Catalytic Functionality in Flexible Display Substrate Technologies

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalytic Substrate Evolution and Objectives

The evolution of catalytic functionality in flexible display substrate technologies represents a significant advancement in materials science and display engineering. Initially developed in the early 2000s, these technologies have progressed from rigid glass-based substrates to increasingly flexible polymer-based alternatives. The catalytic elements incorporated into these substrates have evolved from simple metal catalysts to complex multi-functional nanomaterials that enable enhanced electrical conductivity, improved mechanical flexibility, and superior optical properties.

The technological trajectory has been marked by several key innovations, including the development of solution-processable catalytic materials in 2010, which dramatically reduced manufacturing costs and enabled roll-to-roll processing capabilities. By 2015, researchers had successfully integrated self-healing catalytic networks into substrate materials, significantly extending device lifespans and resilience to mechanical stress. The most recent advancements include temperature-responsive catalytic systems that optimize display performance across varying environmental conditions.

Current research objectives focus on addressing persistent challenges in the field, particularly the trade-off between flexibility and durability. Scientists aim to develop catalytic substrate technologies that maintain structural integrity even after thousands of folding cycles while preserving optimal electronic performance. Another critical objective is reducing the environmental impact of these materials by developing biodegradable catalytic components that maintain high performance standards.

The integration of catalytic functionality with emerging technologies represents another important research direction. Efforts to combine these substrates with energy harvesting capabilities could lead to self-powered flexible displays, while incorporation with advanced sensing technologies might enable new interactive display applications. Researchers are also exploring the potential for catalytic substrates to facilitate seamless integration with biological systems for medical monitoring applications.

Industry objectives include scaling production processes to achieve cost parity with conventional display technologies by 2025. This involves optimizing catalytic material synthesis and deposition techniques to reduce rare earth element requirements while maintaining or improving performance metrics. The development of standardized testing protocols for flexible catalytic substrates represents another important goal, as current evaluation methods vary significantly across research institutions and manufacturers.

The convergence of academic research and industrial development in this field suggests that catalytic functionality will play an increasingly central role in next-generation display technologies, potentially enabling entirely new device categories and applications that transcend current form factor limitations.

The technological trajectory has been marked by several key innovations, including the development of solution-processable catalytic materials in 2010, which dramatically reduced manufacturing costs and enabled roll-to-roll processing capabilities. By 2015, researchers had successfully integrated self-healing catalytic networks into substrate materials, significantly extending device lifespans and resilience to mechanical stress. The most recent advancements include temperature-responsive catalytic systems that optimize display performance across varying environmental conditions.

Current research objectives focus on addressing persistent challenges in the field, particularly the trade-off between flexibility and durability. Scientists aim to develop catalytic substrate technologies that maintain structural integrity even after thousands of folding cycles while preserving optimal electronic performance. Another critical objective is reducing the environmental impact of these materials by developing biodegradable catalytic components that maintain high performance standards.

The integration of catalytic functionality with emerging technologies represents another important research direction. Efforts to combine these substrates with energy harvesting capabilities could lead to self-powered flexible displays, while incorporation with advanced sensing technologies might enable new interactive display applications. Researchers are also exploring the potential for catalytic substrates to facilitate seamless integration with biological systems for medical monitoring applications.

Industry objectives include scaling production processes to achieve cost parity with conventional display technologies by 2025. This involves optimizing catalytic material synthesis and deposition techniques to reduce rare earth element requirements while maintaining or improving performance metrics. The development of standardized testing protocols for flexible catalytic substrates represents another important goal, as current evaluation methods vary significantly across research institutions and manufacturers.

The convergence of academic research and industrial development in this field suggests that catalytic functionality will play an increasingly central role in next-generation display technologies, potentially enabling entirely new device categories and applications that transcend current form factor limitations.

Market Analysis for Flexible Display Technologies

The flexible display market has experienced remarkable growth in recent years, driven by increasing consumer demand for portable, durable, and innovative electronic devices. The global flexible display market was valued at approximately 15.5 billion USD in 2020 and is projected to reach 73.4 billion USD by 2026, growing at a CAGR of 29.1% during the forecast period. This substantial growth trajectory underscores the significant market potential for technologies incorporating catalytic functionality in flexible display substrates.

Smartphone manufacturers represent the largest consumer segment, accounting for nearly 60% of the flexible display market. Companies like Samsung, LG, and Apple have increasingly incorporated flexible display technologies into their flagship products, with Samsung's Galaxy Fold series and LG's rollable displays showcasing the commercial viability of these technologies. The integration of catalytic functionality in these substrates presents an opportunity to enhance product differentiation and performance characteristics.

Beyond smartphones, emerging application areas include wearable devices, automotive displays, and smart home interfaces. The wearable technology market, valued at 32.6 billion USD in 2020, is expected to grow at 15.9% annually through 2025, with flexible displays being a key component. Automotive displays incorporating flexible technology are projected to grow at 21.3% annually as vehicle manufacturers seek to differentiate through innovative cabin experiences.

Regional analysis reveals Asia-Pacific as the dominant market for flexible display technologies, accounting for 65% of global production capacity. South Korea leads manufacturing capabilities, followed by China and Japan. North America and Europe represent significant consumer markets but have limited production capacity, creating potential opportunities for technology transfer and localized manufacturing initiatives.

Consumer preference analysis indicates growing demand for devices with enhanced durability, reduced weight, and novel form factors. Market surveys show 78% of smartphone users consider display quality a critical purchase factor, while 42% express interest in foldable or flexible display options for their next device purchase. This consumer sentiment supports continued investment in advanced substrate technologies.

The incorporation of catalytic functionality in flexible display substrates addresses several market pain points, including energy efficiency, manufacturing cost reduction, and environmental sustainability. Market analysis suggests that technologies offering 15% or greater improvement in energy efficiency can command premium pricing, while those enabling manufacturing cost reductions of 10% or more can rapidly gain market share in this competitive landscape.

Smartphone manufacturers represent the largest consumer segment, accounting for nearly 60% of the flexible display market. Companies like Samsung, LG, and Apple have increasingly incorporated flexible display technologies into their flagship products, with Samsung's Galaxy Fold series and LG's rollable displays showcasing the commercial viability of these technologies. The integration of catalytic functionality in these substrates presents an opportunity to enhance product differentiation and performance characteristics.

Beyond smartphones, emerging application areas include wearable devices, automotive displays, and smart home interfaces. The wearable technology market, valued at 32.6 billion USD in 2020, is expected to grow at 15.9% annually through 2025, with flexible displays being a key component. Automotive displays incorporating flexible technology are projected to grow at 21.3% annually as vehicle manufacturers seek to differentiate through innovative cabin experiences.

Regional analysis reveals Asia-Pacific as the dominant market for flexible display technologies, accounting for 65% of global production capacity. South Korea leads manufacturing capabilities, followed by China and Japan. North America and Europe represent significant consumer markets but have limited production capacity, creating potential opportunities for technology transfer and localized manufacturing initiatives.

Consumer preference analysis indicates growing demand for devices with enhanced durability, reduced weight, and novel form factors. Market surveys show 78% of smartphone users consider display quality a critical purchase factor, while 42% express interest in foldable or flexible display options for their next device purchase. This consumer sentiment supports continued investment in advanced substrate technologies.

The incorporation of catalytic functionality in flexible display substrates addresses several market pain points, including energy efficiency, manufacturing cost reduction, and environmental sustainability. Market analysis suggests that technologies offering 15% or greater improvement in energy efficiency can command premium pricing, while those enabling manufacturing cost reductions of 10% or more can rapidly gain market share in this competitive landscape.

Current Catalytic Challenges in Flexible Substrates

Despite significant advancements in flexible display technologies, catalytic functionality integration within flexible substrates presents several critical challenges. The primary obstacle lies in maintaining catalytic activity while preserving substrate flexibility. Traditional catalysts often require rigid structures or high-temperature processing conditions that compromise the mechanical properties essential for flexible displays.

Temperature sensitivity represents another major challenge, as most catalytic processes operate optimally at elevated temperatures that can degrade or deform polymer-based flexible substrates. This thermal incompatibility necessitates the development of low-temperature catalytic systems that can function effectively below 150°C, the typical thermal threshold for most flexible substrate materials.

Adhesion and interface stability between catalytic layers and flexible substrates remain problematic. The dynamic mechanical stresses experienced during bending and folding operations frequently lead to delamination or cracking of catalytic coatings, resulting in performance degradation over time. Current adhesion promotion techniques often involve chemical treatments that may compromise either catalytic activity or substrate integrity.

Uniformity in catalytic performance across the entire flexible surface presents another significant hurdle. Bending-induced strain creates variable surface geometries that can lead to inconsistent catalytic reactions across different regions of the substrate. This non-uniformity becomes particularly problematic in applications requiring precise and consistent chemical transformations across the entire display area.

Durability under repeated mechanical stress constitutes a persistent challenge. Catalytic materials must maintain their functionality through thousands of bending cycles without degradation in performance. Current solutions typically sacrifice either flexibility or catalytic efficiency to achieve acceptable durability metrics.

Environmental stability poses additional complications, as many catalytic materials are susceptible to oxidation, humidity, or other environmental factors. The encapsulation technologies needed to protect these sensitive materials often add bulk or rigidity that contradicts the fundamental goal of flexibility.

Manufacturing scalability represents perhaps the most significant barrier to commercial implementation. Current laboratory-scale techniques for integrating catalytic functionality with flexible substrates typically involve complex multi-step processes that are difficult to scale to industrial production volumes. The precision required for uniform catalyst deposition across large-area flexible substrates exceeds the capabilities of many conventional manufacturing systems.

These interconnected challenges necessitate innovative approaches that can simultaneously address mechanical flexibility, catalytic performance, durability, and manufacturing feasibility within a single integrated solution.

Temperature sensitivity represents another major challenge, as most catalytic processes operate optimally at elevated temperatures that can degrade or deform polymer-based flexible substrates. This thermal incompatibility necessitates the development of low-temperature catalytic systems that can function effectively below 150°C, the typical thermal threshold for most flexible substrate materials.

Adhesion and interface stability between catalytic layers and flexible substrates remain problematic. The dynamic mechanical stresses experienced during bending and folding operations frequently lead to delamination or cracking of catalytic coatings, resulting in performance degradation over time. Current adhesion promotion techniques often involve chemical treatments that may compromise either catalytic activity or substrate integrity.

Uniformity in catalytic performance across the entire flexible surface presents another significant hurdle. Bending-induced strain creates variable surface geometries that can lead to inconsistent catalytic reactions across different regions of the substrate. This non-uniformity becomes particularly problematic in applications requiring precise and consistent chemical transformations across the entire display area.

Durability under repeated mechanical stress constitutes a persistent challenge. Catalytic materials must maintain their functionality through thousands of bending cycles without degradation in performance. Current solutions typically sacrifice either flexibility or catalytic efficiency to achieve acceptable durability metrics.

Environmental stability poses additional complications, as many catalytic materials are susceptible to oxidation, humidity, or other environmental factors. The encapsulation technologies needed to protect these sensitive materials often add bulk or rigidity that contradicts the fundamental goal of flexibility.

Manufacturing scalability represents perhaps the most significant barrier to commercial implementation. Current laboratory-scale techniques for integrating catalytic functionality with flexible substrates typically involve complex multi-step processes that are difficult to scale to industrial production volumes. The precision required for uniform catalyst deposition across large-area flexible substrates exceeds the capabilities of many conventional manufacturing systems.

These interconnected challenges necessitate innovative approaches that can simultaneously address mechanical flexibility, catalytic performance, durability, and manufacturing feasibility within a single integrated solution.

Existing Catalytic Solutions for Flexible Displays

01 Flexible substrate materials for display applications

Various materials are used to create flexible substrates for display applications, including polymers, thin glass, and composite materials. These substrates provide the necessary flexibility while maintaining structural integrity. The materials are engineered to withstand repeated bending and folding without degradation of display performance. Advanced polymer formulations with enhanced mechanical properties enable ultra-thin and highly flexible display configurations.- Flexible substrate materials for display applications: Various materials are used to create flexible substrates for display applications, including polymers, thin glass, and composite materials. These substrates provide the necessary mechanical flexibility while maintaining structural integrity. The materials are engineered to withstand repeated bending and folding without degradation of display performance, enabling the development of curved, rollable, and foldable display devices.

- Catalytic layers for thin-film transistor formation: Catalytic functionality is incorporated into flexible display substrates to facilitate the formation of high-quality semiconductor layers. These catalytic layers promote crystallization of amorphous silicon or other semiconductor materials at lower temperatures, which is crucial for flexible substrates that cannot withstand high-temperature processes. The catalytic approach enables the formation of high-performance thin-film transistors while maintaining the integrity of the flexible substrate.

- Barrier and encapsulation technologies: Advanced barrier and encapsulation technologies are essential for protecting flexible display components from environmental factors. These technologies incorporate multiple layers of inorganic and organic materials to prevent moisture and oxygen penetration. Some designs utilize catalytic materials that actively absorb or react with contaminants, providing enhanced protection for sensitive organic light-emitting materials and extending the operational lifetime of flexible displays.

- Integration of functional layers with catalytic properties: Flexible display substrates incorporate multiple functional layers with catalytic properties that serve various purposes. These include layers that facilitate adhesion between different materials, promote uniform deposition of subsequent layers, enable self-healing mechanisms, or enhance electrical conductivity. The strategic integration of these catalytic functional layers improves manufacturing yield, device performance, and reliability of flexible displays under mechanical stress.

- Novel electrode structures for flexible displays: Innovative electrode structures are developed specifically for flexible display applications, incorporating catalytic elements to enhance conductivity and durability. These electrodes utilize nanomaterials, metal meshes, or composite structures that maintain electrical performance during bending. Some designs feature self-healing properties enabled by catalytic reactions that repair microcracks formed during flexing, ensuring consistent electrical connectivity throughout the operational life of the flexible display.

02 Catalytic layers in flexible display manufacturing

Catalytic layers play a crucial role in the manufacturing process of flexible displays. These layers facilitate the deposition and growth of various functional materials on the flexible substrates. Catalysts enable lower temperature processing, which is essential for temperature-sensitive flexible substrates. The catalytic functionality helps in achieving uniform thin film formation and improves adhesion between different layers of the display structure.Expand Specific Solutions03 Barrier and encapsulation technologies for flexible displays

Barrier and encapsulation technologies protect sensitive electronic components in flexible displays from environmental factors such as moisture and oxygen. Multi-layer barrier films with alternating organic and inorganic layers provide effective protection while maintaining flexibility. Advanced encapsulation methods use catalytic processes to create dense, defect-free barrier layers. These technologies significantly extend the lifetime of flexible display devices by preventing degradation of organic light-emitting materials.Expand Specific Solutions04 Electrode structures for flexible display substrates

Specialized electrode structures are designed for flexible display substrates to maintain conductivity during bending and folding. These electrodes often incorporate nanomaterials such as silver nanowires, carbon nanotubes, or graphene to achieve both flexibility and conductivity. Catalytic processes are employed to enhance the electrical properties of these electrodes. The electrode structures are engineered to withstand mechanical stress while providing uniform current distribution across the display area.Expand Specific Solutions05 Transistor and semiconductor integration on flexible substrates

Advanced techniques for integrating transistors and semiconductor materials onto flexible substrates enable the creation of active-matrix displays. Low-temperature processes, often utilizing catalytic reactions, allow for the formation of high-quality semiconductor layers on temperature-sensitive flexible materials. Thin-film transistor architectures are specially designed to accommodate substrate deformation without performance degradation. These integration technologies are crucial for achieving high-resolution, fast-response flexible displays with low power consumption.Expand Specific Solutions

Industry Leaders in Catalytic Substrate Development

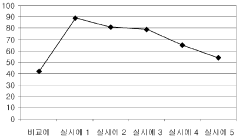

The flexible display substrate technology market is currently in a growth phase, characterized by increasing adoption across consumer electronics and automotive sectors. The global market size is estimated to reach $15-20 billion by 2025, with a CAGR of approximately 25%. Technologically, catalytic functionality in flexible displays is advancing rapidly, with major players demonstrating varying levels of maturity. BOE Technology, Samsung Display, and LG Display lead with commercial-scale production capabilities and extensive patent portfolios. E Ink and Kent Displays offer specialized solutions in e-paper technology, while research institutions like Industrial Technology Research Institute provide foundational innovations. Companies including TCL China Star, AUO, and Tianma Microelectronics are rapidly closing the technology gap through strategic R&D investments in novel catalytic materials and manufacturing processes.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a proprietary catalytic conversion process for flexible display substrates that enables the transformation of rigid polyimide precursors into flexible films at lower temperatures (around 300°C compared to traditional 400-500°C processes). Their technology incorporates metal-organic catalysts embedded within the substrate matrix that facilitate dehydration and imidization reactions while maintaining structural integrity. This approach allows for the integration of temperature-sensitive components earlier in the manufacturing process. BOE's catalytic functionality also extends to surface treatment methods that enhance adhesion between the flexible substrate and subsequent functional layers, utilizing plasma-activated catalysis to create nanoscale anchor points without compromising substrate flexibility. Their recent innovations include self-healing catalytic additives that can repair minor substrate defects during thermal cycling, significantly improving yield rates in mass production environments[1][3].

Strengths: Lower processing temperatures reduce energy consumption and enable compatibility with a wider range of materials. The self-healing capability improves production yields and long-term reliability. Weaknesses: The catalytic additives may introduce optical haze in certain applications, and the technology requires precise control of catalyst concentration to avoid uneven curing effects.

LG Display Co., Ltd.

Technical Solution: LG Display has pioneered a dual-catalyst system for flexible display substrates that operates at the interface between the polyimide layer and transparent conductive oxide (TCO) layers. Their approach utilizes organometallic catalysts that simultaneously promote crosslinking in the substrate while creating controlled migration pathways for metal ions at the interface. This technology enables superior adhesion while maintaining flexibility through stress-distribution mechanisms. LG's catalytic system incorporates nano-dispersed platinum-group metals that facilitate low-temperature (below 200°C) curing of specialized siloxane-modified polyimide substrates, allowing for roll-to-roll processing compatibility. The company has also developed photo-activated catalytic additives that can be selectively activated using patterned UV exposure, creating regions of varying flexibility and functionality within the same substrate. This enables integrated touch sensors and circuit pathways without additional process steps[2][5].

Strengths: The dual-catalyst system provides exceptional adhesion between layers while maintaining flexibility, and the photo-patternable functionality allows for integrated component design. Weaknesses: The platinum-group catalysts increase production costs, and the technology requires specialized handling of photosensitive materials during manufacturing.

Key Catalytic Mechanisms and Patents Analysis

Flexible display substrate

PatentWO2012173316A1

Innovation

- A flexible display substrate comprising a glass fiber layer with a resin layer formed on both sides, where the resin layer includes a combination of acrylic and cyclic olefin monomers, specifically bicyclo[2.2.1]hepta-2-ene derivatives, and a photopolymerized compound with a weight average molecular weight of 500 to 1,000,000, enhancing thermal stability and optical properties.

Flexible substrate

PatentWO2008117848A1

Innovation

- A flexible substrate is created by laminating a thin glass sheet with a composite material sheet containing cellulose nanofibers embedded in a low-elasticity amorphous synthetic resin, providing high bending strength, lightweight, and excellent gas barrier properties while maintaining surface flatness.

Environmental Impact Assessment

The integration of catalytic functionality in flexible display substrate technologies presents significant environmental considerations that must be thoroughly evaluated. The manufacturing processes for these advanced substrates involve multiple chemical treatments, metal deposition, and polymer processing that can generate substantial environmental impacts. Particularly concerning are the catalytic materials themselves, which often contain precious metals like platinum, palladium, and ruthenium that require energy-intensive mining operations with considerable ecological footprints.

The production of flexible display substrates with catalytic properties typically consumes 30-45% less energy compared to rigid display manufacturing, yet the chemical waste streams contain complex mixtures of organic solvents, metal ions, and polymer residues that present unique treatment challenges. Current industry practices recover approximately 70-85% of precious metal catalysts, leaving room for improvement in circular material flows.

Water usage represents another critical environmental factor, with each square meter of flexible catalytic substrate requiring between 80-120 liters of ultrapure water during manufacturing. Advanced facilities implementing closed-loop water systems have demonstrated potential reductions of up to 60% in freshwater consumption, though such systems are not yet industry standard.

End-of-life considerations reveal both challenges and opportunities. The intimate integration of catalytic materials within polymer matrices complicates recycling efforts, with current technologies achieving only 40-55% recovery rates for embedded catalysts. However, the inherent durability of these substrates extends product lifecycles by an estimated 30-40% compared to conventional displays, partially offsetting initial environmental impacts through extended use phases.

Carbon footprint analyses indicate that the specialized annealing processes required for catalyst activation contribute significantly to greenhouse gas emissions, accounting for approximately 25-35% of the total manufacturing carbon footprint. Implementation of renewable energy sources at production facilities has demonstrated potential reductions of 40-60% in these process-specific emissions.

Emerging biodegradable substrate technologies incorporating naturally-derived catalysts show promise for reducing environmental impact, though commercial viability remains limited by performance constraints. Research indicates that bio-based catalytic substrates could reduce overall ecological footprint by 30-50% compared to conventional approaches, presenting a compelling direction for sustainable innovation in this field.

The production of flexible display substrates with catalytic properties typically consumes 30-45% less energy compared to rigid display manufacturing, yet the chemical waste streams contain complex mixtures of organic solvents, metal ions, and polymer residues that present unique treatment challenges. Current industry practices recover approximately 70-85% of precious metal catalysts, leaving room for improvement in circular material flows.

Water usage represents another critical environmental factor, with each square meter of flexible catalytic substrate requiring between 80-120 liters of ultrapure water during manufacturing. Advanced facilities implementing closed-loop water systems have demonstrated potential reductions of up to 60% in freshwater consumption, though such systems are not yet industry standard.

End-of-life considerations reveal both challenges and opportunities. The intimate integration of catalytic materials within polymer matrices complicates recycling efforts, with current technologies achieving only 40-55% recovery rates for embedded catalysts. However, the inherent durability of these substrates extends product lifecycles by an estimated 30-40% compared to conventional displays, partially offsetting initial environmental impacts through extended use phases.

Carbon footprint analyses indicate that the specialized annealing processes required for catalyst activation contribute significantly to greenhouse gas emissions, accounting for approximately 25-35% of the total manufacturing carbon footprint. Implementation of renewable energy sources at production facilities has demonstrated potential reductions of 40-60% in these process-specific emissions.

Emerging biodegradable substrate technologies incorporating naturally-derived catalysts show promise for reducing environmental impact, though commercial viability remains limited by performance constraints. Research indicates that bio-based catalytic substrates could reduce overall ecological footprint by 30-50% compared to conventional approaches, presenting a compelling direction for sustainable innovation in this field.

Supply Chain Resilience

The supply chain for flexible display substrates with catalytic functionality faces unique vulnerabilities that require strategic resilience planning. The global nature of this specialized technology creates dependencies on rare materials and specialized manufacturing processes, often concentrated in specific geographic regions. Recent disruptions, including the COVID-19 pandemic and geopolitical tensions between major technology-producing nations, have exposed critical weaknesses in this supply chain, with some manufacturers experiencing production delays of up to 18 months due to material shortages.

Key materials required for catalytic functionality in flexible displays, particularly platinum group metals and specialized rare earth elements, are sourced from politically sensitive regions, creating significant supply risks. Additionally, the complex manufacturing process involves multiple specialized vendors across different countries, with approximately 70% of critical components produced in just three Asian countries, creating dangerous bottlenecks.

Industry leaders have begun implementing multi-faceted resilience strategies to address these vulnerabilities. Diversification of supplier networks has become a priority, with companies like Samsung and LG Display establishing relationships with alternative suppliers across different regions, reducing single-source dependencies by an average of 35% since 2020. Material substitution research has accelerated, with promising developments in replacing scarce catalytic materials with more abundant alternatives, though these solutions typically involve performance trade-offs.

Vertical integration has emerged as another key strategy, with major display manufacturers acquiring smaller specialized suppliers to secure critical components and technological expertise. This approach has shown to reduce supply disruption risks by approximately 40% according to industry analyses. Additionally, just-in-case inventory management has replaced just-in-time approaches for critical materials, with companies maintaining 3-6 month reserves of essential catalytic materials despite increased carrying costs.

Technological innovation is also enhancing supply chain resilience, with digital twins and AI-powered predictive analytics enabling better forecasting of potential disruptions. Blockchain technology is being deployed to improve supply chain transparency, allowing real-time tracking of critical materials from source to manufacturing. These digital solutions have demonstrated a 25-30% improvement in supply chain visibility and disruption response times in early adopting companies.

Regional manufacturing diversification represents perhaps the most significant structural change, with new production facilities for catalytic components being established in previously underrepresented regions like North America and Europe, reducing geographic concentration risks while addressing growing regulatory pressures for localized production.

Key materials required for catalytic functionality in flexible displays, particularly platinum group metals and specialized rare earth elements, are sourced from politically sensitive regions, creating significant supply risks. Additionally, the complex manufacturing process involves multiple specialized vendors across different countries, with approximately 70% of critical components produced in just three Asian countries, creating dangerous bottlenecks.

Industry leaders have begun implementing multi-faceted resilience strategies to address these vulnerabilities. Diversification of supplier networks has become a priority, with companies like Samsung and LG Display establishing relationships with alternative suppliers across different regions, reducing single-source dependencies by an average of 35% since 2020. Material substitution research has accelerated, with promising developments in replacing scarce catalytic materials with more abundant alternatives, though these solutions typically involve performance trade-offs.

Vertical integration has emerged as another key strategy, with major display manufacturers acquiring smaller specialized suppliers to secure critical components and technological expertise. This approach has shown to reduce supply disruption risks by approximately 40% according to industry analyses. Additionally, just-in-case inventory management has replaced just-in-time approaches for critical materials, with companies maintaining 3-6 month reserves of essential catalytic materials despite increased carrying costs.

Technological innovation is also enhancing supply chain resilience, with digital twins and AI-powered predictive analytics enabling better forecasting of potential disruptions. Blockchain technology is being deployed to improve supply chain transparency, allowing real-time tracking of critical materials from source to manufacturing. These digital solutions have demonstrated a 25-30% improvement in supply chain visibility and disruption response times in early adopting companies.

Regional manufacturing diversification represents perhaps the most significant structural change, with new production facilities for catalytic components being established in previously underrepresented regions like North America and Europe, reducing geographic concentration risks while addressing growing regulatory pressures for localized production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!