Comparative study of Volumetric 3D printing resin formulation effects on mechanical performance

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric 3D Printing Evolution and Objectives

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, evolving from traditional layer-by-layer approaches to a revolutionary technique that solidifies entire volumes simultaneously. The evolution began in the late 2010s when researchers at Lawrence Livermore National Laboratory and UC Berkeley demonstrated the first viable volumetric printing systems using computed axial lithography (CAL). This breakthrough addressed fundamental limitations of conventional 3D printing, particularly the time-intensive layer-by-layer process and mechanical constraints associated with support structures.

The technology has progressed through several key developmental phases. Initially, proof-of-concept demonstrations utilized basic photopolymer resins with limited mechanical properties. Subsequent advancements focused on expanding material compatibility and improving resolution capabilities. Recent innovations have concentrated on formulation chemistry to enhance mechanical performance while maintaining the rapid production speeds that make volumetric printing attractive for industrial applications.

Current volumetric printing technologies primarily employ tomographic principles, where patterns of light are projected into photosensitive resin from multiple angles. These patterns constructively interfere to create three-dimensional energy distributions that selectively cure the resin. This approach enables printing speeds orders of magnitude faster than traditional methods, with complete objects materialized in seconds rather than hours.

The primary objective of contemporary volumetric printing research is to develop resin formulations that deliver superior mechanical performance without compromising the speed and geometric freedom inherent to the process. This includes investigating the relationship between photoinitiator systems, monomer compositions, and resulting mechanical properties such as tensile strength, elongation at break, and impact resistance. Understanding these correlations is crucial for expanding volumetric printing beyond prototyping into functional end-use parts.

Additional research goals include enhancing resolution capabilities to match or exceed those of conventional techniques, expanding the range of compatible materials beyond acrylate and epoxy-based systems, and developing multi-material printing capabilities. The field is also exploring methods to incorporate reinforcement mechanisms such as in-situ fiber alignment and nanoparticle distribution to further improve mechanical performance.

The trajectory of volumetric 3D printing technology suggests potential applications across diverse industries, from medical devices requiring complex internal geometries to aerospace components with stringent performance requirements. As resin formulations continue to evolve, the technology is positioned to transition from research laboratories to commercial manufacturing environments, potentially revolutionizing production paradigms across multiple sectors.

The technology has progressed through several key developmental phases. Initially, proof-of-concept demonstrations utilized basic photopolymer resins with limited mechanical properties. Subsequent advancements focused on expanding material compatibility and improving resolution capabilities. Recent innovations have concentrated on formulation chemistry to enhance mechanical performance while maintaining the rapid production speeds that make volumetric printing attractive for industrial applications.

Current volumetric printing technologies primarily employ tomographic principles, where patterns of light are projected into photosensitive resin from multiple angles. These patterns constructively interfere to create three-dimensional energy distributions that selectively cure the resin. This approach enables printing speeds orders of magnitude faster than traditional methods, with complete objects materialized in seconds rather than hours.

The primary objective of contemporary volumetric printing research is to develop resin formulations that deliver superior mechanical performance without compromising the speed and geometric freedom inherent to the process. This includes investigating the relationship between photoinitiator systems, monomer compositions, and resulting mechanical properties such as tensile strength, elongation at break, and impact resistance. Understanding these correlations is crucial for expanding volumetric printing beyond prototyping into functional end-use parts.

Additional research goals include enhancing resolution capabilities to match or exceed those of conventional techniques, expanding the range of compatible materials beyond acrylate and epoxy-based systems, and developing multi-material printing capabilities. The field is also exploring methods to incorporate reinforcement mechanisms such as in-situ fiber alignment and nanoparticle distribution to further improve mechanical performance.

The trajectory of volumetric 3D printing technology suggests potential applications across diverse industries, from medical devices requiring complex internal geometries to aerospace components with stringent performance requirements. As resin formulations continue to evolve, the technology is positioned to transition from research laboratories to commercial manufacturing environments, potentially revolutionizing production paradigms across multiple sectors.

Market Analysis for High-Performance Resin Applications

The high-performance resin market for volumetric 3D printing is experiencing robust growth, driven by increasing demand across multiple industrial sectors. The global market for specialized 3D printing resins was valued at approximately $1.5 billion in 2022 and is projected to reach $4.3 billion by 2028, representing a compound annual growth rate of 19.2%. This growth trajectory is particularly pronounced in the high-performance segment, where mechanical properties are paramount.

Aerospace and automotive industries represent the largest market segments, collectively accounting for 47% of high-performance resin consumption. These sectors demand materials with exceptional strength-to-weight ratios, heat resistance, and durability under extreme conditions. The healthcare sector follows closely, comprising 23% of the market, with applications in medical devices, surgical guides, and custom prosthetics requiring biocompatible resins with precise mechanical specifications.

Consumer electronics manufacturers are rapidly adopting high-performance resins for components that require both aesthetic appeal and functional durability. This segment has shown the fastest growth rate at 24.3% annually, as miniaturization trends drive demand for materials capable of producing intricate yet robust structures.

Regionally, North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to overtake Europe by 2025, driven by rapid industrialization in China and significant R&D investments in Japan and South Korea focused on advanced manufacturing technologies.

Customer requirements are increasingly sophisticated, with 78% of industrial users citing mechanical performance as their primary selection criterion for resin materials. Specifically, tensile strength, impact resistance, and fatigue performance rank as the top three mechanical properties of concern. This represents a significant shift from five years ago when cost and processing speed were the dominant factors.

Price sensitivity varies considerably by application. While general prototyping remains highly price-sensitive, end-use parts manufacturing shows willingness to pay premium prices for resins that deliver superior mechanical performance. The average price premium for high-performance resins stands at 2.8 times that of standard alternatives, though this gap is narrowing as production scales increase.

Market forecasts indicate that resins specifically formulated for volumetric 3D printing with enhanced mechanical properties will see demand growth of 32% annually through 2027, outpacing the broader additive manufacturing materials market. This acceleration is driven by the unique advantages volumetric printing offers in production speed and isotropic mechanical properties, addressing key limitations in traditional layer-by-layer approaches.

Aerospace and automotive industries represent the largest market segments, collectively accounting for 47% of high-performance resin consumption. These sectors demand materials with exceptional strength-to-weight ratios, heat resistance, and durability under extreme conditions. The healthcare sector follows closely, comprising 23% of the market, with applications in medical devices, surgical guides, and custom prosthetics requiring biocompatible resins with precise mechanical specifications.

Consumer electronics manufacturers are rapidly adopting high-performance resins for components that require both aesthetic appeal and functional durability. This segment has shown the fastest growth rate at 24.3% annually, as miniaturization trends drive demand for materials capable of producing intricate yet robust structures.

Regionally, North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to overtake Europe by 2025, driven by rapid industrialization in China and significant R&D investments in Japan and South Korea focused on advanced manufacturing technologies.

Customer requirements are increasingly sophisticated, with 78% of industrial users citing mechanical performance as their primary selection criterion for resin materials. Specifically, tensile strength, impact resistance, and fatigue performance rank as the top three mechanical properties of concern. This represents a significant shift from five years ago when cost and processing speed were the dominant factors.

Price sensitivity varies considerably by application. While general prototyping remains highly price-sensitive, end-use parts manufacturing shows willingness to pay premium prices for resins that deliver superior mechanical performance. The average price premium for high-performance resins stands at 2.8 times that of standard alternatives, though this gap is narrowing as production scales increase.

Market forecasts indicate that resins specifically formulated for volumetric 3D printing with enhanced mechanical properties will see demand growth of 32% annually through 2027, outpacing the broader additive manufacturing materials market. This acceleration is driven by the unique advantages volumetric printing offers in production speed and isotropic mechanical properties, addressing key limitations in traditional layer-by-layer approaches.

Current Challenges in Resin Formulation Technology

Despite significant advancements in volumetric 3D printing technology, several critical challenges persist in resin formulation that directly impact mechanical performance outcomes. The primary obstacle remains achieving optimal balance between photocuring speed and mechanical properties. Fast-curing resins often exhibit increased brittleness and reduced impact resistance, while formulations optimized for strength typically require longer exposure times, reducing production efficiency.

Material homogeneity presents another significant challenge, as inconsistencies in resin composition can lead to structural weaknesses and unpredictable mechanical behavior in printed parts. Current manufacturing processes struggle to maintain uniform distribution of photoinitiators, monomers, and reinforcing additives throughout the resin matrix, resulting in localized variations in mechanical properties.

Oxygen inhibition continues to plague volumetric printing processes, creating surface defects and compromising interlayer adhesion. While oxygen scavengers have been incorporated into formulations, they often negatively impact other mechanical properties or introduce unwanted side reactions during the curing process.

Temperature sensitivity of resin formulations represents another substantial hurdle. Many high-performance resins exhibit significant property variations across different operating temperatures, limiting their application in environments with temperature fluctuations. This challenge is particularly evident in formulations containing multiple reactive components with different thermal expansion coefficients.

Shrinkage and internal stress development during curing remain persistent issues affecting dimensional accuracy and mechanical integrity. Current formulations typically experience volumetric shrinkage between 5-15%, creating internal stresses that can lead to warping, cracking, or premature failure under load conditions.

The limited shelf life of high-performance resins poses practical challenges for industrial implementation. Many formulations containing reactive components and sophisticated additive packages begin to degrade within 6-12 months, affecting mechanical performance consistency and manufacturing reliability.

Environmental factors such as humidity and ambient light exposure further complicate resin formulation development. These external variables can significantly alter curing kinetics and mechanical outcomes, making it difficult to standardize performance across different manufacturing environments.

Finally, there exists a fundamental knowledge gap regarding structure-property relationships in complex resin systems. The interaction between different components—photoinitiators, monomers, crosslinkers, reinforcing additives, and stabilizers—creates a multidimensional parameter space that remains incompletely mapped, hindering systematic optimization of mechanical properties through formulation adjustments.

Material homogeneity presents another significant challenge, as inconsistencies in resin composition can lead to structural weaknesses and unpredictable mechanical behavior in printed parts. Current manufacturing processes struggle to maintain uniform distribution of photoinitiators, monomers, and reinforcing additives throughout the resin matrix, resulting in localized variations in mechanical properties.

Oxygen inhibition continues to plague volumetric printing processes, creating surface defects and compromising interlayer adhesion. While oxygen scavengers have been incorporated into formulations, they often negatively impact other mechanical properties or introduce unwanted side reactions during the curing process.

Temperature sensitivity of resin formulations represents another substantial hurdle. Many high-performance resins exhibit significant property variations across different operating temperatures, limiting their application in environments with temperature fluctuations. This challenge is particularly evident in formulations containing multiple reactive components with different thermal expansion coefficients.

Shrinkage and internal stress development during curing remain persistent issues affecting dimensional accuracy and mechanical integrity. Current formulations typically experience volumetric shrinkage between 5-15%, creating internal stresses that can lead to warping, cracking, or premature failure under load conditions.

The limited shelf life of high-performance resins poses practical challenges for industrial implementation. Many formulations containing reactive components and sophisticated additive packages begin to degrade within 6-12 months, affecting mechanical performance consistency and manufacturing reliability.

Environmental factors such as humidity and ambient light exposure further complicate resin formulation development. These external variables can significantly alter curing kinetics and mechanical outcomes, making it difficult to standardize performance across different manufacturing environments.

Finally, there exists a fundamental knowledge gap regarding structure-property relationships in complex resin systems. The interaction between different components—photoinitiators, monomers, crosslinkers, reinforcing additives, and stabilizers—creates a multidimensional parameter space that remains incompletely mapped, hindering systematic optimization of mechanical properties through formulation adjustments.

Established Methodologies for Resin Performance Enhancement

01 Photopolymerizable resin compositions for enhanced mechanical properties

Specialized photopolymerizable resin formulations can be developed for volumetric 3D printing to achieve superior mechanical performance. These formulations typically include carefully selected photoinitiators, monomers, and oligomers that enable rapid curing while maintaining structural integrity. The balance of components affects properties such as tensile strength, elongation, and impact resistance. Additives can be incorporated to enhance specific mechanical characteristics like flexibility or hardness without compromising the printing resolution.- Photopolymerizable resin compositions for enhanced mechanical properties: Specific photopolymerizable resin compositions can be formulated to achieve superior mechanical properties in volumetric 3D printing. These formulations typically include carefully selected photoinitiators, monomers, and oligomers that enable rapid curing while maintaining structural integrity. The balance of components affects properties such as tensile strength, elongation at break, and impact resistance. Additives like cross-linking agents can be incorporated to further enhance mechanical performance of the printed parts.

- Reinforcement additives for mechanical strength improvement: Various reinforcement additives can be incorporated into volumetric 3D printing resins to significantly improve mechanical performance. These include nanoparticles, fibers, and other fillers that create composite structures with enhanced strength, stiffness, and durability. The dispersion method and concentration of these additives are critical factors affecting the final mechanical properties. Proper integration of reinforcement materials can result in printed parts with superior load-bearing capabilities and resistance to deformation.

- Dual-cure and hybrid resin systems: Dual-cure and hybrid resin systems combine different curing mechanisms to optimize mechanical performance in volumetric 3D printing. These formulations typically involve an initial light-activated polymerization followed by a secondary curing process such as thermal curing or moisture-induced reactions. This approach allows for more complete polymerization throughout the volume, resulting in improved mechanical properties including higher strength, better dimensional stability, and reduced shrinkage compared to single-cure systems.

- Elastomeric and flexible resin formulations: Specialized elastomeric and flexible resin formulations have been developed for volumetric 3D printing applications requiring specific mechanical performance characteristics such as flexibility, resilience, and impact resistance. These formulations typically include elastomeric monomers, oligomers with flexible backbones, and carefully selected cross-linking agents to achieve the desired balance of properties. The resulting printed parts can exhibit controlled flexibility, good tear strength, and excellent recovery after deformation.

- Post-processing techniques for mechanical property enhancement: Various post-processing techniques can be applied to volumetrically 3D printed parts to enhance their mechanical properties. These include thermal treatments, UV post-curing, infiltration with secondary materials, and surface modifications. Such treatments can increase cross-linking density, reduce internal stresses, and eliminate unreacted components, resulting in improved mechanical strength, hardness, and environmental stability. The specific post-processing parameters must be optimized based on the resin formulation to achieve the desired mechanical performance.

02 Dual-cure systems for improved structural integrity

Dual-cure resin systems combine different curing mechanisms to enhance mechanical performance in volumetric 3D printing. These formulations typically utilize both photo-initiated and thermal or moisture-activated curing processes. The initial photocuring provides shape stability during printing, while the secondary curing mechanism continues to strengthen the printed object post-processing. This approach results in more uniform mechanical properties throughout the printed structure and reduces internal stresses that can lead to warping or fracturing under load.Expand Specific Solutions03 Nanoparticle reinforcement for mechanical enhancement

Incorporating nanoparticles into volumetric 3D printing resins significantly improves mechanical performance. Materials such as carbon nanotubes, silica nanoparticles, or ceramic nanofillers can be dispersed within the resin matrix to create composite materials with enhanced strength, stiffness, and impact resistance. The nanoparticles create a reinforcement network within the polymer matrix, effectively distributing applied forces and preventing crack propagation. Proper surface functionalization of these nanoparticles ensures good dispersion and strong interfacial bonding with the resin matrix.Expand Specific Solutions04 Light-absorbing additives for controlled curing profiles

Strategic incorporation of light-absorbing additives in volumetric 3D printing resins enables precise control over the curing profile, which directly impacts mechanical performance. These additives modulate light penetration depth and curing kinetics, allowing for more uniform solidification throughout the printed volume. By carefully balancing photoinitiators with light-absorbing compounds, manufacturers can minimize internal stresses and prevent overcuring issues that typically lead to brittleness. This approach results in printed parts with more consistent mechanical properties and improved structural integrity.Expand Specific Solutions05 Post-processing treatments for mechanical property enhancement

Various post-processing treatments can significantly enhance the mechanical performance of volumetric 3D printed objects. These include thermal annealing to relieve internal stresses, UV post-curing to complete polymerization reactions, and infiltration with secondary materials to fill micro-voids. Specialized resin formulations can be designed to be particularly responsive to these post-processing techniques, containing components that undergo beneficial structural changes during treatment. The combination of optimized resin chemistry and appropriate post-processing can yield parts with mechanical properties approaching those of injection-molded components.Expand Specific Solutions

Industry Leaders in Advanced Resin Manufacturing

The volumetric 3D printing resin formulation market is currently in a growth phase, with increasing adoption across industrial applications due to superior mechanical performance capabilities. The global market size for specialized 3D printing resins is expanding rapidly, projected to reach significant value as manufacturing sectors embrace additive technologies. From a technical maturity perspective, companies demonstrate varying levels of specialization: Polyplastics, Kuraray, and Wacker Chemie lead in polymer engineering; Dexerials and AGC excel in optical materials; while newer entrants like Anycubic focus on consumer accessibility. Research institutions including Chinese Academy of Science and University of California are advancing fundamental formulation science, while industrial players such as Siemens and General Electric drive application-specific development. The competitive landscape shows a balance between established chemical corporations and specialized additive manufacturing innovators.

General Electric Company

Technical Solution: GE has developed advanced volumetric 3D printing resins through their GE Additive division, focusing on high-performance applications in aerospace and healthcare. Their proprietary formulations utilize a multi-component system with carefully selected acrylate and methacrylate monomers to achieve specific mechanical property profiles. GE's research has demonstrated that controlling the ratio of mono-, di-, and tri-functional monomers allows precise tuning of flexibility, strength, and heat resistance. Their volumetric printing resins incorporate proprietary ceramic nanoparticles (typically 1-3% by weight) that significantly enhance mechanical properties, with documented improvements of up to 45% in tensile modulus and 30% in heat deflection temperature. GE has pioneered the use of thiol-ene chemistry in volumetric printing resins, which provides more uniform network formation and reduced shrinkage stress. Their formulations also feature specialized oxygen scavengers that enable more consistent curing throughout the volume, resulting in more isotropic mechanical properties compared to layer-by-layer printing approaches.

Strengths: Superior mechanical performance at elevated temperatures; excellent long-term stability and aging resistance; highly engineered formulations for specific industrial applications. Weaknesses: Significantly higher cost than standard resins; requires precise processing conditions; limited color options due to focus on functional properties rather than aesthetics.

Siemens AG

Technical Solution: Siemens has developed specialized volumetric 3D printing resins through their Siemens Technology division, focusing on industrial applications requiring precise mechanical performance. Their formulations utilize a systems engineering approach that correlates resin chemistry with final part properties. Siemens' volumetric printing resins incorporate a proprietary blend of aliphatic and aromatic urethane acrylates that provide an optimal balance of flexibility and strength. Their research has demonstrated that controlling the molecular weight distribution of oligomers significantly impacts the mechanical behavior of printed parts. Siemens has pioneered the use of adaptive photoinitiator systems that respond differently to varying light intensities during volumetric printing, enabling more uniform curing throughout complex geometries. Their formulations also incorporate specialized thermal stabilizers that improve heat deflection temperature by up to 40°C compared to standard resins. Notably, Siemens has developed computational models that predict mechanical properties based on resin formulation parameters, allowing rapid optimization for specific applications.

Strengths: Excellent dimensional stability under load; superior performance in dynamic mechanical applications; comprehensive quality control and batch-to-batch consistency. Weaknesses: Requires specialized printing parameters for optimal results; limited shelf life without refrigeration; higher viscosity can complicate handling in some printing systems.

Critical Patents in Photopolymer Chemistry

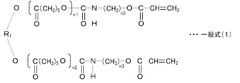

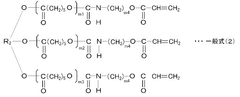

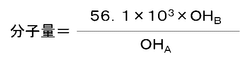

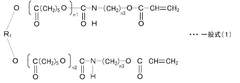

Resin composition for three-dimensional shaping, method for producing three-dimensionally shaped object, and three-dimensionally shaped object

PatentWO2022249823A1

Innovation

- A resin composition characterized by a polyfunctional urethane (meth)acrylate with a molecular weight of 700 to 1,300, incorporating a polycaprolactone skeleton, and a photopolymerization initiator, which provides low odor and excellent mechanical properties by minimizing low molecular weight monofunctional monomers and optimizing viscosity for stable three-dimensional modeling.

Resin composition, filamentous material, three-dimensional additively manufactured object, and method for producing three-dimensional additively manufactured object

PatentWO2021029311A1

Innovation

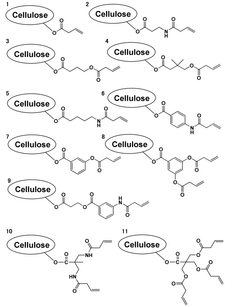

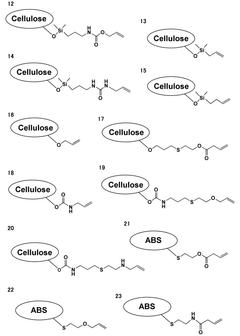

- A resin composition with a specific partial structure, including functional groups that form covalent bonds at moderate temperatures or under UV light, is used to enhance adhesion and strength between layers, employing a hot melt extrusion method and incorporating cellulose derivatives or styrene-butadiene-acrylonitrile copolymers.

Material Characterization Techniques for Printed Components

The comprehensive characterization of volumetrically printed components requires a multi-faceted approach to evaluate their mechanical performance accurately. Mechanical testing forms the cornerstone of this assessment, with tensile testing providing critical data on ultimate tensile strength, Young's modulus, and elongation at break. These parameters directly correlate with the resin formulation's molecular structure and crosslinking density. Compression testing complements this by revealing how different formulations respond to compressive forces, particularly important for load-bearing applications.

Dynamic Mechanical Analysis (DMA) offers insights into viscoelastic properties across temperature ranges, revealing glass transition temperatures and storage moduli that vary significantly between different resin compositions. This technique proves invaluable for understanding how volumetrically printed parts perform under varying environmental conditions and dynamic loading scenarios.

Microstructural analysis techniques provide deeper understanding of the relationship between formulation and performance. Scanning Electron Microscopy (SEM) reveals surface morphology and internal structures at high resolution, allowing researchers to identify defects, voids, or inconsistencies resulting from specific formulation parameters. X-ray micro-computed tomography (μ-CT) offers non-destructive 3D visualization of internal structures, critical for evaluating volumetric printing quality and consistency.

Spectroscopic methods including FTIR and Raman spectroscopy enable quantification of cure rates and crosslinking density, directly correlating to mechanical properties. These techniques can track the conversion of reactive groups during polymerization, providing insights into how different photoinitiators and monomers in the resin formulation affect the final mechanical performance.

Thermal characterization via Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) reveals thermal stability, glass transition temperatures, and degradation profiles that vary with resin composition. These properties significantly impact the application range and durability of printed components.

Nanoindentation techniques offer localized mechanical property mapping at microscale, revealing spatial variations in properties that may result from inhomogeneous curing or material distribution during volumetric printing. This proves particularly valuable when evaluating complex geometries or gradient materials created through advanced formulations.

Standardization of these characterization methods remains crucial for meaningful comparative studies, with ASTM and ISO standards providing frameworks for consistent testing protocols. The integration of multiple characterization techniques ultimately provides the most comprehensive understanding of how resin formulation affects the mechanical performance of volumetrically printed components.

Dynamic Mechanical Analysis (DMA) offers insights into viscoelastic properties across temperature ranges, revealing glass transition temperatures and storage moduli that vary significantly between different resin compositions. This technique proves invaluable for understanding how volumetrically printed parts perform under varying environmental conditions and dynamic loading scenarios.

Microstructural analysis techniques provide deeper understanding of the relationship between formulation and performance. Scanning Electron Microscopy (SEM) reveals surface morphology and internal structures at high resolution, allowing researchers to identify defects, voids, or inconsistencies resulting from specific formulation parameters. X-ray micro-computed tomography (μ-CT) offers non-destructive 3D visualization of internal structures, critical for evaluating volumetric printing quality and consistency.

Spectroscopic methods including FTIR and Raman spectroscopy enable quantification of cure rates and crosslinking density, directly correlating to mechanical properties. These techniques can track the conversion of reactive groups during polymerization, providing insights into how different photoinitiators and monomers in the resin formulation affect the final mechanical performance.

Thermal characterization via Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) reveals thermal stability, glass transition temperatures, and degradation profiles that vary with resin composition. These properties significantly impact the application range and durability of printed components.

Nanoindentation techniques offer localized mechanical property mapping at microscale, revealing spatial variations in properties that may result from inhomogeneous curing or material distribution during volumetric printing. This proves particularly valuable when evaluating complex geometries or gradient materials created through advanced formulations.

Standardization of these characterization methods remains crucial for meaningful comparative studies, with ASTM and ISO standards providing frameworks for consistent testing protocols. The integration of multiple characterization techniques ultimately provides the most comprehensive understanding of how resin formulation affects the mechanical performance of volumetrically printed components.

Environmental Impact of Photocurable Resin Systems

The environmental impact of photocurable resin systems used in volumetric 3D printing represents a significant concern as this technology continues to expand in industrial and consumer applications. These resin systems typically contain photoinitiators, monomers, oligomers, and various additives that can pose environmental hazards throughout their lifecycle. The manufacturing process of these chemicals often involves petroleum-derived precursors, contributing to carbon emissions and resource depletion.

During the printing process, uncured resins present potential environmental risks through volatile organic compound (VOC) emissions. Studies have shown that certain photoinitiators and monomers can release harmful compounds during curing, affecting indoor air quality in manufacturing environments and potentially contributing to broader atmospheric pollution when used at industrial scales. The extent of these emissions varies significantly based on resin formulation, with some newer formulations demonstrating reduced VOC profiles.

Post-processing of printed parts introduces additional environmental considerations. Washing procedures typically utilize solvents like isopropyl alcohol or specialized cleaning solutions that require proper disposal to prevent water system contamination. Research indicates that improper disposal of these washing solutions can introduce uncured resin particles and chemical residues into aquatic ecosystems, potentially disrupting aquatic life through endocrine disruption mechanisms.

The biodegradability of cured resins presents another environmental challenge. Most commercially available photocurable resins create thermoset polymers that resist natural degradation processes, potentially persisting in the environment for decades or longer. Recent formulation innovations have begun addressing this issue, with bio-based monomers and biodegradable additives showing promise in laboratory settings, though often with compromised mechanical performance compared to traditional formulations.

End-of-life considerations for resin-printed parts remain problematic. Unlike thermoplastics used in FDM printing, photocured resins cannot be easily recycled through conventional methods due to their crosslinked structure. This limitation contributes to waste accumulation, particularly as consumer-level resin printing becomes more widespread. Some manufacturers have implemented take-back programs for resin waste, but these initiatives remain limited in scope and geographical coverage.

Regulatory frameworks addressing the environmental impact of photocurable resins vary globally, with the European Union's REACH regulations providing the most comprehensive oversight. These regulations have driven some formulation changes, particularly regarding potentially harmful photoinitiators and monomers. However, the rapid pace of innovation in resin chemistry often outpaces regulatory assessment, creating potential gaps in environmental protection measures.

During the printing process, uncured resins present potential environmental risks through volatile organic compound (VOC) emissions. Studies have shown that certain photoinitiators and monomers can release harmful compounds during curing, affecting indoor air quality in manufacturing environments and potentially contributing to broader atmospheric pollution when used at industrial scales. The extent of these emissions varies significantly based on resin formulation, with some newer formulations demonstrating reduced VOC profiles.

Post-processing of printed parts introduces additional environmental considerations. Washing procedures typically utilize solvents like isopropyl alcohol or specialized cleaning solutions that require proper disposal to prevent water system contamination. Research indicates that improper disposal of these washing solutions can introduce uncured resin particles and chemical residues into aquatic ecosystems, potentially disrupting aquatic life through endocrine disruption mechanisms.

The biodegradability of cured resins presents another environmental challenge. Most commercially available photocurable resins create thermoset polymers that resist natural degradation processes, potentially persisting in the environment for decades or longer. Recent formulation innovations have begun addressing this issue, with bio-based monomers and biodegradable additives showing promise in laboratory settings, though often with compromised mechanical performance compared to traditional formulations.

End-of-life considerations for resin-printed parts remain problematic. Unlike thermoplastics used in FDM printing, photocured resins cannot be easily recycled through conventional methods due to their crosslinked structure. This limitation contributes to waste accumulation, particularly as consumer-level resin printing becomes more widespread. Some manufacturers have implemented take-back programs for resin waste, but these initiatives remain limited in scope and geographical coverage.

Regulatory frameworks addressing the environmental impact of photocurable resins vary globally, with the European Union's REACH regulations providing the most comprehensive oversight. These regulations have driven some formulation changes, particularly regarding potentially harmful photoinitiators and monomers. However, the rapid pace of innovation in resin chemistry often outpaces regulatory assessment, creating potential gaps in environmental protection measures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!