How Flexible Display Substrates Influence Pharmaceutical Packaging

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Display Technology Evolution and Objectives

Flexible display technology has evolved significantly over the past two decades, transforming from laboratory curiosities to commercially viable products. The journey began in the early 2000s with rudimentary flexible electronic paper displays, progressing through various technological breakthroughs in materials science and manufacturing processes. Initially, these displays suffered from limited durability, poor color reproduction, and manufacturing challenges that restricted their practical applications.

The evolution accelerated around 2010 with the development of organic light-emitting diode (OLED) technology on flexible substrates, primarily using polyimide films that could withstand repeated bending while maintaining electronic functionality. This milestone marked a critical turning point, enabling displays that could be not only bent but potentially folded or rolled without compromising performance.

By 2015, major electronics manufacturers had introduced the first commercially available flexible display products, though these were largely limited to curved rather than truly flexible implementations. The subsequent years witnessed rapid advancements in substrate materials, encapsulation technologies, and thin-film transistor designs that collectively enhanced flexibility, durability, and visual performance.

Current flexible display substrates primarily utilize ultra-thin glass, specialized polymers, or hybrid materials that combine the advantages of both. These substrates must simultaneously provide mechanical flexibility, barrier properties against oxygen and moisture, thermal stability, and optical clarity—a challenging combination of requirements that continues to drive materials innovation.

In the pharmaceutical packaging context, the objectives of flexible display technology integration are multifaceted. Primary goals include enhancing medication adherence through dynamic instructions and reminders, improving product authentication to combat counterfeiting, enabling real-time monitoring of storage conditions, and facilitating interactive patient education. Additionally, these displays aim to support variable information display without requiring multiple packaging versions, potentially reducing production costs and environmental impact.

Technical objectives specifically focus on developing display substrates that can withstand pharmaceutical packaging requirements, including chemical resistance to packaging contents, compatibility with sterilization processes, and maintenance of functionality across temperature variations encountered in global supply chains. Furthermore, these substrates must achieve sufficient flexibility to conform to various packaging geometries while maintaining display integrity.

The long-term technological trajectory points toward increasingly sophisticated integration of sensors, power sources, and communication capabilities directly into the display substrate, creating truly smart pharmaceutical packaging systems that can interact with patients, healthcare providers, and supply chain systems simultaneously.

The evolution accelerated around 2010 with the development of organic light-emitting diode (OLED) technology on flexible substrates, primarily using polyimide films that could withstand repeated bending while maintaining electronic functionality. This milestone marked a critical turning point, enabling displays that could be not only bent but potentially folded or rolled without compromising performance.

By 2015, major electronics manufacturers had introduced the first commercially available flexible display products, though these were largely limited to curved rather than truly flexible implementations. The subsequent years witnessed rapid advancements in substrate materials, encapsulation technologies, and thin-film transistor designs that collectively enhanced flexibility, durability, and visual performance.

Current flexible display substrates primarily utilize ultra-thin glass, specialized polymers, or hybrid materials that combine the advantages of both. These substrates must simultaneously provide mechanical flexibility, barrier properties against oxygen and moisture, thermal stability, and optical clarity—a challenging combination of requirements that continues to drive materials innovation.

In the pharmaceutical packaging context, the objectives of flexible display technology integration are multifaceted. Primary goals include enhancing medication adherence through dynamic instructions and reminders, improving product authentication to combat counterfeiting, enabling real-time monitoring of storage conditions, and facilitating interactive patient education. Additionally, these displays aim to support variable information display without requiring multiple packaging versions, potentially reducing production costs and environmental impact.

Technical objectives specifically focus on developing display substrates that can withstand pharmaceutical packaging requirements, including chemical resistance to packaging contents, compatibility with sterilization processes, and maintenance of functionality across temperature variations encountered in global supply chains. Furthermore, these substrates must achieve sufficient flexibility to conform to various packaging geometries while maintaining display integrity.

The long-term technological trajectory points toward increasingly sophisticated integration of sensors, power sources, and communication capabilities directly into the display substrate, creating truly smart pharmaceutical packaging systems that can interact with patients, healthcare providers, and supply chain systems simultaneously.

Pharmaceutical Packaging Market Demand Analysis

The pharmaceutical packaging market is experiencing significant growth driven by several key factors. The global market was valued at approximately $107.6 billion in 2022 and is projected to reach $188.5 billion by 2030, growing at a CAGR of 7.3%. This expansion is primarily fueled by increasing healthcare expenditure worldwide, growing pharmaceutical consumption, and stringent regulations regarding drug safety and quality.

Flexible display substrates are creating new opportunities in this market by enabling smart packaging solutions that can enhance medication adherence, improve supply chain visibility, and provide real-time monitoring of product conditions. Market research indicates that approximately 30-35% of medication non-adherence could potentially be addressed through advanced packaging technologies, representing a substantial market opportunity.

Consumer demographics are significantly influencing market demand patterns. The aging global population, particularly in developed regions like North America, Europe, and Japan, is driving demand for pharmaceutical packaging that offers improved accessibility, readability, and medication management features. Seniors often manage multiple medications simultaneously, creating a need for packaging solutions that can help prevent errors and improve compliance.

Emerging markets in Asia-Pacific, particularly China and India, are showing the fastest growth rates in pharmaceutical packaging demand at 9.2% and 8.7% respectively. These regions are experiencing rapid healthcare infrastructure development, increasing access to medications, and growing middle-class populations with higher disposable incomes and health awareness.

Sustainability concerns are reshaping market demands, with 76% of pharmaceutical companies reporting increased customer inquiries about sustainable packaging options. Flexible display substrates that can reduce overall material usage while maintaining or improving functionality align well with this trend. The market for sustainable pharmaceutical packaging is growing at 10.5% annually, outpacing the overall market growth.

Regulatory requirements continue to evolve globally, with track-and-trace capabilities becoming mandatory in many markets. The EU's Falsified Medicines Directive and the US Drug Supply Chain Security Act have created substantial demand for packaging technologies that can support authentication and verification. Flexible display substrates integrated with RFID or NFC technologies address these requirements while potentially reducing the complexity of implementation compared to traditional approaches.

E-commerce pharmaceutical sales are growing at 17.3% annually, creating unique packaging demands for direct-to-consumer delivery that maintains product integrity while providing necessary information and security features. This channel requires packaging solutions that are both robust for shipping and sophisticated in terms of information display and interaction capabilities.

Flexible display substrates are creating new opportunities in this market by enabling smart packaging solutions that can enhance medication adherence, improve supply chain visibility, and provide real-time monitoring of product conditions. Market research indicates that approximately 30-35% of medication non-adherence could potentially be addressed through advanced packaging technologies, representing a substantial market opportunity.

Consumer demographics are significantly influencing market demand patterns. The aging global population, particularly in developed regions like North America, Europe, and Japan, is driving demand for pharmaceutical packaging that offers improved accessibility, readability, and medication management features. Seniors often manage multiple medications simultaneously, creating a need for packaging solutions that can help prevent errors and improve compliance.

Emerging markets in Asia-Pacific, particularly China and India, are showing the fastest growth rates in pharmaceutical packaging demand at 9.2% and 8.7% respectively. These regions are experiencing rapid healthcare infrastructure development, increasing access to medications, and growing middle-class populations with higher disposable incomes and health awareness.

Sustainability concerns are reshaping market demands, with 76% of pharmaceutical companies reporting increased customer inquiries about sustainable packaging options. Flexible display substrates that can reduce overall material usage while maintaining or improving functionality align well with this trend. The market for sustainable pharmaceutical packaging is growing at 10.5% annually, outpacing the overall market growth.

Regulatory requirements continue to evolve globally, with track-and-trace capabilities becoming mandatory in many markets. The EU's Falsified Medicines Directive and the US Drug Supply Chain Security Act have created substantial demand for packaging technologies that can support authentication and verification. Flexible display substrates integrated with RFID or NFC technologies address these requirements while potentially reducing the complexity of implementation compared to traditional approaches.

E-commerce pharmaceutical sales are growing at 17.3% annually, creating unique packaging demands for direct-to-consumer delivery that maintains product integrity while providing necessary information and security features. This channel requires packaging solutions that are both robust for shipping and sophisticated in terms of information display and interaction capabilities.

Current Challenges in Flexible Display Substrate Technology

Despite significant advancements in flexible display substrate technology, several critical challenges persist that impede its widespread application in pharmaceutical packaging. Material durability remains a primary concern, as flexible substrates must withstand various environmental conditions while maintaining structural integrity throughout the pharmaceutical product's shelf life. Current polymer-based substrates often demonstrate inadequate resistance to moisture, oxygen, and UV radiation, which can compromise drug stability and efficacy.

Temperature sensitivity presents another significant hurdle. Many flexible substrates exhibit performance degradation at temperature extremes commonly encountered in pharmaceutical supply chains. This limitation restricts their use for temperature-sensitive medications that require consistent protection across diverse environmental conditions.

Manufacturing scalability continues to challenge industry adoption. While laboratory-scale production demonstrates promising results, transitioning to high-volume, cost-effective manufacturing processes remains problematic. The precision required for pharmaceutical packaging applications demands exceptional quality control standards that current flexible display substrate production methods struggle to consistently achieve.

Barrier properties represent a critical technical obstacle. Pharmaceutical packaging demands superior oxygen and moisture barrier capabilities to preserve drug stability. Current flexible display substrates typically require additional barrier layers, increasing complexity, cost, and potential points of failure in the final packaging solution.

Regulatory compliance poses substantial challenges for implementation. Flexible display substrates must meet stringent pharmaceutical packaging regulations across global markets. The novel materials used in these substrates often lack established safety profiles and regulatory precedents, necessitating extensive testing and documentation before approval.

Integration complexity with existing pharmaceutical packaging equipment and processes creates adoption barriers. Many pharmaceutical manufacturers have invested heavily in conventional packaging infrastructure, making the transition to flexible display substrate technologies financially challenging without clear return on investment pathways.

Electrical performance stability over time remains problematic. Flexible display components must maintain consistent electrical properties throughout the product lifecycle, particularly when exposed to various environmental stressors. Current technologies often exhibit performance degradation that could compromise critical information display for healthcare providers and patients.

Cost considerations continue to limit market penetration. The advanced materials and manufacturing processes required for high-quality flexible display substrates result in significantly higher costs compared to conventional pharmaceutical packaging solutions. This cost differential presents a substantial barrier to adoption, particularly for generic medications and price-sensitive markets.

Temperature sensitivity presents another significant hurdle. Many flexible substrates exhibit performance degradation at temperature extremes commonly encountered in pharmaceutical supply chains. This limitation restricts their use for temperature-sensitive medications that require consistent protection across diverse environmental conditions.

Manufacturing scalability continues to challenge industry adoption. While laboratory-scale production demonstrates promising results, transitioning to high-volume, cost-effective manufacturing processes remains problematic. The precision required for pharmaceutical packaging applications demands exceptional quality control standards that current flexible display substrate production methods struggle to consistently achieve.

Barrier properties represent a critical technical obstacle. Pharmaceutical packaging demands superior oxygen and moisture barrier capabilities to preserve drug stability. Current flexible display substrates typically require additional barrier layers, increasing complexity, cost, and potential points of failure in the final packaging solution.

Regulatory compliance poses substantial challenges for implementation. Flexible display substrates must meet stringent pharmaceutical packaging regulations across global markets. The novel materials used in these substrates often lack established safety profiles and regulatory precedents, necessitating extensive testing and documentation before approval.

Integration complexity with existing pharmaceutical packaging equipment and processes creates adoption barriers. Many pharmaceutical manufacturers have invested heavily in conventional packaging infrastructure, making the transition to flexible display substrate technologies financially challenging without clear return on investment pathways.

Electrical performance stability over time remains problematic. Flexible display components must maintain consistent electrical properties throughout the product lifecycle, particularly when exposed to various environmental stressors. Current technologies often exhibit performance degradation that could compromise critical information display for healthcare providers and patients.

Cost considerations continue to limit market penetration. The advanced materials and manufacturing processes required for high-quality flexible display substrates result in significantly higher costs compared to conventional pharmaceutical packaging solutions. This cost differential presents a substantial barrier to adoption, particularly for generic medications and price-sensitive markets.

Current Flexible Substrate Solutions for Pharmaceutical Applications

01 Polymer-based flexible substrates

Polymer materials such as polyimide, polyethylene terephthalate (PET), and polyethylene naphthalate (PEN) are widely used as flexible substrates for displays due to their excellent mechanical flexibility, lightweight properties, and thermal stability. These materials can withstand repeated bending and folding while maintaining their structural integrity, making them ideal for flexible display applications. Various surface treatments and coatings can be applied to enhance their barrier properties against moisture and oxygen.- Polymer-based flexible substrates: Polymer materials such as polyimide, polyethylene terephthalate (PET), and polyethylene naphthalate (PEN) are widely used as flexible substrates for displays due to their excellent mechanical flexibility, lightweight properties, and thermal stability. These materials can be processed into thin films that maintain their integrity when bent or folded, making them ideal for flexible display applications. Various surface treatments and coatings can be applied to enhance their barrier properties against moisture and oxygen.

- Thin-film transistor structures for flexible displays: Specialized thin-film transistor (TFT) structures are developed for flexible displays to maintain electrical performance during bending. These include low-temperature processed oxide semiconductors, organic semiconductors, and amorphous silicon designs that can withstand mechanical stress. The TFT backplanes are engineered with stress-relief structures and optimized layer configurations to prevent cracking and delamination when the display is flexed, while maintaining stable electronic properties.

- Barrier and encapsulation technologies: Advanced barrier and encapsulation technologies are essential for protecting flexible display components from environmental factors. Multi-layer barrier films combining inorganic and organic materials create tortuous paths for moisture and oxygen diffusion. Thin-film encapsulation techniques deposit alternating layers of inorganic barriers and organic buffer layers directly onto the display, providing protection while maintaining flexibility. These technologies significantly extend the lifetime of flexible displays by preventing degradation of sensitive organic materials and electrodes.

- Mechanical design for flexibility and durability: Specialized mechanical designs enhance the flexibility and durability of display substrates. These include neutral plane engineering to position sensitive components where mechanical stress is minimized during bending, folding structures with optimized bending radii to prevent damage, and strain-isolation features that protect rigid components. Advanced lamination techniques bond multiple layers while maintaining flexibility, and stress-distribution structures spread mechanical forces evenly across the substrate to prevent localized damage.

- Novel substrate materials and composites: Research into novel substrate materials and composites is advancing flexible display technology. Ultra-thin glass that maintains transparency and barrier properties while offering limited flexibility is being developed. Metal foils provide excellent barrier properties and thermal stability. Hybrid substrates combining different materials leverage the advantages of each component. Nanocomposites incorporating nanomaterials enhance mechanical and barrier properties while maintaining flexibility. These innovations are expanding the performance envelope of flexible displays.

02 Thin-film transistor structures for flexible displays

Advanced thin-film transistor (TFT) structures are essential components of flexible displays, enabling pixel control while maintaining flexibility. These structures typically incorporate low-temperature processed semiconductors such as amorphous silicon, oxide semiconductors, or organic materials that can be fabricated on flexible substrates without causing thermal damage. Special design considerations include stress-resistant circuit layouts and buffer layers that minimize strain during bending, ensuring consistent electrical performance even when the display is flexed.Expand Specific Solutions03 Barrier and encapsulation technologies

Effective barrier and encapsulation technologies are crucial for protecting flexible display components from environmental factors such as moisture and oxygen. Multi-layer barrier films combining inorganic and organic materials can achieve ultra-low permeation rates while maintaining flexibility. Thin-film encapsulation techniques using alternating layers of inorganic barriers and organic planarization layers provide protection for sensitive display elements while preserving the overall flexibility of the device.Expand Specific Solutions04 Mechanical design for flexibility and durability

Specialized mechanical designs are implemented to enhance the flexibility and durability of display substrates. These include neutral plane engineering to position sensitive components at points of minimal strain during bending, multi-layer composite structures that distribute stress evenly, and specialized adhesives that maintain bonding under repeated flexing. Some designs incorporate strain-isolation features such as hinges or segmented structures that localize bending to specific regions, protecting more sensitive components from mechanical stress.Expand Specific Solutions05 Novel materials and fabrication methods

Emerging materials and innovative fabrication methods are advancing flexible display substrate technology. These include ultrathin glass that can be made bendable through special processing techniques, hybrid organic-inorganic composites with enhanced mechanical properties, and nanomaterial-reinforced polymers with improved thermal stability and barrier properties. Advanced manufacturing techniques such as roll-to-roll processing, solution-based deposition, and laser patterning enable cost-effective production of large-area flexible substrates with precise feature control.Expand Specific Solutions

Leading Companies in Flexible Display and Pharma Packaging

The flexible display substrate market in pharmaceutical packaging is in its early growth phase, characterized by increasing adoption of smart packaging solutions. The market is projected to expand significantly as pharmaceutical companies seek innovative ways to enhance medication adherence and product authentication. Technologically, the field remains in development with varying degrees of maturity among key players. BOE Technology, Samsung Electronics, and LG Display lead in flexible display technology development, while pharmaceutical packaging specialists like SHL Medical and Novo Nordisk are exploring integration opportunities. Companies such as E Ink and Royole Technologies offer specialized flexible display solutions that could be adapted for pharmaceutical applications. The convergence of electronics manufacturers and pharmaceutical companies suggests an emerging ecosystem where cross-industry collaboration will drive innovation in smart packaging solutions.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed flexible AMOLED display technology using ultra-thin polyimide substrates specifically adapted for pharmaceutical packaging applications. Their flexible displays utilize a proprietary low-temperature polysilicon (LTPS) backplane technology combined with organic light-emitting materials that maintain functionality when bent or flexed. For pharmaceutical packaging, BOE has created displays as thin as 0.03mm that can be integrated into blister packs, medication bottles, and other common pharmaceutical containers. These displays incorporate touch-sensitive regions that allow patients to access additional information about their medications, including usage instructions, side effects, and expiration dates. BOE's technology enables pharmaceutical companies to implement tamper-evident features through display-integrated sensors that detect package opening or environmental changes. The displays can operate at temperatures ranging from -40°C to 85°C, making them suitable for cold chain applications in pharmaceutical distribution. BOE has also developed low-power display modes that can function for extended periods using small integrated batteries or energy harvesting technologies.

Strengths: Large-scale manufacturing capacity; diverse product portfolio spanning various flexible display technologies; competitive pricing compared to other advanced display manufacturers. Weaknesses: Less established presence in pharmaceutical industry partnerships; potential challenges with regulatory compliance for pharmaceutical applications; display durability may be compromised in certain environmental conditions.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered flexible display technology with their YOUM and OLED flexible displays that can be integrated into pharmaceutical packaging. Their approach utilizes ultra-thin plastic substrates instead of traditional glass, allowing for bendable, foldable displays that maintain functionality while being manipulated. Samsung's flexible display substrates incorporate polyimide (PI) films that offer excellent thermal stability and mechanical durability while maintaining transparency. These displays can be integrated into pharmaceutical packaging to provide real-time information about medication status, dosage instructions, and even patient adherence tracking. The technology enables dynamic content updates through wireless connectivity, allowing pharmaceutical companies to modify information remotely even after packaging distribution. Samsung's flexible displays maintain functionality at bend radii as small as 1.4mm while preserving display quality and touch responsiveness.

Strengths: Industry-leading OLED technology with high resolution and color accuracy; extensive manufacturing capacity; proven durability in consumer electronics applications. Weaknesses: Higher production costs compared to traditional packaging; potential concerns about long-term reliability in pharmaceutical environments; power requirements may limit application in certain packaging formats.

Key Patents and Innovations in Flexible Display Substrates

Substrate for Flexible Displays

PatentActiveUS20070224366A1

Innovation

- A substrate comprising a resin composition layer with an inorganic layer compound, such as clay minerals, dispersed in a solvent, where the inorganic layer compound constitutes between 10 weight % and 70 weight % of the total composition, providing a low thermal expansion coefficient and high visible light transmittance.

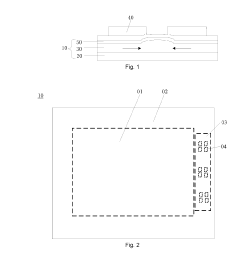

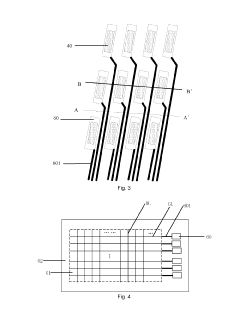

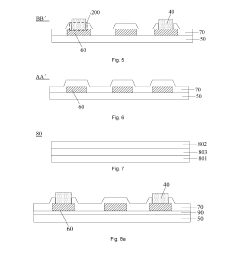

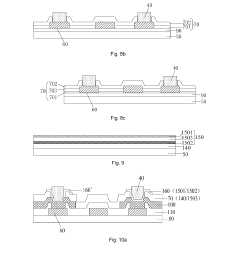

Flexible display substrate and method for manufacturing the same, and flexible display device

PatentActiveUS20190148653A1

Innovation

- A flexible display substrate design featuring conductive terminals with a stress relief layer having via holes for IC bonding, where the stress relief layer is made of inorganic materials like silicon nitride or silicon oxynitride to absorb stress and prevent deformation, and an encapsulation layer that simplifies fabrication processes.

Regulatory Compliance for Smart Pharmaceutical Packaging

The integration of flexible display substrates into pharmaceutical packaging introduces complex regulatory considerations that manufacturers must navigate. Regulatory bodies worldwide, including the FDA, EMA, and various national health authorities, have established stringent requirements for pharmaceutical packaging that directly impact the adoption of smart packaging technologies incorporating flexible displays.

Primary regulatory frameworks focus on material safety, with particular emphasis on leachables and extractables that might migrate from flexible substrate materials into pharmaceutical products. Regulatory agencies require comprehensive stability studies demonstrating that flexible display components do not compromise drug integrity or safety throughout the product's shelf life. These studies must account for various environmental conditions including temperature, humidity, and light exposure.

Electronic components within flexible displays fall under additional regulatory scrutiny. In the United States, combination products incorporating both drug and device elements require compliance with both pharmaceutical (21 CFR Parts 210/211) and medical device regulations (21 CFR Part 820). The FDA's Center for Devices and Radiological Health (CDRH) may become involved in the approval process, adding complexity to regulatory submissions.

Data security and privacy regulations present another critical compliance area. As flexible displays enable data collection and transmission capabilities in pharmaceutical packaging, manufacturers must adhere to regulations such as HIPAA in the US and GDPR in Europe. These regulations govern how patient data is collected, stored, and transmitted, requiring robust encryption and security protocols within the packaging technology.

Environmental sustainability regulations increasingly impact pharmaceutical packaging decisions. The EU's Packaging and Packaging Waste Directive and similar regulations worldwide mandate recyclability and waste reduction targets that must be considered when designing flexible display substrates. Manufacturers must develop end-of-life strategies for electronic components in pharmaceutical packaging to comply with e-waste regulations.

Labeling and information display requirements present unique challenges for flexible display integration. Regulatory bodies mandate specific information be prominently displayed on pharmaceutical packaging, and any dynamic content shown on flexible displays must comply with these requirements. The FDA's guidance on electronic labeling provides some framework, but regulatory gaps remain regarding dynamic content presentation on packaging.

Certification pathways for novel smart packaging technologies remain evolving and inconsistent across global markets. Manufacturers must engage early with regulatory authorities through pre-submission consultations and may need to pioneer new approval pathways for truly innovative flexible display applications in pharmaceutical packaging.

Primary regulatory frameworks focus on material safety, with particular emphasis on leachables and extractables that might migrate from flexible substrate materials into pharmaceutical products. Regulatory agencies require comprehensive stability studies demonstrating that flexible display components do not compromise drug integrity or safety throughout the product's shelf life. These studies must account for various environmental conditions including temperature, humidity, and light exposure.

Electronic components within flexible displays fall under additional regulatory scrutiny. In the United States, combination products incorporating both drug and device elements require compliance with both pharmaceutical (21 CFR Parts 210/211) and medical device regulations (21 CFR Part 820). The FDA's Center for Devices and Radiological Health (CDRH) may become involved in the approval process, adding complexity to regulatory submissions.

Data security and privacy regulations present another critical compliance area. As flexible displays enable data collection and transmission capabilities in pharmaceutical packaging, manufacturers must adhere to regulations such as HIPAA in the US and GDPR in Europe. These regulations govern how patient data is collected, stored, and transmitted, requiring robust encryption and security protocols within the packaging technology.

Environmental sustainability regulations increasingly impact pharmaceutical packaging decisions. The EU's Packaging and Packaging Waste Directive and similar regulations worldwide mandate recyclability and waste reduction targets that must be considered when designing flexible display substrates. Manufacturers must develop end-of-life strategies for electronic components in pharmaceutical packaging to comply with e-waste regulations.

Labeling and information display requirements present unique challenges for flexible display integration. Regulatory bodies mandate specific information be prominently displayed on pharmaceutical packaging, and any dynamic content shown on flexible displays must comply with these requirements. The FDA's guidance on electronic labeling provides some framework, but regulatory gaps remain regarding dynamic content presentation on packaging.

Certification pathways for novel smart packaging technologies remain evolving and inconsistent across global markets. Manufacturers must engage early with regulatory authorities through pre-submission consultations and may need to pioneer new approval pathways for truly innovative flexible display applications in pharmaceutical packaging.

Sustainability Impact of Flexible Display Substrates

The integration of flexible display substrates in pharmaceutical packaging represents a significant advancement in sustainable packaging solutions. These innovative materials offer substantial environmental benefits compared to traditional rigid packaging systems. The reduced material usage in flexible substrates directly translates to lower resource consumption during manufacturing, with studies indicating up to 70% less material required for equivalent packaging functionality.

Energy efficiency constitutes another critical sustainability advantage. The production of flexible display substrates typically consumes 30-45% less energy than conventional glass or rigid plastic alternatives. This reduction stems from lower processing temperatures and simplified manufacturing workflows, resulting in a significantly diminished carbon footprint across the product lifecycle.

Waste reduction represents perhaps the most compelling sustainability benefit. Flexible display substrates enable the development of thinner, lighter pharmaceutical packaging that occupies less volume in transportation and storage. This efficiency translates to reduced fuel consumption during distribution and decreased emissions throughout the supply chain. Additionally, many flexible substrate materials incorporate biodegradable or recyclable components, addressing end-of-life environmental concerns that plague traditional pharmaceutical packaging.

Water conservation emerges as another sustainability dimension worth noting. Manufacturing processes for flexible substrates typically require 25-40% less water compared to conventional packaging materials. This reduction is particularly significant given increasing global water scarcity concerns and regulatory pressures regarding industrial water usage.

The extended shelf-life capabilities of flexible display substrates further enhance sustainability by reducing pharmaceutical waste. Smart packaging features enabled by these substrates—such as real-time monitoring of environmental conditions and product integrity—help prevent premature disposal of medications due to suspected compromises in quality or efficacy.

From a circular economy perspective, flexible display substrates offer promising opportunities. Recent technological innovations have yielded substrates with improved recyclability profiles, with some manufacturers developing closed-loop systems for material recovery and reuse. These advancements align with global sustainability initiatives and increasingly stringent environmental regulations targeting pharmaceutical packaging waste.

However, challenges remain in fully realizing the sustainability potential of these materials. Current limitations include the environmental impact of electronic components embedded within smart packaging systems and the complexity of separating these components during recycling processes. Ongoing research focuses on developing fully biodegradable electronic elements and designing for disassembly to address these concerns.

Energy efficiency constitutes another critical sustainability advantage. The production of flexible display substrates typically consumes 30-45% less energy than conventional glass or rigid plastic alternatives. This reduction stems from lower processing temperatures and simplified manufacturing workflows, resulting in a significantly diminished carbon footprint across the product lifecycle.

Waste reduction represents perhaps the most compelling sustainability benefit. Flexible display substrates enable the development of thinner, lighter pharmaceutical packaging that occupies less volume in transportation and storage. This efficiency translates to reduced fuel consumption during distribution and decreased emissions throughout the supply chain. Additionally, many flexible substrate materials incorporate biodegradable or recyclable components, addressing end-of-life environmental concerns that plague traditional pharmaceutical packaging.

Water conservation emerges as another sustainability dimension worth noting. Manufacturing processes for flexible substrates typically require 25-40% less water compared to conventional packaging materials. This reduction is particularly significant given increasing global water scarcity concerns and regulatory pressures regarding industrial water usage.

The extended shelf-life capabilities of flexible display substrates further enhance sustainability by reducing pharmaceutical waste. Smart packaging features enabled by these substrates—such as real-time monitoring of environmental conditions and product integrity—help prevent premature disposal of medications due to suspected compromises in quality or efficacy.

From a circular economy perspective, flexible display substrates offer promising opportunities. Recent technological innovations have yielded substrates with improved recyclability profiles, with some manufacturers developing closed-loop systems for material recovery and reuse. These advancements align with global sustainability initiatives and increasingly stringent environmental regulations targeting pharmaceutical packaging waste.

However, challenges remain in fully realizing the sustainability potential of these materials. Current limitations include the environmental impact of electronic components embedded within smart packaging systems and the complexity of separating these components during recycling processes. Ongoing research focuses on developing fully biodegradable electronic elements and designing for disassembly to address these concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!