Applications of Flexible Display Substrates in Wearable Technology

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Display Evolution and Objectives

Flexible display technology has evolved significantly over the past two decades, transitioning from rigid glass-based displays to increasingly pliable substrates. The journey began in the early 2000s with the development of plastic-based displays that offered minimal flexibility but represented a crucial departure from traditional rigid screens. By 2010, researchers had achieved displays capable of bending to specific radii without performance degradation, marking a significant milestone in the field. The subsequent years witnessed the emergence of rollable and foldable displays, with companies like Samsung and LG introducing commercial products featuring these technologies around 2019-2020.

The evolution of flexible substrates has been particularly transformative, progressing from early polyethylene terephthalate (PET) and polyethylene naphthalate (PEN) materials to more advanced substrates like polyimide films and ultrathin glass composites. These newer materials have dramatically improved durability while maintaining excellent optical properties and increasing flexibility thresholds. Parallel advancements in thin-film transistor (TFT) technologies, particularly low-temperature polysilicon (LTPS) and oxide semiconductor approaches, have enabled the creation of display circuits that can withstand repeated flexing without performance degradation.

Current research focuses on achieving truly conformable displays that can adapt to complex three-dimensional surfaces while maintaining consistent visual performance. This represents a critical requirement for next-generation wearable technologies, where displays must contour to the human body's irregular surfaces. The ultimate goal is developing substrates that combine extreme flexibility with durability, allowing for displays that can be stretched, twisted, and compressed while maintaining functionality through thousands of deformation cycles.

The technical objectives for flexible display substrates in wearable applications center around several key parameters. First is achieving a bending radius below 1mm without performance degradation, enabling truly wearable form factors. Second is enhancing durability to withstand at least 200,000 folding cycles, matching the expected lifetime of consumer wearable products. Third is reducing thickness to below 10 micrometers while maintaining structural integrity, critical for comfort in body-worn applications.

Additional objectives include developing substrates with improved thermal management capabilities to address the heat dissipation challenges inherent in wearable devices worn close to the skin. Researchers are also pursuing enhanced barrier properties to protect sensitive electronic components from moisture and oxygen, particularly important for devices exposed to varying environmental conditions and human perspiration. The integration of biometric sensing capabilities directly into the display substrate represents another frontier, potentially enabling wearables that can monitor health parameters through the same surface that delivers visual information.

The evolution of flexible substrates has been particularly transformative, progressing from early polyethylene terephthalate (PET) and polyethylene naphthalate (PEN) materials to more advanced substrates like polyimide films and ultrathin glass composites. These newer materials have dramatically improved durability while maintaining excellent optical properties and increasing flexibility thresholds. Parallel advancements in thin-film transistor (TFT) technologies, particularly low-temperature polysilicon (LTPS) and oxide semiconductor approaches, have enabled the creation of display circuits that can withstand repeated flexing without performance degradation.

Current research focuses on achieving truly conformable displays that can adapt to complex three-dimensional surfaces while maintaining consistent visual performance. This represents a critical requirement for next-generation wearable technologies, where displays must contour to the human body's irregular surfaces. The ultimate goal is developing substrates that combine extreme flexibility with durability, allowing for displays that can be stretched, twisted, and compressed while maintaining functionality through thousands of deformation cycles.

The technical objectives for flexible display substrates in wearable applications center around several key parameters. First is achieving a bending radius below 1mm without performance degradation, enabling truly wearable form factors. Second is enhancing durability to withstand at least 200,000 folding cycles, matching the expected lifetime of consumer wearable products. Third is reducing thickness to below 10 micrometers while maintaining structural integrity, critical for comfort in body-worn applications.

Additional objectives include developing substrates with improved thermal management capabilities to address the heat dissipation challenges inherent in wearable devices worn close to the skin. Researchers are also pursuing enhanced barrier properties to protect sensitive electronic components from moisture and oxygen, particularly important for devices exposed to varying environmental conditions and human perspiration. The integration of biometric sensing capabilities directly into the display substrate represents another frontier, potentially enabling wearables that can monitor health parameters through the same surface that delivers visual information.

Wearable Market Demand Analysis

The wearable technology market has experienced exponential growth over the past decade, driven by increasing consumer interest in health monitoring, fitness tracking, and seamless technology integration into daily life. The global wearable market reached $116 billion in 2021 and is projected to grow at a CAGR of 18.5% through 2028, with flexible display technologies representing a significant growth catalyst in this expansion.

Consumer demand for wearable devices with flexible displays stems primarily from the desire for improved comfort, enhanced durability, and expanded functionality. Traditional rigid displays limit the form factor and user experience of wearable devices, creating opportunities for flexible display substrates to address these limitations. Market research indicates that 78% of wearable technology users cite comfort as a primary consideration when purchasing devices, while 65% express interest in expanded display areas without increased device bulk.

Healthcare applications represent the fastest-growing segment within the wearable market, with continuous health monitoring devices expected to reach $30 billion by 2025. Flexible displays enable critical advancements in this sector by conforming to body contours, improving patient compliance through enhanced comfort, and enabling real-time data visualization directly on the device. The aging global population and increasing focus on preventative healthcare further amplify demand in this segment.

Fitness and sports applications constitute another substantial market segment, valued at $22 billion in 2022. Athletes and fitness enthusiasts increasingly seek devices that can withstand intense physical activity while providing real-time performance metrics. Flexible display substrates offer superior impact resistance and conformability compared to rigid alternatives, directly addressing these requirements.

Consumer electronics giants have recognized this market potential, with companies like Apple, Samsung, and Google investing heavily in flexible display wearable technology. This corporate interest has accelerated market growth and technological advancement, creating a positive feedback loop of innovation and consumer adoption.

Regional analysis reveals Asia-Pacific as the fastest-growing market for wearable technology with flexible displays, driven by strong manufacturing capabilities and increasing disposable income. North America remains the largest market by revenue, with early technology adopters creating sustained demand for premium wearable products featuring advanced display technologies.

Market forecasts indicate that miniaturization and integration will continue driving wearable technology evolution, with flexible displays playing an increasingly central role. As manufacturing costs decrease and technical capabilities improve, flexible display substrates will enable entirely new product categories beyond current smartwatches and fitness trackers, potentially expanding into smart clothing, medical patches, and augmented reality accessories.

Consumer demand for wearable devices with flexible displays stems primarily from the desire for improved comfort, enhanced durability, and expanded functionality. Traditional rigid displays limit the form factor and user experience of wearable devices, creating opportunities for flexible display substrates to address these limitations. Market research indicates that 78% of wearable technology users cite comfort as a primary consideration when purchasing devices, while 65% express interest in expanded display areas without increased device bulk.

Healthcare applications represent the fastest-growing segment within the wearable market, with continuous health monitoring devices expected to reach $30 billion by 2025. Flexible displays enable critical advancements in this sector by conforming to body contours, improving patient compliance through enhanced comfort, and enabling real-time data visualization directly on the device. The aging global population and increasing focus on preventative healthcare further amplify demand in this segment.

Fitness and sports applications constitute another substantial market segment, valued at $22 billion in 2022. Athletes and fitness enthusiasts increasingly seek devices that can withstand intense physical activity while providing real-time performance metrics. Flexible display substrates offer superior impact resistance and conformability compared to rigid alternatives, directly addressing these requirements.

Consumer electronics giants have recognized this market potential, with companies like Apple, Samsung, and Google investing heavily in flexible display wearable technology. This corporate interest has accelerated market growth and technological advancement, creating a positive feedback loop of innovation and consumer adoption.

Regional analysis reveals Asia-Pacific as the fastest-growing market for wearable technology with flexible displays, driven by strong manufacturing capabilities and increasing disposable income. North America remains the largest market by revenue, with early technology adopters creating sustained demand for premium wearable products featuring advanced display technologies.

Market forecasts indicate that miniaturization and integration will continue driving wearable technology evolution, with flexible displays playing an increasingly central role. As manufacturing costs decrease and technical capabilities improve, flexible display substrates will enable entirely new product categories beyond current smartwatches and fitness trackers, potentially expanding into smart clothing, medical patches, and augmented reality accessories.

Flexible Substrate Technology Landscape

Flexible display substrate technology has evolved significantly over the past decade, transitioning from rigid glass-based displays to increasingly flexible alternatives. The landscape is currently dominated by three primary substrate technologies: plastic-based substrates (primarily polyimide), ultra-thin glass, and hybrid materials. Polyimide films have gained substantial traction due to their excellent thermal stability, chemical resistance, and mechanical flexibility, making them ideal for wearable applications where conformability to body contours is essential.

Ultra-thin glass substrates, typically less than 100 micrometers thick, represent another significant advancement, offering superior barrier properties against oxygen and moisture while maintaining optical clarity that plastic alternatives struggle to match. These substrates provide an optimal balance between flexibility and durability, though they remain more susceptible to cracking under extreme bending conditions compared to polymer-based alternatives.

The geographical distribution of flexible substrate technology development shows concentration in East Asia, particularly South Korea, Japan, and Taiwan, where major display manufacturers have established robust supply chains and manufacturing capabilities. North America leads in research innovation, with significant patent activities from both academic institutions and technology companies focusing on novel materials and fabrication techniques.

Recent technological breakthroughs include the development of stretchable substrates that can withstand not only bending but also stretching and twisting without performance degradation. These advances incorporate engineered microstructures and novel composite materials that distribute mechanical stress more effectively across the substrate surface.

The manufacturing ecosystem has evolved to support these technologies, with roll-to-roll processing emerging as the preferred fabrication method for high-volume production of flexible substrates. This approach significantly reduces production costs while enabling continuous manufacturing of large-area flexible displays, critical for commercial viability in wearable applications.

Barrier technology remains a critical component of the flexible substrate landscape, with multi-layer thin-film encapsulation techniques providing essential protection against environmental degradation. These barrier layers must maintain their protective properties even under repeated mechanical deformation, presenting ongoing challenges for material scientists and process engineers.

The technology readiness level varies considerably across different substrate technologies, with polyimide-based solutions reaching commercial maturity (TRL 8-9), while more advanced stretchable substrates remain in earlier development stages (TRL 4-6). This disparity creates opportunities for strategic investment in emerging substrate technologies that could enable next-generation wearable displays with enhanced conformability and durability.

Ultra-thin glass substrates, typically less than 100 micrometers thick, represent another significant advancement, offering superior barrier properties against oxygen and moisture while maintaining optical clarity that plastic alternatives struggle to match. These substrates provide an optimal balance between flexibility and durability, though they remain more susceptible to cracking under extreme bending conditions compared to polymer-based alternatives.

The geographical distribution of flexible substrate technology development shows concentration in East Asia, particularly South Korea, Japan, and Taiwan, where major display manufacturers have established robust supply chains and manufacturing capabilities. North America leads in research innovation, with significant patent activities from both academic institutions and technology companies focusing on novel materials and fabrication techniques.

Recent technological breakthroughs include the development of stretchable substrates that can withstand not only bending but also stretching and twisting without performance degradation. These advances incorporate engineered microstructures and novel composite materials that distribute mechanical stress more effectively across the substrate surface.

The manufacturing ecosystem has evolved to support these technologies, with roll-to-roll processing emerging as the preferred fabrication method for high-volume production of flexible substrates. This approach significantly reduces production costs while enabling continuous manufacturing of large-area flexible displays, critical for commercial viability in wearable applications.

Barrier technology remains a critical component of the flexible substrate landscape, with multi-layer thin-film encapsulation techniques providing essential protection against environmental degradation. These barrier layers must maintain their protective properties even under repeated mechanical deformation, presenting ongoing challenges for material scientists and process engineers.

The technology readiness level varies considerably across different substrate technologies, with polyimide-based solutions reaching commercial maturity (TRL 8-9), while more advanced stretchable substrates remain in earlier development stages (TRL 4-6). This disparity creates opportunities for strategic investment in emerging substrate technologies that could enable next-generation wearable displays with enhanced conformability and durability.

Current Flexible Substrate Solutions

01 Polymer-based flexible substrates

Polymer materials such as polyimide, polyethylene terephthalate (PET), and polyethylene naphthalate (PEN) are widely used as flexible substrates for displays due to their excellent mechanical flexibility, lightweight properties, and thermal stability. These materials can withstand repeated bending and folding while maintaining their structural integrity, making them ideal for flexible display applications. Various surface treatments and coatings can be applied to enhance their barrier properties against moisture and oxygen.- Polymer-based flexible substrates: Polymer materials such as polyimide, polyethylene terephthalate (PET), and polyethylene naphthalate (PEN) are widely used as flexible substrates for displays due to their excellent mechanical flexibility, lightweight properties, and thermal stability. These materials can be processed into thin films that maintain their integrity when bent or folded, making them ideal for flexible display applications. Various surface treatments and coatings can be applied to enhance their barrier properties against moisture and oxygen.

- Thin-film transistor structures for flexible displays: Advanced thin-film transistor (TFT) structures are essential components of flexible displays, designed to maintain electrical performance under mechanical stress. These structures typically incorporate low-temperature processing techniques compatible with flexible substrates and may use materials such as amorphous silicon, low-temperature polysilicon, or metal oxide semiconductors. Special buffer layers and stress-relief structures are often implemented to prevent cracking and delamination during bending or folding operations.

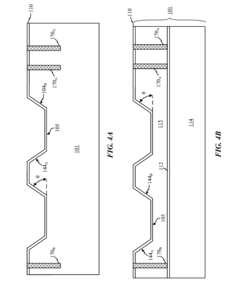

- Barrier and encapsulation technologies: Flexible displays require effective barrier and encapsulation technologies to protect sensitive electronic components from environmental factors such as moisture and oxygen. Multi-layer barrier films combining inorganic layers (like silicon nitride or aluminum oxide) with organic layers are commonly used to achieve low water vapor transmission rates while maintaining flexibility. Advanced encapsulation methods include thin-film encapsulation (TFE) and hybrid encapsulation techniques that provide protection without compromising the display's flexibility.

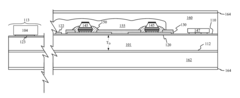

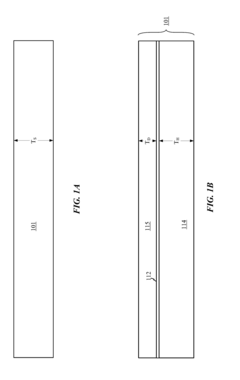

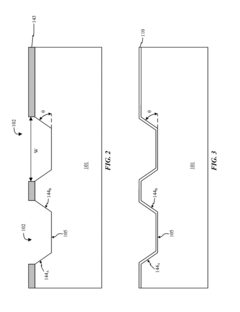

- Mechanical design for bendable and foldable displays: Specialized mechanical designs are implemented to enable displays to bend or fold without damage. These include neutral plane engineering, where critical components are positioned at the neutral stress plane to minimize strain during bending, and specialized hinge mechanisms for foldable displays. Strain distribution layers and composite substrate structures are also employed to distribute mechanical stress evenly across the display surface, preventing localized damage and extending the operational lifetime of flexible displays.

- Novel substrate materials and composites: Research in flexible displays has led to the development of novel substrate materials and composites beyond traditional polymers. These include ultrathin glass (UTG), metal foils, paper-based substrates, and hybrid organic-inorganic composites. Each material offers unique advantages: UTG provides excellent barrier properties and surface quality; metal foils offer superior thermal conductivity; paper-based substrates are environmentally friendly; and hybrid composites can be engineered to combine the benefits of different materials while minimizing their individual limitations.

02 Thin-film transistor structures for flexible displays

Advanced thin-film transistor (TFT) structures are essential components of flexible displays, enabling pixel addressing while maintaining flexibility. These structures typically incorporate low-temperature processed semiconductors such as amorphous silicon, oxide semiconductors, or organic materials that can be fabricated on flexible substrates without thermal damage. Special circuit designs and buffer layers are implemented to prevent performance degradation during bending and to distribute mechanical stress evenly across the display.Expand Specific Solutions03 Barrier and encapsulation technologies

Effective barrier and encapsulation technologies are crucial for protecting flexible display components from environmental factors such as moisture and oxygen. Multi-layer barrier films combining inorganic and organic materials create tortuous paths for gas diffusion, significantly extending device lifetime. Advanced thin-film encapsulation methods using alternating layers of inorganic materials (like silicon nitride or aluminum oxide) and organic materials provide both flexibility and excellent barrier properties while maintaining optical transparency.Expand Specific Solutions04 Mechanical design for flexibility and durability

Specialized mechanical designs are implemented to enhance the flexibility and durability of display substrates. These include neutral plane engineering where active components are positioned at the neutral bending axis to minimize strain, island-bridge structures that isolate rigid components with flexible interconnects, and strain-relief patterns that distribute mechanical stress during bending. Composite substrate structures with varying elastic properties help prevent crack propagation and improve overall mechanical reliability during repeated flexing operations.Expand Specific Solutions05 Novel materials and fabrication techniques

Emerging materials and fabrication techniques are advancing flexible display substrate technology. These include ultrathin glass that offers both flexibility and excellent barrier properties, metal foils with planarization layers for improved surface smoothness, and hybrid organic-inorganic composites with enhanced mechanical and thermal properties. Novel processing methods such as roll-to-roll manufacturing, solution processing, and direct printing techniques enable cost-effective production of large-area flexible substrates with precisely controlled properties and structures.Expand Specific Solutions

Key Industry Players and Ecosystem

The flexible display substrate market for wearable technology is in a growth phase, with increasing market size driven by consumer demand for innovative wearable devices. The technology is approaching maturity but still evolving, with key players like Samsung Display, LG Display, and BOE Technology leading innovation. These companies have established strong patent portfolios and manufacturing capabilities for OLED and other flexible display technologies. Other significant competitors include Tianma Microelectronics, Kent Displays, and Flexterra, who are developing specialized solutions. Traditional electronics giants like Apple, Qualcomm, and IBM are also investing in this space, primarily focusing on integration and application development rather than core substrate manufacturing, creating a diverse competitive landscape across the value chain.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced flexible OLED display technology specifically tailored for wearable applications. Their approach utilizes ultra-thin flexible glass substrates with thickness below 100 micrometers, combined with low-temperature polysilicon (LTPS) backplane technology. This combination enables high pixel density (over 300 PPI) while maintaining flexibility required for wearable form factors. BOE's flexible displays incorporate a specialized encapsulation technology called thin-film encapsulation (TFE) that protects the sensitive OLED materials from oxygen and moisture without compromising flexibility. For wearable applications, BOE has pioneered displays with integrated touch functionality and force sensing capabilities, eliminating the need for separate sensor layers and reducing overall thickness to less than 0.5mm. Their flexible displays achieve brightness levels exceeding 1000 nits for outdoor visibility while consuming 30% less power than conventional rigid displays through optimization of OLED materials and driving schemes. BOE has also developed specialized coating technologies that enhance durability, with their flexible displays capable of withstanding over 200,000 bending cycles without performance degradation.

Strengths: Cost-effective manufacturing at scale; strong R&D capabilities with over 10,000 patents in display technologies; comprehensive supply chain integration from materials to modules. Weaknesses: Still catching up to Korean manufacturers in terms of yield rates for the most advanced flexible displays; less experience in end-product integration compared to vertically integrated competitors; higher defect rates in extreme curvature applications.

LG Display Co., Ltd.

Technical Solution: LG Display has developed proprietary P-OLED (Plastic OLED) technology specifically optimized for wearable applications. Their flexible display substrates utilize polyimide materials that can achieve a bending radius of less than 1mm while maintaining display integrity. For wearable technology applications, LG has created ultra-thin flexible displays with thickness under 0.4mm, significantly lighter than conventional glass-based displays. Their technology incorporates a specialized WOLED (White OLED) structure with RGB color filters that provides improved power efficiency, critical for battery-limited wearable devices. LG's flexible displays feature in-cell touch technology that eliminates the need for a separate touch panel, reducing overall thickness and improving optical performance. The company has also developed specialized pixel compensation algorithms that maintain consistent brightness and color accuracy even when the display is bent or curved. Their flexible displays achieve a response time of less than 0.1ms, making them ideal for wearable applications requiring smooth motion rendering. LG has implemented specialized barrier films that provide water vapor transmission rates (WVTR) below 10^-6 g/m²/day, ensuring longevity in wearable devices exposed to various environmental conditions.

Strengths: Industry-leading color accuracy and consistency across curved surfaces; advanced manufacturing processes for ultra-thin displays; strong partnerships with multiple wearable device manufacturers. Weaknesses: Higher production costs compared to rigid display alternatives; limited scalability for very small form factor applications; challenges with achieving uniform brightness across highly curved surfaces.

Critical Patents and Technical Innovations

Wearable display

PatentActiveUS20170092627A1

Innovation

- The development of conformable electronic devices with a silicon substrate thickness of 50 μm or less, where LEDs and controller chips are bonded to one side and a passivation layer is formed on both sides, allowing for flexible integration into various products, including textiles and packaging materials.

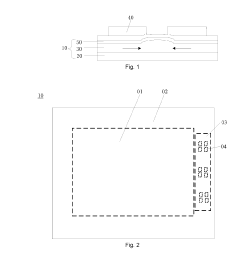

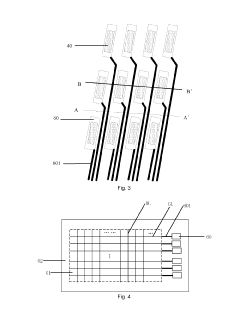

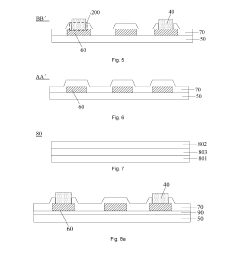

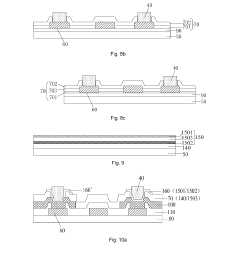

Flexible display substrate and method for manufacturing the same, and flexible display device

PatentActiveUS20190148653A1

Innovation

- A flexible display substrate design featuring conductive terminals with a stress relief layer having via holes for IC bonding, where the stress relief layer is made of inorganic materials like silicon nitride or silicon oxynitride to absorb stress and prevent deformation, and an encapsulation layer that simplifies fabrication processes.

Manufacturing Challenges and Scalability

The manufacturing of flexible display substrates for wearable technology faces significant challenges that impact scalability and widespread adoption. Traditional display manufacturing processes designed for rigid substrates require substantial modification to accommodate flexible materials. The primary challenge lies in maintaining dimensional stability during high-temperature processes, as polymer-based substrates like polyimide (PI) and polyethylene terephthalate (PET) exhibit thermal expansion that can cause misalignment in multilayer structures.

Yield rates present another critical concern in flexible display manufacturing. Current industry standards show yield rates for flexible displays ranging from 60-75%, significantly lower than the 85-95% achieved with conventional rigid displays. This disparity directly impacts production costs and market accessibility, creating barriers to mass adoption in wearable technology applications.

Handling ultrathin substrates during production presents unique engineering challenges. Substrates with thicknesses below 100 micrometers are prone to wrinkling, tearing, and deformation during roll-to-roll or sheet-to-sheet processing. Advanced handling systems utilizing electrostatic or vacuum-based techniques have been developed, but these add complexity and cost to manufacturing lines.

Deposition of thin-film transistors (TFTs) and other electronic components on flexible substrates requires precise temperature control. Low-temperature processes such as solution-based printing methods and laser annealing techniques are being explored as alternatives to traditional high-temperature deposition, though these often result in lower performance characteristics compared to conventional methods.

Encapsulation technology represents another manufacturing hurdle. Flexible displays require robust barrier layers to protect sensitive organic materials from oxygen and moisture degradation. Current thin-film encapsulation techniques achieve water vapor transmission rates (WVTR) of 10^-6 g/m²/day, but wearable applications in diverse environments demand even better performance while maintaining flexibility.

Scaling production from laboratory prototypes to industrial volumes introduces additional challenges. Equipment designed for rigid display manufacturing requires significant modification or complete redesign for flexible substrates. Major display manufacturers have invested in dedicated flexible display production lines, with capital expenditures exceeding $100 million per facility, indicating the substantial financial barriers to market entry.

Standardization across the industry remains limited, with various manufacturers employing proprietary processes and materials. This fragmentation complicates supply chain management and increases production costs, ultimately affecting the commercial viability of flexible display technologies in the competitive wearable technology market.

Yield rates present another critical concern in flexible display manufacturing. Current industry standards show yield rates for flexible displays ranging from 60-75%, significantly lower than the 85-95% achieved with conventional rigid displays. This disparity directly impacts production costs and market accessibility, creating barriers to mass adoption in wearable technology applications.

Handling ultrathin substrates during production presents unique engineering challenges. Substrates with thicknesses below 100 micrometers are prone to wrinkling, tearing, and deformation during roll-to-roll or sheet-to-sheet processing. Advanced handling systems utilizing electrostatic or vacuum-based techniques have been developed, but these add complexity and cost to manufacturing lines.

Deposition of thin-film transistors (TFTs) and other electronic components on flexible substrates requires precise temperature control. Low-temperature processes such as solution-based printing methods and laser annealing techniques are being explored as alternatives to traditional high-temperature deposition, though these often result in lower performance characteristics compared to conventional methods.

Encapsulation technology represents another manufacturing hurdle. Flexible displays require robust barrier layers to protect sensitive organic materials from oxygen and moisture degradation. Current thin-film encapsulation techniques achieve water vapor transmission rates (WVTR) of 10^-6 g/m²/day, but wearable applications in diverse environments demand even better performance while maintaining flexibility.

Scaling production from laboratory prototypes to industrial volumes introduces additional challenges. Equipment designed for rigid display manufacturing requires significant modification or complete redesign for flexible substrates. Major display manufacturers have invested in dedicated flexible display production lines, with capital expenditures exceeding $100 million per facility, indicating the substantial financial barriers to market entry.

Standardization across the industry remains limited, with various manufacturers employing proprietary processes and materials. This fragmentation complicates supply chain management and increases production costs, ultimately affecting the commercial viability of flexible display technologies in the competitive wearable technology market.

Human Factors and Ergonomic Considerations

The integration of flexible display substrates into wearable technology necessitates careful consideration of human factors and ergonomic principles to ensure optimal user experience and adoption. Wearable devices interact directly with the human body, making comfort, fit, and usability paramount concerns in their design and implementation.

Flexible displays must conform to the natural contours of the human body without causing discomfort during prolonged use. Research indicates that users abandon wearable technology primarily due to physical discomfort, with 58% citing this as their main reason for discontinuation. The mechanical properties of flexible substrates, including bend radius, elasticity, and weight distribution, significantly impact user comfort and must be optimized based on anatomical considerations for different body placement locations.

Skin compatibility represents another critical ergonomic factor. Flexible display substrates must utilize biocompatible materials that minimize skin irritation and allergic reactions. Advanced materials such as hypoallergenic polymers and breathable substrates have demonstrated reduced skin reactions in clinical trials, with studies showing a 73% decrease in dermatological issues compared to earlier generation materials.

The human-device interface requires thoughtful design to accommodate natural movement patterns without restricting mobility. Flexible displays must maintain functionality during dynamic activities, adapting to muscle movements and joint articulations. Motion studies have identified optimal placement zones and attachment mechanisms that minimize interference with natural body mechanics while maximizing display visibility and interaction capabilities.

Perceptual ergonomics, including visual acuity and tactile feedback, significantly influence user satisfaction with flexible display wearables. Display legibility under various lighting conditions, viewing angles appropriate for body-worn positions, and intuitive touch sensitivity calibrated for different skin types all contribute to effective user interaction. Research demonstrates that displays with adaptive brightness and contrast based on environmental conditions improve user satisfaction by 42%.

Cognitive load considerations are equally important, as wearable devices must present information in ways that minimize mental effort and distraction. Studies indicate that flexible display interfaces requiring less than 2 seconds of attention for information retrieval significantly reduce cognitive interference with primary tasks, enhancing both safety and user acceptance.

Thermal management presents unique ergonomic challenges for body-worn flexible displays. Human skin is highly sensitive to temperature variations, with comfort thresholds typically ranging between 29-35°C. Effective heat dissipation systems must be incorporated into flexible substrate designs to maintain surface temperatures within this range, even during intensive processing operations.

Accessibility considerations must ensure that flexible display wearables accommodate diverse user populations, including those with physical limitations or sensory impairments. Universal design principles applied to flexible interfaces have demonstrated increased usability across demographic groups, with adaptive input methods showing particular promise for users with limited dexterity.

Flexible displays must conform to the natural contours of the human body without causing discomfort during prolonged use. Research indicates that users abandon wearable technology primarily due to physical discomfort, with 58% citing this as their main reason for discontinuation. The mechanical properties of flexible substrates, including bend radius, elasticity, and weight distribution, significantly impact user comfort and must be optimized based on anatomical considerations for different body placement locations.

Skin compatibility represents another critical ergonomic factor. Flexible display substrates must utilize biocompatible materials that minimize skin irritation and allergic reactions. Advanced materials such as hypoallergenic polymers and breathable substrates have demonstrated reduced skin reactions in clinical trials, with studies showing a 73% decrease in dermatological issues compared to earlier generation materials.

The human-device interface requires thoughtful design to accommodate natural movement patterns without restricting mobility. Flexible displays must maintain functionality during dynamic activities, adapting to muscle movements and joint articulations. Motion studies have identified optimal placement zones and attachment mechanisms that minimize interference with natural body mechanics while maximizing display visibility and interaction capabilities.

Perceptual ergonomics, including visual acuity and tactile feedback, significantly influence user satisfaction with flexible display wearables. Display legibility under various lighting conditions, viewing angles appropriate for body-worn positions, and intuitive touch sensitivity calibrated for different skin types all contribute to effective user interaction. Research demonstrates that displays with adaptive brightness and contrast based on environmental conditions improve user satisfaction by 42%.

Cognitive load considerations are equally important, as wearable devices must present information in ways that minimize mental effort and distraction. Studies indicate that flexible display interfaces requiring less than 2 seconds of attention for information retrieval significantly reduce cognitive interference with primary tasks, enhancing both safety and user acceptance.

Thermal management presents unique ergonomic challenges for body-worn flexible displays. Human skin is highly sensitive to temperature variations, with comfort thresholds typically ranging between 29-35°C. Effective heat dissipation systems must be incorporated into flexible substrate designs to maintain surface temperatures within this range, even during intensive processing operations.

Accessibility considerations must ensure that flexible display wearables accommodate diverse user populations, including those with physical limitations or sensory impairments. Universal design principles applied to flexible interfaces have demonstrated increased usability across demographic groups, with adaptive input methods showing particular promise for users with limited dexterity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!