Volumetric 3D printing for high precision aerospace and automotive structural parts

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric 3D Printing Evolution and Objectives

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, evolving from traditional layer-by-layer approaches to a revolutionary volumetric solidification process. This evolution began in the early 2000s with initial theoretical frameworks, but significant breakthroughs only emerged around 2017-2019 when researchers at Lawrence Livermore National Laboratory and UC Berkeley demonstrated the first practical implementations of computed axial lithography (CAL).

The technology has progressed through several key developmental phases, starting with proof-of-concept demonstrations using photosensitive resins, advancing to multi-material capabilities, and now moving toward high-precision applications in critical industries. The fundamental innovation lies in its ability to solidify an entire volume simultaneously through controlled light projection from multiple angles, eliminating the layer lines and mechanical constraints inherent in conventional additive manufacturing.

For aerospace and automotive applications, volumetric 3D printing aims to address persistent challenges in manufacturing complex, high-performance structural components. Traditional manufacturing methods often require extensive tooling, generate substantial material waste, and struggle with intricate internal geometries. Conventional 3D printing, while offering design freedom, has been limited by surface quality issues, anisotropic mechanical properties, and relatively slow production rates.

The primary technical objectives for volumetric 3D printing in these high-precision sectors include achieving micron-level resolution for critical aerospace tolerances, ensuring consistent material properties throughout the printed volume, and developing specialized photopolymer formulations that meet stringent industry certification requirements. Additionally, there are goals to increase build volumes while maintaining precision, accelerate production speeds to enable economical manufacturing of larger components, and implement real-time quality monitoring systems.

From a materials perspective, the technology aims to expand beyond basic polymers to include high-performance composites, ceramics, and potentially metal-polymer hybrid materials specifically engineered for structural applications in extreme environments. This includes developing materials with exceptional thermal stability, fatigue resistance, and flame-retardant properties required for aerospace certification.

The long-term vision encompasses fully integrated digital manufacturing ecosystems where volumetric printing becomes seamlessly incorporated into aerospace and automotive production lines, enabling on-demand manufacturing of complex structural components with minimal post-processing requirements. This would revolutionize supply chains, reduce inventory needs, and enable rapid iteration of designs based on performance data from field applications.

The technology has progressed through several key developmental phases, starting with proof-of-concept demonstrations using photosensitive resins, advancing to multi-material capabilities, and now moving toward high-precision applications in critical industries. The fundamental innovation lies in its ability to solidify an entire volume simultaneously through controlled light projection from multiple angles, eliminating the layer lines and mechanical constraints inherent in conventional additive manufacturing.

For aerospace and automotive applications, volumetric 3D printing aims to address persistent challenges in manufacturing complex, high-performance structural components. Traditional manufacturing methods often require extensive tooling, generate substantial material waste, and struggle with intricate internal geometries. Conventional 3D printing, while offering design freedom, has been limited by surface quality issues, anisotropic mechanical properties, and relatively slow production rates.

The primary technical objectives for volumetric 3D printing in these high-precision sectors include achieving micron-level resolution for critical aerospace tolerances, ensuring consistent material properties throughout the printed volume, and developing specialized photopolymer formulations that meet stringent industry certification requirements. Additionally, there are goals to increase build volumes while maintaining precision, accelerate production speeds to enable economical manufacturing of larger components, and implement real-time quality monitoring systems.

From a materials perspective, the technology aims to expand beyond basic polymers to include high-performance composites, ceramics, and potentially metal-polymer hybrid materials specifically engineered for structural applications in extreme environments. This includes developing materials with exceptional thermal stability, fatigue resistance, and flame-retardant properties required for aerospace certification.

The long-term vision encompasses fully integrated digital manufacturing ecosystems where volumetric printing becomes seamlessly incorporated into aerospace and automotive production lines, enabling on-demand manufacturing of complex structural components with minimal post-processing requirements. This would revolutionize supply chains, reduce inventory needs, and enable rapid iteration of designs based on performance data from field applications.

Aerospace and Automotive Market Demand Analysis

The aerospace and automotive industries are experiencing a significant shift towards advanced manufacturing technologies, with volumetric 3D printing emerging as a transformative solution for high-precision structural components. Market research indicates that the global aerospace 3D printing market is projected to grow at a compound annual growth rate of 27.4% from 2021 to 2028, reaching approximately $6.8 billion by 2028. Similarly, the automotive 3D printing market is expected to expand at 23.5% CAGR during the same period, with a projected value of $5.3 billion by 2028.

In the aerospace sector, demand is primarily driven by the need for lightweight components that can reduce fuel consumption while maintaining structural integrity. Major aerospace manufacturers are actively seeking solutions that can decrease aircraft weight by 20-30% without compromising safety standards. The industry's push toward more fuel-efficient aircraft has created a substantial market for high-precision 3D printed parts, with particular emphasis on complex geometries that traditional manufacturing methods cannot efficiently produce.

The automotive industry demonstrates parallel demand patterns, with manufacturers focusing on weight reduction to improve fuel efficiency and meet increasingly stringent emissions regulations. Premium automotive manufacturers are leading adoption, incorporating 3D printed components in both prototyping and end-use applications. Market analysis reveals that approximately 65% of automotive manufacturers are currently exploring or implementing additive manufacturing technologies in their production processes.

Regional analysis shows North America and Europe dominating the market adoption of volumetric 3D printing technologies, accounting for approximately 70% of the current market share. However, Asia-Pacific regions, particularly Japan, South Korea, and China, are showing the fastest growth rates, with investments in aerospace and automotive manufacturing technologies increasing by over 30% annually.

Customer requirements across both industries emphasize several key performance indicators: dimensional accuracy within 10-50 microns, surface finish quality comparable to machined parts, mechanical properties matching or exceeding traditional materials, and production speeds compatible with medium-volume manufacturing requirements. Additionally, certification and quality assurance processes represent significant market entry barriers, with aerospace applications requiring extensive testing and validation protocols.

Cost considerations remain paramount, with industry stakeholders indicating willingness to adopt volumetric 3D printing technologies if they can demonstrate a 15-25% total cost reduction compared to traditional manufacturing methods when accounting for material usage efficiency, reduced assembly requirements, and lower tooling costs.

In the aerospace sector, demand is primarily driven by the need for lightweight components that can reduce fuel consumption while maintaining structural integrity. Major aerospace manufacturers are actively seeking solutions that can decrease aircraft weight by 20-30% without compromising safety standards. The industry's push toward more fuel-efficient aircraft has created a substantial market for high-precision 3D printed parts, with particular emphasis on complex geometries that traditional manufacturing methods cannot efficiently produce.

The automotive industry demonstrates parallel demand patterns, with manufacturers focusing on weight reduction to improve fuel efficiency and meet increasingly stringent emissions regulations. Premium automotive manufacturers are leading adoption, incorporating 3D printed components in both prototyping and end-use applications. Market analysis reveals that approximately 65% of automotive manufacturers are currently exploring or implementing additive manufacturing technologies in their production processes.

Regional analysis shows North America and Europe dominating the market adoption of volumetric 3D printing technologies, accounting for approximately 70% of the current market share. However, Asia-Pacific regions, particularly Japan, South Korea, and China, are showing the fastest growth rates, with investments in aerospace and automotive manufacturing technologies increasing by over 30% annually.

Customer requirements across both industries emphasize several key performance indicators: dimensional accuracy within 10-50 microns, surface finish quality comparable to machined parts, mechanical properties matching or exceeding traditional materials, and production speeds compatible with medium-volume manufacturing requirements. Additionally, certification and quality assurance processes represent significant market entry barriers, with aerospace applications requiring extensive testing and validation protocols.

Cost considerations remain paramount, with industry stakeholders indicating willingness to adopt volumetric 3D printing technologies if they can demonstrate a 15-25% total cost reduction compared to traditional manufacturing methods when accounting for material usage efficiency, reduced assembly requirements, and lower tooling costs.

Technical Barriers in High-Precision Volumetric Printing

Despite the promising potential of volumetric 3D printing for aerospace and automotive applications, several significant technical barriers currently impede its widespread industrial adoption for high-precision structural parts. The foremost challenge lies in achieving the necessary resolution and accuracy required for aerospace and automotive components, which often demand tolerances in the micrometer range. Current volumetric printing systems struggle to maintain consistent resolution throughout the entire build volume, with edge and corner regions typically exhibiting lower precision than central areas.

Material limitations represent another substantial hurdle. The photosensitive resins used in volumetric printing must simultaneously satisfy contradictory requirements: rapid curing for efficient production while maintaining controlled polymerization to prevent overcuring and ensure dimensional accuracy. Additionally, these materials must possess the mechanical properties necessary for structural applications, including high strength-to-weight ratios, temperature resistance, and fatigue performance—characteristics that current volumetric printing resins have not fully achieved.

Process control presents complex challenges, particularly in managing the light distribution within the resin volume. Optical aberrations, scattering effects, and absorption gradients can create inconsistencies in energy delivery, resulting in heterogeneous material properties throughout printed parts. These variations are particularly problematic for aerospace and automotive applications where consistent mechanical performance is critical for safety and reliability.

The scalability of volumetric printing technology poses another significant barrier. While laboratory demonstrations have shown promising results for small components, scaling the process to produce larger structural parts while maintaining precision remains technically challenging. The optical systems required for larger build volumes become increasingly complex and expensive, creating economic barriers to industrial implementation.

Post-processing requirements further complicate the manufacturing workflow. Unlike traditional manufacturing methods, volumetric printed parts often require extensive cleaning, curing, and surface finishing to meet aerospace and automotive specifications. These additional steps increase production time and cost while introducing potential quality variations.

Validation and certification represent perhaps the most formidable barriers for safety-critical applications. The aerospace and automotive industries operate under stringent regulatory frameworks that require extensive testing and documentation of manufacturing processes. The relatively novel nature of volumetric printing means that standardized testing protocols and certification pathways are still underdeveloped, creating significant regulatory uncertainty for potential adopters.

Computational challenges also persist in the real-time calculation of optimal light patterns and intensity distributions needed to create complex geometries with consistent material properties. These calculations must account for dynamic changes in optical properties as the resin transitions from liquid to solid state during the printing process.

Material limitations represent another substantial hurdle. The photosensitive resins used in volumetric printing must simultaneously satisfy contradictory requirements: rapid curing for efficient production while maintaining controlled polymerization to prevent overcuring and ensure dimensional accuracy. Additionally, these materials must possess the mechanical properties necessary for structural applications, including high strength-to-weight ratios, temperature resistance, and fatigue performance—characteristics that current volumetric printing resins have not fully achieved.

Process control presents complex challenges, particularly in managing the light distribution within the resin volume. Optical aberrations, scattering effects, and absorption gradients can create inconsistencies in energy delivery, resulting in heterogeneous material properties throughout printed parts. These variations are particularly problematic for aerospace and automotive applications where consistent mechanical performance is critical for safety and reliability.

The scalability of volumetric printing technology poses another significant barrier. While laboratory demonstrations have shown promising results for small components, scaling the process to produce larger structural parts while maintaining precision remains technically challenging. The optical systems required for larger build volumes become increasingly complex and expensive, creating economic barriers to industrial implementation.

Post-processing requirements further complicate the manufacturing workflow. Unlike traditional manufacturing methods, volumetric printed parts often require extensive cleaning, curing, and surface finishing to meet aerospace and automotive specifications. These additional steps increase production time and cost while introducing potential quality variations.

Validation and certification represent perhaps the most formidable barriers for safety-critical applications. The aerospace and automotive industries operate under stringent regulatory frameworks that require extensive testing and documentation of manufacturing processes. The relatively novel nature of volumetric printing means that standardized testing protocols and certification pathways are still underdeveloped, creating significant regulatory uncertainty for potential adopters.

Computational challenges also persist in the real-time calculation of optimal light patterns and intensity distributions needed to create complex geometries with consistent material properties. These calculations must account for dynamic changes in optical properties as the resin transitions from liquid to solid state during the printing process.

Current High-Precision Volumetric Printing Solutions

01 Advanced volumetric 3D printing techniques for high precision

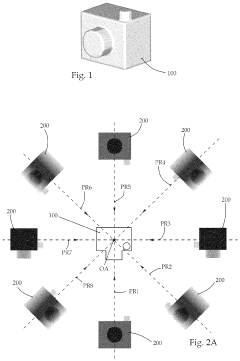

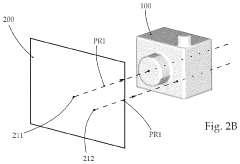

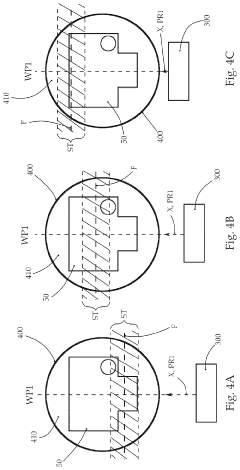

Volumetric 3D printing techniques have evolved to achieve higher precision through advanced methods such as computed axial lithography and tomographic volumetric additive manufacturing. These techniques allow for the simultaneous solidification of an entire volume of photopolymer resin, resulting in faster printing times and improved precision compared to traditional layer-by-layer approaches. The precision is enhanced through sophisticated algorithms that control light projection patterns and optimize energy distribution throughout the printing volume.- Volumetric 3D printing techniques for high precision: Volumetric 3D printing techniques enable high-precision fabrication by simultaneously curing entire volumes of photosensitive resin. These methods use specialized light patterns and optical systems to achieve precise control over the printing process, resulting in higher resolution and accuracy compared to traditional layer-by-layer approaches. The techniques often employ tomographic reconstruction algorithms to generate complex 3D structures with minimal distortion and improved surface quality.

- Light field control systems for enhanced printing precision: Advanced light field control systems are essential for achieving high precision in volumetric 3D printing. These systems utilize spatial light modulators, digital micromirror devices, or specialized optics to precisely shape and direct light patterns during the printing process. By controlling parameters such as light intensity, exposure time, and beam focus, these systems can significantly improve printing resolution and accuracy, enabling the fabrication of complex microstructures with feature sizes in the micrometer range.

- Materials and formulations for high-precision volumetric printing: Specialized photosensitive resins and material formulations play a crucial role in achieving high precision in volumetric 3D printing. These materials are designed with specific viscosity, curing kinetics, and optical properties to enable rapid solidification with minimal shrinkage and distortion. Additives such as photoinitiators, absorbers, and scattering agents can be incorporated to control light penetration depth and curing behavior, resulting in improved printing resolution and structural integrity of the printed objects.

- Calibration and error compensation methods: Calibration and error compensation methods are critical for achieving high precision in volumetric 3D printing. These techniques involve measuring and correcting for various sources of error, including optical distortions, material shrinkage, and mechanical misalignments. Advanced algorithms can analyze printing results and automatically adjust printing parameters to compensate for these errors. Real-time monitoring systems can also detect and correct deviations during the printing process, ensuring consistent precision across the entire printed volume.

- Software algorithms for volumetric data processing: Sophisticated software algorithms are essential for processing volumetric data and achieving high precision in 3D printing. These algorithms convert digital 3D models into optimized printing instructions, taking into account material properties, light propagation physics, and printer capabilities. Advanced computational techniques such as tomographic reconstruction, machine learning-based optimization, and physics-based simulations can predict and compensate for printing artifacts, resulting in significantly improved dimensional accuracy and surface quality of printed objects.

02 Optical systems for precision control in volumetric printing

Specialized optical systems play a crucial role in achieving high precision in volumetric 3D printing. These systems include advanced projection technologies, holographic displays, and precision light control mechanisms that enable accurate formation of complex three-dimensional structures. By precisely controlling light patterns, intensity, and focus across the printing volume, these optical systems can achieve micrometer-level precision in printed objects. Innovations in optical components such as spatial light modulators and specialized lenses have significantly contributed to improving the resolution and accuracy of volumetric printing.Expand Specific Solutions03 Materials and formulations for enhanced printing precision

The development of specialized photopolymer resins and other printing materials has significantly improved the precision capabilities of volumetric 3D printing. These materials are engineered with specific photosensitive properties that respond precisely to controlled light exposure, allowing for accurate solidification at intended locations within the printing volume. Advanced formulations include additives that control light scattering, absorption, and reaction kinetics, which collectively enhance resolution and feature definition in printed objects. The interaction between material properties and printing parameters is carefully optimized to achieve the highest possible precision.Expand Specific Solutions04 Computational methods for precision optimization

Sophisticated computational algorithms and software solutions are essential for achieving high precision in volumetric 3D printing. These include advanced tomographic reconstruction techniques, real-time feedback systems, and AI-driven optimization methods that continuously adjust printing parameters. By processing complex 3D model data and translating it into precise light projection patterns, these computational methods can compensate for material-specific challenges such as light scattering and absorption. Simulation-based approaches are also employed to predict and mitigate potential printing errors before physical fabrication begins.Expand Specific Solutions05 Calibration and error correction systems

Precision in volumetric 3D printing is significantly enhanced through advanced calibration and error correction systems. These systems employ sensors, imaging technologies, and feedback mechanisms to detect and compensate for deviations during the printing process. Real-time monitoring allows for dynamic adjustments to light patterns, intensity, and exposure times to maintain precision throughout the print job. Post-processing algorithms can also analyze printed structures and provide data for iterative improvements in subsequent prints. These calibration systems are crucial for achieving consistent precision across different printing conditions and material batches.Expand Specific Solutions

Leading Companies in Volumetric Additive Manufacturing

Volumetric 3D printing for high-precision aerospace and automotive structural parts is currently in an early growth phase, with the market expected to expand significantly as the technology matures. The global market for this specialized additive manufacturing segment is projected to reach $2-3 billion by 2026, driven by increasing demand for lightweight, complex components with superior mechanical properties. The technology maturity varies across players, with companies like HP Development Co. and Siemens Energy leading commercial applications, while research institutions such as École Polytechnique Fédérale de Lausanne and University of Maine focus on fundamental advancements. Aerospace leaders including Airbus Operations and Lufthansa Technik are actively integrating these technologies, while specialized firms like 3D Fortify and Quadratic 3D are developing proprietary solutions targeting specific material and precision challenges.

HP Development Co. LP

Technical Solution: HP's Multi Jet Fusion (MJF) technology represents a significant advancement in volumetric 3D printing for aerospace and automotive applications. The system works by depositing multiple chemical agents onto a powder bed using inkjet arrays, followed by applying energy to fuse selected areas. This creates parts layer by layer with exceptional precision (±0.2mm accuracy) and isotropic mechanical properties. HP has enhanced this technology specifically for aerospace and automotive structural components by developing specialized materials like PA 11 and PA 12 with glass beads that offer high strength-to-weight ratios and thermal stability up to 175°C[1]. Their latest systems incorporate real-time quality monitoring with thermal sensors and cameras that detect anomalies during printing, ensuring consistent part quality critical for aerospace certification requirements[2]. The technology achieves production speeds up to 10x faster than conventional methods while maintaining precision tolerances of 50-100 microns required for functional aerospace components.

Strengths: Superior surface finish quality compared to other powder-based technologies; excellent dimensional accuracy; high production throughput suitable for medium-volume manufacturing; strong material properties including flame retardancy required for aerospace applications. Weaknesses: Limited build volume compared to some industrial systems; higher initial investment costs; material options still more limited than traditional manufacturing methods.

3D Fortify, Inc.

Technical Solution: 3D Fortify has developed a revolutionary volumetric 3D printing technology called Digital Composite Manufacturing (DCM) specifically designed for high-performance structural components in aerospace and automotive applications. Their approach combines stereolithography with magnetic alignment of reinforcing fibers, creating composite parts with directionally controlled mechanical properties. The system uses a proprietary Continuous Kinetic Mixing (CKM) technology that ensures homogeneous distribution of reinforcement materials throughout the photopolymer resin, preventing sedimentation and maintaining consistent material properties throughout large builds[8]. Their FluxPrint technology applies precisely controlled magnetic fields during the printing process to align reinforcement fibers along optimal stress paths, resulting in parts with mechanical properties comparable to injection-molded composites but with complex geometries impossible to achieve through traditional manufacturing. The company has developed specialized high-temperature resins reinforced with ceramic fibers that maintain structural integrity up to 250°C, making them suitable for under-hood automotive applications and aerospace components exposed to elevated temperatures[9]. Their latest innovation includes an AI-driven process optimization system that automatically adjusts printing parameters based on part geometry and desired mechanical properties.

Strengths: Ability to create fiber-reinforced composites with directionally optimized properties; excellent strength-to-weight ratio; high temperature resistance; superior surface finish compared to filament-based methods. Weaknesses: Limited build volume compared to some industrial systems; higher material costs; longer post-processing requirements for certain applications; technology still relatively new to the market with fewer implementation examples.

Critical Patents in Volumetric 3D Printing Technology

3D Printing Method

PatentActiveUS20240094703A1

Innovation

- The method involves displacing the focal plane relative to the container when imaging projection images, ensuring at least half of the object's extension is within the depth of field range, and adjusting light intensity proportionally to the virtual object material, allowing for larger object production by extending the depth of field coverage.

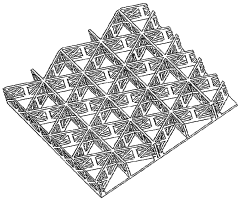

Method for forming microstructures or method for reducing the weight of massive components through the generation of microstructures

PatentWO2010061235A1

Innovation

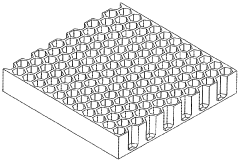

- The use of 3D printing technology to create microstructure materials with open structures at the micrometer scale, enabling the production of lightweight components with improved stability and cooling capabilities, and enabling the production of larger parts such as car bodies and aircraft components by scaling up printer dimensions while maintaining accuracy.

Material Science Advancements for Aerospace Applications

The aerospace industry's demand for high-performance materials has driven significant advancements in material science specifically tailored for volumetric 3D printing applications. These innovations focus on developing materials that can withstand extreme conditions while maintaining precise structural integrity required for aerospace components.

Advanced composite materials incorporating carbon fiber, ceramic matrices, and metal alloys have emerged as frontrunners in aerospace applications. These materials offer exceptional strength-to-weight ratios, thermal stability, and resistance to fatigue—critical properties for aerospace structural parts that must endure high stress and temperature variations during flight operations.

Recent breakthroughs in photopolymer resins have enabled volumetric 3D printing processes to achieve unprecedented precision at the microscale level. These specialized resins contain photoinitiators that respond to specific wavelengths of light, allowing for controlled solidification throughout the entire volume simultaneously rather than layer by layer. This advancement significantly reduces internal stresses and structural weaknesses common in traditional additive manufacturing methods.

Metamaterials engineered at the nanoscale represent another frontier in aerospace material science. These materials exhibit properties not found in nature, such as negative thermal expansion coefficients or programmable mechanical responses. When incorporated into volumetric 3D printing feedstock, they enable the creation of aerospace components with adaptive properties that can respond to environmental changes during flight.

High-temperature ceramic composites have been reformulated specifically for volumetric printing processes. These materials maintain structural integrity at temperatures exceeding 1500°C, making them ideal for components near engine compartments or hypersonic vehicle surfaces. The ability to print these materials volumetrically allows for complex internal cooling channels and thermal barrier structures that would be impossible to manufacture using conventional methods.

Self-healing material systems represent perhaps the most revolutionary advancement. These materials contain microcapsules of healing agents that activate when structural damage occurs. When implemented in critical aerospace components, they can significantly extend service life and enhance safety margins by autonomously repairing microfractures before they propagate into catastrophic failures.

Multi-material volumetric printing capabilities have also evolved, allowing aerospace engineers to design components with functionally graded properties. This enables seamless transitions between rigid and flexible sections, or between thermally conductive and insulating regions, optimizing performance while reducing weight and assembly requirements for complex aerospace structures.

Advanced composite materials incorporating carbon fiber, ceramic matrices, and metal alloys have emerged as frontrunners in aerospace applications. These materials offer exceptional strength-to-weight ratios, thermal stability, and resistance to fatigue—critical properties for aerospace structural parts that must endure high stress and temperature variations during flight operations.

Recent breakthroughs in photopolymer resins have enabled volumetric 3D printing processes to achieve unprecedented precision at the microscale level. These specialized resins contain photoinitiators that respond to specific wavelengths of light, allowing for controlled solidification throughout the entire volume simultaneously rather than layer by layer. This advancement significantly reduces internal stresses and structural weaknesses common in traditional additive manufacturing methods.

Metamaterials engineered at the nanoscale represent another frontier in aerospace material science. These materials exhibit properties not found in nature, such as negative thermal expansion coefficients or programmable mechanical responses. When incorporated into volumetric 3D printing feedstock, they enable the creation of aerospace components with adaptive properties that can respond to environmental changes during flight.

High-temperature ceramic composites have been reformulated specifically for volumetric printing processes. These materials maintain structural integrity at temperatures exceeding 1500°C, making them ideal for components near engine compartments or hypersonic vehicle surfaces. The ability to print these materials volumetrically allows for complex internal cooling channels and thermal barrier structures that would be impossible to manufacture using conventional methods.

Self-healing material systems represent perhaps the most revolutionary advancement. These materials contain microcapsules of healing agents that activate when structural damage occurs. When implemented in critical aerospace components, they can significantly extend service life and enhance safety margins by autonomously repairing microfractures before they propagate into catastrophic failures.

Multi-material volumetric printing capabilities have also evolved, allowing aerospace engineers to design components with functionally graded properties. This enables seamless transitions between rigid and flexible sections, or between thermally conductive and insulating regions, optimizing performance while reducing weight and assembly requirements for complex aerospace structures.

Quality Control and Certification Standards

Quality control and certification standards represent critical components in the adoption of volumetric 3D printing for aerospace and automotive applications. These industries operate under stringent regulatory frameworks that demand exceptional reliability and consistency in manufacturing processes. Currently, organizations such as ASTM International, SAE, and ISO are developing specialized standards for additive manufacturing that address the unique characteristics of volumetric 3D printing technologies.

For aerospace applications, certification standards like AS9100 must be integrated with specific protocols for volumetric printing processes. The FAA and EASA have established certification pathways for additively manufactured parts, requiring comprehensive material property databases, process parameter validation, and non-destructive testing methodologies specifically calibrated for volumetrically printed structures.

In the automotive sector, IATF 16949 quality management standards are being adapted to incorporate volumetric 3D printing processes. These adaptations focus on process capability indices, statistical process control methods, and failure mode analysis techniques tailored to the unique aspects of volumetric printing technologies.

Material certification represents a particular challenge, as volumetric printing introduces novel photopolymer formulations and curing mechanisms. Standards organizations are developing new testing protocols to characterize mechanical properties, environmental stability, and long-term performance of these materials under operational conditions specific to aerospace and automotive applications.

Non-destructive testing methodologies are evolving to address the unique internal structures created through volumetric printing. Advanced CT scanning protocols, ultrasonic testing parameters, and machine learning-based defect detection algorithms are being standardized to ensure consistent quality verification across the industry.

Digital thread certification is emerging as a critical component, establishing standards for data integrity throughout the design-to-manufacturing process. This includes requirements for digital signature verification, secure parameter transfer, and traceability of design changes that affect critical features of aerospace and automotive components.

Qualification procedures for volumetric 3D printing equipment are being formalized, with standards bodies defining calibration requirements, process monitoring parameters, and maintenance protocols necessary to maintain certification status. These standards typically require regular verification of optical systems, resin properties, and energy delivery mechanisms unique to volumetric printing technologies.

For aerospace applications, certification standards like AS9100 must be integrated with specific protocols for volumetric printing processes. The FAA and EASA have established certification pathways for additively manufactured parts, requiring comprehensive material property databases, process parameter validation, and non-destructive testing methodologies specifically calibrated for volumetrically printed structures.

In the automotive sector, IATF 16949 quality management standards are being adapted to incorporate volumetric 3D printing processes. These adaptations focus on process capability indices, statistical process control methods, and failure mode analysis techniques tailored to the unique aspects of volumetric printing technologies.

Material certification represents a particular challenge, as volumetric printing introduces novel photopolymer formulations and curing mechanisms. Standards organizations are developing new testing protocols to characterize mechanical properties, environmental stability, and long-term performance of these materials under operational conditions specific to aerospace and automotive applications.

Non-destructive testing methodologies are evolving to address the unique internal structures created through volumetric printing. Advanced CT scanning protocols, ultrasonic testing parameters, and machine learning-based defect detection algorithms are being standardized to ensure consistent quality verification across the industry.

Digital thread certification is emerging as a critical component, establishing standards for data integrity throughout the design-to-manufacturing process. This includes requirements for digital signature verification, secure parameter transfer, and traceability of design changes that affect critical features of aerospace and automotive components.

Qualification procedures for volumetric 3D printing equipment are being formalized, with standards bodies defining calibration requirements, process monitoring parameters, and maintenance protocols necessary to maintain certification status. These standards typically require regular verification of optical systems, resin properties, and energy delivery mechanisms unique to volumetric printing technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!