Comparative analysis of Volumetric 3D printing photopolymers and ceramic composites

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric 3D Printing Evolution and Objectives

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, evolving from traditional layer-by-layer approaches to a revolutionary technique that solidifies entire volumes simultaneously. The technology's roots can be traced back to computed tomography principles developed in the 1970s, but its application to 3D printing only materialized in the late 2010s when researchers at Lawrence Livermore National Laboratory and UC Berkeley demonstrated the first practical implementations.

The evolution of volumetric 3D printing has been marked by significant breakthroughs in photopolymer chemistry and optical projection systems. Initially limited by slow solidification rates and poor resolution, recent advances have dramatically improved both aspects. The development of dual-wavelength photoinitiation systems and oxygen-inhibition control mechanisms has enabled faster curing times while maintaining structural integrity throughout the printed volume.

Ceramic composite integration represents the latest frontier in this technological evolution. Traditional ceramic manufacturing faces limitations in producing complex geometries, making volumetric 3D printing particularly attractive for this material class. The incorporation of ceramic particles into photopolymer matrices has progressed from simple suspensions with low ceramic loading to sophisticated hybrid systems capable of achieving up to 60% ceramic content by volume.

The primary objective of current research in volumetric 3D printing focuses on expanding material compatibility while maintaining or improving printing speed and resolution. For photopolymers, this means developing systems with lower viscosity, higher reactivity, and better mechanical properties post-curing. The ideal photopolymer formulation must balance rapid solidification with minimal shrinkage stress, a challenge that continues to drive innovation in photoinitiator and monomer design.

For ceramic composites, objectives center on increasing ceramic loading while maintaining printability, followed by successful debinding and sintering processes that preserve geometric accuracy. Researchers aim to achieve fully dense ceramic parts with mechanical properties comparable to traditionally manufactured ceramics, but with the geometric freedom that volumetric printing enables.

A parallel objective involves scaling the technology for industrial applications. Current volumetric printing systems typically operate at laboratory scale, with build volumes rarely exceeding a few cubic centimeters. Expanding these capabilities to industrially relevant sizes while maintaining resolution presents significant optical engineering challenges that researchers are actively addressing through innovations in light delivery systems and computational approaches to tomographic reconstruction.

The evolution of volumetric 3D printing has been marked by significant breakthroughs in photopolymer chemistry and optical projection systems. Initially limited by slow solidification rates and poor resolution, recent advances have dramatically improved both aspects. The development of dual-wavelength photoinitiation systems and oxygen-inhibition control mechanisms has enabled faster curing times while maintaining structural integrity throughout the printed volume.

Ceramic composite integration represents the latest frontier in this technological evolution. Traditional ceramic manufacturing faces limitations in producing complex geometries, making volumetric 3D printing particularly attractive for this material class. The incorporation of ceramic particles into photopolymer matrices has progressed from simple suspensions with low ceramic loading to sophisticated hybrid systems capable of achieving up to 60% ceramic content by volume.

The primary objective of current research in volumetric 3D printing focuses on expanding material compatibility while maintaining or improving printing speed and resolution. For photopolymers, this means developing systems with lower viscosity, higher reactivity, and better mechanical properties post-curing. The ideal photopolymer formulation must balance rapid solidification with minimal shrinkage stress, a challenge that continues to drive innovation in photoinitiator and monomer design.

For ceramic composites, objectives center on increasing ceramic loading while maintaining printability, followed by successful debinding and sintering processes that preserve geometric accuracy. Researchers aim to achieve fully dense ceramic parts with mechanical properties comparable to traditionally manufactured ceramics, but with the geometric freedom that volumetric printing enables.

A parallel objective involves scaling the technology for industrial applications. Current volumetric printing systems typically operate at laboratory scale, with build volumes rarely exceeding a few cubic centimeters. Expanding these capabilities to industrially relevant sizes while maintaining resolution presents significant optical engineering challenges that researchers are actively addressing through innovations in light delivery systems and computational approaches to tomographic reconstruction.

Market Analysis for Advanced 3D Printing Materials

The global market for advanced 3D printing materials, particularly volumetric 3D printing photopolymers and ceramic composites, has experienced significant growth in recent years. The market size for these specialized materials reached approximately $2.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 23.5% through 2028, potentially reaching $8.1 billion by the end of the forecast period.

Volumetric 3D printing photopolymers represent a rapidly expanding segment within this market, valued at roughly $1.4 billion in 2022. These materials are gaining traction due to their superior speed capabilities, enabling the production of complex structures in minutes rather than hours. The healthcare sector has emerged as the primary consumer of these materials, accounting for 38% of the total market share, followed by automotive (22%) and aerospace (17%) industries.

Ceramic composites for 3D printing, while currently a smaller segment valued at approximately $900 million, are demonstrating the highest growth potential with a projected CAGR of 27.3% through 2028. This accelerated growth is driven by increasing demand from industrial manufacturing, particularly for high-temperature applications where traditional photopolymers are unsuitable.

Regional analysis reveals North America as the dominant market for advanced 3D printing materials, holding 42% of the global market share. This leadership position stems from substantial R&D investments and the presence of major industry players. The Asia-Pacific region follows with 31% market share but is expected to demonstrate the fastest growth rate at 26.8% annually, primarily fueled by rapid industrialization in China and significant government initiatives in Japan and South Korea.

End-user segmentation indicates that large enterprises currently consume 64% of these advanced materials, though small and medium enterprises (SMEs) are adopting these technologies at an increasing rate as costs decrease and accessibility improves. This democratization trend is expected to continue, potentially shifting market dynamics significantly by 2026.

Price sensitivity remains a critical factor influencing market adoption. Current pricing for high-quality volumetric photopolymers ranges from $180-450 per kilogram, while specialized ceramic composites command premium prices of $300-700 per kilogram. These high costs represent a significant barrier to wider adoption, particularly among smaller manufacturers and educational institutions.

Market forecasts suggest that technological advancements will drive material costs down by approximately 15-20% annually over the next five years, potentially catalyzing broader market penetration across various industry verticals and geographical regions.

Volumetric 3D printing photopolymers represent a rapidly expanding segment within this market, valued at roughly $1.4 billion in 2022. These materials are gaining traction due to their superior speed capabilities, enabling the production of complex structures in minutes rather than hours. The healthcare sector has emerged as the primary consumer of these materials, accounting for 38% of the total market share, followed by automotive (22%) and aerospace (17%) industries.

Ceramic composites for 3D printing, while currently a smaller segment valued at approximately $900 million, are demonstrating the highest growth potential with a projected CAGR of 27.3% through 2028. This accelerated growth is driven by increasing demand from industrial manufacturing, particularly for high-temperature applications where traditional photopolymers are unsuitable.

Regional analysis reveals North America as the dominant market for advanced 3D printing materials, holding 42% of the global market share. This leadership position stems from substantial R&D investments and the presence of major industry players. The Asia-Pacific region follows with 31% market share but is expected to demonstrate the fastest growth rate at 26.8% annually, primarily fueled by rapid industrialization in China and significant government initiatives in Japan and South Korea.

End-user segmentation indicates that large enterprises currently consume 64% of these advanced materials, though small and medium enterprises (SMEs) are adopting these technologies at an increasing rate as costs decrease and accessibility improves. This democratization trend is expected to continue, potentially shifting market dynamics significantly by 2026.

Price sensitivity remains a critical factor influencing market adoption. Current pricing for high-quality volumetric photopolymers ranges from $180-450 per kilogram, while specialized ceramic composites command premium prices of $300-700 per kilogram. These high costs represent a significant barrier to wider adoption, particularly among smaller manufacturers and educational institutions.

Market forecasts suggest that technological advancements will drive material costs down by approximately 15-20% annually over the next five years, potentially catalyzing broader market penetration across various industry verticals and geographical regions.

Current Landscape of Photopolymers and Ceramic Composites

The photopolymer market for volumetric 3D printing has experienced significant growth in recent years, with major players including Formlabs, Carbon, and 3D Systems dominating the commercial landscape. These companies have developed proprietary resins optimized for various applications, from dental and medical to industrial prototyping. The market is currently segmented into acrylate-based, epoxy-based, and hybrid formulations, with each offering distinct advantages in terms of mechanical properties, cure rates, and post-processing requirements.

Ceramic composite materials for volumetric 3D printing represent a rapidly evolving segment with substantial research activity but more limited commercial availability. Leading research institutions such as Lawrence Livermore National Laboratory and ETH Zurich have demonstrated promising results using ceramic-loaded photopolymers that can be subsequently sintered to produce high-performance ceramic parts. Companies like Lithoz and XJet have commercialized ceramic printing technologies, though primarily using alternative methods rather than true volumetric approaches.

The current technological landscape shows a clear divide between photopolymer and ceramic composite development trajectories. Photopolymers have achieved greater commercial maturity, with formulations optimized for specific printing technologies and end-use applications. These materials typically offer resolution down to 25-100 microns, cure times ranging from seconds to minutes, and increasingly robust mechanical properties approaching those of engineering thermoplastics.

Ceramic composites, while less commercially mature, demonstrate exceptional potential for high-temperature, wear-resistant, and biocompatible applications. Current formulations typically contain 40-60% ceramic loading by volume in a photocurable matrix, requiring post-processing sintering to achieve final properties. The technical challenges include managing viscosity at high ceramic loadings, preventing particle sedimentation during printing, and controlling shrinkage during sintering.

Recent innovations in the field include the development of thiol-ene chemistry for reduced oxygen inhibition in photopolymers, dual-cure systems that combine photo and thermal polymerization for enhanced mechanical properties, and the incorporation of nanoparticles to modify rheological behavior in ceramic composites. Additionally, machine learning approaches are increasingly being applied to formulation development, accelerating the discovery of optimal material compositions.

Regulatory considerations are becoming increasingly important in this landscape, particularly for medical and food-contact applications. Standards organizations such as ASTM and ISO have begun developing specific protocols for testing and certifying 3D printed materials, though comprehensive frameworks specifically for volumetric printing materials remain under development.

Ceramic composite materials for volumetric 3D printing represent a rapidly evolving segment with substantial research activity but more limited commercial availability. Leading research institutions such as Lawrence Livermore National Laboratory and ETH Zurich have demonstrated promising results using ceramic-loaded photopolymers that can be subsequently sintered to produce high-performance ceramic parts. Companies like Lithoz and XJet have commercialized ceramic printing technologies, though primarily using alternative methods rather than true volumetric approaches.

The current technological landscape shows a clear divide between photopolymer and ceramic composite development trajectories. Photopolymers have achieved greater commercial maturity, with formulations optimized for specific printing technologies and end-use applications. These materials typically offer resolution down to 25-100 microns, cure times ranging from seconds to minutes, and increasingly robust mechanical properties approaching those of engineering thermoplastics.

Ceramic composites, while less commercially mature, demonstrate exceptional potential for high-temperature, wear-resistant, and biocompatible applications. Current formulations typically contain 40-60% ceramic loading by volume in a photocurable matrix, requiring post-processing sintering to achieve final properties. The technical challenges include managing viscosity at high ceramic loadings, preventing particle sedimentation during printing, and controlling shrinkage during sintering.

Recent innovations in the field include the development of thiol-ene chemistry for reduced oxygen inhibition in photopolymers, dual-cure systems that combine photo and thermal polymerization for enhanced mechanical properties, and the incorporation of nanoparticles to modify rheological behavior in ceramic composites. Additionally, machine learning approaches are increasingly being applied to formulation development, accelerating the discovery of optimal material compositions.

Regulatory considerations are becoming increasingly important in this landscape, particularly for medical and food-contact applications. Standards organizations such as ASTM and ISO have begun developing specific protocols for testing and certifying 3D printed materials, though comprehensive frameworks specifically for volumetric printing materials remain under development.

Technical Comparison of Current Material Solutions

01 Photopolymer formulations for volumetric 3D printing

Specialized photopolymer formulations designed specifically for volumetric 3D printing applications. These formulations typically include photoinitiators, monomers, and additives that enable rapid curing when exposed to specific wavelengths of light. The compositions are optimized for optical properties that allow light penetration throughout the volume while maintaining high resolution and structural integrity during the printing process.- Photopolymer formulations for volumetric 3D printing: Specialized photopolymer formulations designed specifically for volumetric 3D printing applications. These formulations typically include photoinitiators that respond to specific wavelengths of light, monomers and oligomers that provide structural properties, and additives that control curing kinetics. The photopolymers are engineered to rapidly solidify when exposed to projected light patterns in volumetric printing systems, allowing for the creation of complex 3D structures without the need for layer-by-layer processing.

- Ceramic composite materials for volumetric additive manufacturing: Ceramic-loaded photopolymer composites that combine ceramic particles with photocurable resins for volumetric 3D printing. These materials incorporate ceramic powders such as alumina, zirconia, or silicon nitride suspended in a photosensitive matrix. The formulations are designed to maintain appropriate viscosity and light scattering properties while enabling high ceramic loading. After printing, these composites typically undergo debinding and sintering processes to remove the polymer component and densify the ceramic structure.

- Light projection and tomographic techniques for volumetric printing: Advanced optical systems and computational techniques used in volumetric 3D printing of photopolymers and ceramic composites. These methods utilize computed tomography principles to project multiple 2D light patterns from different angles into a volume of photosensitive material. The overlapping light patterns create 3D intensity distributions that selectively cure the material. This approach enables the creation of complete 3D objects in seconds rather than hours, with no need for support structures or layer-by-layer processing.

- Resin rheology control for volumetric printing of ceramics: Methods for controlling the rheological properties of ceramic-loaded photopolymer resins to optimize their performance in volumetric 3D printing. These techniques involve the use of dispersants, thixotropic agents, and viscosity modifiers to maintain stable ceramic particle suspensions while ensuring appropriate flow characteristics during the printing process. Proper rheology control prevents particle sedimentation, reduces light scattering, and enables the production of high-quality ceramic parts with minimal defects and high dimensional accuracy.

- Post-processing techniques for volumetrically printed ceramic composites: Specialized post-processing methods for volumetrically printed ceramic composite parts. These techniques include carefully controlled thermal debinding cycles to remove the polymer matrix without causing defects, followed by sintering processes to densify the ceramic structure. Additional post-processing may include surface treatments, infiltration with secondary materials, or machining operations to achieve final dimensional tolerances and surface finish. These steps are critical for transforming the as-printed composite parts into fully functional ceramic components with the desired mechanical, thermal, and electrical properties.

02 Ceramic-polymer composite materials for volumetric printing

Composite materials combining ceramic particles with photocurable polymers for volumetric 3D printing. These materials incorporate ceramic powders such as alumina, zirconia, or silica into photopolymer matrices to create printable slurries. The resulting parts can be post-processed through debinding and sintering to remove the polymer component, leaving behind pure ceramic structures with enhanced mechanical, thermal, and electrical properties.Expand Specific Solutions03 Light projection and tomographic techniques for volumetric printing

Advanced optical systems and computational approaches for volumetric 3D printing that utilize tomographic principles. These techniques involve projecting multiple light patterns from different angles simultaneously or sequentially into a volume of photosensitive material. By carefully controlling the light patterns and their intensities, complex three-dimensional structures can be formed in a single exposure without the need for layer-by-layer processing.Expand Specific Solutions04 Post-processing methods for ceramic-polymer printed parts

Specialized post-processing techniques for volumetrically printed ceramic-polymer composites. These methods include controlled thermal treatments for polymer removal (debinding), sintering protocols to densify the ceramic component, and surface finishing techniques. The processes are designed to minimize defects such as warping, cracking, or porosity while achieving the desired material properties and dimensional accuracy in the final ceramic parts.Expand Specific Solutions05 High-resolution volumetric printing systems for complex structures

Advanced volumetric 3D printing systems capable of producing complex microstructures with high resolution using photopolymers and ceramic composites. These systems incorporate precise optical components, specialized resin delivery mechanisms, and sophisticated control software to achieve feature sizes in the micron range. The technology enables the fabrication of intricate structures with internal features that would be difficult or impossible to produce using conventional layer-by-layer printing approaches.Expand Specific Solutions

Industry Leaders in Advanced 3D Printing Materials

The volumetric 3D printing photopolymers and ceramic composites market is currently in a growth phase, with increasing adoption across manufacturing sectors. The global market size is estimated to reach $2.5 billion by 2025, driven by demand for advanced materials with superior mechanical properties. Technology maturity varies significantly among key players: established companies like 3M Innovative Properties and BASF Corp. lead in photopolymer development, while HRL Laboratories and Mighty Buildings are pioneering ceramic composite innovations. Academic institutions including EPFL and University of California are advancing fundamental research, while specialized manufacturers like JSR Corp. and LG Display are commercializing novel formulations. The competitive landscape features collaboration between industry and academia, with Asian manufacturers like ShenZhen Longer3D rapidly gaining market share through cost-effective solutions.

Mighty Buildings, Inc.

Technical Solution: Mighty Buildings has developed a proprietary Light-Enabled Additive Manufacturing (LEAM) technology for volumetric 3D printing of housing components. Their system uses a specialized photopolymer resin that cures rapidly when exposed to light, allowing for the creation of complex architectural structures in a single print. The company's material formulation combines thermoset polymers with mineral additives to create a composite that meets building code requirements for structural integrity and fire resistance. Their photopolymer-mineral composite material achieves strength comparable to concrete while maintaining significantly lower weight characteristics. The technology enables printing of complete wall sections with integrated insulation cavities, reducing assembly steps and improving thermal performance. Mighty Buildings has also developed ceramic-infused photopolymers that provide enhanced durability and weather resistance for exterior applications.

Strengths: Superior production speed compared to traditional layer-by-layer printing; ability to create complex geometries without support structures; excellent strength-to-weight ratio. Weaknesses: Limited material options compared to traditional construction; higher material costs than conventional building materials; relatively new technology with limited long-term performance data.

HRL Laboratories LLC

Technical Solution: HRL Laboratories has pioneered advanced ceramic precursor photopolymers for volumetric 3D printing applications. Their technology utilizes silicon oxycarbide (SiOC) preceramic polymers that can be photocured during the printing process and subsequently pyrolyzed to form high-performance ceramic components. The process involves a specialized formulation that maintains printability while achieving minimal shrinkage during the ceramic conversion phase. HRL's photopolymer systems incorporate nanoscale ceramic particles suspended in a photosensitive resin matrix, allowing for homogeneous distribution and consistent material properties throughout the printed part. Their volumetric printing approach enables the creation of complex ceramic geometries with feature resolutions below 100 microns, which would be extremely difficult to achieve using traditional ceramic forming techniques. The resulting ceramic composites demonstrate exceptional high-temperature stability (up to 1400°C), chemical resistance, and mechanical strength, making them suitable for aerospace, energy, and high-temperature industrial applications.

Strengths: Exceptional high-temperature performance; ability to create complex ceramic geometries impossible with traditional manufacturing; excellent chemical resistance and mechanical properties. Weaknesses: Multi-step process requiring post-print pyrolysis adds production time; some dimensional shrinkage during ceramic conversion; higher cost compared to traditional ceramic forming methods.

Key Patents and Research in Volumetric Printing Materials

Compositions and method of printing ceramic materials

PatentWO2021046615A1

Innovation

- A sinterable composition comprising a photosensitive resin, ceramic particles, and a dispersant, optionally with a low viscosity additive, allowing for 3D printing of ceramic objects with varied properties and complex shapes through differential ceramic particle concentrations that change shape during sintering, known as 4D printing.

Composition with polymer and ceramic and methods of use thereof

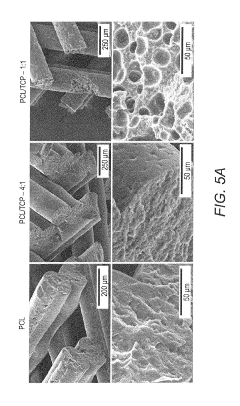

PatentActiveUS20190203038A1

Innovation

- A biocompatible polymer-ceramic composite with a ratio of 3:1 to 1:3 by weight, incorporating tricalcium phosphate (TCP) and polycaprolactone (PCL), featuring improved printability, elastic modulus, and accelerated degradation, with reduced solvent content and a customized microporous structure for enhanced bone implant performance.

Material Performance Metrics and Testing Standards

The evaluation of volumetric 3D printing materials requires standardized performance metrics and testing protocols to ensure consistency, reliability, and comparability across different material systems. For photopolymers and ceramic composites, these metrics must address their unique properties and application requirements.

Mechanical performance testing for these materials typically includes tensile strength, compressive strength, flexural modulus, and impact resistance measurements following ASTM D638, D695, D790, and D256 standards respectively. Photopolymers generally exhibit tensile strengths ranging from 30-65 MPa, while ceramic composites can achieve compressive strengths exceeding 300 MPa after sintering, though with lower tensile capabilities due to their inherent brittleness.

Resolution and dimensional accuracy testing follows ISO 527 and custom protocols that evaluate minimum feature size, surface roughness (Ra values), and dimensional tolerance. Volumetric printing with photopolymers can achieve feature resolutions down to 80-100 μm with surface roughness values of 1-5 μm Ra, while ceramic composites typically demonstrate resolutions of 150-200 μm with post-sintering shrinkage considerations of 10-20%.

Thermal stability metrics include glass transition temperature (Tg), heat deflection temperature (HDT), and coefficient of thermal expansion (CTE) measured according to ASTM E1356, D648, and E831 respectively. Photopolymers generally show Tg values between 45-120°C depending on formulation, while ceramic composites exhibit superior thermal stability with service temperatures potentially exceeding 1000°C after sintering.

Chemical resistance testing follows ASTM D543 protocols, evaluating material degradation when exposed to solvents, acids, bases, and environmental conditions. Photopolymers typically show moderate resistance to common solvents but may degrade in harsh chemical environments, while ceramic composites demonstrate exceptional chemical stability across a wide pH range and solvent exposures.

Optical properties assessment includes refractive index, light transmission, and photobleaching characteristics for photopolymers, which are critical for volumetric printing processes that rely on controlled light penetration and curing dynamics. Ceramic composites require evaluation of light scattering properties that affect printing resolution and cure depth.

Biocompatibility testing following ISO 10993 standards is essential for medical applications, with cytotoxicity, sensitization, and irritation tests being fundamental. Several photopolymer formulations have achieved USP Class VI or ISO 10993 compliance, while specific ceramic composites like hydroxyapatite-based materials demonstrate excellent biocompatibility for tissue engineering applications.

Long-term stability metrics include accelerated aging tests (ASTM F1980), UV resistance (ASTM G154), and moisture absorption characteristics (ASTM D570), providing critical data on material performance throughout the product lifecycle.

Mechanical performance testing for these materials typically includes tensile strength, compressive strength, flexural modulus, and impact resistance measurements following ASTM D638, D695, D790, and D256 standards respectively. Photopolymers generally exhibit tensile strengths ranging from 30-65 MPa, while ceramic composites can achieve compressive strengths exceeding 300 MPa after sintering, though with lower tensile capabilities due to their inherent brittleness.

Resolution and dimensional accuracy testing follows ISO 527 and custom protocols that evaluate minimum feature size, surface roughness (Ra values), and dimensional tolerance. Volumetric printing with photopolymers can achieve feature resolutions down to 80-100 μm with surface roughness values of 1-5 μm Ra, while ceramic composites typically demonstrate resolutions of 150-200 μm with post-sintering shrinkage considerations of 10-20%.

Thermal stability metrics include glass transition temperature (Tg), heat deflection temperature (HDT), and coefficient of thermal expansion (CTE) measured according to ASTM E1356, D648, and E831 respectively. Photopolymers generally show Tg values between 45-120°C depending on formulation, while ceramic composites exhibit superior thermal stability with service temperatures potentially exceeding 1000°C after sintering.

Chemical resistance testing follows ASTM D543 protocols, evaluating material degradation when exposed to solvents, acids, bases, and environmental conditions. Photopolymers typically show moderate resistance to common solvents but may degrade in harsh chemical environments, while ceramic composites demonstrate exceptional chemical stability across a wide pH range and solvent exposures.

Optical properties assessment includes refractive index, light transmission, and photobleaching characteristics for photopolymers, which are critical for volumetric printing processes that rely on controlled light penetration and curing dynamics. Ceramic composites require evaluation of light scattering properties that affect printing resolution and cure depth.

Biocompatibility testing following ISO 10993 standards is essential for medical applications, with cytotoxicity, sensitization, and irritation tests being fundamental. Several photopolymer formulations have achieved USP Class VI or ISO 10993 compliance, while specific ceramic composites like hydroxyapatite-based materials demonstrate excellent biocompatibility for tissue engineering applications.

Long-term stability metrics include accelerated aging tests (ASTM F1980), UV resistance (ASTM G154), and moisture absorption characteristics (ASTM D570), providing critical data on material performance throughout the product lifecycle.

Sustainability Considerations in Advanced 3D Printing

The environmental impact of advanced 3D printing technologies, particularly volumetric 3D printing using photopolymers and ceramic composites, demands critical examination as these manufacturing methods gain wider adoption. Volumetric 3D printing offers significant sustainability advantages over traditional manufacturing through material efficiency, with up to 90% less waste generation compared to subtractive manufacturing processes.

When comparing photopolymers and ceramic composites from a sustainability perspective, several key differences emerge. Photopolymers, while offering excellent printing precision and surface quality, typically derive from petroleum-based sources, raising concerns about resource depletion and end-of-life disposal. Recent innovations have introduced bio-based photopolymers with 30-50% renewable content, though complete biodegradability remains challenging due to the cross-linked polymer networks essential for structural integrity.

Ceramic composites present a more favorable environmental profile in terms of raw material sourcing, as they primarily utilize abundant minerals like silica and alumina. The energy intensity of ceramic processing, however, constitutes a significant environmental burden, with firing temperatures often exceeding 1200°C and contributing substantially to the carbon footprint of ceramic 3D printed components.

Life cycle assessment (LCA) studies indicate that the environmental impact of volumetric 3D printing varies significantly based on energy source, material selection, and post-processing requirements. Photopolymer-based processes typically consume 40-60% less energy during printing compared to traditional manufacturing but may require energy-intensive post-curing. Ceramic composites demand higher energy inputs during printing and sintering but offer superior longevity and recyclability.

Circular economy principles are increasingly being applied to both material systems. Photopolymer recycling technologies have advanced to allow mechanical grinding and reincorporation of up to 15% recycled content without significant property degradation. Ceramic composites offer more straightforward recycling pathways, with unfired material being nearly 100% recoverable and fired components potentially serving as aggregate in new formulations.

Water consumption presents another sustainability consideration, with photopolymer processing requiring significant volumes for washing and post-processing (approximately 2-5 liters per kg of material). Ceramic slurries similarly demand water for preparation, though closed-loop systems are becoming more common, reducing net consumption by up to 80%.

Future sustainability improvements will likely focus on developing fully bio-based photopolymers, reducing energy requirements for ceramic sintering through microwave or cold sintering processes, and implementing comprehensive material recovery systems. These advancements could potentially reduce the environmental footprint of volumetric 3D printing by an estimated 40-60% over the next decade.

When comparing photopolymers and ceramic composites from a sustainability perspective, several key differences emerge. Photopolymers, while offering excellent printing precision and surface quality, typically derive from petroleum-based sources, raising concerns about resource depletion and end-of-life disposal. Recent innovations have introduced bio-based photopolymers with 30-50% renewable content, though complete biodegradability remains challenging due to the cross-linked polymer networks essential for structural integrity.

Ceramic composites present a more favorable environmental profile in terms of raw material sourcing, as they primarily utilize abundant minerals like silica and alumina. The energy intensity of ceramic processing, however, constitutes a significant environmental burden, with firing temperatures often exceeding 1200°C and contributing substantially to the carbon footprint of ceramic 3D printed components.

Life cycle assessment (LCA) studies indicate that the environmental impact of volumetric 3D printing varies significantly based on energy source, material selection, and post-processing requirements. Photopolymer-based processes typically consume 40-60% less energy during printing compared to traditional manufacturing but may require energy-intensive post-curing. Ceramic composites demand higher energy inputs during printing and sintering but offer superior longevity and recyclability.

Circular economy principles are increasingly being applied to both material systems. Photopolymer recycling technologies have advanced to allow mechanical grinding and reincorporation of up to 15% recycled content without significant property degradation. Ceramic composites offer more straightforward recycling pathways, with unfired material being nearly 100% recoverable and fired components potentially serving as aggregate in new formulations.

Water consumption presents another sustainability consideration, with photopolymer processing requiring significant volumes for washing and post-processing (approximately 2-5 liters per kg of material). Ceramic slurries similarly demand water for preparation, though closed-loop systems are becoming more common, reducing net consumption by up to 80%.

Future sustainability improvements will likely focus on developing fully bio-based photopolymers, reducing energy requirements for ceramic sintering through microwave or cold sintering processes, and implementing comprehensive material recovery systems. These advancements could potentially reduce the environmental footprint of volumetric 3D printing by an estimated 40-60% over the next decade.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!