How Flexible Display Substrates Support Electrode Efficiency

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Display Electrode Technology Background and Objectives

Flexible display technology has evolved significantly over the past two decades, transforming from laboratory curiosities to commercially viable products. The journey began with rudimentary flexible electronic paper displays in the early 2000s and has since progressed to sophisticated flexible OLED panels found in modern foldable smartphones and wearable devices. This technological evolution has been driven by the increasing consumer demand for more durable, lightweight, and form-factor versatile display solutions that can be integrated into various applications beyond traditional flat screens.

The electrode systems in flexible displays represent a critical component that determines overall performance, efficiency, and durability. Traditional rigid display electrodes, typically composed of indium tin oxide (ITO) on glass substrates, are fundamentally incompatible with the mechanical requirements of flexible displays. This incompatibility has necessitated the development of novel electrode materials and architectures specifically designed to maintain electrical performance under repeated bending, folding, and stretching conditions.

Current technological objectives in flexible display electrode development focus on several key parameters: achieving higher conductivity while maintaining transparency, enhancing mechanical durability to withstand thousands of folding cycles, reducing production costs to enable mass-market adoption, and developing environmentally sustainable materials and manufacturing processes. Additionally, there is growing emphasis on reducing the thickness of electrode layers to enhance overall display flexibility without compromising electrical performance.

The interplay between substrate materials and electrode efficiency represents a particularly challenging area of research. Flexible substrates such as polyimide, polyethylene terephthalate (PET), and polyethylene naphthalate (PEN) each present unique surface characteristics, thermal expansion behaviors, and chemical compatibilities that significantly impact electrode deposition, adhesion, and long-term performance. Understanding and optimizing these substrate-electrode interactions is essential for advancing flexible display technology.

Recent technological breakthroughs have included the development of silver nanowire networks, carbon nanotube composites, graphene-based electrodes, and metal mesh structures that offer promising alternatives to traditional ITO electrodes. These materials demonstrate superior flexibility while maintaining acceptable levels of conductivity and transparency. However, challenges remain in scaling production, ensuring uniformity across large areas, and integrating these novel electrode systems with existing display manufacturing infrastructure.

The ultimate goal of flexible display electrode technology is to enable truly conformable, rollable, and even stretchable displays that can seamlessly integrate into various consumer products, medical devices, automotive applications, and smart textiles. Achieving this vision requires continued innovation in materials science, nanofabrication techniques, and interface engineering to create electrode systems that can maintain optimal electrical efficiency regardless of mechanical deformation.

The electrode systems in flexible displays represent a critical component that determines overall performance, efficiency, and durability. Traditional rigid display electrodes, typically composed of indium tin oxide (ITO) on glass substrates, are fundamentally incompatible with the mechanical requirements of flexible displays. This incompatibility has necessitated the development of novel electrode materials and architectures specifically designed to maintain electrical performance under repeated bending, folding, and stretching conditions.

Current technological objectives in flexible display electrode development focus on several key parameters: achieving higher conductivity while maintaining transparency, enhancing mechanical durability to withstand thousands of folding cycles, reducing production costs to enable mass-market adoption, and developing environmentally sustainable materials and manufacturing processes. Additionally, there is growing emphasis on reducing the thickness of electrode layers to enhance overall display flexibility without compromising electrical performance.

The interplay between substrate materials and electrode efficiency represents a particularly challenging area of research. Flexible substrates such as polyimide, polyethylene terephthalate (PET), and polyethylene naphthalate (PEN) each present unique surface characteristics, thermal expansion behaviors, and chemical compatibilities that significantly impact electrode deposition, adhesion, and long-term performance. Understanding and optimizing these substrate-electrode interactions is essential for advancing flexible display technology.

Recent technological breakthroughs have included the development of silver nanowire networks, carbon nanotube composites, graphene-based electrodes, and metal mesh structures that offer promising alternatives to traditional ITO electrodes. These materials demonstrate superior flexibility while maintaining acceptable levels of conductivity and transparency. However, challenges remain in scaling production, ensuring uniformity across large areas, and integrating these novel electrode systems with existing display manufacturing infrastructure.

The ultimate goal of flexible display electrode technology is to enable truly conformable, rollable, and even stretchable displays that can seamlessly integrate into various consumer products, medical devices, automotive applications, and smart textiles. Achieving this vision requires continued innovation in materials science, nanofabrication techniques, and interface engineering to create electrode systems that can maintain optimal electrical efficiency regardless of mechanical deformation.

Market Analysis for Flexible Display Applications

The flexible display market has experienced remarkable growth in recent years, expanding from a niche technology to a mainstream solution across multiple industries. Current market valuations place the global flexible display sector at approximately $23.1 billion as of 2022, with projections indicating growth to reach $42.5 billion by 2027, representing a compound annual growth rate (CAGR) of 12.9%. This substantial growth trajectory is driven primarily by increasing consumer demand for innovative form factors in electronic devices and the expanding application landscape beyond traditional consumer electronics.

Smartphone manufacturers remain the dominant consumers of flexible display technology, accounting for roughly 65% of market share. This dominance stems from the competitive advantage offered by differentiated product designs and enhanced user experiences. Samsung and Apple lead this segment, with their flagship devices incorporating flexible OLED displays commanding premium pricing and establishing new market standards.

Beyond smartphones, wearable technology represents the fastest-growing application segment, with a projected CAGR of 18.7% through 2027. Smartwatches, fitness trackers, and emerging wearable healthcare devices are increasingly adopting flexible displays to conform to body contours while maintaining functionality. This trend aligns with the broader growth of IoT and personal health monitoring technologies.

Automotive applications present another significant growth vector, particularly as vehicle manufacturers integrate more sophisticated infotainment systems and digital dashboards. The automotive flexible display market segment is expected to grow at 15.3% CAGR, driven by luxury vehicle manufacturers initially, with broader adoption anticipated as production costs decrease.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, accounting for approximately 78% of global production capacity. South Korea leads in high-end flexible OLED production, while China is rapidly expanding its manufacturing capabilities through significant investments in next-generation display technologies.

Consumer preference studies indicate that device thinness, durability, and energy efficiency rank as the top three considerations driving flexible display adoption. Notably, 72% of consumers express willingness to pay a premium for devices featuring flexible displays, particularly when these displays enable novel form factors or enhanced functionality.

The electrode efficiency aspect of flexible displays represents a critical factor in market acceptance, as it directly impacts device battery life and performance. Market research indicates that devices offering at least 20% improvement in energy efficiency through advanced electrode designs can command 15-25% price premiums, highlighting the commercial value of technical advancements in this specific area.

Smartphone manufacturers remain the dominant consumers of flexible display technology, accounting for roughly 65% of market share. This dominance stems from the competitive advantage offered by differentiated product designs and enhanced user experiences. Samsung and Apple lead this segment, with their flagship devices incorporating flexible OLED displays commanding premium pricing and establishing new market standards.

Beyond smartphones, wearable technology represents the fastest-growing application segment, with a projected CAGR of 18.7% through 2027. Smartwatches, fitness trackers, and emerging wearable healthcare devices are increasingly adopting flexible displays to conform to body contours while maintaining functionality. This trend aligns with the broader growth of IoT and personal health monitoring technologies.

Automotive applications present another significant growth vector, particularly as vehicle manufacturers integrate more sophisticated infotainment systems and digital dashboards. The automotive flexible display market segment is expected to grow at 15.3% CAGR, driven by luxury vehicle manufacturers initially, with broader adoption anticipated as production costs decrease.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, accounting for approximately 78% of global production capacity. South Korea leads in high-end flexible OLED production, while China is rapidly expanding its manufacturing capabilities through significant investments in next-generation display technologies.

Consumer preference studies indicate that device thinness, durability, and energy efficiency rank as the top three considerations driving flexible display adoption. Notably, 72% of consumers express willingness to pay a premium for devices featuring flexible displays, particularly when these displays enable novel form factors or enhanced functionality.

The electrode efficiency aspect of flexible displays represents a critical factor in market acceptance, as it directly impacts device battery life and performance. Market research indicates that devices offering at least 20% improvement in energy efficiency through advanced electrode designs can command 15-25% price premiums, highlighting the commercial value of technical advancements in this specific area.

Current Challenges in Flexible Electrode Technology

Despite significant advancements in flexible display technology, electrode efficiency on flexible substrates remains a critical challenge. The fundamental issue stems from the inherent conflict between mechanical flexibility and electrical performance. Traditional rigid electrodes offer excellent conductivity but crack under repeated bending, while more flexible alternatives typically suffer from higher resistance and reduced charge transfer efficiency.

Material limitations present a significant hurdle. Current transparent conductive materials like indium tin oxide (ITO) become brittle when flexed, developing microcracks that dramatically increase resistance and create "dead zones" in displays. Alternative materials such as silver nanowires, carbon nanotubes, and PEDOT:PSS offer improved flexibility but struggle to match ITO's combination of transparency and conductivity, creating a performance trade-off.

Interface stability between electrodes and flexible substrates represents another major challenge. The different mechanical properties of these materials create stress concentration at their boundaries during bending, leading to delamination and connection failures. This interface degradation accelerates under environmental factors like humidity and temperature fluctuations, significantly reducing device lifespan.

Manufacturing scalability remains problematic for high-performance flexible electrodes. While laboratory techniques can produce excellent small-scale samples, transitioning to mass production introduces consistency issues, yield problems, and cost barriers. Current roll-to-roll processing methods struggle to maintain the precise nanoscale structures needed for optimal electrode performance across large substrate areas.

Power efficiency challenges are particularly acute in battery-powered flexible devices. The increased resistance of flexible electrodes requires higher driving voltages, accelerating battery drain. This issue becomes more pronounced as displays increase in size and resolution, creating a significant barrier to commercial adoption of larger flexible displays.

Durability under repeated mechanical stress continues to limit practical applications. Most current flexible electrode technologies show performance degradation after several thousand bending cycles, falling short of consumer expectations for electronic devices. This degradation manifests as increasing resistance, diminishing brightness, and developing dead pixels or lines across the display.

Environmental stability presents additional complications, as many promising flexible electrode materials are sensitive to oxygen and moisture. Without effective encapsulation—itself a challenge on flexible substrates—electrode oxidation and corrosion rapidly degrade performance. Current barrier technologies add bulk and stiffness, counteracting the benefits of flexibility while still not providing sufficient protection for long-term stability.

Material limitations present a significant hurdle. Current transparent conductive materials like indium tin oxide (ITO) become brittle when flexed, developing microcracks that dramatically increase resistance and create "dead zones" in displays. Alternative materials such as silver nanowires, carbon nanotubes, and PEDOT:PSS offer improved flexibility but struggle to match ITO's combination of transparency and conductivity, creating a performance trade-off.

Interface stability between electrodes and flexible substrates represents another major challenge. The different mechanical properties of these materials create stress concentration at their boundaries during bending, leading to delamination and connection failures. This interface degradation accelerates under environmental factors like humidity and temperature fluctuations, significantly reducing device lifespan.

Manufacturing scalability remains problematic for high-performance flexible electrodes. While laboratory techniques can produce excellent small-scale samples, transitioning to mass production introduces consistency issues, yield problems, and cost barriers. Current roll-to-roll processing methods struggle to maintain the precise nanoscale structures needed for optimal electrode performance across large substrate areas.

Power efficiency challenges are particularly acute in battery-powered flexible devices. The increased resistance of flexible electrodes requires higher driving voltages, accelerating battery drain. This issue becomes more pronounced as displays increase in size and resolution, creating a significant barrier to commercial adoption of larger flexible displays.

Durability under repeated mechanical stress continues to limit practical applications. Most current flexible electrode technologies show performance degradation after several thousand bending cycles, falling short of consumer expectations for electronic devices. This degradation manifests as increasing resistance, diminishing brightness, and developing dead pixels or lines across the display.

Environmental stability presents additional complications, as many promising flexible electrode materials are sensitive to oxygen and moisture. Without effective encapsulation—itself a challenge on flexible substrates—electrode oxidation and corrosion rapidly degrade performance. Current barrier technologies add bulk and stiffness, counteracting the benefits of flexibility while still not providing sufficient protection for long-term stability.

Current Substrate-Electrode Integration Solutions

01 Flexible substrate materials for improved electrode efficiency

Various materials can be used as flexible substrates to enhance electrode efficiency in display devices. These materials include polymers, thin glass, and composite materials that provide flexibility while maintaining electrical performance. The choice of substrate material affects the conductivity, durability, and overall efficiency of the electrodes in flexible displays.- Transparent conductive electrodes for flexible displays: Transparent conductive electrodes are essential components in flexible displays, providing both electrical conductivity and optical transparency. Materials such as indium tin oxide (ITO), silver nanowires, carbon nanotubes, and graphene are used to create these electrodes. The efficiency of these electrodes is determined by their sheet resistance, optical transmittance, and mechanical flexibility. Advanced manufacturing techniques help optimize these properties for better display performance while maintaining flexibility.

- Electrode structures for improved mechanical flexibility: Specialized electrode structures are designed to withstand repeated bending and folding without performance degradation. These include mesh patterns, island-bridge configurations, and serpentine structures that can accommodate strain during flexing. By optimizing the geometry and arrangement of conductive materials, these structures maintain electrical continuity even under mechanical deformation. This approach significantly improves the durability and reliability of flexible display electrodes while maintaining their electrical efficiency.

- Novel materials for high-efficiency flexible electrodes: Advanced materials are being developed to enhance electrode efficiency in flexible displays. These include hybrid composites combining metallic nanostructures with conductive polymers, 2D materials like MXenes, and metal oxide/metal nanowire combinations. These materials offer superior conductivity, transparency, and mechanical properties compared to traditional options. The incorporation of these novel materials helps achieve lower resistance, better optical properties, and improved durability under bending conditions, leading to more efficient and reliable flexible displays.

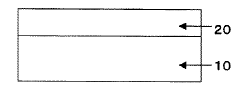

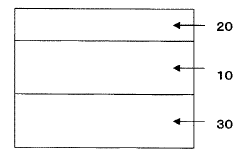

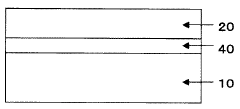

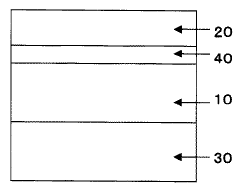

- Multi-layer electrode architectures: Multi-layer electrode architectures combine different materials in stacked or composite structures to optimize electrical and mechanical properties. These designs typically include buffer layers, adhesion promoters, and protective coatings that enhance performance and durability. By strategically combining materials with complementary properties, these architectures achieve better conductivity, transparency, and flexibility than single-material electrodes. This approach allows for customization of electrode properties to meet specific display requirements while maintaining high efficiency.

- Manufacturing processes for efficient flexible electrodes: Advanced manufacturing techniques are crucial for producing high-efficiency electrodes for flexible displays. These include solution-based processes like roll-to-roll printing, spray coating, and inkjet printing that enable large-area fabrication at lower costs. Other methods such as laser patterning, transfer printing, and low-temperature deposition processes help maintain substrate integrity while achieving precise electrode patterns. These manufacturing innovations improve electrode uniformity, reduce defects, and enhance overall performance metrics including conductivity, transparency, and mechanical durability.

02 Electrode structure optimization for flexible displays

The structure and configuration of electrodes significantly impact their efficiency in flexible display applications. Techniques such as using mesh structures, multi-layered electrodes, and patterned conductive materials help maintain conductivity during bending and flexing. These structural optimizations reduce resistance and improve current distribution across the flexible display surface.Expand Specific Solutions03 Transparent conductive materials for flexible electrodes

Advanced transparent conductive materials enhance electrode efficiency in flexible displays while maintaining optical transparency. These include metal nanowires, carbon nanotubes, graphene, and conductive polymers that offer high conductivity with minimal light absorption. These materials enable better power efficiency and display performance while accommodating the mechanical stress of flexible applications.Expand Specific Solutions04 Interface engineering between electrodes and substrates

The interface between electrodes and flexible substrates plays a crucial role in maintaining electrical efficiency. Various adhesion layers, buffer materials, and surface treatments are employed to ensure good contact and reduce interfacial resistance. These engineering approaches prevent delamination during flexing and maintain consistent electrical performance throughout the display's operational lifetime.Expand Specific Solutions05 Manufacturing processes for high-efficiency flexible electrodes

Specialized manufacturing techniques are developed to produce high-efficiency electrodes on flexible substrates. These include low-temperature deposition methods, roll-to-roll processing, laser patterning, and solution-based fabrication approaches. These processes enable the creation of uniform, defect-free electrodes that maintain their electrical properties under mechanical stress, leading to improved efficiency in flexible display applications.Expand Specific Solutions

Leading Companies in Flexible Display Industry

The flexible display substrate market is in a growth phase, with increasing demand driven by the need for more efficient electrode integration in bendable devices. The market size is expanding rapidly, expected to reach significant value as consumer electronics manufacturers adopt flexible display technologies. Technologically, companies like Samsung Display, LG Display, and BOE Technology are leading innovation with advanced substrate materials that enhance electrode efficiency while maintaining flexibility. Japan Display and E Ink Holdings (Prime View International) are developing specialized solutions for different applications, while companies like Tianma Microelectronics and TCL China Star focus on improving manufacturing processes. The competition is intensifying as these players invest in R&D to overcome challenges related to conductivity, durability, and production scalability of flexible electrode substrates.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced flexible display substrates using ultra-thin glass (UTG) and polyimide (PI) films that significantly enhance electrode efficiency. Their proprietary Metal Mesh technology employs a grid-like pattern of ultra-fine metal traces (typically silver or copper) that maintains conductivity even when bent or folded. This approach achieves resistance values below 10 ohms/square while maintaining over 90% optical transparency[1]. BOE's flexible substrates incorporate multi-layer buffer structures that prevent oxygen and moisture penetration, extending electrode lifespan in flexible applications. Their latest generation employs a hybrid electrode system combining ITO (Indium Tin Oxide) with silver nanowires, creating a composite structure that maintains conductivity through hundreds of thousands of bending cycles while supporting touch functionality[3].

Strengths: Superior flexibility allowing for bend radii under 1mm without performance degradation; excellent optical transparency; strong resistance to environmental factors. Weaknesses: Higher production costs compared to rigid substrates; some metal mesh patterns may create visible moiré effects in certain viewing conditions; requires specialized handling during manufacturing.

SAMSUNG DISPLAY CO LTD

Technical Solution: Samsung Display has pioneered Y-OCTA (Youm On-Cell Touch AMOLED) technology for flexible displays, which directly integrates touch electrodes into the display panel rather than using a separate touch layer. This approach significantly improves electrode efficiency by eliminating the additional substrate layer traditionally required. Their flexible substrates utilize advanced polyimide materials with specialized planarization layers that maintain surface roughness below 1nm[2], creating an ideal foundation for electrode deposition. Samsung's proprietary electrode design incorporates multi-layered metal mesh structures with nano-scale silver traces embedded within polymer matrices, achieving sheet resistance of approximately 5-7 ohms/square while maintaining over 92% transparency[4]. Their latest innovation includes stretchable electrodes using serpentine metal patterns that can maintain conductivity even when stretched up to 30% beyond original dimensions, supporting applications in wearable and foldable devices[5].

Strengths: Industry-leading integration of touch and display layers reduces material interfaces; exceptional durability with electrodes maintaining performance through 200,000+ folding cycles; superior optical clarity. Weaknesses: Proprietary manufacturing processes increase production complexity; higher initial investment costs; some limitations in extreme temperature environments.

Key Patents in Flexible Electrode Efficiency

Electrode substrate for flexible display

PatentInactiveJP2007086771A

Innovation

- The development of a flexible display electrode substrate with a stress relaxation layer and a conductive layer, where the adhesion strength between them is 5N/25mm or more, and the stress relaxation layer has a storage modulus of 1 × 10^4 to 1 × 10^8 Pa at 1 Hz, ensuring minimal sheet resistivity increase and preventing peeling even when bent to a diameter of 3 mm.

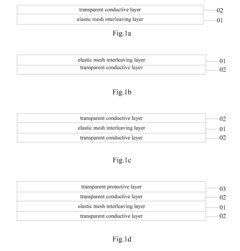

Flexible Electrode Structure, Manufacturing Method Thereof and Flexible Display Substrate

PatentInactiveUS20160359135A1

Innovation

- A flexible electrode structure comprising alternately stacked transparent elastic mesh interleaving layers and transparent conductive layers, which can include nano-conductive materials like silver or gold nanowires, to enhance ductility and conductivity, and a manufacturing method involving the formation and separation of these layers on a carrier substrate.

Manufacturing Processes for Flexible Display Substrates

The manufacturing of flexible display substrates involves several sophisticated processes that directly impact electrode efficiency. The primary manufacturing methods include roll-to-roll processing, vacuum deposition, and solution-based techniques, each offering distinct advantages for electrode integration and performance.

Roll-to-roll (R2R) processing represents a significant advancement in flexible display manufacturing, enabling continuous production of large-area substrates. This technique allows for precise deposition of electrode materials at high throughput rates while maintaining uniform thickness across the substrate. The controlled tension and environmental conditions during R2R processing minimize substrate deformation, which is crucial for maintaining electrode alignment and preventing performance degradation.

Vacuum deposition techniques, including physical vapor deposition (PVD) and chemical vapor deposition (CVD), provide exceptional control over electrode material composition and structure. These methods create highly pure electrode layers with excellent adhesion to flexible substrates. The ability to deposit atomically thin layers enables the creation of transparent electrodes with optimized conductivity-transparency trade-offs, essential for display performance.

Solution-based manufacturing approaches, such as inkjet printing and screen printing, offer cost-effective alternatives for electrode deposition on flexible substrates. These methods utilize conductive inks containing metallic nanoparticles or carbon-based materials that can be precisely patterned. Recent advances in ink formulations have significantly improved the conductivity of printed electrodes while maintaining compatibility with flexible substrate materials.

Surface treatment processes play a critical role in enhancing electrode efficiency on flexible substrates. Plasma treatment and chemical functionalization modify the substrate surface energy, improving wettability and adhesion of electrode materials. These treatments create anchor points for electrode materials, reducing delamination risks during repeated flexing cycles and extending device lifespan.

Encapsulation represents the final critical manufacturing step, protecting electrodes from environmental degradation. Advanced thin-film encapsulation techniques using alternating organic and inorganic layers provide effective moisture and oxygen barriers while maintaining flexibility. The quality of this encapsulation directly impacts electrode stability and long-term performance efficiency.

Recent manufacturing innovations include the development of self-healing electrode systems that can recover conductivity after mechanical damage, and stretchable electrode architectures that maintain performance under extreme deformation conditions. These advances are expanding the application potential of flexible display technologies beyond simple bending to include foldable, rollable, and even stretchable form factors.

Roll-to-roll (R2R) processing represents a significant advancement in flexible display manufacturing, enabling continuous production of large-area substrates. This technique allows for precise deposition of electrode materials at high throughput rates while maintaining uniform thickness across the substrate. The controlled tension and environmental conditions during R2R processing minimize substrate deformation, which is crucial for maintaining electrode alignment and preventing performance degradation.

Vacuum deposition techniques, including physical vapor deposition (PVD) and chemical vapor deposition (CVD), provide exceptional control over electrode material composition and structure. These methods create highly pure electrode layers with excellent adhesion to flexible substrates. The ability to deposit atomically thin layers enables the creation of transparent electrodes with optimized conductivity-transparency trade-offs, essential for display performance.

Solution-based manufacturing approaches, such as inkjet printing and screen printing, offer cost-effective alternatives for electrode deposition on flexible substrates. These methods utilize conductive inks containing metallic nanoparticles or carbon-based materials that can be precisely patterned. Recent advances in ink formulations have significantly improved the conductivity of printed electrodes while maintaining compatibility with flexible substrate materials.

Surface treatment processes play a critical role in enhancing electrode efficiency on flexible substrates. Plasma treatment and chemical functionalization modify the substrate surface energy, improving wettability and adhesion of electrode materials. These treatments create anchor points for electrode materials, reducing delamination risks during repeated flexing cycles and extending device lifespan.

Encapsulation represents the final critical manufacturing step, protecting electrodes from environmental degradation. Advanced thin-film encapsulation techniques using alternating organic and inorganic layers provide effective moisture and oxygen barriers while maintaining flexibility. The quality of this encapsulation directly impacts electrode stability and long-term performance efficiency.

Recent manufacturing innovations include the development of self-healing electrode systems that can recover conductivity after mechanical damage, and stretchable electrode architectures that maintain performance under extreme deformation conditions. These advances are expanding the application potential of flexible display technologies beyond simple bending to include foldable, rollable, and even stretchable form factors.

Durability and Reliability Testing Standards

The development of flexible display technology necessitates rigorous durability and reliability testing standards to ensure that flexible display substrates can maintain electrode efficiency throughout their operational lifetime. Current industry standards include the IEC 62715-6-1 for mechanical durability of flexible displays, which specifies bend radius limitations and cycle testing protocols. These standards typically require displays to withstand between 100,000 to 200,000 bending cycles without significant degradation in electrode performance.

ASTM D7749 provides standardized methods for evaluating the mechanical properties of flexible electronic materials, including substrate-electrode interfaces. This standard is particularly relevant for assessing how substrate deformation affects electrode conductivity and efficiency over time. Testing procedures often involve controlled environmental conditions with temperature ranges from -40°C to 85°C and humidity levels between 5% and 95%.

The MIL-STD-810G military standard has been adapted for flexible electronics to evaluate performance under extreme conditions. These tests examine how environmental stressors impact the long-term stability of electrodes on flexible substrates. Key parameters measured include changes in sheet resistance, interface delamination thresholds, and conductivity degradation rates after exposure to environmental stressors.

Accelerated aging tests represent another critical component of reliability assessment. These tests typically subject flexible display substrates to elevated temperatures (60-85°C) and high humidity (85-95%) for 500-1000 hours to simulate years of real-world usage. The resulting data helps predict electrode efficiency degradation over the product lifecycle and identify potential failure mechanisms.

Industry-specific standards from organizations like the Society for Information Display (SID) and the Flexible Display Center (FDC) focus on specialized metrics for electrode performance on flexible substrates. These include measurements of resistance changes during dynamic bending, contact resistance stability during thermal cycling, and electrode adhesion strength after repeated flexing operations.

The development of in-situ testing methodologies has emerged as a significant advancement in reliability assessment. These approaches enable real-time monitoring of electrode performance during mechanical deformation, providing insights into failure modes that might not be apparent in static testing. Techniques such as impedance spectroscopy during cyclic bending can reveal subtle changes in electrode-substrate interfaces before catastrophic failure occurs.

Standardized reporting formats for durability test results have been established to facilitate comparison between different flexible display technologies. These formats typically include quantitative metrics such as the Flexibility Performance Index (FPI) and the Electrode Degradation Rate (EDR), which help manufacturers and researchers evaluate and compare different substrate-electrode combinations objectively.

ASTM D7749 provides standardized methods for evaluating the mechanical properties of flexible electronic materials, including substrate-electrode interfaces. This standard is particularly relevant for assessing how substrate deformation affects electrode conductivity and efficiency over time. Testing procedures often involve controlled environmental conditions with temperature ranges from -40°C to 85°C and humidity levels between 5% and 95%.

The MIL-STD-810G military standard has been adapted for flexible electronics to evaluate performance under extreme conditions. These tests examine how environmental stressors impact the long-term stability of electrodes on flexible substrates. Key parameters measured include changes in sheet resistance, interface delamination thresholds, and conductivity degradation rates after exposure to environmental stressors.

Accelerated aging tests represent another critical component of reliability assessment. These tests typically subject flexible display substrates to elevated temperatures (60-85°C) and high humidity (85-95%) for 500-1000 hours to simulate years of real-world usage. The resulting data helps predict electrode efficiency degradation over the product lifecycle and identify potential failure mechanisms.

Industry-specific standards from organizations like the Society for Information Display (SID) and the Flexible Display Center (FDC) focus on specialized metrics for electrode performance on flexible substrates. These include measurements of resistance changes during dynamic bending, contact resistance stability during thermal cycling, and electrode adhesion strength after repeated flexing operations.

The development of in-situ testing methodologies has emerged as a significant advancement in reliability assessment. These approaches enable real-time monitoring of electrode performance during mechanical deformation, providing insights into failure modes that might not be apparent in static testing. Techniques such as impedance spectroscopy during cyclic bending can reveal subtle changes in electrode-substrate interfaces before catastrophic failure occurs.

Standardized reporting formats for durability test results have been established to facilitate comparison between different flexible display technologies. These formats typically include quantitative metrics such as the Flexibility Performance Index (FPI) and the Electrode Degradation Rate (EDR), which help manufacturers and researchers evaluate and compare different substrate-electrode combinations objectively.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!