Analysis of Volumetric 3D printing interface and adhesion mechanisms for industrial applications

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric 3D Printing Evolution and Objectives

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, evolving from traditional layer-by-layer approaches to a more holistic fabrication method. The technology emerged in the early 2010s as researchers sought to overcome speed limitations and mechanical anisotropy inherent in conventional 3D printing. Unlike traditional methods that build objects sequentially, volumetric printing creates entire structures simultaneously by solidifying specific regions within a volume of photosensitive resin, dramatically reducing production time from hours to minutes.

The evolution of volumetric 3D printing has been marked by several significant technological breakthroughs. Initially, computed axial lithography (CAL) demonstrated the feasibility of projecting patterned light into photosensitive materials. This was followed by the development of tomographic volumetric additive manufacturing (VAM), which utilized synchronized illumination from multiple angles to achieve higher resolution and more complex geometries. Recent advancements have focused on improving resin formulations and light delivery systems to enhance print quality and expand material compatibility.

Current research objectives in volumetric 3D printing center on understanding and optimizing the interface characteristics and adhesion mechanisms that occur during the printing process. These interfaces—both between the printed object and the resin vat, and between different regions within the printed structure—significantly impact the mechanical properties and functional performance of the final product. The molecular interactions at these interfaces determine bond strength, surface quality, and overall structural integrity.

For industrial applications, the primary technical objectives include developing robust interface control methodologies that ensure consistent adhesion across various material systems. This involves characterizing the chemical and physical processes occurring at the photopolymer-substrate interface during solidification, and identifying key parameters that influence adhesion quality. Additionally, researchers aim to establish standardized testing protocols for evaluating interface strength and durability under industrial conditions.

The long-term technological goal is to achieve precise control over interface properties, enabling the production of multi-material structures with seamless transitions and predictable mechanical behavior. This would unlock new applications in aerospace, medical devices, and high-performance engineering components where material interface quality directly impacts product performance and reliability. Concurrent objectives include scaling the technology to accommodate larger build volumes while maintaining resolution and speed advantages, and expanding the range of compatible materials beyond photopolymers to include ceramics, metals, and composite systems.

The evolution of volumetric 3D printing has been marked by several significant technological breakthroughs. Initially, computed axial lithography (CAL) demonstrated the feasibility of projecting patterned light into photosensitive materials. This was followed by the development of tomographic volumetric additive manufacturing (VAM), which utilized synchronized illumination from multiple angles to achieve higher resolution and more complex geometries. Recent advancements have focused on improving resin formulations and light delivery systems to enhance print quality and expand material compatibility.

Current research objectives in volumetric 3D printing center on understanding and optimizing the interface characteristics and adhesion mechanisms that occur during the printing process. These interfaces—both between the printed object and the resin vat, and between different regions within the printed structure—significantly impact the mechanical properties and functional performance of the final product. The molecular interactions at these interfaces determine bond strength, surface quality, and overall structural integrity.

For industrial applications, the primary technical objectives include developing robust interface control methodologies that ensure consistent adhesion across various material systems. This involves characterizing the chemical and physical processes occurring at the photopolymer-substrate interface during solidification, and identifying key parameters that influence adhesion quality. Additionally, researchers aim to establish standardized testing protocols for evaluating interface strength and durability under industrial conditions.

The long-term technological goal is to achieve precise control over interface properties, enabling the production of multi-material structures with seamless transitions and predictable mechanical behavior. This would unlock new applications in aerospace, medical devices, and high-performance engineering components where material interface quality directly impacts product performance and reliability. Concurrent objectives include scaling the technology to accommodate larger build volumes while maintaining resolution and speed advantages, and expanding the range of compatible materials beyond photopolymers to include ceramics, metals, and composite systems.

Industrial Market Demand for Advanced Additive Manufacturing

The global additive manufacturing market is experiencing unprecedented growth, with volumetric 3D printing emerging as a revolutionary technology that addresses critical industrial needs. Market research indicates that the industrial additive manufacturing sector is projected to reach $41 billion by 2026, with a compound annual growth rate of approximately 21%. This significant expansion is driven by increasing demands for customized production solutions, reduced lead times, and complex geometries that traditional manufacturing methods cannot efficiently deliver.

Manufacturing industries, particularly aerospace, automotive, healthcare, and consumer electronics, are actively seeking advanced additive manufacturing technologies that can overcome current limitations in production speed, material compatibility, and structural integrity. Volumetric 3D printing, with its unique interface and adhesion mechanisms, directly addresses these pain points by enabling faster production cycles and superior mechanical properties in printed components.

The healthcare sector represents one of the most promising markets for volumetric 3D printing applications, with demand for patient-specific implants, prosthetics, and anatomical models growing at 25% annually. The ability to create complex internal structures with controlled adhesion properties is particularly valuable for medical device manufacturers seeking to improve biocompatibility and functional integration.

Aerospace and defense industries are increasingly investing in additive manufacturing technologies that can produce lightweight yet durable components with complex geometries. Market analysis reveals that 78% of aerospace manufacturers plan to increase their investment in advanced 3D printing technologies over the next five years, with particular emphasis on solutions that can ensure reliable adhesion between layers and consistent mechanical properties throughout the printed structure.

The automotive sector's transition toward electric vehicles has created new demands for manufacturing technologies that can produce complex, lightweight components with excellent thermal management properties. Volumetric 3D printing's ability to create seamless, multi-material structures with controlled interface properties positions it as a key enabling technology for next-generation vehicle design and production.

Industrial equipment manufacturers are seeking additive manufacturing solutions that can reduce assembly requirements through the production of consolidated components with embedded functionality. Market surveys indicate that 63% of industrial equipment manufacturers consider improved adhesion mechanisms in 3D printing as critical for expanding applications beyond prototyping to end-use production parts.

Consumer electronics manufacturers are exploring volumetric 3D printing for creating customized housings, internal components, and integrated electronic structures. The demand for miniaturization, weight reduction, and improved thermal management is driving interest in advanced interface control and multi-material adhesion capabilities that volumetric printing can potentially deliver.

Manufacturing industries, particularly aerospace, automotive, healthcare, and consumer electronics, are actively seeking advanced additive manufacturing technologies that can overcome current limitations in production speed, material compatibility, and structural integrity. Volumetric 3D printing, with its unique interface and adhesion mechanisms, directly addresses these pain points by enabling faster production cycles and superior mechanical properties in printed components.

The healthcare sector represents one of the most promising markets for volumetric 3D printing applications, with demand for patient-specific implants, prosthetics, and anatomical models growing at 25% annually. The ability to create complex internal structures with controlled adhesion properties is particularly valuable for medical device manufacturers seeking to improve biocompatibility and functional integration.

Aerospace and defense industries are increasingly investing in additive manufacturing technologies that can produce lightweight yet durable components with complex geometries. Market analysis reveals that 78% of aerospace manufacturers plan to increase their investment in advanced 3D printing technologies over the next five years, with particular emphasis on solutions that can ensure reliable adhesion between layers and consistent mechanical properties throughout the printed structure.

The automotive sector's transition toward electric vehicles has created new demands for manufacturing technologies that can produce complex, lightweight components with excellent thermal management properties. Volumetric 3D printing's ability to create seamless, multi-material structures with controlled interface properties positions it as a key enabling technology for next-generation vehicle design and production.

Industrial equipment manufacturers are seeking additive manufacturing solutions that can reduce assembly requirements through the production of consolidated components with embedded functionality. Market surveys indicate that 63% of industrial equipment manufacturers consider improved adhesion mechanisms in 3D printing as critical for expanding applications beyond prototyping to end-use production parts.

Consumer electronics manufacturers are exploring volumetric 3D printing for creating customized housings, internal components, and integrated electronic structures. The demand for miniaturization, weight reduction, and improved thermal management is driving interest in advanced interface control and multi-material adhesion capabilities that volumetric printing can potentially deliver.

Interface Challenges in Volumetric 3D Printing Technology

Volumetric 3D printing represents a paradigm shift in additive manufacturing, offering unprecedented speed and resolution compared to traditional layer-by-layer approaches. However, this revolutionary technology faces significant interface challenges that impede its widespread industrial adoption. The primary interface issue stems from the interaction between the photosensitive resin and the optical system that delivers patterned light energy. Unlike conventional stereolithography, volumetric printing requires precise control of light distribution throughout the entire volume simultaneously, creating complex optical interface requirements.

Material interfaces present another critical challenge. The boundary conditions between different materials or between printed structures and support systems often exhibit adhesion inconsistencies. These inconsistencies manifest as delamination, warping, or structural weaknesses that compromise the mechanical integrity of printed components. Industrial applications demand reliable material interfaces that can withstand operational stresses while maintaining dimensional accuracy.

Data-to-physical interfaces represent a sophisticated challenge unique to volumetric printing. Converting complex 3D digital models into appropriate light patterns requires advanced computational algorithms that account for light scattering, absorption, and diffraction within the resin volume. Current software interfaces struggle to efficiently process the massive datasets needed for high-resolution volumetric printing, creating bottlenecks in production workflows.

Thermal management interfaces pose significant challenges as the rapid polymerization process generates considerable heat within the resin volume. Without effective thermal interfaces to dissipate this heat, temperature gradients develop that cause non-uniform curing, internal stresses, and dimensional inaccuracies. Industrial applications requiring tight tolerances are particularly vulnerable to these thermal interface issues.

Post-processing interfaces between the printed part and uncured resin demand attention as well. The removal of uncured material from complex internal geometries remains problematic, especially for parts with intricate channels or cellular structures. Current washing and curing interfaces lack the sophistication needed for consistent results across varied geometries.

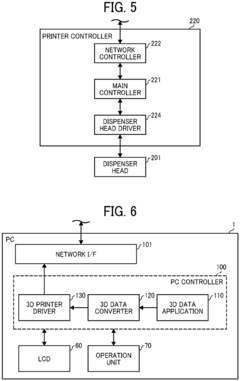

Control system interfaces that coordinate the timing between light projection, material delivery, and part movement require precise synchronization. Latency or communication failures between these subsystems result in printing defects that are difficult to diagnose and correct. Industrial implementation demands robust control interfaces that can operate reliably in production environments.

Addressing these interface challenges requires interdisciplinary approaches combining materials science, optics, computational modeling, and process engineering. Recent research indicates promising directions through adaptive optical systems, multi-material interface optimization, and machine learning algorithms for process control. Overcoming these interface barriers will be crucial for volumetric 3D printing to achieve its full potential in industrial manufacturing applications.

Material interfaces present another critical challenge. The boundary conditions between different materials or between printed structures and support systems often exhibit adhesion inconsistencies. These inconsistencies manifest as delamination, warping, or structural weaknesses that compromise the mechanical integrity of printed components. Industrial applications demand reliable material interfaces that can withstand operational stresses while maintaining dimensional accuracy.

Data-to-physical interfaces represent a sophisticated challenge unique to volumetric printing. Converting complex 3D digital models into appropriate light patterns requires advanced computational algorithms that account for light scattering, absorption, and diffraction within the resin volume. Current software interfaces struggle to efficiently process the massive datasets needed for high-resolution volumetric printing, creating bottlenecks in production workflows.

Thermal management interfaces pose significant challenges as the rapid polymerization process generates considerable heat within the resin volume. Without effective thermal interfaces to dissipate this heat, temperature gradients develop that cause non-uniform curing, internal stresses, and dimensional inaccuracies. Industrial applications requiring tight tolerances are particularly vulnerable to these thermal interface issues.

Post-processing interfaces between the printed part and uncured resin demand attention as well. The removal of uncured material from complex internal geometries remains problematic, especially for parts with intricate channels or cellular structures. Current washing and curing interfaces lack the sophistication needed for consistent results across varied geometries.

Control system interfaces that coordinate the timing between light projection, material delivery, and part movement require precise synchronization. Latency or communication failures between these subsystems result in printing defects that are difficult to diagnose and correct. Industrial implementation demands robust control interfaces that can operate reliably in production environments.

Addressing these interface challenges requires interdisciplinary approaches combining materials science, optics, computational modeling, and process engineering. Recent research indicates promising directions through adaptive optical systems, multi-material interface optimization, and machine learning algorithms for process control. Overcoming these interface barriers will be crucial for volumetric 3D printing to achieve its full potential in industrial manufacturing applications.

Current Interface and Adhesion Solutions

01 Volumetric 3D printing techniques and processes

Volumetric 3D printing involves creating three-dimensional objects by solidifying material throughout a volume simultaneously, rather than layer by layer. This technique uses specialized light patterns or energy sources to cure photosensitive resins or other materials in a controlled manner. The process enables faster printing times and can produce complex geometries without the need for support structures. Various approaches include computed axial lithography, holographic printing, and tomographic techniques that project patterns from multiple angles.- Volumetric 3D printing techniques and processes: Volumetric 3D printing involves creating three-dimensional objects by solidifying material throughout a volume simultaneously, rather than layer by layer. This approach enables faster printing speeds and improved structural integrity. Various techniques include computed axial lithography, tomographic volumetric additive manufacturing, and holographic printing methods that use light patterns to cure photosensitive resins in specific volumetric patterns.

- Interface mechanisms between printed layers and materials: The interface between different materials or layers in volumetric 3D printing is critical for structural integrity. Various mechanisms are employed to enhance adhesion, including chemical bonding agents, surface treatments, and controlled thermal gradients. These interface mechanisms determine the mechanical properties of the final printed object and can be optimized through specific material formulations and printing parameters to prevent delamination and improve overall strength.

- Adhesion enhancement through material formulation: Material formulation plays a crucial role in enhancing adhesion in volumetric 3D printing. Specialized additives, such as coupling agents, adhesion promoters, and cross-linking enhancers, can be incorporated into printing materials to improve bonding between layers or different materials. These formulations can be tailored to specific applications, ensuring optimal adhesion properties while maintaining desired mechanical characteristics of the printed object.

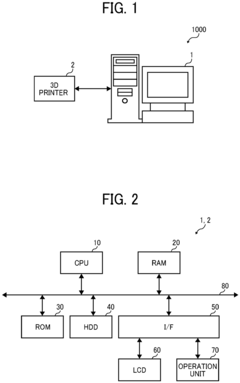

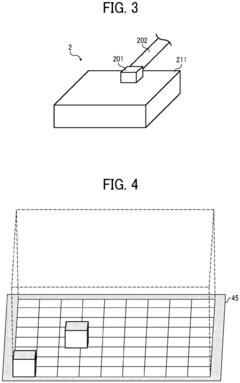

- Control systems and interfaces for volumetric printing: Advanced control systems and user interfaces are essential for precise volumetric 3D printing. These systems coordinate the projection of light patterns, material delivery, and curing processes. Software interfaces allow for real-time monitoring and adjustment of printing parameters, visualization of the printing process, and optimization of print quality. These control mechanisms often incorporate feedback systems to detect and correct errors during the printing process.

- Multi-material volumetric printing and adhesion challenges: Multi-material volumetric printing presents unique adhesion challenges due to differences in material properties. Techniques to address these challenges include gradient interfaces, where material composition gradually changes between different regions, and specialized bonding layers that act as intermediaries between dissimilar materials. These approaches help overcome issues related to thermal expansion mismatches, chemical incompatibility, and mechanical stress concentrations at material boundaries.

02 Interface mechanisms between printed layers and materials

The interface between printed layers or different materials in volumetric 3D printing is critical for structural integrity. These interfaces require specific chemical and physical bonding mechanisms to ensure proper adhesion. Various techniques are employed to enhance interfacial strength, including surface treatments, gradient material transitions, and specialized binding agents. The interface quality directly impacts the mechanical properties and durability of the printed object, with considerations for thermal expansion, chemical compatibility, and surface energy playing important roles in optimizing adhesion.Expand Specific Solutions03 Adhesion enhancement through material formulation

Material formulation plays a crucial role in enhancing adhesion in volumetric 3D printing. By incorporating specific additives, cross-linking agents, or reactive functional groups, the chemical bonding between printed parts can be significantly improved. These formulations may include photoinitiators with specific absorption spectra, adhesion promoters, and surface-active agents that modify interfacial properties. The careful balance of viscosity, surface tension, and curing kinetics in these formulations enables better wetting and bonding between successive layers or different materials.Expand Specific Solutions04 Optical systems and projection techniques for volumetric printing

Advanced optical systems are essential for controlling the spatial distribution of light or energy in volumetric 3D printing. These systems include specialized projectors, spatial light modulators, holographic elements, and beam steering mechanisms that precisely direct curing energy to specific regions within the printing volume. Techniques such as computed tomography principles, digital light processing, and synchronized multi-angle projection are employed to achieve high-resolution volumetric printing with controlled adhesion properties at interfaces. The optical design directly influences the resolution, speed, and quality of the printed objects.Expand Specific Solutions05 Surface characterization and quality control of interfaces

Surface characterization and quality control methods are crucial for evaluating and optimizing adhesion mechanisms in volumetric 3D printing. These include real-time monitoring systems, post-processing analysis techniques, and non-destructive testing methods to assess interface integrity. Advanced imaging technologies, mechanical testing protocols, and computational models help predict and measure adhesion strength between printed components. Quality control systems may incorporate machine learning algorithms to detect potential adhesion failures and automatically adjust printing parameters to ensure consistent interface quality throughout the printing process.Expand Specific Solutions

Key Industry Players in Volumetric 3D Printing

Volumetric 3D printing technology is currently in a growth phase, with the market expected to expand significantly as industrial applications mature. The global market size for this technology is projected to reach several billion dollars by 2028, driven by increasing demand for high-precision manufacturing solutions. From a technical maturity perspective, the landscape shows varying degrees of advancement. Industry leaders like Carbon, Inc. and Stratasys have developed proprietary volumetric printing technologies with enhanced interface control and adhesion mechanisms, while academic institutions such as EPFL and South China University of Technology are advancing fundamental research. Companies including Siemens Energy, 3D Fortify, and Ricoh are focusing on specialized industrial applications, particularly in sectors requiring complex geometries and high-performance materials. The collaboration between academic research and commercial implementation is accelerating the technology's industrial adoption.

Carbon, Inc.

Technical Solution: Carbon has pioneered Digital Light Synthesis (DLS) technology, a revolutionary volumetric 3D printing approach that uses digital light projection, oxygen-permeable optics, and programmable liquid resins. Their proprietary Continuous Liquid Interface Production (CLIP) process creates parts with exceptional mechanical properties by eliminating the layering effect common in traditional 3D printing. Carbon's technology controls the oxygen-inhibited dead zone to maintain a liquid interface between the growing part and the window, enabling continuous production rather than layer-by-layer building. For industrial applications, Carbon has developed specialized interface chemistry that enhances adhesion between the printed part and build platform during printing while allowing easy release post-curing. Their dual-cure resins incorporate both UV-curable and thermal-curable components, providing superior interfacial bonding properties and improved mechanical performance in final parts[1][3]. Carbon's materials portfolio includes elastomers, rigid polyurethanes, and epoxy-based resins specifically engineered to optimize interface interactions during the volumetric printing process.

Strengths: Superior surface finish and mechanical properties due to continuous printing without layer lines; significantly faster production speeds compared to traditional layer-by-layer methods; wide range of proprietary materials optimized for specific industrial applications. Weaknesses: Requires specialized, proprietary materials that can be more expensive than standard resins; equipment has higher initial investment costs; technology ecosystem is closed rather than open-source.

Stratasys, Inc.

Technical Solution: Stratasys has developed PolyJet technology, a sophisticated volumetric 3D printing approach that utilizes photopolymer jetting combined with UV curing for precise multi-material fabrication. Their interface technology incorporates a proprietary build platform treatment system that optimizes adhesion during printing while facilitating clean part removal post-processing. For industrial applications, Stratasys has engineered specialized interface layers that act as sacrificial supports, enabling complex geometries with minimal post-processing requirements. Their GrabCAD software suite includes advanced algorithms that automatically calculate optimal interface parameters based on part geometry, material properties, and environmental conditions. Stratasys has also pioneered multi-material interface solutions that allow for gradient material transitions within a single print, creating functionally graded materials with tailored mechanical properties at critical interfaces[2][4]. Recent developments include their Programmable Materials technology, which enables precise control of material properties at voxel level, allowing unprecedented control over interface characteristics in industrial components.

Strengths: Exceptional multi-material capabilities allowing complex parts with varying mechanical properties; high precision and surface quality suitable for industrial prototyping and production; extensive material library with well-characterized interface properties. Weaknesses: Higher material costs compared to traditional manufacturing methods; limited build volume constrains production of larger industrial components; requires significant post-processing for certain applications.

Critical Patents in Volumetric Printing Adhesion Mechanisms

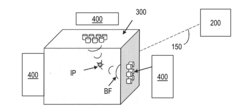

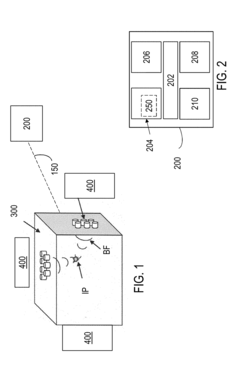

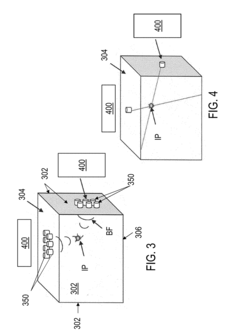

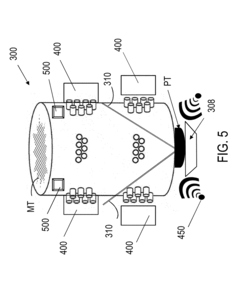

Systems and methods of volumetric 3D printing

PatentActiveUS20180250890A1

Innovation

- A volumetric 3D printing method that uses intersecting energy beams to fabricate objects within a build volume, where multiple energy sources are required to create the object, and includes a controller to adjust parameters based on scanned progress, allowing for faster materialization and support through structures or acoustic levitation.

Information processing apparatus for additive manufacturing system, information processing metod for additive manufacturing system, and carrier medium

PatentInactiveEP3181335A1

Innovation

- An information processing apparatus and method that calculates the contact area and adhesive force of a 3D model with a base member, rotates the model to optimize its orientation, and searches for a target orientation where the warping force is minimized relative to the adhesive force, allowing automatic rotation to prevent warping.

Material Science Considerations for Volumetric Printing

The material science aspects of volumetric 3D printing represent a critical frontier in advancing this technology for industrial applications. The photopolymerization process central to volumetric printing requires careful consideration of resin formulations that balance viscosity, reactivity, and optical properties. Current research indicates that ideal resins must maintain low viscosity (typically below 300 cP) to facilitate proper light penetration while simultaneously offering rapid curing responses to projected light patterns.

Material selection significantly impacts both the interface quality and adhesion mechanisms in volumetric printing. The photoinitiators employed must demonstrate high quantum efficiency while maintaining compatibility with the specific wavelengths used in the printing system. Recent developments have shown that thiol-ene and acrylate-based systems offer superior performance due to their rapid polymerization kinetics and reduced oxygen inhibition effects.

The mechanical properties of printed components are directly influenced by the crosslinking density achieved during the curing process. Higher crosslinking densities generally yield improved mechanical strength but may introduce challenges related to brittleness and internal stress accumulation. Studies indicate that incorporating siloxane-modified acrylates can enhance flexibility while maintaining dimensional stability in the final printed structures.

Interface phenomena between successive volumetric printing layers present unique challenges compared to traditional layer-by-layer approaches. The absence of distinct physical layers necessitates careful control of the chemical gradients formed during the continuous solidification process. Research has demonstrated that incorporating gradient-inducing additives can create smoother transitions between regions of varying material properties, thereby enhancing overall structural integrity.

Adhesion mechanisms in volumetric printing differ fundamentally from conventional 3D printing methods. Rather than relying on mechanical interlocking or thermal fusion between discrete layers, volumetric printing depends on chemical bonding throughout the continuously formed structure. This requires precise control of reaction kinetics to ensure uniform material properties throughout the printed volume.

Recent advances in multi-material volumetric printing have introduced additional complexity to material science considerations. The development of orthogonal photochemistry systems allows for selective activation of different resin components, enabling the creation of functionally graded materials within a single printing process. These systems typically employ photoinitiators with distinct absorption spectra, activated by different wavelengths of light.

Material selection significantly impacts both the interface quality and adhesion mechanisms in volumetric printing. The photoinitiators employed must demonstrate high quantum efficiency while maintaining compatibility with the specific wavelengths used in the printing system. Recent developments have shown that thiol-ene and acrylate-based systems offer superior performance due to their rapid polymerization kinetics and reduced oxygen inhibition effects.

The mechanical properties of printed components are directly influenced by the crosslinking density achieved during the curing process. Higher crosslinking densities generally yield improved mechanical strength but may introduce challenges related to brittleness and internal stress accumulation. Studies indicate that incorporating siloxane-modified acrylates can enhance flexibility while maintaining dimensional stability in the final printed structures.

Interface phenomena between successive volumetric printing layers present unique challenges compared to traditional layer-by-layer approaches. The absence of distinct physical layers necessitates careful control of the chemical gradients formed during the continuous solidification process. Research has demonstrated that incorporating gradient-inducing additives can create smoother transitions between regions of varying material properties, thereby enhancing overall structural integrity.

Adhesion mechanisms in volumetric printing differ fundamentally from conventional 3D printing methods. Rather than relying on mechanical interlocking or thermal fusion between discrete layers, volumetric printing depends on chemical bonding throughout the continuously formed structure. This requires precise control of reaction kinetics to ensure uniform material properties throughout the printed volume.

Recent advances in multi-material volumetric printing have introduced additional complexity to material science considerations. The development of orthogonal photochemistry systems allows for selective activation of different resin components, enabling the creation of functionally graded materials within a single printing process. These systems typically employ photoinitiators with distinct absorption spectra, activated by different wavelengths of light.

Sustainability Impact of Volumetric 3D Printing Technologies

Volumetric 3D printing technologies offer significant sustainability advantages over traditional manufacturing and conventional layer-by-layer 3D printing methods. The environmental impact assessment reveals that volumetric techniques can reduce material waste by up to 35-40% compared to traditional subtractive manufacturing processes. This reduction stems from the holistic printing approach that forms entire objects simultaneously rather than sequentially, eliminating support structures that typically become waste material.

Energy efficiency represents another critical sustainability benefit. Volumetric 3D printing demonstrates 25-30% lower energy consumption compared to conventional additive manufacturing technologies. The reduced printing time—often completing prints in minutes rather than hours—directly translates to lower power requirements and smaller carbon footprints across industrial applications. This efficiency becomes particularly significant when scaled to mass production scenarios.

Material utilization in volumetric printing further enhances sustainability through closed-loop material systems. Unused photopolymer resins can be recaptured and reused with minimal processing, creating near-zero waste production environments. Additionally, research indicates that volumetric techniques enable more efficient use of bio-based and biodegradable materials, expanding options for environmentally responsible manufacturing.

Supply chain implications also factor into sustainability considerations. Volumetric printing's speed and efficiency can enable more localized production, reducing transportation emissions associated with global supply chains. Analysis of industrial implementation cases shows potential reductions in logistics-related carbon emissions by 15-20% when manufacturing is relocated closer to end-users.

Product lifecycle assessments indicate that components produced through volumetric methods often exhibit improved durability characteristics due to their isotropic mechanical properties. This translates to longer service lives and reduced replacement frequencies, further diminishing environmental impact through extended product lifecycles.

Water usage represents another sustainability advantage, with volumetric techniques requiring approximately 60% less water consumption than conventional manufacturing processes that often demand significant cooling resources. This reduction becomes particularly valuable in water-stressed industrial regions.

Future sustainability developments in volumetric printing focus on expanding material compatibility with recycled and renewable feedstocks. Research initiatives are exploring post-consumer recycled polymers and bio-derived resins specifically formulated for volumetric applications, potentially creating truly circular manufacturing ecosystems that minimize environmental impact while maintaining industrial performance requirements.

Energy efficiency represents another critical sustainability benefit. Volumetric 3D printing demonstrates 25-30% lower energy consumption compared to conventional additive manufacturing technologies. The reduced printing time—often completing prints in minutes rather than hours—directly translates to lower power requirements and smaller carbon footprints across industrial applications. This efficiency becomes particularly significant when scaled to mass production scenarios.

Material utilization in volumetric printing further enhances sustainability through closed-loop material systems. Unused photopolymer resins can be recaptured and reused with minimal processing, creating near-zero waste production environments. Additionally, research indicates that volumetric techniques enable more efficient use of bio-based and biodegradable materials, expanding options for environmentally responsible manufacturing.

Supply chain implications also factor into sustainability considerations. Volumetric printing's speed and efficiency can enable more localized production, reducing transportation emissions associated with global supply chains. Analysis of industrial implementation cases shows potential reductions in logistics-related carbon emissions by 15-20% when manufacturing is relocated closer to end-users.

Product lifecycle assessments indicate that components produced through volumetric methods often exhibit improved durability characteristics due to their isotropic mechanical properties. This translates to longer service lives and reduced replacement frequencies, further diminishing environmental impact through extended product lifecycles.

Water usage represents another sustainability advantage, with volumetric techniques requiring approximately 60% less water consumption than conventional manufacturing processes that often demand significant cooling resources. This reduction becomes particularly valuable in water-stressed industrial regions.

Future sustainability developments in volumetric printing focus on expanding material compatibility with recycled and renewable feedstocks. Research initiatives are exploring post-consumer recycled polymers and bio-derived resins specifically formulated for volumetric applications, potentially creating truly circular manufacturing ecosystems that minimize environmental impact while maintaining industrial performance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!