing for lightweight structural components, complex cooling systems, and specialized parts that would be difficult or impossible to manufacture using traditional methods. The aerospace segment is projected to grow at 27% annually, driven by the need for weight reduction, fuel efficiency, and supply chain optimization.

Biomedical applications constitute the fastest-growing segment for volumetric 3D printing, with particular emphasis on tissue engineering, personalized implants, and drug delivery systems. The ability to create complex biological structures with precise control over material properties positions volumetric printing as a transformative technology in healthcare manufacturing. Market analysts predict this segment will reach $4.2 billion by 2027, representing a significant portion of the overall volumetric printing market.

Regional analysis reveals North America currently leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to increasing industrial adoption in China, Japan, and South Korea, coupled with substantial government investments in advanced manufacturing technologies.

Key market drivers include increasing demand for customized products, reduced manufacturing lead times, material efficiency improvements, and the ability to create previously impossible geometries. However, market challenges persist, including high initial equipment costs, limited material selection, technical expertise requirements, and regulatory uncertainties particularly in biomedical applications.

The competitive landscape features established 3D printing companies expanding into volumetric technologies alongside innovative startups developing specialized solutions. Strategic partnerships between technology providers, material suppliers, and end-users are becoming increasingly common as the ecosystem matures and applications diversify across industrial sectors.

Technical Challenges in Volumetric 3D Printing

Volumetric 3D printing faces significant technical challenges despite its revolutionary potential across electronics, aerospace, and biomedical applications. The fundamental limitation lies in achieving precise spatial control of photopolymerization within the resin volume. Current systems struggle to maintain uniform light intensity throughout the printing volume, resulting in inconsistent curing and dimensional inaccuracies, particularly in larger objects or complex geometries with internal features.

Material compatibility presents another major obstacle. The specialized photosensitive resins required for volumetric printing must simultaneously satisfy contradictory properties: high optical transparency to allow light penetration while maintaining sufficient photoreactivity for rapid solidification. Additionally, these materials must possess the mechanical, electrical, or biological properties demanded by specific applications, creating a complex multi-parameter optimization problem that remains largely unsolved.

Resolution constraints significantly impact application potential. While conventional layer-by-layer printing can achieve sub-micron resolution, volumetric techniques typically offer resolution in the tens of micrometers range. This limitation particularly affects electronics applications where circuit miniaturization is essential, and biomedical applications requiring precise cellular-scale features for tissue engineering.

Heat management during the printing process presents critical challenges. The simultaneous curing of entire volumes generates substantial thermal energy that can cause material degradation, internal stress, and warping. This is especially problematic for aerospace components where dimensional stability and structural integrity are paramount.

Support structures—or rather their absence—create unique difficulties. Unlike layer-by-layer methods where temporary supports can be incorporated, volumetric printing must address the challenge of creating suspended or hollow features without intermediate support. This often necessitates complex computational modeling to predict and compensate for gravitational effects during solidification.

Process monitoring and quality control remain underdeveloped. The enclosed nature of volumetric printing systems makes real-time observation and verification challenging. Current technologies lack robust in-situ monitoring capabilities to detect defects or inconsistencies during the printing process, creating significant barriers to quality assurance and repeatability.

Computational demands represent a substantial bottleneck. Calculating optimal light patterns for complex geometries requires sophisticated algorithms and substantial processing power. The inverse problem of determining projection patterns that will produce the desired 3D structure remains computationally intensive, limiting the complexity of printable objects and extending design-to-production timelines.

Material compatibility presents another major obstacle. The specialized photosensitive resins required for volumetric printing must simultaneously satisfy contradictory properties: high optical transparency to allow light penetration while maintaining sufficient photoreactivity for rapid solidification. Additionally, these materials must possess the mechanical, electrical, or biological properties demanded by specific applications, creating a complex multi-parameter optimization problem that remains largely unsolved.

Resolution constraints significantly impact application potential. While conventional layer-by-layer printing can achieve sub-micron resolution, volumetric techniques typically offer resolution in the tens of micrometers range. This limitation particularly affects electronics applications where circuit miniaturization is essential, and biomedical applications requiring precise cellular-scale features for tissue engineering.

Heat management during the printing process presents critical challenges. The simultaneous curing of entire volumes generates substantial thermal energy that can cause material degradation, internal stress, and warping. This is especially problematic for aerospace components where dimensional stability and structural integrity are paramount.

Support structures—or rather their absence—create unique difficulties. Unlike layer-by-layer methods where temporary supports can be incorporated, volumetric printing must address the challenge of creating suspended or hollow features without intermediate support. This often necessitates complex computational modeling to predict and compensate for gravitational effects during solidification.

Process monitoring and quality control remain underdeveloped. The enclosed nature of volumetric printing systems makes real-time observation and verification challenging. Current technologies lack robust in-situ monitoring capabilities to detect defects or inconsistencies during the printing process, creating significant barriers to quality assurance and repeatability.

Computational demands represent a substantial bottleneck. Calculating optimal light patterns for complex geometries requires sophisticated algorithms and substantial processing power. The inverse problem of determining projection patterns that will produce the desired 3D structure remains computationally intensive, limiting the complexity of printable objects and extending design-to-production timelines.

Current Volumetric 3D Printing Solutions

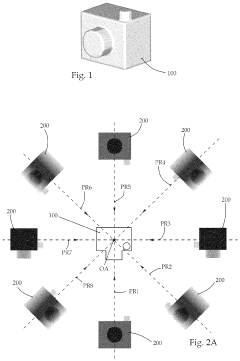

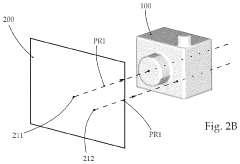

01 Light-based volumetric 3D printing techniques

Volumetric 3D printing using light-based techniques involves the projection of light patterns into photosensitive resins to create three-dimensional objects. These methods include computed axial lithography (CAL) and holographic techniques that allow for the simultaneous solidification of the entire volume rather than layer-by-layer approaches. This results in faster printing times and the ability to create complex internal structures without support materials.- Light-based volumetric 3D printing techniques: Volumetric 3D printing can be achieved using light-based techniques where photosensitive resins are cured by controlled light patterns. These methods include computed axial lithography (CAL) and tomographic volumetric additive manufacturing, which project synchronized patterns of light into a volume of photopolymer resin to create complex 3D structures simultaneously rather than layer by layer. This approach significantly reduces printing time and enables the creation of structures without support materials.

- Holographic and projection-based volumetric printing: Holographic and projection-based methods for volumetric 3D printing utilize digital light processing technology to create three-dimensional objects. These techniques employ spatial light modulators, digital micromirror devices, or holographic displays to project complex patterns into photosensitive materials. By controlling the interference patterns of light beams, these systems can create detailed structures with high resolution throughout an entire volume simultaneously.

- Materials and formulations for volumetric 3D printing: Specialized materials and formulations are essential for successful volumetric 3D printing. These include photopolymer resins with tailored viscosity, curing characteristics, and optical properties. Advanced formulations may incorporate multiple photoinitiators with different activation wavelengths, oxygen inhibition modifiers, and additives to control light scattering and absorption within the volume. These materials enable the creation of complex structures with varying mechanical properties and functional characteristics.

- Volumetric bioprinting applications: Volumetric 3D printing techniques have been adapted for bioprinting applications, allowing the creation of complex biological structures and tissue constructs. These methods enable the embedding of living cells within biocompatible hydrogels that can be rapidly solidified using controlled light exposure. The volumetric approach reduces cell exposure to potentially harmful conditions and allows for the creation of structures with embedded vasculature and varying cell densities, advancing tissue engineering and regenerative medicine applications.

- Multi-material and hybrid volumetric printing systems: Advanced volumetric 3D printing systems incorporate multi-material capabilities and hybrid approaches that combine different printing technologies. These systems may utilize multiple resin reservoirs, selective material activation methods, or integration with conventional layer-by-layer techniques. Such hybrid approaches enable the creation of complex objects with varying material properties, embedded components, and functional gradients throughout the printed structure, expanding the application range of volumetric printing technology.

02 Materials and formulations for volumetric printing

Specialized photopolymer resins and materials have been developed specifically for volumetric 3D printing applications. These materials are designed to respond to specific wavelengths of light and feature controlled curing properties that enable precise volumetric solidification. Additives and modifiers can be incorporated to enhance mechanical properties, optical clarity, or biocompatibility of the printed objects, expanding the range of potential applications.Expand Specific Solutions03 Tomographic volumetric printing systems

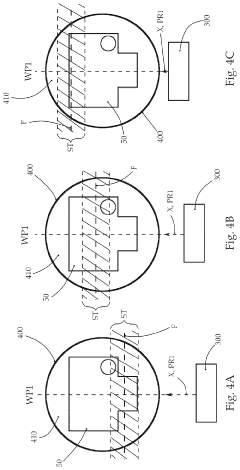

Tomographic approaches to volumetric 3D printing involve rotating a container of photosensitive resin while projecting synchronized light patterns from different angles. This technique, similar to computed tomography in reverse, allows for the creation of complex geometries with high resolution. The synchronization of rotation and projection enables precise control over the solidification process throughout the entire volume simultaneously.Expand Specific Solutions04 Biomedical applications of volumetric 3D printing

Volumetric 3D printing has significant applications in the biomedical field, including the creation of tissue scaffolds, personalized medical devices, and anatomical models. The ability to print complex internal structures with biocompatible materials makes this technology particularly valuable for creating structures that mimic natural tissues. The speed of volumetric printing also allows for the incorporation of living cells in some applications, as the reduced printing time minimizes cell exposure to potentially harmful conditions.Expand Specific Solutions05 Advanced control systems and algorithms

Sophisticated control systems and computational algorithms are essential for volumetric 3D printing. These include image processing techniques to generate appropriate projection patterns, real-time feedback mechanisms to monitor and adjust the printing process, and optimization algorithms to improve print quality and efficiency. Machine learning approaches are also being integrated to predict and compensate for material behavior during the printing process, resulting in higher precision and reproducibility.Expand Specific Solutions

Industry Leaders in Volumetric 3D Printing

Volumetric 3D printing technology is currently in the early growth phase of its industry lifecycle, with applications expanding across electronics, aerospace, and biomedical sectors. The global market is projected to reach significant scale as adoption increases, particularly in high-value applications requiring complex geometries and multi-material capabilities. From a technical maturity perspective, the landscape shows varied development stages with established players like HP Development, Koninklijke Philips, and Hon Hai Precision Industry focusing on industrial applications, while specialized companies such as Regenovo Biotechnology, FabRx, and Quadratic 3D are advancing niche biomedical applications. Academic institutions including Cornell University, École Polytechnique Fédérale de Lausanne, and Guangzhou Medical University are driving fundamental research, creating a dynamic ecosystem where commercial applications are emerging alongside continued technological innovation.

Hangzhou Regenovo Biotechnology Co. Ltd.

Technical Solution: Regenovo has developed proprietary Bio-3D printing technology specifically optimized for volumetric bioprinting applications. Their flagship Regenovo Bio-printer utilizes a multi-nozzle extrusion system with temperature-controlled print heads that can precisely deposit multiple bioinks simultaneously in a true volumetric approach. The company's technology employs a unique hydrogel support matrix system that enables the creation of complex 3D tissue structures with embedded vascular networks - a critical advancement for creating viable tissue constructs. Their proprietary bioinks are formulated with varying viscosities and crosslinking mechanisms to maintain cell viability throughout the printing process while achieving structural integrity. Regenovo's systems incorporate real-time monitoring with optical coherence tomography to verify internal structure formation during the printing process[2]. The company has successfully demonstrated the printing of liver tissue models with functional bile ducts and vascular channels, as well as cartilage constructs with mechanical properties closely matching native tissue. Their technology platform includes specialized software that translates medical imaging data directly into printable volumetric models with tissue-specific material assignments.

Strengths: Specialized expertise in biocompatible materials and cell-laden bioinks; demonstrated success in creating complex tissue structures with vascular networks; integrated quality control systems for verification of internal structures. Weaknesses: Limited scalability for larger tissue constructs; challenges with long-term stability of printed tissues; relatively slower printing speeds compared to non-biological volumetric printing technologies.

HP Development Co. LP

Technical Solution: HP has pioneered Multi Jet Fusion (MJF) technology for volumetric 3D printing, which uses a unique voxel-level approach allowing precise control over physical properties throughout the printed object. Their system deposits multiple materials simultaneously using arrays of thousands of nozzles, enabling functional electronics integration directly into printed structures. HP's technology achieves this through selective application of fusing and detailing agents onto powder beds, followed by uniform energy application that creates parts with exceptional mechanical properties and electrical conductivity pathways. For aerospace applications, HP has developed specialized high-temperature materials capable of withstanding extreme conditions while maintaining dimensional stability. Their process allows embedding of sensors and circuitry within structural components, reducing weight while enhancing functionality[1][3]. Recent advancements include HP's Metal Jet technology, which extends volumetric printing capabilities to metal components with complex internal geometries impossible to manufacture through traditional methods.

Strengths: Superior precision at the voxel level enabling multi-material integration; high production speeds compared to traditional 3D printing; ability to create functional electronics within structural components. Weaknesses: Higher initial equipment investment compared to simpler 3D printing technologies; material options still more limited than traditional manufacturing; complex workflow requiring specialized expertise for optimal results.

Key Patents and Research in Volumetric Fabrication

3D Printing Method

PatentActiveUS20240094703A1

Innovation

- The method involves displacing the focal plane relative to the container when imaging projection images, ensuring at least half of the object's extension is within the depth of field range, and adjusting light intensity proportionally to the virtual object material, allowing for larger object production by extending the depth of field coverage.

Shrinkable hydrogels

PatentWO2022109284A1

Innovation

- A post-printing treatment method involving immersion of 3D-printed hydrogel patterns in a solution of polyions with opposite net charge, causing complex coacervation and water expulsion, which reduces the hydrogel's dimensions without altering its shape, enabling sub-50 micrometer feature sizes and maintaining cytocompatibility.

Material Science Developments for Multi-industry Applications

Material science advancements have become critical enablers for volumetric 3D printing applications across multiple industries. Recent developments in photopolymer chemistry have yielded materials with enhanced mechanical properties, thermal stability, and electrical conductivity specifically designed for electronics manufacturing. These materials incorporate nanoparticles and conductive elements that maintain structural integrity while providing necessary electrical pathways, addressing previous limitations in printed circuit complexity.

For aerospace applications, material scientists have developed high-performance composites that combine lightweight characteristics with exceptional strength-to-weight ratios. Carbon fiber-reinforced polymers and ceramic-metal hybrids have emerged as particularly promising, offering heat resistance up to 300°C while maintaining dimensional stability under extreme conditions. These materials enable the production of complex aerospace components with integrated functionality that traditional manufacturing methods cannot achieve.

In the biomedical sector, biocompatible and biodegradable materials have undergone significant refinement. Hydrogels with tunable mechanical properties now closely mimic natural tissue environments, while maintaining printability in volumetric processes. These materials incorporate growth factors and cellular components that promote tissue integration and reduce rejection risks, representing a major advancement for implantable medical devices and tissue engineering scaffolds.

Cross-industry material developments include stimuli-responsive materials that change properties in response to environmental conditions. These "4D materials" can transform their shape, stiffness, or functionality post-printing, enabling adaptive components for all three target industries. Additionally, multi-material systems that seamlessly transition between rigid and flexible zones within a single print have overcome previous interface compatibility challenges.

Sustainability considerations have driven research into recyclable and environmentally friendly materials for volumetric printing. Bio-based resins derived from renewable resources show comparable performance to petroleum-based alternatives while reducing environmental impact. This addresses growing regulatory pressures and consumer demands for greener manufacturing processes across electronics, aerospace, and medical industries.

Material characterization techniques have evolved alongside these developments, with advanced spectroscopy and mechanical testing methods specifically adapted for volumetric printed structures. These techniques provide crucial data on material behavior under various conditions, enabling more accurate predictive modeling and quality control processes essential for high-reliability applications in all three industries.

For aerospace applications, material scientists have developed high-performance composites that combine lightweight characteristics with exceptional strength-to-weight ratios. Carbon fiber-reinforced polymers and ceramic-metal hybrids have emerged as particularly promising, offering heat resistance up to 300°C while maintaining dimensional stability under extreme conditions. These materials enable the production of complex aerospace components with integrated functionality that traditional manufacturing methods cannot achieve.

In the biomedical sector, biocompatible and biodegradable materials have undergone significant refinement. Hydrogels with tunable mechanical properties now closely mimic natural tissue environments, while maintaining printability in volumetric processes. These materials incorporate growth factors and cellular components that promote tissue integration and reduce rejection risks, representing a major advancement for implantable medical devices and tissue engineering scaffolds.

Cross-industry material developments include stimuli-responsive materials that change properties in response to environmental conditions. These "4D materials" can transform their shape, stiffness, or functionality post-printing, enabling adaptive components for all three target industries. Additionally, multi-material systems that seamlessly transition between rigid and flexible zones within a single print have overcome previous interface compatibility challenges.

Sustainability considerations have driven research into recyclable and environmentally friendly materials for volumetric printing. Bio-based resins derived from renewable resources show comparable performance to petroleum-based alternatives while reducing environmental impact. This addresses growing regulatory pressures and consumer demands for greener manufacturing processes across electronics, aerospace, and medical industries.

Material characterization techniques have evolved alongside these developments, with advanced spectroscopy and mechanical testing methods specifically adapted for volumetric printed structures. These techniques provide crucial data on material behavior under various conditions, enabling more accurate predictive modeling and quality control processes essential for high-reliability applications in all three industries.

Regulatory Framework for Advanced Manufacturing Technologies

The regulatory landscape for volumetric 3D printing technologies spans multiple domains, requiring careful navigation across electronics, aerospace, and biomedical sectors. In the United States, the FDA has established specific guidelines for 3D-printed medical devices through its "Technical Considerations for Additive Manufactured Medical Devices" framework, which addresses quality system requirements, device testing, and biocompatibility concerns specific to volumetric printing methods that create cellular structures.

For electronics applications, regulatory compliance focuses primarily on safety standards established by organizations such as Underwriters Laboratories (UL) and the International Electrotechnical Commission (IEC). These frameworks address electrical safety, electromagnetic compatibility, and hazardous substance restrictions. The novel nature of volumetrically printed electronics presents unique challenges for certification processes, as existing standards may not fully account for the distinctive material properties and structural characteristics of these components.

Aerospace implementations face particularly stringent regulatory requirements governed by the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA). These agencies have developed certification pathways for additively manufactured parts through initiatives like the FAA's Additive Manufacturing Strategic Roadmap. Volumetric printing technologies must demonstrate compliance with material property specifications, process controls, and quality assurance protocols that ensure consistent performance under extreme operational conditions.

Intellectual property considerations represent another critical regulatory dimension. The novel nature of volumetric 3D printing has triggered a surge in patent filings, creating a complex landscape of protected technologies. Organizations implementing these manufacturing methods must conduct thorough freedom-to-operate analyses to navigate potential infringement risks, particularly as the technology crosses traditional industry boundaries.

Environmental regulations also impact volumetric 3D printing adoption. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives impose strict controls on materials used in manufacturing processes. These regulations are particularly relevant for biomedical applications, where biocompatibility and biodegradability requirements intersect with environmental compliance concerns.

International standardization efforts are gradually emerging to address the regulatory gaps. Organizations including ISO, ASTM International, and IEEE are developing technical standards specific to volumetric printing technologies. These initiatives aim to establish consistent terminology, testing methodologies, and performance metrics that can facilitate regulatory approval processes across different jurisdictions and application domains.

For electronics applications, regulatory compliance focuses primarily on safety standards established by organizations such as Underwriters Laboratories (UL) and the International Electrotechnical Commission (IEC). These frameworks address electrical safety, electromagnetic compatibility, and hazardous substance restrictions. The novel nature of volumetrically printed electronics presents unique challenges for certification processes, as existing standards may not fully account for the distinctive material properties and structural characteristics of these components.

Aerospace implementations face particularly stringent regulatory requirements governed by the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA). These agencies have developed certification pathways for additively manufactured parts through initiatives like the FAA's Additive Manufacturing Strategic Roadmap. Volumetric printing technologies must demonstrate compliance with material property specifications, process controls, and quality assurance protocols that ensure consistent performance under extreme operational conditions.

Intellectual property considerations represent another critical regulatory dimension. The novel nature of volumetric 3D printing has triggered a surge in patent filings, creating a complex landscape of protected technologies. Organizations implementing these manufacturing methods must conduct thorough freedom-to-operate analyses to navigate potential infringement risks, particularly as the technology crosses traditional industry boundaries.

Environmental regulations also impact volumetric 3D printing adoption. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives impose strict controls on materials used in manufacturing processes. These regulations are particularly relevant for biomedical applications, where biocompatibility and biodegradability requirements intersect with environmental compliance concerns.

International standardization efforts are gradually emerging to address the regulatory gaps. Organizations including ISO, ASTM International, and IEEE are developing technical standards specific to volumetric printing technologies. These initiatives aim to establish consistent terminology, testing methodologies, and performance metrics that can facilitate regulatory approval processes across different jurisdictions and application domains.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!