What material parameters are essential for Volumetric 3D printing mechanical and thermal performance

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric 3D Printing Evolution and Objectives

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, evolving from traditional layer-by-layer approaches to a more holistic, simultaneous solidification process. The technology originated in the early 2010s with the development of computed axial lithography (CAL), which utilized projected light patterns to cure photosensitive resins volumetrically. This revolutionary approach addressed fundamental limitations of conventional 3D printing, particularly speed constraints and mechanical anisotropy resulting from layer interfaces.

The evolution of volumetric 3D printing has been marked by significant technological milestones. Initial proof-of-concept demonstrations achieved limited resolution and material compatibility. By 2019, researchers at Lawrence Livermore National Laboratory and UC Berkeley demonstrated high-resolution volumetric printing using tomographic reconstruction techniques. Recent advancements have expanded material options beyond simple photopolymers to include composite materials, hydrogels, and even certain metal-infused resins.

Current technological objectives focus on enhancing the mechanical and thermal performance of volumetrically printed parts. Unlike traditional layer-based printing where mechanical properties often vary directionally due to layer interfaces, volumetric printing offers the potential for more isotropic material properties. However, achieving optimal mechanical and thermal performance requires precise control of material parameters during the simultaneous solidification process.

The primary technical goal is to identify and optimize material parameters that directly influence mechanical strength, elasticity, thermal stability, and heat transfer characteristics in volumetrically printed objects. This includes understanding how photoinitiator concentration, resin viscosity, light absorption coefficients, and thermal diffusivity affect the final printed structure at both macro and microscopic levels.

Another critical objective is developing predictive models that correlate material parameters with expected mechanical and thermal performance. Such models would enable engineers to design materials specifically optimized for volumetric printing processes, rather than adapting existing materials designed for conventional manufacturing methods.

The field aims to establish standardized testing protocols for evaluating the mechanical and thermal properties of volumetrically printed parts. This standardization would facilitate meaningful comparisons between different material formulations and processing parameters, accelerating the development of application-specific materials with tailored performance characteristics.

Long-term objectives include expanding the range of printable materials to include high-performance engineering polymers, ceramics, and metal-polymer composites with enhanced mechanical and thermal properties. Researchers are particularly focused on developing materials that can maintain structural integrity under extreme temperature conditions while providing the design freedom inherent to volumetric printing techniques.

The evolution of volumetric 3D printing has been marked by significant technological milestones. Initial proof-of-concept demonstrations achieved limited resolution and material compatibility. By 2019, researchers at Lawrence Livermore National Laboratory and UC Berkeley demonstrated high-resolution volumetric printing using tomographic reconstruction techniques. Recent advancements have expanded material options beyond simple photopolymers to include composite materials, hydrogels, and even certain metal-infused resins.

Current technological objectives focus on enhancing the mechanical and thermal performance of volumetrically printed parts. Unlike traditional layer-based printing where mechanical properties often vary directionally due to layer interfaces, volumetric printing offers the potential for more isotropic material properties. However, achieving optimal mechanical and thermal performance requires precise control of material parameters during the simultaneous solidification process.

The primary technical goal is to identify and optimize material parameters that directly influence mechanical strength, elasticity, thermal stability, and heat transfer characteristics in volumetrically printed objects. This includes understanding how photoinitiator concentration, resin viscosity, light absorption coefficients, and thermal diffusivity affect the final printed structure at both macro and microscopic levels.

Another critical objective is developing predictive models that correlate material parameters with expected mechanical and thermal performance. Such models would enable engineers to design materials specifically optimized for volumetric printing processes, rather than adapting existing materials designed for conventional manufacturing methods.

The field aims to establish standardized testing protocols for evaluating the mechanical and thermal properties of volumetrically printed parts. This standardization would facilitate meaningful comparisons between different material formulations and processing parameters, accelerating the development of application-specific materials with tailored performance characteristics.

Long-term objectives include expanding the range of printable materials to include high-performance engineering polymers, ceramics, and metal-polymer composites with enhanced mechanical and thermal properties. Researchers are particularly focused on developing materials that can maintain structural integrity under extreme temperature conditions while providing the design freedom inherent to volumetric printing techniques.

Market Analysis for High-Performance Volumetric 3D Printing

The global market for volumetric 3D printing technologies is experiencing robust growth, driven by increasing demand for high-performance parts across multiple industries. Current market valuations place the high-performance 3D printing segment at approximately 2.3 billion USD, with volumetric techniques representing a rapidly expanding subsector projected to grow at a CAGR of 28% through 2028.

Aerospace and defense sectors currently dominate the market demand for high-performance volumetric 3D printing, accounting for nearly 35% of the total market share. These industries require components with exceptional mechanical properties, thermal stability, and precise dimensional accuracy. The healthcare sector follows closely, representing about 30% of the market, with particular emphasis on biocompatible materials for medical implants and tissue engineering applications.

Automotive and industrial manufacturing sectors collectively contribute approximately 25% of market demand, primarily seeking materials that offer superior strength-to-weight ratios, thermal resistance, and production efficiency. Consumer electronics and energy sectors make up the remaining market share, with growing interest in materials that can deliver enhanced thermal management properties.

Regional analysis reveals North America as the dominant market for high-performance volumetric 3D printing, holding approximately 40% of global market share. This leadership position stems from substantial R&D investments and strong aerospace and healthcare industries. Europe follows with roughly 30% market share, demonstrating particular strength in automotive and industrial applications. The Asia-Pacific region represents the fastest-growing market segment, expanding at nearly 32% annually, driven by rapid industrialization in China, Japan, and South Korea.

Customer requirements analysis indicates five primary material performance parameters driving market demand: mechanical strength, thermal stability, dimensional accuracy, processing speed, and material cost. End-users consistently rank mechanical performance and thermal stability as the two most critical parameters, with 78% of surveyed manufacturers citing these as "extremely important" considerations in material selection.

Market forecasts suggest that materials optimized for both mechanical and thermal performance will command premium pricing, with customers willing to pay 40-60% more for materials that deliver superior performance in these areas. This price premium reflects the critical nature of these properties in high-value applications where component failure is not an option.

The competitive landscape features both established materials science companies and innovative startups developing proprietary formulations. Recent market entrants have secured significant venture funding by demonstrating novel approaches to enhancing mechanical-thermal performance relationships in volumetric printing materials, indicating strong investor confidence in this market segment.

Aerospace and defense sectors currently dominate the market demand for high-performance volumetric 3D printing, accounting for nearly 35% of the total market share. These industries require components with exceptional mechanical properties, thermal stability, and precise dimensional accuracy. The healthcare sector follows closely, representing about 30% of the market, with particular emphasis on biocompatible materials for medical implants and tissue engineering applications.

Automotive and industrial manufacturing sectors collectively contribute approximately 25% of market demand, primarily seeking materials that offer superior strength-to-weight ratios, thermal resistance, and production efficiency. Consumer electronics and energy sectors make up the remaining market share, with growing interest in materials that can deliver enhanced thermal management properties.

Regional analysis reveals North America as the dominant market for high-performance volumetric 3D printing, holding approximately 40% of global market share. This leadership position stems from substantial R&D investments and strong aerospace and healthcare industries. Europe follows with roughly 30% market share, demonstrating particular strength in automotive and industrial applications. The Asia-Pacific region represents the fastest-growing market segment, expanding at nearly 32% annually, driven by rapid industrialization in China, Japan, and South Korea.

Customer requirements analysis indicates five primary material performance parameters driving market demand: mechanical strength, thermal stability, dimensional accuracy, processing speed, and material cost. End-users consistently rank mechanical performance and thermal stability as the two most critical parameters, with 78% of surveyed manufacturers citing these as "extremely important" considerations in material selection.

Market forecasts suggest that materials optimized for both mechanical and thermal performance will command premium pricing, with customers willing to pay 40-60% more for materials that deliver superior performance in these areas. This price premium reflects the critical nature of these properties in high-value applications where component failure is not an option.

The competitive landscape features both established materials science companies and innovative startups developing proprietary formulations. Recent market entrants have secured significant venture funding by demonstrating novel approaches to enhancing mechanical-thermal performance relationships in volumetric printing materials, indicating strong investor confidence in this market segment.

Current Material Challenges in Volumetric 3D Printing

Volumetric 3D printing faces significant material challenges that limit its mechanical and thermal performance capabilities. Current photopolymer resins used in volumetric additive manufacturing (VAM) exhibit inherent limitations in mechanical properties, often resulting in printed parts with insufficient strength, elasticity, and durability for industrial applications. The viscosity of these resins presents a particular challenge, as it must be carefully balanced to allow for proper light penetration while maintaining structural integrity during the printing process.

Thermal stability remains a critical concern, with many available materials demonstrating poor performance under elevated temperatures. This limitation restricts the application of volumetric 3D printed components in environments requiring heat resistance. Additionally, the photoinitiator systems currently employed often lack the speed and efficiency necessary for truly rapid volumetric printing, creating a bottleneck in production capabilities.

Material homogeneity presents another significant challenge. The tomographic volumetric printing approach requires materials with consistent optical properties throughout the resin volume. Variations in refractive index or light scattering properties can lead to printing defects and compromised mechanical integrity. Current materials struggle to maintain this homogeneity, particularly when additives are incorporated to enhance specific properties.

The biocompatibility of volumetric printing materials remains limited, restricting potential applications in medical and bioengineering fields. Most high-performance resins contain components that are not suitable for biological applications, creating a significant gap in the material portfolio for volumetric printing technologies.

Multi-material capabilities, essential for creating functionally graded components with varying mechanical and thermal properties, are still in their infancy. The current generation of volumetric printing systems typically operates with single materials, limiting design flexibility and functional performance of printed parts.

Post-processing requirements further complicate material selection, as many resins require extensive curing, washing, or heat treatment to achieve optimal mechanical properties. These additional steps reduce the overall efficiency advantage that volumetric printing offers over traditional layer-by-layer approaches.

Recyclability and environmental impact pose growing concerns, with most current materials offering limited options for sustainable use. The chemical composition of high-performance resins often makes them difficult to recycle or safely dispose of, creating environmental challenges that must be addressed for broader industrial adoption.

Thermal stability remains a critical concern, with many available materials demonstrating poor performance under elevated temperatures. This limitation restricts the application of volumetric 3D printed components in environments requiring heat resistance. Additionally, the photoinitiator systems currently employed often lack the speed and efficiency necessary for truly rapid volumetric printing, creating a bottleneck in production capabilities.

Material homogeneity presents another significant challenge. The tomographic volumetric printing approach requires materials with consistent optical properties throughout the resin volume. Variations in refractive index or light scattering properties can lead to printing defects and compromised mechanical integrity. Current materials struggle to maintain this homogeneity, particularly when additives are incorporated to enhance specific properties.

The biocompatibility of volumetric printing materials remains limited, restricting potential applications in medical and bioengineering fields. Most high-performance resins contain components that are not suitable for biological applications, creating a significant gap in the material portfolio for volumetric printing technologies.

Multi-material capabilities, essential for creating functionally graded components with varying mechanical and thermal properties, are still in their infancy. The current generation of volumetric printing systems typically operates with single materials, limiting design flexibility and functional performance of printed parts.

Post-processing requirements further complicate material selection, as many resins require extensive curing, washing, or heat treatment to achieve optimal mechanical properties. These additional steps reduce the overall efficiency advantage that volumetric printing offers over traditional layer-by-layer approaches.

Recyclability and environmental impact pose growing concerns, with most current materials offering limited options for sustainable use. The chemical composition of high-performance resins often makes them difficult to recycle or safely dispose of, creating environmental challenges that must be addressed for broader industrial adoption.

Current Material Parameter Optimization Approaches

01 Materials for enhanced mechanical properties in volumetric 3D printing

Various materials can be incorporated into volumetric 3D printing processes to enhance mechanical properties of the printed objects. These materials include specialized polymers, composites, and reinforcement additives that improve strength, durability, and structural integrity. The selection of appropriate materials is crucial for achieving desired mechanical performance in volumetric 3D printed parts, particularly for applications requiring load-bearing capabilities or resistance to mechanical stress.- Materials for enhanced mechanical properties in volumetric 3D printing: Various materials can be incorporated into volumetric 3D printing processes to enhance mechanical properties of the printed objects. These materials include specialized polymers, composites, and reinforcement additives that improve strength, durability, and structural integrity. The selection of appropriate materials significantly impacts the mechanical performance of the final printed parts, allowing for customization based on specific application requirements.

- Thermal management techniques in volumetric 3D printing: Effective thermal management is crucial in volumetric 3D printing to ensure dimensional accuracy and structural integrity. Techniques include controlled cooling rates, temperature gradient manipulation, and thermal stabilization methods that prevent warping and internal stress formation. Advanced thermal monitoring systems can be integrated into the printing process to maintain optimal temperature conditions throughout the build, resulting in improved mechanical properties and performance of the printed objects.

- Process parameters optimization for mechanical performance: Optimization of process parameters such as printing speed, layer thickness, and energy input significantly affects the mechanical performance of volumetrically printed parts. Careful calibration of these parameters can lead to improved layer adhesion, reduced porosity, and enhanced overall strength. Advanced algorithms and machine learning techniques can be employed to determine optimal printing conditions for specific geometries and material combinations.

- Post-processing treatments for improved thermal and mechanical properties: Various post-processing treatments can be applied to volumetrically printed objects to enhance their thermal and mechanical properties. These include thermal annealing, surface treatments, and infiltration techniques that can significantly improve strength, heat resistance, and dimensional stability. Post-curing processes using UV light or heat can complete polymerization reactions, resulting in superior mechanical performance compared to as-printed parts.

- Testing and characterization methods for volumetric 3D printed parts: Specialized testing and characterization methods are essential for evaluating the mechanical and thermal performance of volumetrically printed parts. These include tensile, compression, and flexural testing, as well as thermal analysis techniques such as differential scanning calorimetry and thermogravimetric analysis. Advanced imaging methods like micro-CT scanning can be used to assess internal structures and defects that may affect performance. These testing protocols help establish correlations between printing parameters and final part properties.

02 Thermal management techniques in volumetric 3D printing

Effective thermal management is essential in volumetric 3D printing to control material properties and prevent defects. Techniques include precise temperature control during printing, post-processing heat treatments, and thermal gradient management. These approaches help optimize crystallinity, reduce internal stresses, and enhance the overall thermal performance of printed objects. Advanced thermal management systems can significantly improve dimensional accuracy and mechanical properties of the final printed parts.Expand Specific Solutions03 Process parameters affecting mechanical and thermal performance

Various process parameters in volumetric 3D printing significantly impact the mechanical and thermal performance of printed objects. These parameters include printing speed, energy input, layer thickness, and curing conditions. Optimizing these parameters is crucial for achieving desired mechanical properties such as tensile strength, flexibility, and impact resistance, as well as thermal characteristics like heat resistance and thermal conductivity. Careful calibration of these parameters enables customization of material properties for specific applications.Expand Specific Solutions04 Novel volumetric printing technologies for improved performance

Innovative volumetric 3D printing technologies have been developed to enhance mechanical and thermal performance. These include tomographic volumetric additive manufacturing, computed axial lithography, and holographic printing approaches. These technologies enable simultaneous solidification throughout the printing volume rather than layer-by-layer processing, resulting in improved isotropy of mechanical properties, reduced internal stresses, and enhanced thermal stability. These novel approaches also allow for complex internal structures that can be designed to optimize specific mechanical and thermal characteristics.Expand Specific Solutions05 Testing and characterization methods for volumetric 3D printed parts

Specialized testing and characterization methods have been developed to evaluate the mechanical and thermal performance of volumetric 3D printed parts. These include mechanical testing protocols for strength, elasticity, and fatigue resistance, as well as thermal analysis techniques to assess heat resistance, thermal expansion, and conductivity. Advanced imaging and analytical methods such as X-ray tomography, scanning electron microscopy, and thermal imaging are employed to characterize internal structures and identify potential defects that might affect performance. These testing methodologies are essential for quality control and performance validation of volumetric 3D printed components.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Volumetric 3D printing technology is currently in its growth phase, with the market expected to reach significant expansion due to increasing applications in aerospace, healthcare, and manufacturing sectors. Key material parameters essential for mechanical and thermal performance include viscosity, curing kinetics, thermal stability, and mechanical strength. The competitive landscape features established players like Jabil and IBM developing proprietary materials, while specialized companies such as Chromatic 3D Materials and AIM3D focus on innovative formulations. Research institutions including Zhejiang University and IIT Delhi are advancing fundamental material science. The industry is moving toward more sophisticated multi-material systems, with companies like INEOS Styrolution and Wacker Chemie developing specialized polymers and composites that balance printability with end-use performance requirements.

Jabil, Inc.

Technical Solution: Jabil has developed an advanced volumetric 3D printing platform that focuses on material parameter optimization for both mechanical and thermal performance. Their technology incorporates real-time monitoring of critical material parameters including viscosity, surface tension, curing kinetics, and thermal conductivity during the printing process. Jabil's approach emphasizes the importance of material crystallinity and molecular weight distribution in determining final part performance. Their research has established correlations between printing parameters (temperature, speed, layer thickness) and resulting mechanical properties such as tensile strength, impact resistance, and fatigue performance. For thermal performance, Jabil has developed proprietary additives that enhance thermal conductivity while maintaining mechanical integrity, particularly important for electronic applications. Their material science team has created a comprehensive database mapping the relationship between material composition, processing parameters, and resulting performance metrics, enabling predictive modeling for new applications. Jabil's technology allows for gradient material properties within a single printed part by dynamically adjusting material parameters during the printing process.

Strengths: Extensive material science expertise across multiple polymer families with proven industrial-scale implementation. Their integrated quality control systems ensure consistent mechanical and thermal properties across production runs. Weaknesses: Higher material costs compared to conventional manufacturing methods. Some of their advanced material formulations require specific environmental conditions during printing, limiting flexibility in manufacturing environments.

Relativity Space, Inc.

Technical Solution: Relativity Space has developed a proprietary volumetric 3D printing technology called "Stargate" that focuses on metal printing for aerospace applications. Their approach integrates material science with machine learning to optimize mechanical performance parameters including tensile strength, fatigue resistance, and thermal conductivity. The company's materials research emphasizes aluminum alloys with specific attention to grain structure control during the printing process, which directly impacts mechanical properties. Their thermal performance optimization includes developing materials with tailored thermal expansion coefficients and heat dissipation characteristics critical for rocket components that experience extreme temperature gradients. Relativity's material parameter monitoring system continuously tracks viscosity, surface tension, and solidification rates during printing to ensure consistent mechanical properties throughout complex geometries. Their technology allows for in-situ adjustment of material parameters based on real-time feedback from embedded sensors that monitor structural integrity during the printing process.

Strengths: Highly specialized for aerospace applications with proven capability to produce large-scale functional rocket components with optimized weight-to-strength ratios. Their integrated machine learning approach enables continuous material parameter refinement. Weaknesses: Material parameter optimization is narrowly focused on metal alloys for aerospace, limiting applicability to other industries. High capital investment requirements for implementation of their technology stack.

Critical Material Properties Analysis for Mechanical Performance

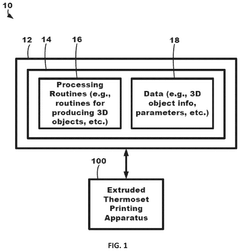

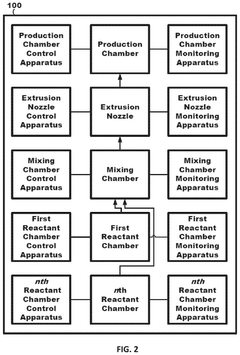

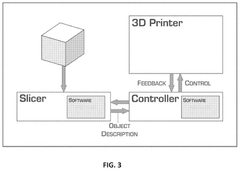

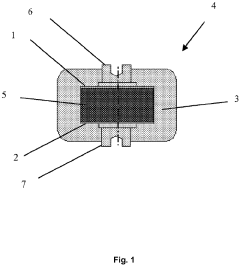

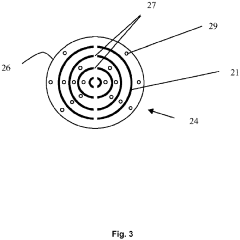

Three dimensional printing control

PatentPendingUS20250256459A1

Innovation

- The system controls various parameters like viscosity, degree of polymerization, and aspect ratio to print 3D objects using thermoset compositions, including extruded thermoset printing apparatus that monitors and adjusts environmental conditions, detects obstructions, and cleans nozzles to improve print quality and resolution.

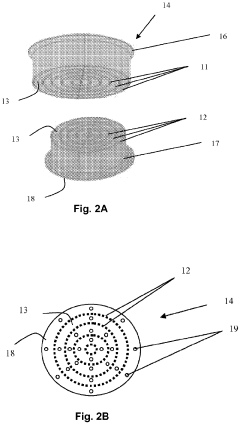

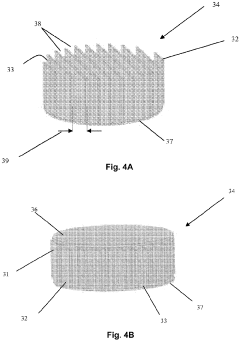

Material for 3D printing and a 3D printed device

PatentInactiveEP3459995A1

Innovation

- A 3D printing material comprising a polymeric composition with 50-99 wt.% ceramic particles of specific diameters (10-100 µm) and a thermoplastic polymer, enhancing dielectric strength to at least 5 kV/mm and dielectric constant to at least 5, allowing for complex device shapes and simplified electrode design.

Standardization and Testing Protocols for Material Parameters

The standardization of material parameters for volumetric 3D printing represents a critical foundation for ensuring consistent mechanical and thermal performance across different manufacturing environments. Currently, the industry faces significant challenges due to the lack of universally accepted testing protocols specifically designed for volumetric additive manufacturing processes. This gap hampers reliable comparison between different material formulations and printing techniques.

Established organizations including ASTM International, ISO, and the Additive Manufacturing Standardization Collaborative (AMSC) have begun developing specialized testing frameworks for volumetric 3D printing materials. These emerging protocols focus on quantifying key parameters such as photopolymerization kinetics, resin viscosity behavior under varying temperature conditions, and optical penetration depth—all crucial factors affecting final print quality and performance.

Material characterization methods must address the unique challenges of volumetric printing, particularly the simultaneous solidification throughout the material volume. Standard testing procedures should include rheological assessments at different exposure intensities, thermal conductivity measurements during curing processes, and mechanical property evaluations under various post-processing conditions. These protocols must account for the complex interplay between light absorption, scattering properties, and thermal management during the printing process.

Round-robin testing initiatives involving multiple research institutions have demonstrated that variations in testing equipment and environmental conditions can significantly impact measured material parameters. This underscores the urgent need for standardized calibration materials and reference samples specifically designed for volumetric printing technologies. Several international consortia are currently developing these reference materials to enable meaningful cross-laboratory comparisons.

Quality assurance frameworks for volumetric printing materials should incorporate both in-process monitoring techniques and post-fabrication testing protocols. Non-destructive evaluation methods such as optical coherence tomography and ultrasonic inspection are increasingly being adapted for volumetric printing applications to verify internal structural integrity without compromising the printed components.

The development of digital material passports containing standardized parameter sets represents an emerging trend in the field. These digital records enable manufacturers to precisely document material properties and processing conditions, facilitating reproducibility across different production environments. Such standardization efforts are essential for the industrial adoption of volumetric 3D printing technologies, particularly in highly regulated sectors such as aerospace, medical devices, and automotive applications.

Established organizations including ASTM International, ISO, and the Additive Manufacturing Standardization Collaborative (AMSC) have begun developing specialized testing frameworks for volumetric 3D printing materials. These emerging protocols focus on quantifying key parameters such as photopolymerization kinetics, resin viscosity behavior under varying temperature conditions, and optical penetration depth—all crucial factors affecting final print quality and performance.

Material characterization methods must address the unique challenges of volumetric printing, particularly the simultaneous solidification throughout the material volume. Standard testing procedures should include rheological assessments at different exposure intensities, thermal conductivity measurements during curing processes, and mechanical property evaluations under various post-processing conditions. These protocols must account for the complex interplay between light absorption, scattering properties, and thermal management during the printing process.

Round-robin testing initiatives involving multiple research institutions have demonstrated that variations in testing equipment and environmental conditions can significantly impact measured material parameters. This underscores the urgent need for standardized calibration materials and reference samples specifically designed for volumetric printing technologies. Several international consortia are currently developing these reference materials to enable meaningful cross-laboratory comparisons.

Quality assurance frameworks for volumetric printing materials should incorporate both in-process monitoring techniques and post-fabrication testing protocols. Non-destructive evaluation methods such as optical coherence tomography and ultrasonic inspection are increasingly being adapted for volumetric printing applications to verify internal structural integrity without compromising the printed components.

The development of digital material passports containing standardized parameter sets represents an emerging trend in the field. These digital records enable manufacturers to precisely document material properties and processing conditions, facilitating reproducibility across different production environments. Such standardization efforts are essential for the industrial adoption of volumetric 3D printing technologies, particularly in highly regulated sectors such as aerospace, medical devices, and automotive applications.

Environmental Impact of Advanced Printing Materials

The environmental impact of advanced printing materials used in volumetric 3D printing represents a critical consideration as this technology continues to evolve. Photopolymer resins, the primary material class employed in volumetric additive manufacturing, present significant environmental challenges throughout their lifecycle. These materials often contain potentially harmful components including photoinitiators, monomers, and various additives that can persist in ecosystems if improperly disposed of.

Material biodegradability emerges as a paramount concern, as conventional photopolymers typically exhibit poor degradation characteristics. Recent research has focused on developing bio-based alternatives derived from renewable resources such as cellulose, lignin, and plant oils. These materials demonstrate promising mechanical and thermal performance while offering improved environmental profiles compared to petroleum-based counterparts.

Energy consumption during material production represents another significant environmental factor. Traditional photopolymer synthesis processes are energy-intensive, contributing substantially to the carbon footprint of volumetric 3D printing. Materials requiring lower curing energies can significantly reduce the overall environmental impact of the printing process while maintaining essential mechanical and thermal properties.

Waste generation during printing operations presents ongoing challenges. Material parameters that enable higher printing precision and reduced support structure requirements directly correlate with decreased waste production. Additionally, materials designed with recyclability in mind can substantially mitigate environmental impact through closed-loop manufacturing systems, where post-consumer printed objects can be reprocessed into new printing materials.

Toxicity profiles of printing materials affect both environmental and human health outcomes. Low-toxicity formulations that maintain required mechanical and thermal performance specifications represent a critical research direction. Parameters such as leachable compound content, volatile organic compound (VOC) emissions during printing, and end-of-life toxicity all require careful optimization to minimize environmental harm.

Water consumption and contamination risks associated with material processing and post-processing steps present additional environmental considerations. Materials requiring minimal post-processing and washing steps can significantly reduce water usage and potential contamination issues, while still delivering the mechanical and thermal performance necessary for functional applications.

Material biodegradability emerges as a paramount concern, as conventional photopolymers typically exhibit poor degradation characteristics. Recent research has focused on developing bio-based alternatives derived from renewable resources such as cellulose, lignin, and plant oils. These materials demonstrate promising mechanical and thermal performance while offering improved environmental profiles compared to petroleum-based counterparts.

Energy consumption during material production represents another significant environmental factor. Traditional photopolymer synthesis processes are energy-intensive, contributing substantially to the carbon footprint of volumetric 3D printing. Materials requiring lower curing energies can significantly reduce the overall environmental impact of the printing process while maintaining essential mechanical and thermal properties.

Waste generation during printing operations presents ongoing challenges. Material parameters that enable higher printing precision and reduced support structure requirements directly correlate with decreased waste production. Additionally, materials designed with recyclability in mind can substantially mitigate environmental impact through closed-loop manufacturing systems, where post-consumer printed objects can be reprocessed into new printing materials.

Toxicity profiles of printing materials affect both environmental and human health outcomes. Low-toxicity formulations that maintain required mechanical and thermal performance specifications represent a critical research direction. Parameters such as leachable compound content, volatile organic compound (VOC) emissions during printing, and end-of-life toxicity all require careful optimization to minimize environmental harm.

Water consumption and contamination risks associated with material processing and post-processing steps present additional environmental considerations. Materials requiring minimal post-processing and washing steps can significantly reduce water usage and potential contamination issues, while still delivering the mechanical and thermal performance necessary for functional applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!