Impact Analysis of Flexible Display Substrates on OLED Displays

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible OLED Display Technology Evolution and Objectives

Flexible OLED display technology has undergone significant evolution since its conceptualization in the early 2000s. The journey began with rudimentary prototypes featuring limited flexibility and durability, primarily constrained by rigid substrate materials. The technological progression accelerated around 2010 when researchers at Samsung and LG Display achieved breakthroughs in polymer-based substrates, enabling displays with greater bending capabilities while maintaining optical performance.

The evolution trajectory has been characterized by three distinct phases: initial rigid OLED displays with limited flexibility (2000-2010), semi-flexible displays capable of bending but not folding (2010-2017), and the current generation of highly flexible and foldable displays (2018-present). Each phase has been marked by significant improvements in substrate materials, from modified glass to polyimide films, which directly impact the mechanical properties and durability of OLED displays.

A critical milestone was reached in 2013 when Samsung introduced the first commercially viable flexible OLED display using a polyimide substrate. This innovation catalyzed industry-wide research into alternative substrate materials and manufacturing processes, leading to the development of ultra-thin glass (UTG) substrates around 2019, which combine glass's optical clarity with enhanced flexibility.

The technical objectives driving flexible OLED display development encompass several dimensions. Primary goals include achieving greater flexibility without compromising display quality, enhancing durability to withstand repeated folding cycles (targeting 200,000+ folds), and reducing thickness while maintaining structural integrity. Additionally, researchers aim to minimize the visible crease at fold points, a persistent challenge in current foldable displays.

Another crucial objective is improving the barrier properties of flexible substrates against oxygen and moisture penetration, as OLED materials are highly susceptible to degradation when exposed to these elements. Current technologies employ multi-layer barrier films, but achieving perfect impermeability while maintaining flexibility remains challenging.

Looking forward, the field is moving toward substrates that enable not just folding but rolling and stretching capabilities. This evolution requires fundamental innovations in material science, particularly in developing elastomeric substrates with consistent electrical properties under deformation. The ultimate vision encompasses conformable displays that can adapt to various surface geometries while delivering high-resolution visual experiences.

The technological trajectory also aims to address manufacturing scalability, as current production methods for flexible substrates involve complex processes that limit yield rates and increase costs. Achieving cost-effective mass production represents a significant objective that will determine the widespread adoption of flexible OLED technology across diverse application domains.

The evolution trajectory has been characterized by three distinct phases: initial rigid OLED displays with limited flexibility (2000-2010), semi-flexible displays capable of bending but not folding (2010-2017), and the current generation of highly flexible and foldable displays (2018-present). Each phase has been marked by significant improvements in substrate materials, from modified glass to polyimide films, which directly impact the mechanical properties and durability of OLED displays.

A critical milestone was reached in 2013 when Samsung introduced the first commercially viable flexible OLED display using a polyimide substrate. This innovation catalyzed industry-wide research into alternative substrate materials and manufacturing processes, leading to the development of ultra-thin glass (UTG) substrates around 2019, which combine glass's optical clarity with enhanced flexibility.

The technical objectives driving flexible OLED display development encompass several dimensions. Primary goals include achieving greater flexibility without compromising display quality, enhancing durability to withstand repeated folding cycles (targeting 200,000+ folds), and reducing thickness while maintaining structural integrity. Additionally, researchers aim to minimize the visible crease at fold points, a persistent challenge in current foldable displays.

Another crucial objective is improving the barrier properties of flexible substrates against oxygen and moisture penetration, as OLED materials are highly susceptible to degradation when exposed to these elements. Current technologies employ multi-layer barrier films, but achieving perfect impermeability while maintaining flexibility remains challenging.

Looking forward, the field is moving toward substrates that enable not just folding but rolling and stretching capabilities. This evolution requires fundamental innovations in material science, particularly in developing elastomeric substrates with consistent electrical properties under deformation. The ultimate vision encompasses conformable displays that can adapt to various surface geometries while delivering high-resolution visual experiences.

The technological trajectory also aims to address manufacturing scalability, as current production methods for flexible substrates involve complex processes that limit yield rates and increase costs. Achieving cost-effective mass production represents a significant objective that will determine the widespread adoption of flexible OLED technology across diverse application domains.

Market Demand Analysis for Flexible Display Technologies

The flexible display market has witnessed exponential growth in recent years, driven primarily by increasing consumer demand for innovative form factors in electronic devices. Market research indicates that the global flexible display market reached approximately $23.1 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 33.1% through 2028. This remarkable growth trajectory underscores the significant market potential for flexible OLED technologies utilizing advanced substrate materials.

Consumer electronics represents the largest application segment for flexible displays, with smartphones accounting for over 60% of the current market share. Major smartphone manufacturers have increasingly adopted flexible OLED displays to enable foldable, rollable, and curved screen designs that differentiate their premium product lines. Market surveys reveal that consumers are willing to pay a premium of 15-30% for devices featuring flexible displays, highlighting strong value perception for this technology.

Beyond smartphones, emerging application areas demonstrate substantial growth potential. The wearable technology sector, including smartwatches and fitness trackers, is expected to grow at a CAGR of 28.7% through 2027, with flexible displays being a key enabling technology. Automotive displays represent another high-growth segment, with flexible OLED integration in dashboard and entertainment systems projected to increase by 41% annually over the next five years.

Regional analysis shows Asia-Pacific dominating the flexible display market with approximately 67% market share, led by South Korea, Japan, and China. North America and Europe follow with 18% and 12% respectively, though these regions are showing accelerated adoption rates in premium consumer segments.

Market challenges primarily revolve around cost factors, with flexible displays currently commanding a manufacturing premium of 30-40% compared to rigid alternatives. However, industry forecasts predict this cost differential will narrow to 15-20% by 2025 as production scales and manufacturing processes mature. Supply chain constraints, particularly regarding specialized substrate materials and manufacturing equipment, remain significant market barriers that impact production capacity and time-to-market.

Consumer preference studies indicate growing demand for devices with improved durability, with 78% of smartphone users citing screen durability as a "very important" purchase consideration. This directly relates to substrate material selection in flexible OLED displays, as advanced polymer and ultra-thin glass substrates can significantly impact device longevity and resistance to repeated folding or bending cycles.

Consumer electronics represents the largest application segment for flexible displays, with smartphones accounting for over 60% of the current market share. Major smartphone manufacturers have increasingly adopted flexible OLED displays to enable foldable, rollable, and curved screen designs that differentiate their premium product lines. Market surveys reveal that consumers are willing to pay a premium of 15-30% for devices featuring flexible displays, highlighting strong value perception for this technology.

Beyond smartphones, emerging application areas demonstrate substantial growth potential. The wearable technology sector, including smartwatches and fitness trackers, is expected to grow at a CAGR of 28.7% through 2027, with flexible displays being a key enabling technology. Automotive displays represent another high-growth segment, with flexible OLED integration in dashboard and entertainment systems projected to increase by 41% annually over the next five years.

Regional analysis shows Asia-Pacific dominating the flexible display market with approximately 67% market share, led by South Korea, Japan, and China. North America and Europe follow with 18% and 12% respectively, though these regions are showing accelerated adoption rates in premium consumer segments.

Market challenges primarily revolve around cost factors, with flexible displays currently commanding a manufacturing premium of 30-40% compared to rigid alternatives. However, industry forecasts predict this cost differential will narrow to 15-20% by 2025 as production scales and manufacturing processes mature. Supply chain constraints, particularly regarding specialized substrate materials and manufacturing equipment, remain significant market barriers that impact production capacity and time-to-market.

Consumer preference studies indicate growing demand for devices with improved durability, with 78% of smartphone users citing screen durability as a "very important" purchase consideration. This directly relates to substrate material selection in flexible OLED displays, as advanced polymer and ultra-thin glass substrates can significantly impact device longevity and resistance to repeated folding or bending cycles.

Current Flexible Substrate Technologies and Challenges

The flexible display market has witnessed significant growth in recent years, with various substrate technologies emerging as viable alternatives to traditional rigid glass. Currently, the most widely adopted flexible substrate technologies include polyimide (PI) films, ultra-thin glass (UTG), and metal foils, each offering distinct advantages and presenting unique challenges for OLED implementation.

Polyimide films dominate the current flexible display substrate market due to their excellent thermal stability, chemical resistance, and mechanical flexibility. Major manufacturers like Samsung and LG Display utilize PI substrates in their commercial flexible OLED products. These films can withstand temperatures up to 400°C, making them compatible with OLED fabrication processes. However, PI substrates face challenges including limited transparency, yellowing over time, and moisture permeability that can compromise OLED device longevity.

Ultra-thin glass, typically ranging from 30-100μm in thickness, represents a promising alternative that combines glass's superior barrier properties with enhanced flexibility. Companies like Corning and Schott have developed specialized UTG products that offer excellent optical clarity and superior moisture barrier performance compared to polymeric substrates. The primary challenges with UTG involve manufacturing complexity, handling fragility during production, and higher costs. Additionally, UTG still requires careful radius control to prevent fracture during bending operations.

Metal foils, particularly stainless steel and aluminum alloys, provide exceptional thermal stability and near-perfect barrier properties against moisture and oxygen. These substrates enable high-temperature processing compatible with traditional OLED manufacturing. However, their opacity necessitates top-emission OLED architectures, and their electrical conductivity requires additional insulation layers, increasing manufacturing complexity and cost.

Emerging substrate technologies include hybrid structures that combine multiple materials to leverage their respective advantages. For instance, polymer-glass composites aim to balance flexibility with barrier performance, while nanomaterial-reinforced polymers seek to enhance mechanical durability without sacrificing flexibility.

A significant technical challenge across all flexible substrates remains the development of effective thin-film encapsulation (TFE) solutions. Unlike rigid glass displays that can utilize glass encapsulation, flexible OLEDs require specialized barrier layers that maintain flexibility while providing sufficient protection against environmental degradation factors. Current TFE technologies struggle to maintain consistent barrier performance during repeated flexing operations.

Surface roughness control represents another critical challenge, as nanoscale surface irregularities can lead to electrical shorts and non-uniform light emission in OLED devices. Advanced planarization techniques are being developed to address this issue, but they add complexity and cost to the manufacturing process.

Polyimide films dominate the current flexible display substrate market due to their excellent thermal stability, chemical resistance, and mechanical flexibility. Major manufacturers like Samsung and LG Display utilize PI substrates in their commercial flexible OLED products. These films can withstand temperatures up to 400°C, making them compatible with OLED fabrication processes. However, PI substrates face challenges including limited transparency, yellowing over time, and moisture permeability that can compromise OLED device longevity.

Ultra-thin glass, typically ranging from 30-100μm in thickness, represents a promising alternative that combines glass's superior barrier properties with enhanced flexibility. Companies like Corning and Schott have developed specialized UTG products that offer excellent optical clarity and superior moisture barrier performance compared to polymeric substrates. The primary challenges with UTG involve manufacturing complexity, handling fragility during production, and higher costs. Additionally, UTG still requires careful radius control to prevent fracture during bending operations.

Metal foils, particularly stainless steel and aluminum alloys, provide exceptional thermal stability and near-perfect barrier properties against moisture and oxygen. These substrates enable high-temperature processing compatible with traditional OLED manufacturing. However, their opacity necessitates top-emission OLED architectures, and their electrical conductivity requires additional insulation layers, increasing manufacturing complexity and cost.

Emerging substrate technologies include hybrid structures that combine multiple materials to leverage their respective advantages. For instance, polymer-glass composites aim to balance flexibility with barrier performance, while nanomaterial-reinforced polymers seek to enhance mechanical durability without sacrificing flexibility.

A significant technical challenge across all flexible substrates remains the development of effective thin-film encapsulation (TFE) solutions. Unlike rigid glass displays that can utilize glass encapsulation, flexible OLEDs require specialized barrier layers that maintain flexibility while providing sufficient protection against environmental degradation factors. Current TFE technologies struggle to maintain consistent barrier performance during repeated flexing operations.

Surface roughness control represents another critical challenge, as nanoscale surface irregularities can lead to electrical shorts and non-uniform light emission in OLED devices. Advanced planarization techniques are being developed to address this issue, but they add complexity and cost to the manufacturing process.

Current Flexible Substrate Solutions for OLED Displays

01 Materials for flexible display substrates

Various materials are used in flexible display substrates to achieve the necessary flexibility while maintaining structural integrity. These materials include polymers, thin films, and composite structures that can withstand repeated bending and folding without degradation. The selection of substrate materials significantly impacts the overall performance, durability, and flexibility of the display. Advanced materials enable displays to be thinner, lighter, and more resistant to mechanical stress.- Materials for flexible display substrates: Various materials are used in flexible display substrates to achieve the desired flexibility while maintaining structural integrity. These materials include polymers, thin films, and composite structures that can withstand repeated bending and folding without degradation. The selection of substrate materials significantly impacts the overall performance, durability, and flexibility of the display. Advanced materials enable thinner profiles while providing sufficient mechanical support for the display components.

- Manufacturing techniques for flexible displays: Specialized manufacturing processes are essential for producing effective flexible display substrates. These techniques include roll-to-roll processing, thin film deposition methods, laser patterning, and advanced lamination processes. The manufacturing approach directly impacts the quality, cost, and scalability of flexible displays. Innovations in production methods have enabled more efficient fabrication of flexible substrates with improved performance characteristics and reduced thickness.

- Mechanical properties and durability considerations: The mechanical properties of flexible display substrates are crucial for their performance and longevity. Key considerations include bend radius limitations, tensile strength, fatigue resistance, and impact resistance. Substrates must maintain their integrity through repeated flexing cycles while protecting the electronic components. Engineering solutions such as neutral plane designs and stress-relieving structures help distribute mechanical forces and prevent damage during bending operations.

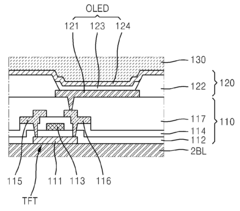

- Integration with electronic components: Flexible substrates must effectively integrate with various electronic components including thin-film transistors, organic light-emitting diodes, and touch sensors. The interface between the substrate and these components is critical for display performance. Specialized bonding techniques and interface layers are employed to ensure reliable electrical connections while accommodating mechanical movement. The substrate design must consider thermal management, electrical isolation, and signal integrity across the flexible structure.

- Environmental stability and barrier properties: Flexible display substrates require excellent barrier properties to protect sensitive electronic components from environmental factors such as moisture, oxygen, and contaminants. Multi-layer barrier films and encapsulation technologies are employed to extend device lifetime while maintaining flexibility. The substrate must provide stable performance across varying temperature and humidity conditions. Advanced barrier technologies balance the competing requirements of flexibility, transparency, and protective capabilities.

02 Manufacturing processes for flexible displays

Specialized manufacturing techniques are essential for producing effective flexible display substrates. These processes include roll-to-roll fabrication, thin film deposition, laser processing, and lamination methods that enable the creation of ultra-thin, flexible structures. Manufacturing innovations focus on improving yield rates, reducing production costs, and enhancing the uniformity of flexible substrates. Advanced process control systems ensure consistent quality across large substrate areas.Expand Specific Solutions03 Mechanical properties and durability enhancements

Flexible display substrates require specific mechanical properties to withstand repeated bending, folding, and other physical stresses. Innovations in this area include multi-layer structures, reinforcement technologies, and stress distribution designs that prevent cracking and delamination. Durability enhancements focus on improving bend radius capabilities, increasing folding cycle lifetimes, and maintaining optical performance under mechanical stress. These improvements are critical for applications requiring frequent folding or rolling of displays.Expand Specific Solutions04 Integration with electronic components

Effective integration of electronic components with flexible substrates presents unique challenges that impact overall display performance. Solutions include specialized bonding techniques, flexible interconnects, and component placement strategies that maintain functionality during bending. Innovations focus on minimizing stress at connection points, developing stretchable electronics, and creating seamless interfaces between rigid components and flexible substrates. These integration methods enable the development of fully functional flexible display systems.Expand Specific Solutions05 Optical performance optimization

Maintaining optimal optical performance in flexible displays requires specialized substrate designs that preserve light transmission, color accuracy, and viewing angles during deformation. Innovations include anti-reflection coatings, light management structures, and optical compensation layers that function effectively on curved surfaces. These technologies address challenges such as color shift during bending, maintaining brightness uniformity, and reducing glare on flexible displays. Optical optimization is essential for ensuring display quality across various viewing conditions and form factors.Expand Specific Solutions

Key Industry Players in Flexible OLED Display Market

The flexible display substrate market for OLED displays is currently in a growth phase, with an expanding market size driven by increasing demand for foldable smartphones and wearable devices. The technology maturity varies across key players, with Samsung Display and LG Display leading as established pioneers with advanced commercialized solutions. Chinese manufacturers including BOE Technology, Tianma Microelectronics, and Visionox are rapidly closing the gap through aggressive R&D investments. TCL's China Star Optoelectronics (CSOT) has made significant progress in flexible AMOLED technology. The competitive landscape is characterized by intense patent activity and strategic partnerships, with companies focusing on improving substrate durability, flexibility, and production yield to address remaining technical challenges in mass production.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive flexible OLED solution based on their proprietary "BOE Flexible+" technology platform. Their approach utilizes ultra-thin polyimide (PI) substrates with thickness ranging from 8-12μm, manufactured through a specialized coating and imidization process that achieves high temperature resistance (>300°C) and exceptional mechanical stability. BOE's flexible displays incorporate a multi-layer thin-film encapsulation (TFE) structure consisting of alternating inorganic (SiNx/Al2O3) and organic layers that achieve water vapor transmission rates below 10^-5 g/m²/day[3]. Their manufacturing process includes a specialized low-temperature polycrystalline oxide (LTPO) backplane technology that enables variable refresh rates (1-120Hz) while maintaining flexibility, reducing power consumption by up to 30% compared to conventional approaches. BOE has also pioneered a "stress-neutral layer" design methodology that positions the OLED emitting layers at the optimal position within the display stack to minimize mechanical stress during bending, allowing for fold radii as small as 1.5mm. Their flexible displays demonstrate operational stability after more than 150,000 folding cycles while maintaining over 95% of original brightness and color accuracy.

Strengths: Cost-effective manufacturing process with high yield rates; excellent mechanical durability with proven reliability in commercial products; advanced power efficiency through LTPO backplane technology. Weaknesses: Slightly larger minimum bending radius compared to industry leaders; challenges in achieving uniform brightness across bent surfaces; encapsulation barrier properties slightly below top competitors.

LG Display Co., Ltd.

Technical Solution: LG Display has pioneered flexible OLED technology through their proprietary plastic-based polyimide (PI) substrate solution that replaces traditional glass substrates. Their P-OLED (Plastic OLED) technology employs a multi-layer structure where the OLED components are deposited on a flexible PI film that can withstand repeated bending without performance degradation. The company has developed specialized thin-film encapsulation (TFE) technology that creates an effective moisture and oxygen barrier using alternating inorganic and organic layers, critical for protecting flexible OLEDs from environmental degradation. LG's manufacturing process includes a proprietary neutral plane engineering approach that positions the OLED elements at the optimal layer within the display stack to minimize mechanical stress during bending, allowing for radii as small as 1.5mm without significant performance loss[1]. Their flexible displays maintain high color accuracy with over 100% DCI-P3 color gamut coverage even when flexed, and demonstrate operational stability after more than 200,000 folding cycles.

Strengths: Superior mechanical durability with proven reliability in commercial products; advanced encapsulation technology providing excellent barrier properties against moisture and oxygen; industry-leading color performance maintained during flexing. Weaknesses: Higher production costs compared to rigid displays; thickness limitations when implementing multiple barrier layers; potential for pixel non-uniformity at extreme bending angles.

Critical Substrate-OLED Interface Technologies

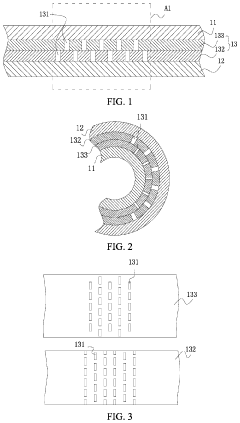

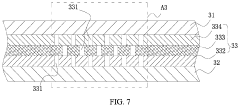

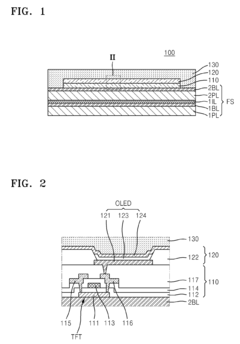

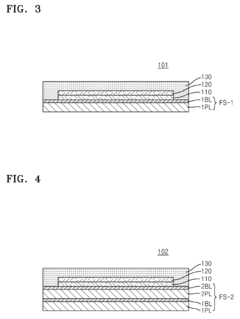

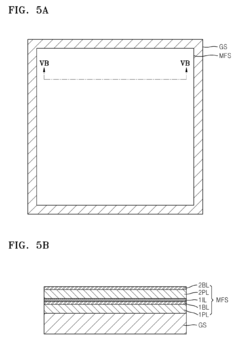

Flexible organic light-emitting diode display panel and flexible organic light-emitting diode display device

PatentActiveUS20210193941A1

Innovation

- A flexible OLED display panel with a substrate structure comprising a base substrate and a flexible structural layer composed of multiple polyimide layers, where the relief holes in adjacent layers are staggered to distribute compression and tensile forces effectively, with the diameter of relief holes varying to absorb these forces without damaging the panel.

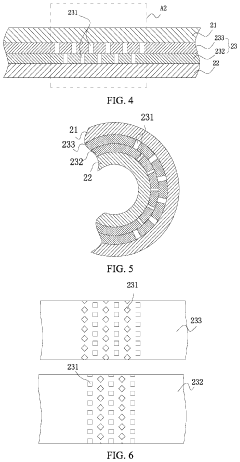

Organic light-emitting diode display having improved adhesion and damage resistance characteristics, an electronic device including the same, and method of manufacturing the organic light-emitting diode display

PatentActiveUS9178178B2

Innovation

- The OLED display incorporates a flexible substrate with alternating layers of plastic and silicon nitride barrier layers, where the density and refractive index of silicon nitride in the barrier layers vary to enhance water vapor barrier properties and adhesive strength, and an intermediate layer is added between the barrier and plastic layers to improve adhesion.

Environmental Impact of Flexible Display Materials

The environmental impact of flexible display materials represents a critical consideration in the evolution of OLED display technology. Flexible substrates, primarily composed of polymers like polyimide (PI), polyethylene terephthalate (PET), and polyethylene naphthalate (PEN), present distinct environmental challenges compared to traditional rigid glass substrates.

Manufacturing processes for flexible substrates typically require extensive use of chemical solvents and high-temperature curing, resulting in significant energy consumption and potential toxic emissions. The production of polyimide, the most commonly used flexible substrate material, involves hazardous chemicals including pyromellitic dianhydride and aromatic diamines, which pose environmental risks if not properly managed during manufacturing.

Lifecycle assessment studies indicate that flexible displays generally have a smaller carbon footprint during transportation due to their lighter weight and reduced breakage risk compared to glass-based displays. However, this advantage is often offset by the energy-intensive manufacturing processes required for flexible substrate production and the additional barrier layers needed to protect OLEDs from moisture and oxygen.

End-of-life management presents particular challenges for flexible OLED displays. Unlike glass, which has established recycling infrastructure, most flexible substrate materials have limited recyclability. The multi-layer structure of flexible displays, combining organic materials, thin-film metals, and polymer substrates, creates significant separation difficulties in conventional recycling processes.

Recent innovations in bio-based polymers offer promising alternatives to petroleum-derived substrates. Materials such as cellulose-based films and polylactic acid (PLA) derivatives demonstrate potential for reducing environmental impact while maintaining necessary performance characteristics for OLED applications. These materials feature lower embodied energy and improved biodegradability compared to conventional synthetic polymers.

Water usage represents another significant environmental concern, with flexible display manufacturing requiring ultra-pure water for cleaning processes. Industry data suggests that producing one square meter of flexible display substrate can consume between 1,500-2,000 liters of water, substantially higher than many other electronic components of comparable size.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions have prompted manufacturers to develop halogen-free flexible substrates and reduce heavy metal content in barrier and electrode materials used in flexible OLED displays.

Manufacturing processes for flexible substrates typically require extensive use of chemical solvents and high-temperature curing, resulting in significant energy consumption and potential toxic emissions. The production of polyimide, the most commonly used flexible substrate material, involves hazardous chemicals including pyromellitic dianhydride and aromatic diamines, which pose environmental risks if not properly managed during manufacturing.

Lifecycle assessment studies indicate that flexible displays generally have a smaller carbon footprint during transportation due to their lighter weight and reduced breakage risk compared to glass-based displays. However, this advantage is often offset by the energy-intensive manufacturing processes required for flexible substrate production and the additional barrier layers needed to protect OLEDs from moisture and oxygen.

End-of-life management presents particular challenges for flexible OLED displays. Unlike glass, which has established recycling infrastructure, most flexible substrate materials have limited recyclability. The multi-layer structure of flexible displays, combining organic materials, thin-film metals, and polymer substrates, creates significant separation difficulties in conventional recycling processes.

Recent innovations in bio-based polymers offer promising alternatives to petroleum-derived substrates. Materials such as cellulose-based films and polylactic acid (PLA) derivatives demonstrate potential for reducing environmental impact while maintaining necessary performance characteristics for OLED applications. These materials feature lower embodied energy and improved biodegradability compared to conventional synthetic polymers.

Water usage represents another significant environmental concern, with flexible display manufacturing requiring ultra-pure water for cleaning processes. Industry data suggests that producing one square meter of flexible display substrate can consume between 1,500-2,000 liters of water, substantially higher than many other electronic components of comparable size.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions have prompted manufacturers to develop halogen-free flexible substrates and reduce heavy metal content in barrier and electrode materials used in flexible OLED displays.

Durability and Reliability Assessment Methods

The assessment of durability and reliability in flexible OLED displays requires systematic methodologies that address the unique challenges posed by bendable substrates. Traditional rigid display testing protocols are insufficient for evaluating the complex mechanical stresses experienced by flexible displays during repeated bending and folding operations.

Accelerated life testing (ALT) has emerged as a primary methodology for evaluating flexible display durability. This approach subjects displays to intensified environmental and mechanical stresses to simulate years of usage within compressed timeframes. For flexible OLEDs, specialized ALT protocols incorporate cyclic bending tests with controlled parameters including bending radius, frequency, and temperature conditions to accurately model real-world usage scenarios.

Environmental stress testing constitutes another critical assessment dimension, exposing flexible displays to extreme temperature cycling (-40°C to 85°C), humidity variations (up to 95% RH), and UV radiation to evaluate substrate degradation and interface stability between layers. These tests are particularly important for polymer-based substrates which may exhibit different thermal expansion coefficients compared to the functional layers deposited upon them.

Mechanical reliability assessment employs specialized equipment including dynamic mechanical analyzers and custom-designed bending test apparatus capable of precisely controlling bending radius and force application. Advanced imaging techniques such as high-resolution microscopy and X-ray tomography enable real-time observation of microstructural changes during bending cycles, providing insights into failure mechanisms at the microscopic level.

Electrical performance monitoring during mechanical stress represents a crucial component of reliability assessment. Researchers employ in-situ measurement systems that track changes in pixel luminance, current-voltage characteristics, and impedance parameters while displays undergo bending. These measurements help identify early indicators of performance degradation before visible defects appear.

Statistical reliability modeling has gained prominence in flexible display assessment, with Weibull distribution analysis and Monte Carlo simulations being employed to predict failure rates and establish meaningful lifetime estimates. These models incorporate data from accelerated testing to extrapolate expected performance under normal usage conditions.

Industry standards for flexible display reliability continue to evolve, with organizations like the Society for Information Display (SID) and the International Electrotechnical Commission (IEC) developing specialized testing protocols. The IEC 62715 series specifically addresses mechanical durability testing for flexible display technologies, providing standardized methodologies that enable meaningful comparisons between different substrate materials and manufacturing approaches.

Accelerated life testing (ALT) has emerged as a primary methodology for evaluating flexible display durability. This approach subjects displays to intensified environmental and mechanical stresses to simulate years of usage within compressed timeframes. For flexible OLEDs, specialized ALT protocols incorporate cyclic bending tests with controlled parameters including bending radius, frequency, and temperature conditions to accurately model real-world usage scenarios.

Environmental stress testing constitutes another critical assessment dimension, exposing flexible displays to extreme temperature cycling (-40°C to 85°C), humidity variations (up to 95% RH), and UV radiation to evaluate substrate degradation and interface stability between layers. These tests are particularly important for polymer-based substrates which may exhibit different thermal expansion coefficients compared to the functional layers deposited upon them.

Mechanical reliability assessment employs specialized equipment including dynamic mechanical analyzers and custom-designed bending test apparatus capable of precisely controlling bending radius and force application. Advanced imaging techniques such as high-resolution microscopy and X-ray tomography enable real-time observation of microstructural changes during bending cycles, providing insights into failure mechanisms at the microscopic level.

Electrical performance monitoring during mechanical stress represents a crucial component of reliability assessment. Researchers employ in-situ measurement systems that track changes in pixel luminance, current-voltage characteristics, and impedance parameters while displays undergo bending. These measurements help identify early indicators of performance degradation before visible defects appear.

Statistical reliability modeling has gained prominence in flexible display assessment, with Weibull distribution analysis and Monte Carlo simulations being employed to predict failure rates and establish meaningful lifetime estimates. These models incorporate data from accelerated testing to extrapolate expected performance under normal usage conditions.

Industry standards for flexible display reliability continue to evolve, with organizations like the Society for Information Display (SID) and the International Electrotechnical Commission (IEC) developing specialized testing protocols. The IEC 62715 series specifically addresses mechanical durability testing for flexible display technologies, providing standardized methodologies that enable meaningful comparisons between different substrate materials and manufacturing approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!