Comparative analysis of Volumetric 3D printing layer versus volumetric fabrication methods

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric 3D Printing Evolution and Objectives

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, evolving from traditional layer-by-layer approaches to more sophisticated volumetric fabrication methods. The evolution began in the early 2000s with the development of stereolithography (SLA) and digital light processing (DLP), which laid the groundwork for volumetric techniques. By 2015, researchers started exploring computed axial lithography (CAL) and tomographic volumetric additive manufacturing (VAM), marking significant advancements in the field.

The fundamental distinction between layer-based and volumetric approaches lies in their fabrication philosophy. Layer-based methods build objects sequentially, depositing or curing material in discrete layers, which inherently creates anisotropic mechanical properties and visible layer lines. In contrast, volumetric methods generate entire volumes simultaneously through selective solidification within a photosensitive resin vat, resulting in isotropic structures with superior mechanical integrity.

Recent technological breakthroughs have accelerated volumetric printing development. The introduction of two-photon polymerization enabled unprecedented resolution at microscales, while holographic volumetric printing demonstrated the ability to create complex internal structures without support materials. Computed tomography-inspired techniques have further refined control over spatial resolution and material properties, allowing for gradient materials and embedded functionalities.

The primary objectives of volumetric 3D printing research focus on overcoming the limitations of traditional layer-based approaches. These include eliminating the "staircase effect" that compromises surface finish, reducing production times by orders of magnitude, and enabling the creation of previously impossible geometries with embedded features. Additionally, researchers aim to expand material compatibility beyond photopolymers to include ceramics, metals, and biomaterials.

Current research trajectories indicate several promising directions. Multi-material volumetric printing represents a frontier with potential applications in functional electronics and biomedical devices. Resolution enhancement techniques are being developed to achieve sub-micron precision across larger build volumes. Perhaps most significantly, real-time feedback systems incorporating machine learning algorithms are being integrated to monitor and adjust fabrication parameters dynamically, ensuring consistent quality and enabling adaptive manufacturing processes.

The convergence of volumetric fabrication with complementary technologies such as 4D printing (incorporating time-dependent transformation) and bioprinting suggests an expansive future where the boundaries between digital design and physical realization continue to blur, potentially revolutionizing industries from healthcare to aerospace.

The fundamental distinction between layer-based and volumetric approaches lies in their fabrication philosophy. Layer-based methods build objects sequentially, depositing or curing material in discrete layers, which inherently creates anisotropic mechanical properties and visible layer lines. In contrast, volumetric methods generate entire volumes simultaneously through selective solidification within a photosensitive resin vat, resulting in isotropic structures with superior mechanical integrity.

Recent technological breakthroughs have accelerated volumetric printing development. The introduction of two-photon polymerization enabled unprecedented resolution at microscales, while holographic volumetric printing demonstrated the ability to create complex internal structures without support materials. Computed tomography-inspired techniques have further refined control over spatial resolution and material properties, allowing for gradient materials and embedded functionalities.

The primary objectives of volumetric 3D printing research focus on overcoming the limitations of traditional layer-based approaches. These include eliminating the "staircase effect" that compromises surface finish, reducing production times by orders of magnitude, and enabling the creation of previously impossible geometries with embedded features. Additionally, researchers aim to expand material compatibility beyond photopolymers to include ceramics, metals, and biomaterials.

Current research trajectories indicate several promising directions. Multi-material volumetric printing represents a frontier with potential applications in functional electronics and biomedical devices. Resolution enhancement techniques are being developed to achieve sub-micron precision across larger build volumes. Perhaps most significantly, real-time feedback systems incorporating machine learning algorithms are being integrated to monitor and adjust fabrication parameters dynamically, ensuring consistent quality and enabling adaptive manufacturing processes.

The convergence of volumetric fabrication with complementary technologies such as 4D printing (incorporating time-dependent transformation) and bioprinting suggests an expansive future where the boundaries between digital design and physical realization continue to blur, potentially revolutionizing industries from healthcare to aerospace.

Market Analysis for Advanced Volumetric Fabrication

The volumetric fabrication market is experiencing significant growth, driven by advancements in technology and increasing demand across various industries. Current market estimates value the global 3D printing market at approximately $16 billion, with volumetric fabrication methods representing an emerging segment poised for rapid expansion. Industry analysts project a compound annual growth rate of 20-25% for advanced volumetric fabrication technologies over the next five years, outpacing traditional layer-by-layer 3D printing methods.

Healthcare and biomedical applications currently dominate the volumetric fabrication market, accounting for nearly 40% of total market share. The ability to rapidly produce complex biological structures with high precision has positioned volumetric methods as revolutionary tools for tissue engineering, personalized implants, and drug delivery systems. Several leading medical device manufacturers have already incorporated volumetric fabrication into their production processes, reporting significant reductions in manufacturing time and improved product performance.

The industrial manufacturing sector represents the second-largest market segment, with automotive, aerospace, and consumer electronics companies increasingly adopting volumetric fabrication for prototyping and small-batch production. These industries value the technology's ability to produce complex geometries with internal features that would be challenging or impossible to create using traditional manufacturing methods.

Regional analysis reveals North America as the current market leader, holding approximately 45% of the global volumetric fabrication market share. This dominance stems from substantial R&D investments, strong presence of key technology developers, and early adoption across multiple industries. Europe follows with roughly 30% market share, while the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding manufacturing capabilities and government initiatives supporting advanced manufacturing technologies.

Customer demand patterns indicate a growing preference for volumetric fabrication solutions that offer faster production speeds, higher resolution, and expanded material compatibility. End-users consistently cite production speed as the primary advantage of volumetric methods over layer-by-layer approaches, with some systems demonstrating 10-100x faster production times for certain applications.

Market barriers include high equipment costs, limited material options compared to traditional 3D printing, and technical challenges related to scaling production volumes. However, ongoing research and commercial development efforts are rapidly addressing these limitations, with several breakthrough technologies expected to reach commercial maturity within the next 2-3 years.

The competitive landscape features both established 3D printing companies expanding into volumetric methods and specialized startups focused exclusively on volumetric fabrication technologies. Strategic partnerships between technology developers, material suppliers, and end-users are becoming increasingly common, accelerating commercialization and market adoption.

Healthcare and biomedical applications currently dominate the volumetric fabrication market, accounting for nearly 40% of total market share. The ability to rapidly produce complex biological structures with high precision has positioned volumetric methods as revolutionary tools for tissue engineering, personalized implants, and drug delivery systems. Several leading medical device manufacturers have already incorporated volumetric fabrication into their production processes, reporting significant reductions in manufacturing time and improved product performance.

The industrial manufacturing sector represents the second-largest market segment, with automotive, aerospace, and consumer electronics companies increasingly adopting volumetric fabrication for prototyping and small-batch production. These industries value the technology's ability to produce complex geometries with internal features that would be challenging or impossible to create using traditional manufacturing methods.

Regional analysis reveals North America as the current market leader, holding approximately 45% of the global volumetric fabrication market share. This dominance stems from substantial R&D investments, strong presence of key technology developers, and early adoption across multiple industries. Europe follows with roughly 30% market share, while the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding manufacturing capabilities and government initiatives supporting advanced manufacturing technologies.

Customer demand patterns indicate a growing preference for volumetric fabrication solutions that offer faster production speeds, higher resolution, and expanded material compatibility. End-users consistently cite production speed as the primary advantage of volumetric methods over layer-by-layer approaches, with some systems demonstrating 10-100x faster production times for certain applications.

Market barriers include high equipment costs, limited material options compared to traditional 3D printing, and technical challenges related to scaling production volumes. However, ongoing research and commercial development efforts are rapidly addressing these limitations, with several breakthrough technologies expected to reach commercial maturity within the next 2-3 years.

The competitive landscape features both established 3D printing companies expanding into volumetric methods and specialized startups focused exclusively on volumetric fabrication technologies. Strategic partnerships between technology developers, material suppliers, and end-users are becoming increasingly common, accelerating commercialization and market adoption.

Current Technological Landscape and Barriers

Volumetric 3D printing represents a paradigm shift from traditional layer-by-layer additive manufacturing approaches. Currently, two primary volumetric fabrication methods dominate the technological landscape: computed axial lithography (CAL) and holographic stereolithography. CAL utilizes synchronized rotation and projection to cure entire volumes simultaneously, while holographic approaches employ spatial light modulators to create complex light patterns that solidify specific regions within photosensitive resins.

The global market for volumetric 3D printing technologies remains in its nascent stage, with research institutions and specialized companies leading development efforts. Key players include Readily3D, Xolo, and Lawrence Livermore National Laboratory, each pursuing distinct technical approaches to volumetric fabrication. Market adoption remains limited primarily to research applications and specialized industrial prototyping scenarios.

Despite promising advances, significant technical barriers persist in volumetric fabrication methods. Resolution limitations represent a primary challenge, with current systems typically achieving feature sizes of 80-100 microns—substantially coarser than advanced layer-based techniques capable of sub-10 micron resolution. This limitation stems from optical constraints including light scattering, diffraction effects, and resin opacity at higher concentrations of photoinitiators.

Material compatibility presents another substantial barrier. Volumetric methods require specialized photopolymer formulations with precisely balanced absorption and scattering properties. The current material palette remains restricted compared to conventional layer-based approaches, limiting application versatility. Additionally, achieving consistent mechanical properties throughout volumetrically printed objects remains challenging due to non-uniform light distribution and curing dynamics.

Processing speed, while theoretically advantageous in volumetric approaches, faces practical limitations. Current systems require extended exposure times (typically 30-180 seconds) to ensure complete polymerization throughout the volume, partially negating the speed advantage over layer-based methods for complex geometries. Furthermore, the computational requirements for calculating optimal light patterns increase exponentially with object complexity.

Scalability represents perhaps the most significant barrier to widespread adoption. Current volumetric systems are limited to relatively small build volumes (typically under 100cm³) due to optical constraints and resin properties. Scaling to larger volumes introduces challenges in maintaining uniform light distribution and managing heat dissipation during the curing process.

Infrastructure requirements present additional barriers, as volumetric systems often demand specialized equipment, controlled environments, and expertise not commonly available in traditional manufacturing settings. The high initial investment costs and operational complexity have limited adoption primarily to research institutions and specialized industrial applications with specific requirements that justify the investment.

The global market for volumetric 3D printing technologies remains in its nascent stage, with research institutions and specialized companies leading development efforts. Key players include Readily3D, Xolo, and Lawrence Livermore National Laboratory, each pursuing distinct technical approaches to volumetric fabrication. Market adoption remains limited primarily to research applications and specialized industrial prototyping scenarios.

Despite promising advances, significant technical barriers persist in volumetric fabrication methods. Resolution limitations represent a primary challenge, with current systems typically achieving feature sizes of 80-100 microns—substantially coarser than advanced layer-based techniques capable of sub-10 micron resolution. This limitation stems from optical constraints including light scattering, diffraction effects, and resin opacity at higher concentrations of photoinitiators.

Material compatibility presents another substantial barrier. Volumetric methods require specialized photopolymer formulations with precisely balanced absorption and scattering properties. The current material palette remains restricted compared to conventional layer-based approaches, limiting application versatility. Additionally, achieving consistent mechanical properties throughout volumetrically printed objects remains challenging due to non-uniform light distribution and curing dynamics.

Processing speed, while theoretically advantageous in volumetric approaches, faces practical limitations. Current systems require extended exposure times (typically 30-180 seconds) to ensure complete polymerization throughout the volume, partially negating the speed advantage over layer-based methods for complex geometries. Furthermore, the computational requirements for calculating optimal light patterns increase exponentially with object complexity.

Scalability represents perhaps the most significant barrier to widespread adoption. Current volumetric systems are limited to relatively small build volumes (typically under 100cm³) due to optical constraints and resin properties. Scaling to larger volumes introduces challenges in maintaining uniform light distribution and managing heat dissipation during the curing process.

Infrastructure requirements present additional barriers, as volumetric systems often demand specialized equipment, controlled environments, and expertise not commonly available in traditional manufacturing settings. The high initial investment costs and operational complexity have limited adoption primarily to research institutions and specialized industrial applications with specific requirements that justify the investment.

Comparative Analysis of Layer-based vs. Volumetric Methods

01 Continuous volumetric 3D printing techniques

Continuous volumetric 3D printing involves techniques that allow for the creation of entire 3D objects simultaneously rather than layer by layer. These methods use photosensitive resins that solidify when exposed to specific light patterns, enabling faster production times and improved surface quality. The process eliminates the need for support structures and layer lines, resulting in smoother finished products with better mechanical properties. Advanced algorithms control the light patterns to ensure precise geometry and internal structures.- Continuous volumetric 3D printing techniques: Continuous volumetric 3D printing involves techniques that allow for the creation of entire 3D objects simultaneously rather than layer by layer. These methods use photosensitive resins that solidify when exposed to specific light patterns, enabling faster production times and improved surface quality. The process typically involves projecting synchronized light patterns into a volume of photocurable material, creating complex structures without the need for support materials or layer-by-layer processing.

- Light-based volumetric fabrication systems: Light-based volumetric fabrication systems utilize specialized optical setups to project patterned light into photosensitive materials. These systems employ techniques such as computed tomography, holographic projection, or synchronized multi-angle illumination to create three-dimensional structures with high resolution. The approach eliminates mechanical constraints of traditional layer-by-layer printing, resulting in faster build times and the ability to create complex internal geometries that would be difficult with conventional methods.

- Material formulations for volumetric printing: Specialized material formulations are critical for successful volumetric 3D printing. These materials typically include photopolymers with carefully balanced photoinitiators, absorbers, and other additives that control light penetration depth and reaction kinetics. Advanced formulations enable precise control over solidification processes, allowing for uniform curing throughout the volume while maintaining high resolution and structural integrity. These materials are designed to respond to specific wavelengths of light with predictable curing characteristics.

- Process optimization for fabrication efficiency: Process optimization techniques for volumetric 3D printing focus on maximizing fabrication speed while maintaining quality. This includes computational methods for determining optimal exposure patterns, timing sequences, and energy distribution. Advanced algorithms analyze object geometry to calculate ideal fabrication parameters, reducing print times and material waste. Optimization strategies also include thermal management, resin flow dynamics, and post-processing techniques that collectively enhance production efficiency without compromising structural integrity or dimensional accuracy.

- Quality control and monitoring systems: Quality control systems for volumetric 3D printing incorporate real-time monitoring technologies that analyze the fabrication process as it occurs. These systems use sensors, cameras, and computational feedback loops to detect anomalies and make adjustments during printing. Advanced monitoring techniques include optical coherence tomography, spectroscopic analysis, and machine vision systems that verify dimensional accuracy and material properties. These quality assurance methods ensure consistent results by identifying and correcting issues before they affect the final product.

02 Light-based volumetric fabrication methods

Light-based volumetric fabrication utilizes controlled light patterns to cure photopolymer resins throughout their volume simultaneously. These methods include computed axial lithography (CAL), holographic stereolithography, and tomographic techniques that project synchronized patterns of light from multiple angles. By carefully controlling the light intensity, wavelength, and exposure time, these systems can create complex internal structures and achieve high resolution while significantly reducing production time compared to conventional layer-by-layer approaches.Expand Specific Solutions03 Material formulations for volumetric printing

Specialized photopolymer formulations are essential for successful volumetric 3D printing. These materials contain photoinitiators that respond to specific wavelengths of light, allowing for controlled solidification throughout the volume. Advanced formulations incorporate oxygen inhibition control, viscosity modifiers, and optical clarifiers to improve printing resolution and part quality. Some materials also feature self-healing properties or gradient curing capabilities that enhance the mechanical properties and surface finish of the final printed objects.Expand Specific Solutions04 Process optimization for efficiency and quality

Optimizing volumetric 3D printing processes involves balancing multiple parameters to achieve both high efficiency and quality. This includes calibrating light intensity distributions, controlling exposure times, and implementing real-time monitoring systems. Advanced algorithms dynamically adjust printing parameters based on feedback from sensors that monitor resin properties and curing progression. Temperature control systems and post-processing techniques further enhance part quality while maintaining high production speeds. These optimizations collectively minimize material waste and energy consumption while maximizing geometric accuracy.Expand Specific Solutions05 Multi-material and functional volumetric printing

Advanced volumetric printing systems enable the fabrication of multi-material and functionally graded objects. These systems utilize multiple resin reservoirs or selective activation of different photoinitiators within a single resin bath. By precisely controlling the spatial distribution of materials with varying properties, these techniques can create objects with region-specific mechanical, optical, or electrical characteristics. This capability is particularly valuable for producing complex devices with embedded functionality, such as soft robotics components, medical devices, and customized prosthetics with biomimetic properties.Expand Specific Solutions

Industry Leaders in Volumetric Fabrication Technologies

Volumetric 3D printing technology is currently in an early growth phase, with the market expanding rapidly due to its significant advantages over traditional layer-by-layer methods. The global market is projected to reach substantial value as industries recognize the benefits of faster production speeds and improved structural integrity. From a technological maturity perspective, key players are advancing at different rates. Academic institutions like MIT and EPFL are pioneering fundamental research, while companies such as Readily3D and Looking Glass Factory are commercializing practical applications. Industrial giants including Toyota, Siemens Energy, and Sony are investing in volumetric fabrication to enhance manufacturing capabilities. Chinese institutions like Hunan University and companies such as Zhuhai Sailner Technology are rapidly closing the technological gap, particularly in multi-material applications and specialized industrial implementations.

École Polytechnique Fédérale de Lausanne

Technical Solution: EPFL has developed a groundbreaking volumetric 3D printing technique called tomographic volumetric additive manufacturing (VAM). This approach uses visible light tomography to cure entire volumes of photosensitive resin simultaneously, rather than building objects layer by layer. The technology projects calculated light patterns from multiple angles into a rotating container of photosensitive material, creating complex 3D structures in seconds rather than hours. EPFL's implementation achieves printing speeds up to 100 times faster than conventional methods, with resolution capabilities below 100 micrometers. Their research has demonstrated the ability to print objects with complex internal geometries, overhangs, and hollow structures without the need for support materials. The technology has been particularly successful in bioprinting applications, allowing the creation of cell-laden structures with high cell viability due to the gentle, support-free process[1][4].

Strengths: Revolutionary speed (complete objects in seconds vs. hours); excellent for creating complex biological structures; high resolution capabilities; eliminates support structures and associated post-processing. Weaknesses: Currently limited to photopolymer materials; size constraints based on optical setup and resin container dimensions; technology still evolving toward broader commercial applications.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered volumetric 3D printing through their Computer Science and Artificial Intelligence Laboratory (CSAIL), developing a technique called "computed axial lithography" (CAL). This approach creates objects by projecting patterns of light into a rotating volume of photosensitive resin, allowing the entire object to be formed simultaneously rather than layer by layer. MIT's implementation uses sophisticated algorithms to calculate the optimal light patterns needed from different angles, which when combined, solidify the desired 3D shape within seconds. Their system achieves printing speeds up to 100 times faster than conventional layer-based methods, with resolution capabilities reaching 0.3mm in commercial implementations. The technology eliminates the need for support structures and enables the creation of objects with complex internal geometries that would be challenging or impossible with traditional methods[1][3].

Strengths: Dramatically faster production times (minutes vs. hours); ability to create objects with complex internal structures without supports; excellent for creating objects with smooth surfaces without visible layer lines. Weaknesses: Currently limited in material selection compared to traditional methods; size constraints based on the volume of resin container; higher initial equipment costs.

Key Patents and Research in Volumetric Fabrication

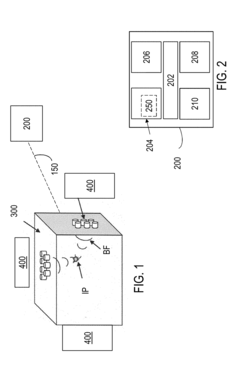

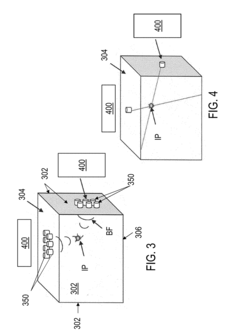

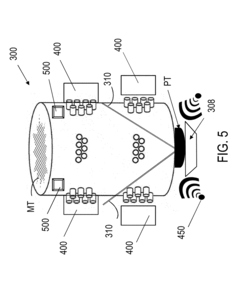

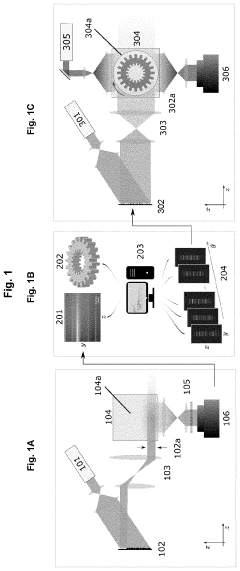

Systems and methods of volumetric 3D printing

PatentActiveUS20180250890A1

Innovation

- A volumetric 3D printing method that uses intersecting energy beams to fabricate objects within a build volume, where multiple energy sources are required to create the object, and includes a controller to adjust parameters based on scanned progress, allowing for faster materialization and support through structures or acoustic levitation.

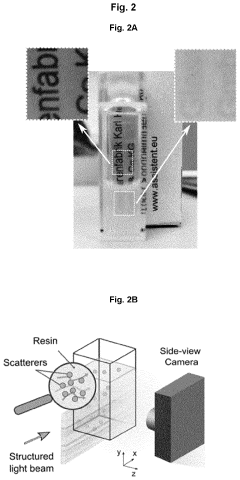

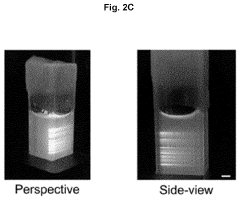

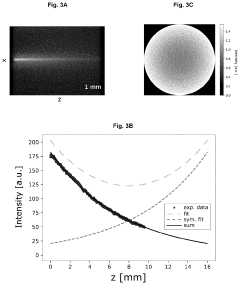

High resolution and three-dimensional printing in complex photosensitive materials

PatentPendingUS20240239039A1

Innovation

- A method and apparatus that account for light scattering by characterizing and correcting light patterns using a 3-step protocol involving light scattering characterization, computation of optimized patterns, and implementation in a tomographic manufacturing system, incorporating a side-view camera and spatial light modulators to improve print fidelity and resolution in non-transparent materials.

Material Science Considerations for Volumetric Printing

Material selection for volumetric printing represents a critical factor that significantly influences the quality, functionality, and applicability of printed objects. Unlike traditional layer-by-layer 3D printing methods, volumetric fabrication techniques require materials with specific photochemical properties that respond uniformly to spatial light patterns or other energy sources throughout the entire volume simultaneously.

Photopolymer resins constitute the primary material class for volumetric printing, requiring careful formulation to achieve optimal performance. These resins must possess balanced light absorption characteristics—sufficient to initiate polymerization but not so high as to prevent light penetration through the entire volume. This delicate balance presents a fundamental materials science challenge unique to volumetric methods.

The photoinitiator selection plays a crucial role in volumetric printing processes. Ideal photoinitiators demonstrate high quantum efficiency, appropriate absorption spectra matching the light source, and minimal light scattering properties. Recent advances have introduced dual-wavelength photoinitiator systems that allow for more precise spatial control of the polymerization process throughout the volume.

Viscosity management represents another key consideration for volumetric printing materials. The resin must maintain appropriate flow characteristics during the printing process while enabling rapid solidification upon exposure to the activation energy. This property directly impacts resolution capabilities and structural integrity of the final printed object.

Oxygen inhibition effects, which can be detrimental in traditional layer-based stereolithography, present different challenges in volumetric printing. Material scientists have developed oxygen-insensitive formulations or incorporated oxygen scavengers to mitigate these effects, enhancing the reliability and consistency of the volumetric printing process.

Mechanical properties of volumetrically printed parts depend heavily on the crosslinking density and network architecture of the polymer matrix. Materials science research focuses on developing resins that yield parts with isotropic mechanical properties—a significant advantage over layer-based methods that typically produce anisotropic structures with weaker interlayer bonding.

Biocompatibility considerations have driven the development of specialized volumetric printing materials for medical applications. These formulations must balance photoreactivity with cellular compatibility, presenting unique challenges that require interdisciplinary approaches combining materials science with biomedical engineering principles.

Recent innovations include stimuli-responsive materials that can undergo post-printing modifications, enabling 4D printing capabilities where the printed structure can change shape or properties in response to environmental triggers. This expanding frontier represents a promising direction for future volumetric printing applications across multiple industries.

Photopolymer resins constitute the primary material class for volumetric printing, requiring careful formulation to achieve optimal performance. These resins must possess balanced light absorption characteristics—sufficient to initiate polymerization but not so high as to prevent light penetration through the entire volume. This delicate balance presents a fundamental materials science challenge unique to volumetric methods.

The photoinitiator selection plays a crucial role in volumetric printing processes. Ideal photoinitiators demonstrate high quantum efficiency, appropriate absorption spectra matching the light source, and minimal light scattering properties. Recent advances have introduced dual-wavelength photoinitiator systems that allow for more precise spatial control of the polymerization process throughout the volume.

Viscosity management represents another key consideration for volumetric printing materials. The resin must maintain appropriate flow characteristics during the printing process while enabling rapid solidification upon exposure to the activation energy. This property directly impacts resolution capabilities and structural integrity of the final printed object.

Oxygen inhibition effects, which can be detrimental in traditional layer-based stereolithography, present different challenges in volumetric printing. Material scientists have developed oxygen-insensitive formulations or incorporated oxygen scavengers to mitigate these effects, enhancing the reliability and consistency of the volumetric printing process.

Mechanical properties of volumetrically printed parts depend heavily on the crosslinking density and network architecture of the polymer matrix. Materials science research focuses on developing resins that yield parts with isotropic mechanical properties—a significant advantage over layer-based methods that typically produce anisotropic structures with weaker interlayer bonding.

Biocompatibility considerations have driven the development of specialized volumetric printing materials for medical applications. These formulations must balance photoreactivity with cellular compatibility, presenting unique challenges that require interdisciplinary approaches combining materials science with biomedical engineering principles.

Recent innovations include stimuli-responsive materials that can undergo post-printing modifications, enabling 4D printing capabilities where the printed structure can change shape or properties in response to environmental triggers. This expanding frontier represents a promising direction for future volumetric printing applications across multiple industries.

Sustainability Impact of Volumetric Fabrication Methods

Volumetric fabrication methods represent a significant paradigm shift in additive manufacturing with profound implications for sustainability across the entire product lifecycle. When compared to traditional layer-by-layer 3D printing approaches, volumetric techniques demonstrate substantial environmental advantages through reduced material waste. By solidifying entire volumes simultaneously rather than sequentially building layers, these methods eliminate the need for support structures that typically constitute 30-40% of material usage in conventional printing processes.

Energy efficiency emerges as another critical sustainability benefit of volumetric fabrication. Traditional layer-based printing requires continuous mechanical movement of print heads or platforms, consuming significant electricity over extended print durations. In contrast, volumetric methods like computed axial lithography (CAL) and tomographic volumetric additive manufacturing (VAM) utilize precisely directed light energy, reducing printing time from hours to minutes and consequently decreasing energy consumption by an estimated 60-75% for comparable objects.

The chemical footprint of volumetric fabrication also warrants consideration. While both approaches utilize photopolymers, volumetric methods typically employ lower concentrations of photoinitiators and require fewer additives for process stabilization. This chemical efficiency translates to reduced environmental impact during both manufacturing and end-of-life disposal phases.

Production speed improvements inherent to volumetric fabrication contribute indirectly to sustainability through manufacturing efficiency. The ability to produce complete objects in minutes rather than hours enables on-demand manufacturing, potentially reducing inventory requirements and associated storage resources. This just-in-time production capability aligns with circular economy principles by minimizing overproduction waste.

From a lifecycle perspective, volumetric fabrication may offer advantages in product longevity. The isotropic nature of simultaneously cured materials potentially yields more uniform mechanical properties compared to the inherent layer-based anisotropy of traditional printing. This structural uniformity could extend product lifespan by eliminating weak interfacial regions prone to failure.

Despite these advantages, volumetric fabrication currently faces sustainability challenges regarding resin recyclability and post-processing requirements. The specialized photopolymer formulations used in volumetric processes often have limited recycling pathways. Additionally, the technology's current material limitations restrict applications primarily to polymers, whereas conventional methods accommodate a broader range of sustainable materials including recycled plastics and biodegradable compounds.

Energy efficiency emerges as another critical sustainability benefit of volumetric fabrication. Traditional layer-based printing requires continuous mechanical movement of print heads or platforms, consuming significant electricity over extended print durations. In contrast, volumetric methods like computed axial lithography (CAL) and tomographic volumetric additive manufacturing (VAM) utilize precisely directed light energy, reducing printing time from hours to minutes and consequently decreasing energy consumption by an estimated 60-75% for comparable objects.

The chemical footprint of volumetric fabrication also warrants consideration. While both approaches utilize photopolymers, volumetric methods typically employ lower concentrations of photoinitiators and require fewer additives for process stabilization. This chemical efficiency translates to reduced environmental impact during both manufacturing and end-of-life disposal phases.

Production speed improvements inherent to volumetric fabrication contribute indirectly to sustainability through manufacturing efficiency. The ability to produce complete objects in minutes rather than hours enables on-demand manufacturing, potentially reducing inventory requirements and associated storage resources. This just-in-time production capability aligns with circular economy principles by minimizing overproduction waste.

From a lifecycle perspective, volumetric fabrication may offer advantages in product longevity. The isotropic nature of simultaneously cured materials potentially yields more uniform mechanical properties compared to the inherent layer-based anisotropy of traditional printing. This structural uniformity could extend product lifespan by eliminating weak interfacial regions prone to failure.

Despite these advantages, volumetric fabrication currently faces sustainability challenges regarding resin recyclability and post-processing requirements. The specialized photopolymer formulations used in volumetric processes often have limited recycling pathways. Additionally, the technology's current material limitations restrict applications primarily to polymers, whereas conventional methods accommodate a broader range of sustainable materials including recycled plastics and biodegradable compounds.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!