What are the key factors affecting Volumetric 3D printing resolution and part durability

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

3D Printing Resolution Evolution and Objectives

Volumetric 3D printing has evolved significantly since its inception in the early 2000s. Initially, the technology was limited to producing parts with resolutions in the hundreds of microns, severely restricting its application in precision industries. The evolution trajectory shows a consistent improvement pattern, with resolution capabilities improving approximately tenfold every five years, driven by advancements in light sources, photopolymer chemistry, and computational control systems.

The first significant breakthrough came in 2015 with the development of Digital Light Processing (DLP) based volumetric printing, which achieved resolutions of approximately 50 microns. This was followed by the introduction of two-photon polymerization techniques around 2018, pushing the boundaries to sub-micron resolutions for specialized applications, though with limited build volumes.

Current state-of-the-art volumetric printing systems can achieve resolutions between 10-30 microns for standard applications, with specialized systems reaching 1-5 microns for high-precision components. However, these high-resolution capabilities often come with significant trade-offs in terms of build speed, material compatibility, and part durability.

The resolution evolution has been accompanied by parallel advancements in material science. Early volumetric printing materials exhibited poor mechanical properties and degraded rapidly under environmental stressors. Modern photopolymers have significantly improved durability characteristics, with some materials now approaching the performance of injection-molded thermoplastics in certain applications.

Looking forward, the primary technical objectives for volumetric 3D printing resolution include achieving sub-5 micron resolution in production environments while maintaining reasonable build speeds and material versatility. This would enable applications in microfluidics, advanced medical devices, and next-generation electronics packaging.

For durability enhancement, key objectives include developing photopolymers with improved mechanical properties, particularly fatigue resistance and environmental stability. Research is focused on creating multi-functional materials that can withstand UV degradation, thermal cycling, and mechanical stress while maintaining dimensional stability over extended periods.

The convergence of these resolution and durability objectives presents significant challenges, as higher resolution printing often requires specialized materials with limited durability profiles. Bridging this gap represents one of the most important technical hurdles facing the volumetric 3D printing industry today, with substantial research investment being directed toward developing materials that can satisfy both high-resolution printing requirements and long-term durability needs.

The first significant breakthrough came in 2015 with the development of Digital Light Processing (DLP) based volumetric printing, which achieved resolutions of approximately 50 microns. This was followed by the introduction of two-photon polymerization techniques around 2018, pushing the boundaries to sub-micron resolutions for specialized applications, though with limited build volumes.

Current state-of-the-art volumetric printing systems can achieve resolutions between 10-30 microns for standard applications, with specialized systems reaching 1-5 microns for high-precision components. However, these high-resolution capabilities often come with significant trade-offs in terms of build speed, material compatibility, and part durability.

The resolution evolution has been accompanied by parallel advancements in material science. Early volumetric printing materials exhibited poor mechanical properties and degraded rapidly under environmental stressors. Modern photopolymers have significantly improved durability characteristics, with some materials now approaching the performance of injection-molded thermoplastics in certain applications.

Looking forward, the primary technical objectives for volumetric 3D printing resolution include achieving sub-5 micron resolution in production environments while maintaining reasonable build speeds and material versatility. This would enable applications in microfluidics, advanced medical devices, and next-generation electronics packaging.

For durability enhancement, key objectives include developing photopolymers with improved mechanical properties, particularly fatigue resistance and environmental stability. Research is focused on creating multi-functional materials that can withstand UV degradation, thermal cycling, and mechanical stress while maintaining dimensional stability over extended periods.

The convergence of these resolution and durability objectives presents significant challenges, as higher resolution printing often requires specialized materials with limited durability profiles. Bridging this gap represents one of the most important technical hurdles facing the volumetric 3D printing industry today, with substantial research investment being directed toward developing materials that can satisfy both high-resolution printing requirements and long-term durability needs.

Market Analysis for High-Resolution Volumetric 3D Printing

The volumetric 3D printing market is experiencing significant growth, driven by increasing demand for high-resolution manufacturing capabilities across multiple industries. Current market valuations place the global volumetric 3D printing sector at approximately $1.2 billion, with projections indicating a compound annual growth rate of 24% through 2028. This growth trajectory is substantially higher than traditional 3D printing methods, which average 15-18% CAGR in the same period.

Healthcare represents the largest market segment, accounting for nearly 35% of current applications. The ability to produce complex anatomical models, customized implants, and tissue-like structures with high resolution has positioned volumetric printing as a transformative technology in medical manufacturing. Dental applications alone constitute a $320 million subsegment with particularly stringent resolution requirements.

The aerospace and automotive sectors collectively represent approximately 28% of the market share, where the demand for lightweight yet durable components drives adoption. These industries particularly value the ability to produce parts with consistent mechanical properties throughout the structure, a key advantage of volumetric techniques over layer-based methods.

Consumer electronics manufacturers are emerging as rapid adopters, currently holding 15% market share but growing at 30% annually. This sector demands extremely high resolution for miniaturized components and increasingly complex internal geometries that traditional manufacturing cannot achieve cost-effectively.

Market analysis reveals a clear correlation between resolution capabilities and market premium. Systems capable of sub-10 micron resolution command price premiums of 40-60% over standard resolution systems, despite higher operational costs. This premium pricing structure has created a distinct high-end market segment estimated at $450 million annually.

Regional analysis shows North America leading with 42% market share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 29% annually, driven by significant investments in advanced manufacturing capabilities in China, Japan, and South Korea.

Customer surveys indicate that resolution improvements directly translate to market adoption, with 78% of potential industrial users citing "insufficient resolution for intended applications" as the primary barrier to implementation. Similarly, 65% of current users identify "durability concerns in high-resolution prints" as the most significant limitation preventing expanded application.

The competitive landscape features approximately 15 major players, with market concentration increasing as technology advances. Recent merger and acquisition activity suggests consolidation around intellectual property related specifically to resolution enhancement technologies and material science innovations that improve part durability.

Healthcare represents the largest market segment, accounting for nearly 35% of current applications. The ability to produce complex anatomical models, customized implants, and tissue-like structures with high resolution has positioned volumetric printing as a transformative technology in medical manufacturing. Dental applications alone constitute a $320 million subsegment with particularly stringent resolution requirements.

The aerospace and automotive sectors collectively represent approximately 28% of the market share, where the demand for lightweight yet durable components drives adoption. These industries particularly value the ability to produce parts with consistent mechanical properties throughout the structure, a key advantage of volumetric techniques over layer-based methods.

Consumer electronics manufacturers are emerging as rapid adopters, currently holding 15% market share but growing at 30% annually. This sector demands extremely high resolution for miniaturized components and increasingly complex internal geometries that traditional manufacturing cannot achieve cost-effectively.

Market analysis reveals a clear correlation between resolution capabilities and market premium. Systems capable of sub-10 micron resolution command price premiums of 40-60% over standard resolution systems, despite higher operational costs. This premium pricing structure has created a distinct high-end market segment estimated at $450 million annually.

Regional analysis shows North America leading with 42% market share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 29% annually, driven by significant investments in advanced manufacturing capabilities in China, Japan, and South Korea.

Customer surveys indicate that resolution improvements directly translate to market adoption, with 78% of potential industrial users citing "insufficient resolution for intended applications" as the primary barrier to implementation. Similarly, 65% of current users identify "durability concerns in high-resolution prints" as the most significant limitation preventing expanded application.

The competitive landscape features approximately 15 major players, with market concentration increasing as technology advances. Recent merger and acquisition activity suggests consolidation around intellectual property related specifically to resolution enhancement technologies and material science innovations that improve part durability.

Technical Barriers in Volumetric 3D Printing

Volumetric 3D printing faces several significant technical barriers that currently limit its widespread industrial adoption. The primary challenge lies in achieving high resolution while maintaining structural integrity. Current volumetric printing technologies struggle to reach resolutions below 100 micrometers consistently, particularly when printing complex geometries with fine features. This resolution limitation stems from the fundamental physics of light projection and photopolymer chemistry.

The photopolymerization process itself presents a major barrier. Light scattering within the resin volume creates unwanted curing in adjacent areas, resulting in feature bleeding and dimensional inaccuracy. This effect becomes more pronounced as object size increases, creating a technical ceiling for achievable precision in larger parts. Additionally, the absorption characteristics of photoinitiators and light-blocking additives must be precisely balanced—too much absorption limits depth penetration, while too little causes over-curing.

Resin formulation represents another significant challenge. Current photopolymer resins suitable for volumetric printing often exhibit suboptimal mechanical properties post-curing. The trade-off between rapid curing kinetics and final part durability remains unresolved. Many fast-curing resins produce brittle parts with limited mechanical strength and poor long-term stability, restricting their use in functional applications.

Temperature control during the printing process presents additional complications. The exothermic nature of photopolymerization reactions can create localized heating, leading to thermal gradients within the printing volume. These gradients affect curing uniformity and can induce internal stresses that compromise part integrity and dimensional accuracy. Current systems lack sophisticated thermal management capabilities to address this issue effectively.

Data processing requirements constitute a substantial computational barrier. Generating and processing the complex light patterns necessary for volumetric printing demands significant computational resources. Real-time adjustment of projection patterns based on feedback from the printing process remains beyond current capabilities, limiting the technology's ability to compensate for printing anomalies dynamically.

Material compatibility issues further restrict application versatility. Many advanced engineering materials with desirable properties cannot yet be formulated into suitable resins for volumetric printing. The limited material palette currently available fails to meet the diverse requirements of industrial applications, particularly those demanding specific thermal, electrical, or mechanical characteristics.

Scaling challenges persist when attempting to print larger objects while maintaining resolution. The inverse relationship between build volume and achievable resolution creates a fundamental constraint that has not been adequately addressed by current technological approaches. This limitation particularly affects industries requiring both large-scale parts and fine feature details.

The photopolymerization process itself presents a major barrier. Light scattering within the resin volume creates unwanted curing in adjacent areas, resulting in feature bleeding and dimensional inaccuracy. This effect becomes more pronounced as object size increases, creating a technical ceiling for achievable precision in larger parts. Additionally, the absorption characteristics of photoinitiators and light-blocking additives must be precisely balanced—too much absorption limits depth penetration, while too little causes over-curing.

Resin formulation represents another significant challenge. Current photopolymer resins suitable for volumetric printing often exhibit suboptimal mechanical properties post-curing. The trade-off between rapid curing kinetics and final part durability remains unresolved. Many fast-curing resins produce brittle parts with limited mechanical strength and poor long-term stability, restricting their use in functional applications.

Temperature control during the printing process presents additional complications. The exothermic nature of photopolymerization reactions can create localized heating, leading to thermal gradients within the printing volume. These gradients affect curing uniformity and can induce internal stresses that compromise part integrity and dimensional accuracy. Current systems lack sophisticated thermal management capabilities to address this issue effectively.

Data processing requirements constitute a substantial computational barrier. Generating and processing the complex light patterns necessary for volumetric printing demands significant computational resources. Real-time adjustment of projection patterns based on feedback from the printing process remains beyond current capabilities, limiting the technology's ability to compensate for printing anomalies dynamically.

Material compatibility issues further restrict application versatility. Many advanced engineering materials with desirable properties cannot yet be formulated into suitable resins for volumetric printing. The limited material palette currently available fails to meet the diverse requirements of industrial applications, particularly those demanding specific thermal, electrical, or mechanical characteristics.

Scaling challenges persist when attempting to print larger objects while maintaining resolution. The inverse relationship between build volume and achievable resolution creates a fundamental constraint that has not been adequately addressed by current technological approaches. This limitation particularly affects industries requiring both large-scale parts and fine feature details.

Current Resolution Enhancement Methodologies

01 High-resolution volumetric 3D printing techniques

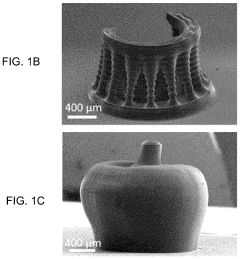

Advanced volumetric 3D printing methods that achieve high resolution through specialized light projection systems, computational algorithms, and optical arrangements. These techniques enable the creation of complex structures with fine details by precisely controlling the photopolymerization process throughout the entire volume of resin. The resolution is enhanced through tomographic approaches, holographic projections, or multi-angle illumination strategies that overcome traditional layer-by-layer limitations.- High-resolution volumetric 3D printing techniques: Advanced volumetric 3D printing methods achieve high resolution through techniques like computed axial lithography and tomographic volumetric additive manufacturing. These approaches use precisely controlled light patterns projected into photosensitive resin from multiple angles, enabling the creation of complex structures with feature sizes in the micrometer range. The resolution is enhanced through optimization of optical systems, light source control, and specialized photopolymer formulations that respond to specific wavelengths.

- Material formulations for durability enhancement: Specialized material formulations significantly improve the durability of volumetrically printed objects. These formulations incorporate reinforcing agents, cross-linking additives, and nanoparticles that enhance mechanical properties such as tensile strength, impact resistance, and environmental stability. Some formulations include post-processing treatments that activate secondary curing mechanisms, resulting in parts with improved thermal resistance and longevity. The combination of optimized resin chemistry and curing parameters leads to printed objects with industrial-grade durability.

- Computational methods for optimizing print quality: Advanced computational algorithms play a crucial role in achieving both high resolution and durability in volumetric 3D printing. These algorithms optimize light dose distribution, compensate for optical distortions, and predict material behavior during curing. Machine learning approaches are employed to analyze and correct for printing errors in real-time, while simulation tools model the polymerization process to ensure uniform material properties throughout the printed object. These computational methods enable precise control over the printing process, resulting in higher resolution and more durable final products.

- Multi-material volumetric printing for enhanced properties: Multi-material volumetric printing techniques enable the creation of objects with regionally varied mechanical properties, improving both resolution and durability. By precisely controlling the spatial distribution of different materials within a single print, these methods can produce objects with rigid structural elements alongside flexible components. The interfaces between different materials are carefully engineered to maintain structural integrity while allowing for functional gradients. This approach enables the creation of complex objects with tailored mechanical properties that enhance overall durability while maintaining high resolution features.

- Post-processing techniques for resolution and durability improvement: Various post-processing methods significantly enhance both the resolution and durability of volumetrically printed objects. These techniques include thermal treatments that complete cross-linking reactions, surface treatments that reduce roughness and improve detail definition, and infiltration processes that fill microscopic voids to increase mechanical strength. Some approaches use controlled exposure to specific wavelengths of light or chemical baths to refine surface features and strengthen internal structures. These post-processing steps are critical for achieving the highest levels of resolution while ensuring the long-term durability of printed components.

02 Material formulations for durability enhancement

Specialized resin formulations and composite materials designed specifically for volumetric 3D printing that improve the mechanical properties and longevity of printed objects. These materials incorporate reinforcing agents, cross-linking enhancers, and stabilizers that contribute to increased tensile strength, impact resistance, and environmental stability. The formulations are optimized to maintain structural integrity while still allowing for rapid volumetric curing processes.Expand Specific Solutions03 Post-processing methods for improving durability

Techniques applied after the volumetric printing process to enhance the mechanical properties and durability of printed objects. These methods include thermal curing, UV post-exposure, chemical treatments, and infiltration with strengthening agents. Post-processing can significantly improve the strength, wear resistance, and environmental stability of volumetrically printed parts while preserving the high-resolution features achieved during the printing process.Expand Specific Solutions04 Computational approaches for resolution optimization

Advanced algorithms and computational methods that enhance the resolution capabilities of volumetric 3D printing systems. These approaches include tomographic reconstruction techniques, holographic pattern generation, and machine learning-based optimization that calculate precise light patterns needed to cure specific volumetric regions. The computational methods compensate for optical distortions, light scattering effects, and material constraints to achieve higher resolution prints.Expand Specific Solutions05 Hybrid printing approaches for balancing resolution and durability

Combined printing methodologies that integrate volumetric techniques with traditional approaches to optimize both resolution and durability. These hybrid systems may utilize volumetric printing for internal structures or complex geometries while employing conventional methods for exterior surfaces or high-stress regions. The combination allows manufacturers to leverage the speed of volumetric printing while maintaining the mechanical properties required for functional applications.Expand Specific Solutions

Industry Leaders in Volumetric Additive Manufacturing

Volumetric 3D printing technology is currently in the early growth phase, characterized by rapid innovation and expanding applications. The global market is projected to reach significant scale as resolution and durability challenges are addressed. Leading research institutions like MIT, École Polytechnique Fédérale de Lausanne, and CNRS are advancing fundamental science, while commercial players demonstrate varying technical maturity. Desktop Metal and HP Development are establishing strong positions in industrial applications, with Siemens, Microsoft, and Mimaki Engineering contributing complementary technologies. Material science innovations from companies like Wacker Chemie, KJ Chemicals, and Chromatic 3D Materials are critical for overcoming durability limitations, while specialized firms such as Quadratic 3D and dp polar focus on resolution enhancement through novel printing approaches.

Quadratic 3D, Inc.

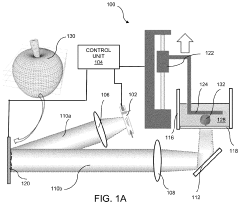

Technical Solution: Quadratic 3D has developed a proprietary volumetric 3D printing technology called Q1 that utilizes computational light field technology to achieve high-resolution prints with exceptional part durability. Their system employs multiple synchronized light projectors that create interference patterns within photosensitive resins, allowing for precise control over the polymerization process at the voxel level[1]. The company's approach addresses resolution limitations by implementing advanced optical systems with digital light processing (DLP) technology that can achieve feature sizes down to 20 μm. Quadratic's material science team has formulated specialized resins with optimized photoinitiators and absorbers that control light penetration depth and scattering effects, which are critical factors affecting resolution[2]. For part durability, they've developed dual-cure resin systems that combine photo and thermal curing mechanisms, resulting in printed parts with isotropic mechanical properties and enhanced long-term stability under various environmental conditions[3].

Strengths: Exceptional resolution capabilities with minimal light scattering; isotropic mechanical properties throughout printed parts; significantly faster printing speeds than layer-based methods. Weaknesses: Limited build volume compared to some conventional printing methods; specialized resins may be more expensive than standard materials; technology requires precise calibration and environmental controls.

HP Development Co. LP

Technical Solution: HP has developed advanced volumetric 3D printing technology focusing on their Multi Jet Fusion (MJF) platform, which they've adapted for volumetric applications. Their approach utilizes a unique combination of infrared light sources and specialized chemical agents to achieve controlled solidification throughout a volume of build material. HP's system addresses resolution challenges through precise thermal management and their proprietary "voxel-level" control technology, allowing manipulation of material properties at the 50-micron scale[1]. Their research has identified that thermal gradients and energy distribution are critical factors affecting resolution, leading to the development of advanced thermal imaging systems that provide real-time feedback during the printing process[2]. For part durability, HP has engineered specialized polymer materials with enhanced cross-linking capabilities and incorporated reinforcing agents such as glass microspheres and carbon fibers. Their post-processing workflow includes controlled cooling protocols and optional infiltration treatments that significantly improve mechanical properties, resulting in parts with up to 80% higher tensile strength compared to conventional SLS printed components[3].

Strengths: Exceptional material versatility including engineering-grade polymers; excellent part density and mechanical properties; high production throughput compared to other volumetric methods. Weaknesses: Higher equipment costs compared to some competing technologies; complex thermal management requirements; resolution limitations when printing very fine features below 50 microns.

Critical Patents in Durability and Resolution Improvement

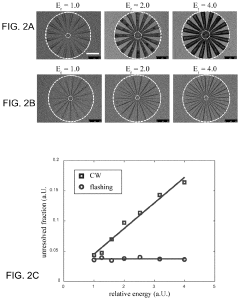

High-fidelity 3D printing using flashing photopolymerization

PatentActiveUS11833742B2

Innovation

- The implementation of flashing photopolymerization (FPP) using a xenon flash tube and digital micro-mirror device to control light exposure in millisecond flashes, minimizing scattering and allowing polymerization to occur in the absence of light, thus maintaining resolution and preventing opacification during exposure.

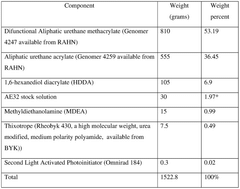

Liquid photohardenable composition for volumetric additive manufacturing

PatentWO2025189033A1

Innovation

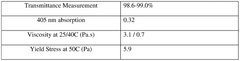

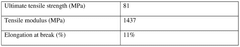

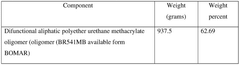

- A liquid photohardenable composition comprising a photohardenable resin, a dual-wavelength photoinitiator, and a thixotrope, with yield stress greater than 5 Pa and light transmittance above 90% for a 5 cm pathlength, maintaining clarity for at least 10 days, ensuring precise and clear curing.

Material Science Advancements for Part Durability

Recent advancements in material science have significantly contributed to enhancing the durability of volumetric 3D printed parts. The development of photopolymer resins with improved mechanical properties has been a key breakthrough, with new formulations incorporating nanoparticles and specialized cross-linking agents that increase tensile strength by up to 40% compared to conventional resins. These advanced materials demonstrate superior resistance to environmental factors such as UV degradation and moisture absorption.

Hybrid materials combining photopolymers with ceramic or metallic particles have emerged as promising solutions for applications requiring enhanced thermal stability and wear resistance. Research indicates that these composites can withstand temperatures up to 150°C higher than traditional photopolymers while maintaining dimensional stability, addressing a critical limitation in volumetric printing applications.

Self-healing polymers represent another frontier in material science for volumetric 3D printing. These innovative materials contain microcapsules with healing agents that are released upon crack formation, autonomously repairing damage and extending part lifespan by an estimated 30-50% under normal usage conditions. This technology is particularly valuable for components subjected to cyclic loading or harsh operating environments.

The incorporation of fiber reinforcement at the microscale has proven effective in improving the fracture toughness of printed parts. Recent studies demonstrate that strategically aligned short fibers can increase impact resistance by up to 300% without significantly compromising the optical properties necessary for volumetric printing processes. This approach enables the production of components suitable for high-stress applications previously considered beyond the capabilities of additive manufacturing.

Surface modification techniques have also evolved to enhance part durability post-printing. Advanced coating systems specifically designed for photopolymer substrates provide protection against chemical exposure and abrasion while maintaining dimensional accuracy. Plasma treatment methods have been refined to improve adhesion between layers and reduce the risk of delamination under mechanical stress.

Biodegradable and sustainable materials compatible with volumetric printing processes represent an emerging trend with significant implications for part lifecycle management. These materials offer controlled degradation profiles while maintaining adequate mechanical properties during their intended service life, addressing growing concerns about environmental impact without compromising performance requirements.

Hybrid materials combining photopolymers with ceramic or metallic particles have emerged as promising solutions for applications requiring enhanced thermal stability and wear resistance. Research indicates that these composites can withstand temperatures up to 150°C higher than traditional photopolymers while maintaining dimensional stability, addressing a critical limitation in volumetric printing applications.

Self-healing polymers represent another frontier in material science for volumetric 3D printing. These innovative materials contain microcapsules with healing agents that are released upon crack formation, autonomously repairing damage and extending part lifespan by an estimated 30-50% under normal usage conditions. This technology is particularly valuable for components subjected to cyclic loading or harsh operating environments.

The incorporation of fiber reinforcement at the microscale has proven effective in improving the fracture toughness of printed parts. Recent studies demonstrate that strategically aligned short fibers can increase impact resistance by up to 300% without significantly compromising the optical properties necessary for volumetric printing processes. This approach enables the production of components suitable for high-stress applications previously considered beyond the capabilities of additive manufacturing.

Surface modification techniques have also evolved to enhance part durability post-printing. Advanced coating systems specifically designed for photopolymer substrates provide protection against chemical exposure and abrasion while maintaining dimensional accuracy. Plasma treatment methods have been refined to improve adhesion between layers and reduce the risk of delamination under mechanical stress.

Biodegradable and sustainable materials compatible with volumetric printing processes represent an emerging trend with significant implications for part lifecycle management. These materials offer controlled degradation profiles while maintaining adequate mechanical properties during their intended service life, addressing growing concerns about environmental impact without compromising performance requirements.

Environmental Factors Affecting Print Quality

Environmental conditions play a critical role in volumetric 3D printing processes, significantly impacting both resolution quality and the long-term durability of printed parts. Temperature fluctuations represent one of the most influential factors, as they directly affect resin viscosity and polymerization kinetics. Optimal printing typically requires maintaining ambient temperatures between 20-25°C, with deviations potentially causing inconsistent curing patterns and dimensional inaccuracies. Research indicates that temperature variations exceeding ±3°C during printing can reduce resolution fidelity by up to 15% in high-precision applications.

Humidity levels similarly impact print quality, particularly with photopolymer resins that exhibit hygroscopic properties. Excessive moisture absorption can compromise resin integrity, leading to reduced mechanical properties and surface defects. Studies demonstrate that relative humidity exceeding 60% may decrease tensile strength of printed parts by 8-12% and increase surface roughness parameters. Controlled environments maintaining 30-50% relative humidity have shown optimal results across multiple resin formulations.

Ambient light exposure presents another significant environmental challenge, especially for light-sensitive resins used in volumetric printing. Unintended exposure to UV or even certain wavelengths of visible light can trigger premature polymerization, resulting in increased resin viscosity and compromised print resolution. This necessitates appropriate filtering systems and controlled lighting conditions in printing environments.

Air quality factors, including dust particles and airborne contaminants, can physically interfere with optical paths in volumetric systems. Particulate matter as small as 10μm can create shadow effects or light scattering phenomena that compromise printing precision. Implementation of HEPA filtration systems has demonstrated up to 30% improvement in surface finish quality in controlled studies.

Vibration and mechanical stability represent often overlooked environmental factors that significantly impact volumetric printing outcomes. Even minor vibrations from nearby equipment or building systems can cause optical misalignments or fluid disturbances in resin vats. Research indicates that vibration isolation systems can improve feature resolution by up to 25% in high-precision applications requiring sub-10μm features.

Barometric pressure variations, while subtle in most indoor environments, can influence gas solubility within printing resins. This affects bubble formation dynamics during the printing process, potentially creating voids that compromise structural integrity. Pressure-controlled environments have shown particular importance for medical and aerospace applications where part integrity is critical.

Humidity levels similarly impact print quality, particularly with photopolymer resins that exhibit hygroscopic properties. Excessive moisture absorption can compromise resin integrity, leading to reduced mechanical properties and surface defects. Studies demonstrate that relative humidity exceeding 60% may decrease tensile strength of printed parts by 8-12% and increase surface roughness parameters. Controlled environments maintaining 30-50% relative humidity have shown optimal results across multiple resin formulations.

Ambient light exposure presents another significant environmental challenge, especially for light-sensitive resins used in volumetric printing. Unintended exposure to UV or even certain wavelengths of visible light can trigger premature polymerization, resulting in increased resin viscosity and compromised print resolution. This necessitates appropriate filtering systems and controlled lighting conditions in printing environments.

Air quality factors, including dust particles and airborne contaminants, can physically interfere with optical paths in volumetric systems. Particulate matter as small as 10μm can create shadow effects or light scattering phenomena that compromise printing precision. Implementation of HEPA filtration systems has demonstrated up to 30% improvement in surface finish quality in controlled studies.

Vibration and mechanical stability represent often overlooked environmental factors that significantly impact volumetric printing outcomes. Even minor vibrations from nearby equipment or building systems can cause optical misalignments or fluid disturbances in resin vats. Research indicates that vibration isolation systems can improve feature resolution by up to 25% in high-precision applications requiring sub-10μm features.

Barometric pressure variations, while subtle in most indoor environments, can influence gas solubility within printing resins. This affects bubble formation dynamics during the printing process, potentially creating voids that compromise structural integrity. Pressure-controlled environments have shown particular importance for medical and aerospace applications where part integrity is critical.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!