Flexible Display Substrates and their Role in EV Battery Design

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Display Technology Evolution and Objectives

Flexible display technology has evolved significantly over the past two decades, transitioning from conceptual research to commercial applications. The journey began in the early 2000s with rudimentary flexible electronic paper displays, progressing through several technological generations to today's advanced flexible OLED and AMOLED displays. This evolution has been driven by continuous improvements in substrate materials, from early plastic films to more sophisticated polymers and ultra-thin glass that can withstand repeated bending while maintaining display integrity.

The development trajectory shows a clear trend toward increasing flexibility, durability, and performance metrics. Initial flexible displays could only achieve limited bending angles and had relatively short lifespans, whereas current technologies support folding, rolling, and even stretching capabilities with significantly improved durability. Resolution, color reproduction, and response times have also seen remarkable enhancements, approaching or matching those of rigid displays.

Key technological milestones include the introduction of flexible OLED technology around 2013, the commercialization of foldable smartphones in 2019, and recent advancements in stretchable display substrates that can accommodate up to 50% strain without performance degradation. These developments have progressively expanded the application scope from simple curved displays to fully foldable and rollable consumer electronics.

The primary technical objectives for flexible display substrates in EV battery design focus on several critical aspects. First, creating display substrates that can conform to the complex geometries of battery components while maintaining operational stability under varying temperature conditions typical in EV environments (-40°C to 85°C). Second, developing substrates with enhanced thermal management properties to address the heat dissipation challenges in battery systems. Third, engineering materials that provide electromagnetic shielding to prevent interference between display components and battery management systems.

Additionally, there are objectives related to sustainability and manufacturing efficiency. These include developing bio-based or recyclable substrate materials to reduce environmental impact, and designing substrates compatible with roll-to-roll manufacturing processes to enable cost-effective mass production for the automotive industry. The integration of sensors within flexible substrates represents another important goal, potentially allowing for real-time monitoring of battery health and performance parameters.

The convergence of flexible display technology with EV battery design aims ultimately to transform how drivers interact with vehicle systems, enabling more intuitive interfaces while optimizing space utilization and weight distribution within electric vehicles. This synergy could significantly enhance both user experience and functional efficiency in next-generation EVs.

The development trajectory shows a clear trend toward increasing flexibility, durability, and performance metrics. Initial flexible displays could only achieve limited bending angles and had relatively short lifespans, whereas current technologies support folding, rolling, and even stretching capabilities with significantly improved durability. Resolution, color reproduction, and response times have also seen remarkable enhancements, approaching or matching those of rigid displays.

Key technological milestones include the introduction of flexible OLED technology around 2013, the commercialization of foldable smartphones in 2019, and recent advancements in stretchable display substrates that can accommodate up to 50% strain without performance degradation. These developments have progressively expanded the application scope from simple curved displays to fully foldable and rollable consumer electronics.

The primary technical objectives for flexible display substrates in EV battery design focus on several critical aspects. First, creating display substrates that can conform to the complex geometries of battery components while maintaining operational stability under varying temperature conditions typical in EV environments (-40°C to 85°C). Second, developing substrates with enhanced thermal management properties to address the heat dissipation challenges in battery systems. Third, engineering materials that provide electromagnetic shielding to prevent interference between display components and battery management systems.

Additionally, there are objectives related to sustainability and manufacturing efficiency. These include developing bio-based or recyclable substrate materials to reduce environmental impact, and designing substrates compatible with roll-to-roll manufacturing processes to enable cost-effective mass production for the automotive industry. The integration of sensors within flexible substrates represents another important goal, potentially allowing for real-time monitoring of battery health and performance parameters.

The convergence of flexible display technology with EV battery design aims ultimately to transform how drivers interact with vehicle systems, enabling more intuitive interfaces while optimizing space utilization and weight distribution within electric vehicles. This synergy could significantly enhance both user experience and functional efficiency in next-generation EVs.

Market Demand Analysis for EV Battery Integration

The electric vehicle (EV) market is experiencing unprecedented growth, with global sales surpassing 10 million units in 2022, representing a 55% increase year-over-year. This rapid expansion has created substantial demand for innovative battery solutions that can address the key challenges facing EV adoption: range anxiety, charging time, and overall vehicle weight. Flexible display substrates integrated into battery design present a compelling solution to these challenges.

Market research indicates that consumers consistently rank battery performance and range as their top concerns when considering EV purchases. A 2023 survey by McKinsey revealed that 78% of potential EV buyers consider range the most critical factor in their purchasing decision, while 65% expressed concerns about battery longevity and performance monitoring. This consumer sentiment has created a significant market pull for advanced battery management systems that can provide real-time, accurate information about battery health and performance.

The integration of flexible displays directly into EV batteries addresses these market demands by enabling continuous monitoring and visualization of battery status. Industry analysts project that the market for smart battery systems incorporating flexible display technology will grow at a CAGR of 24% through 2030, reaching a market value of $12 billion. This growth is driven by both consumer demand and regulatory requirements for improved battery safety and performance transparency.

From a geographical perspective, the demand for advanced battery solutions with integrated displays is particularly strong in premium EV markets such as North America and Europe, where consumers demonstrate higher willingness to pay for enhanced functionality. However, rapid adoption is also expected in the Chinese market, where domestic manufacturers are aggressively pursuing technological differentiation.

Vehicle manufacturers are increasingly recognizing the competitive advantage offered by advanced battery visualization systems. A recent industry survey found that 82% of automotive OEMs plan to incorporate some form of enhanced battery monitoring display in their EV models by 2026, with 47% specifically exploring flexible display integration options.

The commercial vehicle segment represents another significant market opportunity, with fleet operators placing high value on battery management systems that can optimize performance and extend battery life. The ability to monitor battery health in real-time using integrated flexible displays can reduce total cost of ownership by extending battery lifespan by an estimated 15-20%, creating compelling economic incentives for adoption.

Supply chain considerations are also driving market demand, as battery manufacturers seek to differentiate their products in an increasingly competitive landscape. The integration of flexible display technology represents a high-value addition that can command premium pricing while addressing critical customer needs.

Market research indicates that consumers consistently rank battery performance and range as their top concerns when considering EV purchases. A 2023 survey by McKinsey revealed that 78% of potential EV buyers consider range the most critical factor in their purchasing decision, while 65% expressed concerns about battery longevity and performance monitoring. This consumer sentiment has created a significant market pull for advanced battery management systems that can provide real-time, accurate information about battery health and performance.

The integration of flexible displays directly into EV batteries addresses these market demands by enabling continuous monitoring and visualization of battery status. Industry analysts project that the market for smart battery systems incorporating flexible display technology will grow at a CAGR of 24% through 2030, reaching a market value of $12 billion. This growth is driven by both consumer demand and regulatory requirements for improved battery safety and performance transparency.

From a geographical perspective, the demand for advanced battery solutions with integrated displays is particularly strong in premium EV markets such as North America and Europe, where consumers demonstrate higher willingness to pay for enhanced functionality. However, rapid adoption is also expected in the Chinese market, where domestic manufacturers are aggressively pursuing technological differentiation.

Vehicle manufacturers are increasingly recognizing the competitive advantage offered by advanced battery visualization systems. A recent industry survey found that 82% of automotive OEMs plan to incorporate some form of enhanced battery monitoring display in their EV models by 2026, with 47% specifically exploring flexible display integration options.

The commercial vehicle segment represents another significant market opportunity, with fleet operators placing high value on battery management systems that can optimize performance and extend battery life. The ability to monitor battery health in real-time using integrated flexible displays can reduce total cost of ownership by extending battery lifespan by an estimated 15-20%, creating compelling economic incentives for adoption.

Supply chain considerations are also driving market demand, as battery manufacturers seek to differentiate their products in an increasingly competitive landscape. The integration of flexible display technology represents a high-value addition that can command premium pricing while addressing critical customer needs.

Current Challenges in Flexible Substrate Implementation

Despite the promising potential of flexible display substrates in EV battery design, several significant challenges impede their widespread implementation. Material stability remains a primary concern, as flexible substrates must maintain structural integrity under extreme temperature fluctuations typical in EV operations, ranging from -40°C to over 60°C. Current polymer-based substrates often exhibit degradation when exposed to these conditions for extended periods, compromising their reliability in automotive applications.

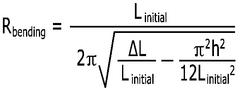

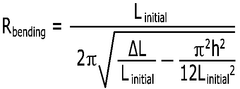

Mechanical durability presents another critical challenge. Flexible substrates in EV batteries must withstand constant vibration, potential impact, and repeated flexing cycles without developing microcracks or delamination. Testing has shown that many current materials begin to show performance deterioration after 10,000-15,000 flex cycles, falling short of automotive industry standards that require stability over hundreds of thousands of cycles throughout a vehicle's lifespan.

Manufacturing scalability remains problematic for high-quality flexible substrates. Current production methods struggle with maintaining uniform thickness and performance characteristics across large surface areas, leading to inconsistent battery performance. Roll-to-roll processing techniques show promise but still face yield issues exceeding 15% when scaled to automotive production volumes.

Barrier properties represent a significant technical hurdle. Flexible substrates must provide effective barriers against moisture and oxygen to protect sensitive battery components. Current materials achieve water vapor transmission rates (WVTR) of approximately 10^-3 g/m²/day, whereas EV battery applications require rates below 10^-6 g/m²/day to ensure long-term stability and safety.

Cost considerations further complicate implementation. High-performance flexible substrates currently cost 5-10 times more than traditional rigid alternatives, making them economically unfeasible for mass-market EV production. This cost differential stems from complex manufacturing processes and expensive raw materials, creating a significant barrier to adoption.

Integration challenges with existing battery manufacturing infrastructure also hinder implementation. Current battery production lines are optimized for rigid components, requiring substantial retooling and process modification to accommodate flexible substrates. This necessitates significant capital investment and production downtime that many manufacturers are reluctant to undertake without proven long-term benefits.

Regulatory and safety certification presents additional obstacles. Flexible substrate-based battery designs must undergo extensive testing to meet stringent automotive safety standards, including thermal runaway prevention and crash safety requirements. The novel nature of these materials means certification pathways are not yet well-established, extending development timelines.

Mechanical durability presents another critical challenge. Flexible substrates in EV batteries must withstand constant vibration, potential impact, and repeated flexing cycles without developing microcracks or delamination. Testing has shown that many current materials begin to show performance deterioration after 10,000-15,000 flex cycles, falling short of automotive industry standards that require stability over hundreds of thousands of cycles throughout a vehicle's lifespan.

Manufacturing scalability remains problematic for high-quality flexible substrates. Current production methods struggle with maintaining uniform thickness and performance characteristics across large surface areas, leading to inconsistent battery performance. Roll-to-roll processing techniques show promise but still face yield issues exceeding 15% when scaled to automotive production volumes.

Barrier properties represent a significant technical hurdle. Flexible substrates must provide effective barriers against moisture and oxygen to protect sensitive battery components. Current materials achieve water vapor transmission rates (WVTR) of approximately 10^-3 g/m²/day, whereas EV battery applications require rates below 10^-6 g/m²/day to ensure long-term stability and safety.

Cost considerations further complicate implementation. High-performance flexible substrates currently cost 5-10 times more than traditional rigid alternatives, making them economically unfeasible for mass-market EV production. This cost differential stems from complex manufacturing processes and expensive raw materials, creating a significant barrier to adoption.

Integration challenges with existing battery manufacturing infrastructure also hinder implementation. Current battery production lines are optimized for rigid components, requiring substantial retooling and process modification to accommodate flexible substrates. This necessitates significant capital investment and production downtime that many manufacturers are reluctant to undertake without proven long-term benefits.

Regulatory and safety certification presents additional obstacles. Flexible substrate-based battery designs must undergo extensive testing to meet stringent automotive safety standards, including thermal runaway prevention and crash safety requirements. The novel nature of these materials means certification pathways are not yet well-established, extending development timelines.

Existing Flexible Substrate Solutions for EV Applications

01 Polymer-based flexible substrates

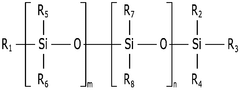

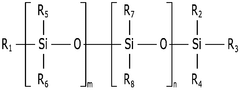

Polymer materials such as polyimide, polyethylene terephthalate (PET), and polyethylene naphthalate (PEN) are widely used as flexible substrates for displays due to their excellent mechanical flexibility, lightweight properties, and thermal stability. These materials can withstand repeated bending and folding while maintaining their structural integrity, making them ideal for flexible display applications. Various surface treatments and coatings can be applied to enhance their barrier properties against moisture and oxygen.- Polymer-based flexible substrates: Polymer materials such as polyimide, polyethylene terephthalate (PET), and polyethylene naphthalate (PEN) are widely used as flexible substrates for displays due to their excellent mechanical flexibility, lightweight properties, and thermal stability. These materials can withstand repeated bending and folding while maintaining their structural integrity, making them ideal for flexible display applications. Various surface treatments and coatings can be applied to enhance their barrier properties against moisture and oxygen.

- Thin-film transistor structures for flexible displays: Advanced thin-film transistor (TFT) structures are essential components of flexible displays, designed to maintain electrical performance under mechanical stress. These structures incorporate specialized semiconductor materials, electrode configurations, and passivation layers that can withstand bending without degradation. Low-temperature fabrication processes are employed to create these TFTs on temperature-sensitive flexible substrates, enabling the development of bendable and foldable display devices with stable electronic properties.

- Barrier and encapsulation technologies: Effective barrier and encapsulation technologies are crucial for protecting flexible display components from environmental factors. Multi-layer barrier films combining inorganic and organic materials are used to prevent moisture and oxygen penetration while maintaining flexibility. Thin-film encapsulation techniques provide hermetic sealing of sensitive display elements such as OLEDs without compromising the overall flexibility of the device. These technologies significantly extend the operational lifetime of flexible displays by preventing degradation of organic materials and metal electrodes.

- Manufacturing processes for flexible substrates: Specialized manufacturing processes have been developed for producing flexible display substrates with consistent quality and performance. These include roll-to-roll processing techniques that enable continuous production of large-area flexible substrates, laser patterning methods for creating precise circuit patterns without damaging the substrate, and low-temperature deposition processes for forming functional layers. Advanced lamination and transfer techniques are also employed to integrate different materials and components while maintaining the flexibility of the overall structure.

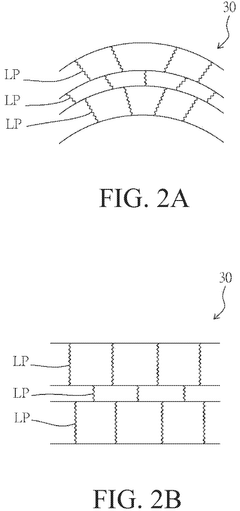

- Mechanical support and stress management systems: Innovative mechanical support and stress management systems are implemented to enhance the durability of flexible displays. These include specialized backing layers that distribute mechanical stress during bending, neutral plane engineering to position sensitive components where bending stress is minimized, and reinforcement structures at critical junctions. Stress-relief patterns and structures are incorporated into the substrate design to prevent crack propagation and delamination during repeated flexing, significantly improving the mechanical reliability and lifetime of flexible display devices.

02 Thin-film transistor structures for flexible displays

Advanced thin-film transistor (TFT) structures are essential components of flexible displays, enabling pixel control while maintaining flexibility. These structures typically incorporate low-temperature processed semiconductors such as amorphous silicon, oxide semiconductors, or organic materials that can be fabricated on flexible substrates without thermal damage. Special circuit designs and buffer layers are implemented to prevent performance degradation during bending and to distribute mechanical stress evenly across the display.Expand Specific Solutions03 Barrier and encapsulation technologies

Effective barrier and encapsulation technologies are crucial for protecting flexible display components from environmental factors such as moisture and oxygen. Multi-layer barrier films combining organic and inorganic materials are commonly used to achieve ultra-low permeation rates while maintaining flexibility. Advanced encapsulation methods include thin-film encapsulation (TFE) with alternating organic/inorganic layers and edge sealing techniques that prevent lateral diffusion of harmful elements into the active display area.Expand Specific Solutions04 Mechanical support and stress distribution systems

Specialized mechanical support structures and stress distribution systems are implemented in flexible displays to prevent damage during bending and folding operations. These include neutral plane engineering where active components are positioned at the neutral bending axis, reinforcement layers that distribute mechanical stress, and specially designed hinges or folding zones that concentrate bending in predetermined areas. Some designs incorporate variable thickness regions to optimize flexibility where needed while maintaining rigidity in other areas.Expand Specific Solutions05 Novel substrate materials and hybrid structures

Research in flexible displays has led to the development of novel substrate materials and hybrid structures that offer enhanced performance characteristics. These include ultra-thin glass that provides better barrier properties than polymers while maintaining some flexibility, metal foils with planarization layers that offer excellent thermal stability, and composite substrates combining multiple materials to achieve an optimal balance of properties. Some advanced approaches incorporate stretchable components or engineered microstructures that enhance mechanical resilience during deformation.Expand Specific Solutions

Key Industry Players in Flexible Display and EV Sectors

The flexible display substrate market is currently in a growth phase, with increasing applications in EV battery design due to its potential for lightweight, space-efficient power solutions. The market is expanding rapidly, projected to reach significant scale as automotive manufacturers seek innovative energy storage solutions. Technologically, companies are at varying maturity levels: Samsung Display, LG Display, and BOE Technology lead with advanced flexible OLED technologies; Japan Display and E Ink (Prime View International) offer specialized solutions in LCD and e-paper respectively; while automotive-focused players like Toyota, Honda, and Prime Planet Energy & Solutions are integrating these technologies into battery systems. Semiconductor Energy Laboratory and ITRI are advancing next-generation substrate materials, while traditional battery manufacturers like Samsung SDI are adapting their technologies for flexible applications in EVs.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive flexible display substrate solution for EV battery applications called "FlexEnergy." This technology utilizes ultra-thin glass substrates (UTG) with thickness below 30μm combined with specialized polymer layers that provide both flexibility and protection against the harsh chemical environment inside batteries. BOE's approach incorporates transparent conductive oxide (TCO) layers that maintain conductivity even under repeated bending cycles, with reported performance retention above 95% after 200,000 bend cycles. Their flexible substrates feature integrated temperature sensors and strain gauges that enable real-time monitoring of battery conditions. The technology allows for the creation of curved battery interfaces that can display critical information directly on the battery surface, including charge status, temperature warnings, and diagnostic data. BOE has also developed specialized encapsulation techniques that protect the flexible electronics from electrolyte exposure while maintaining thermal management capabilities.

Strengths: Industry-leading display manufacturing capacity; established supply chain for key materials; advanced encapsulation technology that extends operational lifetime. Weaknesses: Less experience in automotive-grade reliability testing compared to dedicated battery manufacturers; higher cost structure than conventional solutions.

LG Display Co., Ltd.

Technical Solution: LG Display has developed "FlexBattery" technology that integrates flexible display substrates directly into EV battery designs. Their approach utilizes proprietary thin-film encapsulation (TFE) techniques that protect flexible electronics from the harsh chemical environment of battery cells while maintaining mechanical flexibility. The technology incorporates multi-layer barrier films with water vapor transmission rates below 10^-6 g/m²/day, ensuring long-term reliability in battery applications. LG's flexible substrates feature embedded sensor arrays that monitor temperature distribution, mechanical stress, and electrochemical conditions across the battery surface. Their solution enables the creation of curved battery packs that conform to vehicle design constraints while maximizing energy density. The technology also incorporates transparent conductive materials that maintain performance under mechanical stress, allowing for integrated touch interfaces directly on battery surfaces. LG Display has demonstrated prototype systems that achieve approximately 25% improvement in volumetric efficiency compared to conventional rigid battery designs.

Strengths: Vertical integration with LG's battery manufacturing capabilities; proven mass production techniques for flexible substrates; extensive automotive supply chain relationships. Weaknesses: Higher initial investment requirements; more complex integration with existing battery management systems; potential thermal management challenges.

Critical Patents and Innovations in Flexible Display Materials

Flexible electrode substrate including porous electrode, and method for manufacturing same

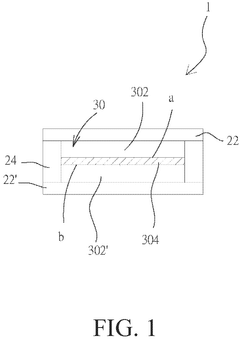

PatentWO2021029458A1

Innovation

- A flexible electrode substrate with a porous electrode is developed, featuring a patterned porous structure that allows for easy attachment and detachment from various substrates, using materials like reduced graphene oxide and activated carbon, and a coating layer with functional groups for improved electrochemical performance.

Flexible battery

PatentActiveUS12107207B2

Innovation

- A flexible battery design featuring a glue frame sandwiched between substrates with an electrochemical reaction element, utilizing a first adhesive containing a linear polymer and a crystallization inhibitor to prevent cracking and enhance adhesion and flexibility, while maintaining electrical insulation and conductivity.

Sustainability Impact of Flexible Display Technologies

The integration of flexible display technologies into various industries, particularly electric vehicle manufacturing, presents significant sustainability implications that extend beyond mere technological advancement. These technologies offer substantial environmental benefits through reduced material consumption, as flexible substrates typically require fewer raw materials compared to traditional rigid displays. This material efficiency translates directly into reduced resource extraction and processing, decreasing the overall environmental footprint of display manufacturing.

Energy consumption during production represents another critical sustainability factor. Flexible display manufacturing processes generally consume less energy than conventional display production, particularly when utilizing roll-to-roll processing techniques. This energy efficiency contributes to lower carbon emissions throughout the production lifecycle, aligning with global carbon reduction initiatives and sustainability goals in manufacturing.

The extended lifespan of flexible displays in EV applications further enhances their sustainability profile. Their inherent resistance to breakage and mechanical stress results in fewer replacements and repairs, reducing electronic waste generation. Additionally, the lightweight nature of these displays contributes to overall vehicle weight reduction, improving energy efficiency during operation—a particularly valuable attribute for electric vehicles where battery range optimization remains paramount.

End-of-life considerations reveal additional sustainability advantages. Many flexible display substrates can be designed for improved recyclability compared to traditional displays, potentially creating closed-loop material systems. Some advanced flexible substrates incorporate biodegradable or bio-based materials, further reducing environmental impact when these components reach end-of-life.

When specifically applied to EV battery design, flexible displays enable more efficient monitoring systems that optimize battery performance and longevity. These displays can be integrated directly onto battery surfaces or housings, providing real-time data visualization without adding significant weight or complexity. This integration supports more efficient battery management, potentially extending battery life and reducing the frequency of battery replacements.

The manufacturing synergies between flexible display production and sustainable practices also merit consideration. Companies investing in flexible display technologies often simultaneously adopt greener manufacturing processes, including reduced solvent use, water conservation measures, and renewable energy integration. These parallel developments create a compounding positive effect on the overall sustainability profile of both the display technology and its applications in electric vehicles.

Energy consumption during production represents another critical sustainability factor. Flexible display manufacturing processes generally consume less energy than conventional display production, particularly when utilizing roll-to-roll processing techniques. This energy efficiency contributes to lower carbon emissions throughout the production lifecycle, aligning with global carbon reduction initiatives and sustainability goals in manufacturing.

The extended lifespan of flexible displays in EV applications further enhances their sustainability profile. Their inherent resistance to breakage and mechanical stress results in fewer replacements and repairs, reducing electronic waste generation. Additionally, the lightweight nature of these displays contributes to overall vehicle weight reduction, improving energy efficiency during operation—a particularly valuable attribute for electric vehicles where battery range optimization remains paramount.

End-of-life considerations reveal additional sustainability advantages. Many flexible display substrates can be designed for improved recyclability compared to traditional displays, potentially creating closed-loop material systems. Some advanced flexible substrates incorporate biodegradable or bio-based materials, further reducing environmental impact when these components reach end-of-life.

When specifically applied to EV battery design, flexible displays enable more efficient monitoring systems that optimize battery performance and longevity. These displays can be integrated directly onto battery surfaces or housings, providing real-time data visualization without adding significant weight or complexity. This integration supports more efficient battery management, potentially extending battery life and reducing the frequency of battery replacements.

The manufacturing synergies between flexible display production and sustainable practices also merit consideration. Companies investing in flexible display technologies often simultaneously adopt greener manufacturing processes, including reduced solvent use, water conservation measures, and renewable energy integration. These parallel developments create a compounding positive effect on the overall sustainability profile of both the display technology and its applications in electric vehicles.

Safety Standards and Testing Protocols for EV Display Systems

The integration of flexible display technologies in electric vehicles necessitates rigorous safety standards and testing protocols to ensure passenger safety and system reliability. Current EV display safety standards are governed by automotive regulatory bodies including ISO 26262, which specifically addresses functional safety for electrical and electronic systems in production automobiles. These standards have been expanded to incorporate requirements for flexible display substrates used in battery monitoring systems.

Testing protocols for flexible displays in EV applications follow a multi-tiered approach. Environmental testing includes temperature cycling (-40°C to 85°C), humidity resistance (up to 95% RH), and vibration testing to simulate real-world driving conditions. These tests are particularly critical for flexible substrates that may experience physical stress when integrated with curved battery casings or when subjected to vehicle vibrations.

Impact and crash safety testing has evolved to include specific protocols for flexible display components. These tests evaluate how display substrates behave during collision events, ensuring they don't create additional hazards such as sharp fragments or electrical shorts that could compromise battery safety. The UL 94 flammability standard has been adapted for flexible display materials, with most EV applications requiring a V-0 rating to minimize fire propagation risks.

Electromagnetic compatibility (EMC) testing has gained prominence as flexible displays are increasingly positioned near high-voltage battery systems. These tests verify that display substrates and their associated electronics neither emit harmful interference nor are susceptible to the electromagnetic fields generated by EV powertrains. The IEC 61000 series provides the framework for these evaluations.

Accelerated aging tests simulate years of use in compressed timeframes, evaluating how flexible substrates maintain their integrity when exposed to UV radiation, temperature fluctuations, and mechanical stress. For battery-adjacent displays, chemical resistance testing ensures substrates can withstand exposure to electrolyte leakage without degradation or generating toxic byproducts.

Recent developments include specialized testing for flexible displays that serve as interactive interfaces for battery management systems. These protocols assess touch accuracy and responsiveness under various environmental conditions, ensuring critical battery information remains accessible to drivers even in extreme situations. Additionally, optical performance testing under various lighting conditions ensures display legibility in all driving scenarios.

Testing protocols for flexible displays in EV applications follow a multi-tiered approach. Environmental testing includes temperature cycling (-40°C to 85°C), humidity resistance (up to 95% RH), and vibration testing to simulate real-world driving conditions. These tests are particularly critical for flexible substrates that may experience physical stress when integrated with curved battery casings or when subjected to vehicle vibrations.

Impact and crash safety testing has evolved to include specific protocols for flexible display components. These tests evaluate how display substrates behave during collision events, ensuring they don't create additional hazards such as sharp fragments or electrical shorts that could compromise battery safety. The UL 94 flammability standard has been adapted for flexible display materials, with most EV applications requiring a V-0 rating to minimize fire propagation risks.

Electromagnetic compatibility (EMC) testing has gained prominence as flexible displays are increasingly positioned near high-voltage battery systems. These tests verify that display substrates and their associated electronics neither emit harmful interference nor are susceptible to the electromagnetic fields generated by EV powertrains. The IEC 61000 series provides the framework for these evaluations.

Accelerated aging tests simulate years of use in compressed timeframes, evaluating how flexible substrates maintain their integrity when exposed to UV radiation, temperature fluctuations, and mechanical stress. For battery-adjacent displays, chemical resistance testing ensures substrates can withstand exposure to electrolyte leakage without degradation or generating toxic byproducts.

Recent developments include specialized testing for flexible displays that serve as interactive interfaces for battery management systems. These protocols assess touch accuracy and responsiveness under various environmental conditions, ensuring critical battery information remains accessible to drivers even in extreme situations. Additionally, optical performance testing under various lighting conditions ensures display legibility in all driving scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!