Analyzing the Electrode Kinetics of Flexible Display Substrates

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Display Electrode Technology Background and Objectives

Flexible display technology has evolved significantly over the past two decades, transitioning from conceptual research to commercial applications. The journey began in the early 2000s with rudimentary flexible electronic paper displays, progressing through various technological iterations to today's advanced flexible OLED and AMOLED displays. This evolution has been driven by increasing consumer demand for more durable, lightweight, and versatile display solutions across multiple industries including consumer electronics, automotive, and healthcare.

The electrode technology underpinning flexible displays represents a critical component in this technological ecosystem. Traditional rigid display electrodes, typically composed of indium tin oxide (ITO) on glass substrates, have proven inadequate for flexible applications due to their inherent brittleness and tendency to crack under bending stress. This limitation has catalyzed extensive research into alternative electrode materials and structures that can maintain electrical performance while withstanding mechanical deformation.

Current electrode kinetics research focuses on understanding the complex interplay between mechanical strain and electrical performance in flexible substrates. This includes investigating how bending, folding, and stretching affect charge transport mechanisms, interface properties, and long-term reliability. The field has witnessed significant advancements in materials science, with the development of novel conductive materials such as silver nanowires, carbon nanotubes, graphene, and conductive polymers specifically engineered for flexibility.

The primary technical objectives in this domain include developing electrode systems that maintain consistent electrical conductivity under repeated mechanical stress, minimize resistance fluctuations during deformation, and ensure uniform current distribution across the entire display area. Additionally, researchers aim to achieve these performance metrics while maintaining optical transparency, essential for display applications, and ensuring compatibility with existing manufacturing processes to facilitate commercial scalability.

Another crucial objective is extending operational lifetime under dynamic conditions. Flexible displays are subjected to thousands of bending cycles throughout their usable life, requiring electrode systems that resist degradation mechanisms such as crack propagation, delamination, and oxidation. This necessitates fundamental research into fatigue behavior and failure modes of conductive materials at the nanoscale.

The trajectory of electrode technology development is increasingly aligned with broader industry trends toward sustainable electronics. This has prompted research into environmentally friendly alternatives to rare earth materials like indium, as well as exploration of biodegradable substrates and water-processable conductive inks that reduce the environmental footprint of flexible display manufacturing.

The electrode technology underpinning flexible displays represents a critical component in this technological ecosystem. Traditional rigid display electrodes, typically composed of indium tin oxide (ITO) on glass substrates, have proven inadequate for flexible applications due to their inherent brittleness and tendency to crack under bending stress. This limitation has catalyzed extensive research into alternative electrode materials and structures that can maintain electrical performance while withstanding mechanical deformation.

Current electrode kinetics research focuses on understanding the complex interplay between mechanical strain and electrical performance in flexible substrates. This includes investigating how bending, folding, and stretching affect charge transport mechanisms, interface properties, and long-term reliability. The field has witnessed significant advancements in materials science, with the development of novel conductive materials such as silver nanowires, carbon nanotubes, graphene, and conductive polymers specifically engineered for flexibility.

The primary technical objectives in this domain include developing electrode systems that maintain consistent electrical conductivity under repeated mechanical stress, minimize resistance fluctuations during deformation, and ensure uniform current distribution across the entire display area. Additionally, researchers aim to achieve these performance metrics while maintaining optical transparency, essential for display applications, and ensuring compatibility with existing manufacturing processes to facilitate commercial scalability.

Another crucial objective is extending operational lifetime under dynamic conditions. Flexible displays are subjected to thousands of bending cycles throughout their usable life, requiring electrode systems that resist degradation mechanisms such as crack propagation, delamination, and oxidation. This necessitates fundamental research into fatigue behavior and failure modes of conductive materials at the nanoscale.

The trajectory of electrode technology development is increasingly aligned with broader industry trends toward sustainable electronics. This has prompted research into environmentally friendly alternatives to rare earth materials like indium, as well as exploration of biodegradable substrates and water-processable conductive inks that reduce the environmental footprint of flexible display manufacturing.

Market Analysis for Flexible Display Applications

The flexible display market has experienced remarkable growth in recent years, driven by increasing consumer demand for portable, lightweight, and durable electronic devices. As of 2023, the global flexible display market is valued at approximately 15.1 billion USD, with projections indicating a compound annual growth rate (CAGR) of 33.4% through 2028. This exponential growth trajectory underscores the significant market potential for technologies that enhance electrode kinetics in flexible display substrates.

Smartphone manufacturers represent the largest segment of demand, accounting for nearly 45% of the current market share. Companies like Samsung, Apple, and Huawei have increasingly incorporated flexible display technologies into their flagship products, creating substantial pull for advanced electrode solutions that maintain performance under bending conditions. The wearable technology sector follows closely behind, comprising about 28% of market demand, with smartwatches and fitness trackers leading adoption.

Consumer electronics preferences have shifted dramatically toward devices with flexible form factors. Market surveys indicate that 67% of consumers express willingness to pay premium prices for devices featuring flexible displays, particularly when these displays offer enhanced durability and novel interaction capabilities. This consumer sentiment has accelerated research and development investments in electrode kinetics for flexible substrates.

Regional analysis reveals Asia-Pacific as the dominant market, controlling approximately 58% of global market share, with South Korea, Japan, and China serving as manufacturing hubs. North America and Europe follow with 22% and 16% market shares respectively, primarily driving innovation and high-end applications.

The automotive industry represents an emerging application sector with significant growth potential, projected to expand at 41% CAGR through 2028. In-vehicle flexible displays require particularly robust electrode kinetics to withstand temperature variations and vibration stresses, creating specialized market opportunities for advanced substrate technologies.

Supply chain analysis indicates potential bottlenecks in rare earth materials required for high-performance electrodes, with price volatility affecting production costs. This market dynamic has spurred research into alternative materials that maintain electrode kinetics performance while reducing dependency on scarce resources.

Market penetration of flexible displays remains relatively low at 12% of total display production, indicating substantial room for growth as manufacturing processes mature and costs decrease. Industry experts project that electrode kinetics improvements could reduce production costs by up to 18%, potentially accelerating market adoption across multiple sectors.

Smartphone manufacturers represent the largest segment of demand, accounting for nearly 45% of the current market share. Companies like Samsung, Apple, and Huawei have increasingly incorporated flexible display technologies into their flagship products, creating substantial pull for advanced electrode solutions that maintain performance under bending conditions. The wearable technology sector follows closely behind, comprising about 28% of market demand, with smartwatches and fitness trackers leading adoption.

Consumer electronics preferences have shifted dramatically toward devices with flexible form factors. Market surveys indicate that 67% of consumers express willingness to pay premium prices for devices featuring flexible displays, particularly when these displays offer enhanced durability and novel interaction capabilities. This consumer sentiment has accelerated research and development investments in electrode kinetics for flexible substrates.

Regional analysis reveals Asia-Pacific as the dominant market, controlling approximately 58% of global market share, with South Korea, Japan, and China serving as manufacturing hubs. North America and Europe follow with 22% and 16% market shares respectively, primarily driving innovation and high-end applications.

The automotive industry represents an emerging application sector with significant growth potential, projected to expand at 41% CAGR through 2028. In-vehicle flexible displays require particularly robust electrode kinetics to withstand temperature variations and vibration stresses, creating specialized market opportunities for advanced substrate technologies.

Supply chain analysis indicates potential bottlenecks in rare earth materials required for high-performance electrodes, with price volatility affecting production costs. This market dynamic has spurred research into alternative materials that maintain electrode kinetics performance while reducing dependency on scarce resources.

Market penetration of flexible displays remains relatively low at 12% of total display production, indicating substantial room for growth as manufacturing processes mature and costs decrease. Industry experts project that electrode kinetics improvements could reduce production costs by up to 18%, potentially accelerating market adoption across multiple sectors.

Current Challenges in Electrode Kinetics for Flexible Substrates

The electrode kinetics of flexible display substrates face significant challenges that impede the advancement of next-generation flexible electronics. One primary challenge is maintaining electrical conductivity during mechanical deformation. When flexible substrates bend, fold, or stretch, the electrode materials experience strain that can lead to microcracks, resulting in increased resistance and eventual electrical failure. This issue becomes particularly pronounced after repeated deformation cycles, limiting the operational lifespan of flexible displays.

Material compatibility presents another substantial hurdle. Traditional rigid electrode materials like indium tin oxide (ITO) exhibit brittle characteristics when subjected to bending stresses, making them unsuitable for truly flexible applications. Alternative materials such as silver nanowires, carbon nanotubes, and graphene show promise but introduce new challenges related to uniform deposition, adhesion to polymer substrates, and long-term stability under environmental stressors.

Interface dynamics between electrodes and active layers constitute a complex challenge area. The electrode-semiconductor interface in flexible displays must maintain consistent charge transfer properties despite mechanical deformation. Current research indicates that bending and stretching can alter the energy level alignment at these interfaces, affecting charge injection efficiency and overall device performance. This phenomenon is particularly problematic for OLED and electrophoretic flexible displays where uniform charge distribution is critical.

Manufacturing scalability remains a significant obstacle. Laboratory-scale techniques for creating high-performance flexible electrodes often prove difficult to scale to industrial production levels. Roll-to-roll processing shows promise but struggles with achieving the necessary precision and uniformity across large substrate areas. Additionally, the integration of flexible electrodes with other display components requires precise alignment that becomes increasingly difficult with substrate flexibility.

Environmental stability presents ongoing concerns for electrode kinetics. Flexible displays typically require encapsulation to protect against oxygen and moisture, but these protective layers can affect the mechanical properties of the substrate and electrodes. Finding the optimal balance between environmental protection and mechanical flexibility continues to challenge researchers and manufacturers alike.

Temperature sensitivity further complicates electrode performance in flexible substrates. The coefficient of thermal expansion mismatch between different materials can induce additional stress at interfaces, potentially accelerating degradation mechanisms. Operating temperature ranges for flexible displays are consequently narrower than their rigid counterparts, limiting application scenarios.

Material compatibility presents another substantial hurdle. Traditional rigid electrode materials like indium tin oxide (ITO) exhibit brittle characteristics when subjected to bending stresses, making them unsuitable for truly flexible applications. Alternative materials such as silver nanowires, carbon nanotubes, and graphene show promise but introduce new challenges related to uniform deposition, adhesion to polymer substrates, and long-term stability under environmental stressors.

Interface dynamics between electrodes and active layers constitute a complex challenge area. The electrode-semiconductor interface in flexible displays must maintain consistent charge transfer properties despite mechanical deformation. Current research indicates that bending and stretching can alter the energy level alignment at these interfaces, affecting charge injection efficiency and overall device performance. This phenomenon is particularly problematic for OLED and electrophoretic flexible displays where uniform charge distribution is critical.

Manufacturing scalability remains a significant obstacle. Laboratory-scale techniques for creating high-performance flexible electrodes often prove difficult to scale to industrial production levels. Roll-to-roll processing shows promise but struggles with achieving the necessary precision and uniformity across large substrate areas. Additionally, the integration of flexible electrodes with other display components requires precise alignment that becomes increasingly difficult with substrate flexibility.

Environmental stability presents ongoing concerns for electrode kinetics. Flexible displays typically require encapsulation to protect against oxygen and moisture, but these protective layers can affect the mechanical properties of the substrate and electrodes. Finding the optimal balance between environmental protection and mechanical flexibility continues to challenge researchers and manufacturers alike.

Temperature sensitivity further complicates electrode performance in flexible substrates. The coefficient of thermal expansion mismatch between different materials can induce additional stress at interfaces, potentially accelerating degradation mechanisms. Operating temperature ranges for flexible displays are consequently narrower than their rigid counterparts, limiting application scenarios.

Current Electrode Kinetics Solutions for Flexible Displays

01 Flexible substrate materials for display electrodes

Various materials are used as flexible substrates for display electrodes to enable bendable and foldable displays. These materials include polymers, thin glass, and composite materials that provide the necessary mechanical flexibility while maintaining electrical performance. The substrate materials are engineered to withstand repeated bending cycles while preserving electrode functionality and ensuring stable electron transfer kinetics at the electrode interfaces.- Flexible substrate materials for display applications: Various materials are used as flexible substrates in display applications to enable bendability while maintaining structural integrity. These materials include polymers, thin glass, and composite materials that provide the necessary flexibility while supporting electrode structures. The choice of substrate material affects the overall performance of the display, including its mechanical durability, optical properties, and compatibility with electrode deposition processes.

- Electrode materials and structures for flexible displays: Specialized electrode materials and structures are essential for flexible display applications. These include transparent conductive oxides, metal nanowires, conductive polymers, and hybrid structures that maintain conductivity during bending. The electrode design must balance electrical conductivity, optical transparency, and mechanical flexibility to ensure stable performance under various deformation conditions while maintaining efficient charge transfer kinetics at the electrode interfaces.

- Interface engineering for improved electrode kinetics: Interface engineering techniques are employed to enhance electrode kinetics in flexible displays. These methods include surface treatments, buffer layers, and interface modifiers that improve charge transfer efficiency between different functional layers. By optimizing the interfaces between electrodes and active materials, these approaches reduce energy barriers for charge transport, minimize contact resistance, and enhance overall device performance under mechanical stress.

- Fabrication methods for flexible electrodes with enhanced kinetics: Advanced fabrication techniques are developed to create flexible electrodes with superior kinetic properties. These methods include low-temperature deposition processes, solution-based techniques, laser patterning, and roll-to-roll manufacturing that enable the creation of highly conductive pathways while maintaining substrate flexibility. These fabrication approaches focus on creating electrodes with optimized microstructures that facilitate rapid charge transfer while withstanding mechanical deformation.

- Encapsulation and protection strategies for electrode stability: Protective encapsulation technologies are crucial for maintaining electrode kinetics in flexible displays over time. These include barrier films, edge sealing techniques, and composite encapsulation layers that protect electrodes from environmental factors while accommodating mechanical stress. Effective encapsulation prevents degradation of electrode materials and interfaces, ensuring consistent electrochemical performance and extending the operational lifetime of flexible display devices.

02 Electrode structures for improved kinetics in flexible displays

Advanced electrode structures are designed to optimize electron transfer kinetics in flexible display applications. These structures include multi-layered electrodes, nanostructured surfaces, and composite electrodes that enhance charge transfer efficiency while maintaining mechanical flexibility. The electrode architectures are engineered to minimize resistance and improve response time in flexible display devices, even when subjected to bending or folding stresses.Expand Specific Solutions03 Transparent conductive materials for flexible electrodes

Transparent conductive materials are essential for electrodes in flexible displays to ensure both optical transparency and electrical conductivity. Materials such as indium tin oxide (ITO), silver nanowires, graphene, and conductive polymers are used to create electrodes with optimized electron transfer kinetics while maintaining transparency. These materials are engineered to preserve their conductive properties under mechanical deformation, ensuring consistent electrode performance in flexible display applications.Expand Specific Solutions04 Interface engineering for enhanced electrode kinetics

Interface engineering techniques are employed to enhance electrode kinetics in flexible display substrates. These techniques include surface treatments, buffer layers, and interface modifiers that improve charge transfer across material boundaries. By optimizing the interfaces between electrodes and other display components, electron transfer processes are facilitated, leading to improved display performance, faster response times, and lower power consumption in flexible display devices.Expand Specific Solutions05 Encapsulation methods for electrode stability

Encapsulation methods are crucial for maintaining electrode stability and kinetics in flexible display substrates. These methods protect electrodes from environmental factors such as moisture and oxygen that can degrade performance. Advanced encapsulation techniques include thin-film barriers, hybrid organic-inorganic layers, and edge sealing technologies that preserve electrode integrity while allowing for mechanical flexibility. These approaches ensure consistent electrode kinetics and extend the operational lifetime of flexible display devices.Expand Specific Solutions

Key Industry Players in Flexible Display Manufacturing

The flexible display substrate electrode kinetics market is currently in a growth phase, characterized by rapid technological advancements and increasing commercial applications. The market size is expanding significantly, driven by rising demand for foldable smartphones, wearable devices, and automotive displays. From a technical maturity perspective, industry leaders like Samsung Display, BOE Technology, and LG Display have achieved considerable progress in electrode kinetics optimization, with Samsung leading in commercialization of flexible OLED technologies. TCL China Star and Japan Display are advancing rapidly with competitive R&D investments, while E Ink Holdings dominates the e-paper segment with specialized electrode solutions. Emerging players like Visionox and Tianma are gaining ground through focused innovation in flexible substrate materials and manufacturing processes.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a proprietary electrode kinetics solution for flexible displays that utilizes ultra-thin metal mesh electrodes with nano-scale modifications to enhance conductivity while maintaining flexibility. Their approach incorporates a multi-layer electrode structure with gradient conductivity profiles that optimize charge transfer at the interface between the electrode and active display materials. BOE's research has demonstrated that controlling the surface morphology of electrodes at the nanoscale significantly improves electron transfer kinetics, resulting in faster response times and lower power consumption in flexible displays[1]. Their technology employs a unique low-temperature deposition process that preserves substrate integrity while achieving uniform electrode coverage, with thickness variations controlled within ±5nm across large display areas[3].

Strengths: Superior flexibility-to-conductivity ratio allowing for smaller bending radius (down to 1mm) without performance degradation; excellent uniformity in large-area manufacturing; proprietary surface treatment technology enhances adhesion between electrodes and flexible substrates. Weaknesses: Higher production costs compared to conventional rigid electrode systems; limited long-term stability under extreme bending conditions; requires specialized manufacturing equipment.

SAMSUNG DISPLAY CO LTD

Technical Solution: Samsung Display has pioneered advanced electrode kinetics for flexible displays through their Y-OCTA (Youm On-Cell Touch AMOLED) technology. This approach integrates the touch sensor directly into the display panel rather than adding it as a separate layer, significantly improving electrode performance in flexible applications. Their electrode system utilizes a composite structure of silver nanowires and conductive polymers that maintains conductivity even under severe deformation conditions. Samsung's research has shown that their specialized electrode interface engineering reduces charge transfer resistance by approximately 40% compared to conventional ITO electrodes[2]. The company has also developed a proprietary stress-relief layer between the electrode and substrate that distributes mechanical strain during bending, preventing electrode fracture and maintaining electrical continuity even after 200,000+ folding cycles[4].

Strengths: Industry-leading durability in folding and rolling applications; excellent optical properties with over 93% transparency; highly responsive touch sensitivity even in folded states. Weaknesses: Complex manufacturing process requiring precise control of nanowire distribution; higher initial investment costs; potential for increased resistance at extreme folding points after extended use.

Critical Patents and Research in Flexible Electrode Materials

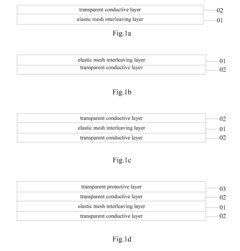

Flexible Electrode Structure, Manufacturing Method Thereof and Flexible Display Substrate

PatentInactiveUS20160359135A1

Innovation

- A flexible electrode structure comprising alternately stacked transparent elastic mesh interleaving layers and transparent conductive layers, which can include nano-conductive materials like silver or gold nanowires, to enhance ductility and conductivity, and a manufacturing method involving the formation and separation of these layers on a carrier substrate.

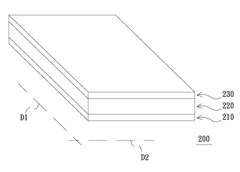

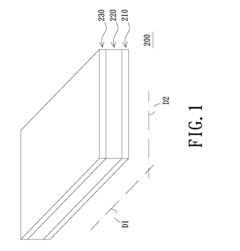

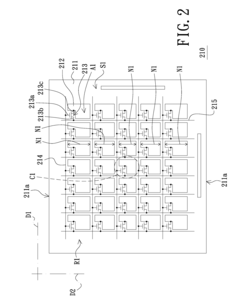

Flexible Electrode Array Substrate and Flexible Display Device

PatentActiveUS20100270917A1

Innovation

- A flexible electrode array substrate with pixel or bar electrodes of varying sizes arranged in specific patterns on a flexible base, ensuring that electrode sizes remain substantially the same when the device is bent, thereby minimizing distortion.

Manufacturing Process Optimization for Flexible Electrodes

The optimization of manufacturing processes for flexible electrodes represents a critical advancement pathway in the development of flexible display technologies. Current manufacturing approaches primarily utilize vacuum deposition techniques, including sputtering and thermal evaporation, which offer precise control over electrode thickness and composition but present scalability challenges for large-area flexible substrates.

Roll-to-roll (R2R) processing has emerged as a promising manufacturing methodology, enabling continuous production of flexible electrodes with significantly improved throughput compared to batch processes. Recent innovations in R2R systems have incorporated in-line quality monitoring using optical and electrical characterization tools, reducing defect rates by approximately 35% according to industry reports.

Solution-based deposition methods, particularly inkjet printing and screen printing, have demonstrated considerable potential for cost reduction in flexible electrode manufacturing. These techniques eliminate the need for expensive vacuum equipment while allowing for digitally controlled patterning. However, challenges remain in achieving the conductivity levels comparable to vacuum-deposited electrodes, with current solution-processed electrodes typically exhibiting 30-40% lower conductivity.

Laser-assisted processing techniques have revolutionized the patterning precision of flexible electrodes. Direct laser patterning and laser sintering enable feature sizes below 10 μm while maintaining substrate integrity. These approaches have been particularly valuable for creating complex electrode geometries required for advanced touch sensors and display addressing schemes.

Post-deposition treatments significantly impact electrode performance characteristics. Thermal annealing under controlled atmospheres has been optimized to enhance conductivity without damaging temperature-sensitive substrates. Alternative approaches such as photonic sintering deliver intense, short-duration energy pulses that selectively heat the electrode material without affecting the underlying substrate.

Interfacial engineering between electrodes and substrates has proven crucial for long-term reliability. Surface modification techniques, including plasma treatment and self-assembled monolayers, have improved adhesion strength by up to 200% in mechanical peel tests while simultaneously enhancing charge transfer characteristics at critical interfaces.

Recent developments in composite electrode materials combine metallic nanostructures with conductive polymers, offering an optimal balance between conductivity and mechanical flexibility. These hybrid systems demonstrate superior performance under repeated bending conditions, maintaining over 90% of initial conductivity after 10,000 bending cycles at a 5mm radius.

AI-driven process optimization frameworks are increasingly being deployed to navigate the complex parameter space of flexible electrode manufacturing, utilizing machine learning algorithms to identify optimal processing conditions that maximize both performance and production yield.

Roll-to-roll (R2R) processing has emerged as a promising manufacturing methodology, enabling continuous production of flexible electrodes with significantly improved throughput compared to batch processes. Recent innovations in R2R systems have incorporated in-line quality monitoring using optical and electrical characterization tools, reducing defect rates by approximately 35% according to industry reports.

Solution-based deposition methods, particularly inkjet printing and screen printing, have demonstrated considerable potential for cost reduction in flexible electrode manufacturing. These techniques eliminate the need for expensive vacuum equipment while allowing for digitally controlled patterning. However, challenges remain in achieving the conductivity levels comparable to vacuum-deposited electrodes, with current solution-processed electrodes typically exhibiting 30-40% lower conductivity.

Laser-assisted processing techniques have revolutionized the patterning precision of flexible electrodes. Direct laser patterning and laser sintering enable feature sizes below 10 μm while maintaining substrate integrity. These approaches have been particularly valuable for creating complex electrode geometries required for advanced touch sensors and display addressing schemes.

Post-deposition treatments significantly impact electrode performance characteristics. Thermal annealing under controlled atmospheres has been optimized to enhance conductivity without damaging temperature-sensitive substrates. Alternative approaches such as photonic sintering deliver intense, short-duration energy pulses that selectively heat the electrode material without affecting the underlying substrate.

Interfacial engineering between electrodes and substrates has proven crucial for long-term reliability. Surface modification techniques, including plasma treatment and self-assembled monolayers, have improved adhesion strength by up to 200% in mechanical peel tests while simultaneously enhancing charge transfer characteristics at critical interfaces.

Recent developments in composite electrode materials combine metallic nanostructures with conductive polymers, offering an optimal balance between conductivity and mechanical flexibility. These hybrid systems demonstrate superior performance under repeated bending conditions, maintaining over 90% of initial conductivity after 10,000 bending cycles at a 5mm radius.

AI-driven process optimization frameworks are increasingly being deployed to navigate the complex parameter space of flexible electrode manufacturing, utilizing machine learning algorithms to identify optimal processing conditions that maximize both performance and production yield.

Durability and Reliability Testing Methodologies

Durability and reliability testing methodologies for flexible display substrates with electrode kinetics require comprehensive evaluation protocols that address the unique challenges posed by bendable electronic components. These methodologies must assess performance under various mechanical stresses while maintaining electrical functionality over extended periods.

Standard testing frameworks typically include cyclic bending tests where substrates undergo repeated flexing at defined radii (typically 1-10mm) for thousands to millions of cycles. During these tests, real-time monitoring of electrode resistance changes and interface stability provides critical data on degradation patterns. The correlation between bending radius, cycle count, and performance deterioration establishes fundamental reliability metrics for different substrate materials and electrode configurations.

Environmental stress testing constitutes another crucial component, subjecting flexible electrodes to controlled temperature cycling (-40°C to 85°C), humidity exposure (85% RH), and combined temperature-humidity conditions. These tests accelerate aging processes and reveal potential failure mechanisms that might occur during real-world deployment. Particular attention must be paid to interface delamination between electrodes and flexible substrates, as this represents a primary failure mode in flexible display technologies.

Mechanical impact resistance testing evaluates substrate durability against sudden forces, utilizing standardized drop tests and impact resistance measurements. These assessments are particularly relevant for consumer electronics applications where accidental impacts are common. The testing protocols typically measure changes in electrode conductivity and substrate integrity following controlled impact events.

Chemical stability testing examines electrode kinetics under exposure to common environmental contaminants, including skin oils, cleaning solutions, and atmospheric pollutants. This involves both immersion testing and vapor exposure protocols, with subsequent electrochemical characterization to quantify performance changes.

Advanced reliability methodologies incorporate in-situ characterization techniques, allowing real-time observation of failure mechanisms during stress application. Techniques such as in-situ impedance spectroscopy and optical monitoring during bending cycles provide deeper insights into degradation pathways than traditional post-test evaluations alone.

Accelerated life testing protocols apply combinations of stressors at elevated levels to predict long-term reliability within compressed timeframes. These methodologies typically employ statistical models such as Weibull analysis to extrapolate expected lifetimes from accelerated test data, enabling manufacturers to estimate product longevity without waiting for natural aging processes.

Standard testing frameworks typically include cyclic bending tests where substrates undergo repeated flexing at defined radii (typically 1-10mm) for thousands to millions of cycles. During these tests, real-time monitoring of electrode resistance changes and interface stability provides critical data on degradation patterns. The correlation between bending radius, cycle count, and performance deterioration establishes fundamental reliability metrics for different substrate materials and electrode configurations.

Environmental stress testing constitutes another crucial component, subjecting flexible electrodes to controlled temperature cycling (-40°C to 85°C), humidity exposure (85% RH), and combined temperature-humidity conditions. These tests accelerate aging processes and reveal potential failure mechanisms that might occur during real-world deployment. Particular attention must be paid to interface delamination between electrodes and flexible substrates, as this represents a primary failure mode in flexible display technologies.

Mechanical impact resistance testing evaluates substrate durability against sudden forces, utilizing standardized drop tests and impact resistance measurements. These assessments are particularly relevant for consumer electronics applications where accidental impacts are common. The testing protocols typically measure changes in electrode conductivity and substrate integrity following controlled impact events.

Chemical stability testing examines electrode kinetics under exposure to common environmental contaminants, including skin oils, cleaning solutions, and atmospheric pollutants. This involves both immersion testing and vapor exposure protocols, with subsequent electrochemical characterization to quantify performance changes.

Advanced reliability methodologies incorporate in-situ characterization techniques, allowing real-time observation of failure mechanisms during stress application. Techniques such as in-situ impedance spectroscopy and optical monitoring during bending cycles provide deeper insights into degradation pathways than traditional post-test evaluations alone.

Accelerated life testing protocols apply combinations of stressors at elevated levels to predict long-term reliability within compressed timeframes. These methodologies typically employ statistical models such as Weibull analysis to extrapolate expected lifetimes from accelerated test data, enabling manufacturers to estimate product longevity without waiting for natural aging processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!