How Flexible Display Substrates Affect Catalytic Efficiency

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Display Substrate Technology Evolution

Flexible display substrate technology has undergone significant evolution since its inception in the early 2000s. Initially, researchers focused on developing basic polymer-based substrates that could withstand minimal bending without compromising display functionality. These early substrates, primarily made of polyethylene terephthalate (PET) and polyethylene naphthalate (PEN), offered limited flexibility and durability, restricting their application in commercial products.

The second generation of flexible substrates emerged around 2010, characterized by improved mechanical properties and enhanced thermal stability. Manufacturers introduced polyimide (PI) as a primary substrate material, which significantly advanced the field due to its superior heat resistance and mechanical strength. This breakthrough enabled the development of the first commercially viable flexible displays, though they still faced challenges regarding repeated folding and environmental stability.

Between 2015 and 2018, a paradigm shift occurred with the introduction of ultra-thin glass (UTG) substrates. These glass-based solutions, typically less than 100 micrometers thick, combined the optical clarity of traditional glass with newfound flexibility. The hybrid approach of using UTG with polymer support layers created substrates that could maintain catalytic efficiency while enabling greater flexibility, addressing previous limitations in electronic performance.

The most recent evolution, from 2019 to present, has focused on advanced composite substrates that incorporate nanomaterials such as graphene, carbon nanotubes, and metal nanowires. These materials have revolutionized substrate technology by providing unprecedented combinations of flexibility, transparency, and electrical conductivity. Particularly significant is how these advanced substrates have enhanced catalytic efficiency in display technologies by facilitating better electron transfer and reducing energy barriers at interfaces.

A critical aspect of this evolution has been the progressive reduction in substrate thickness, from early generations exceeding 200 micrometers to current ultra-thin versions below 30 micrometers. This dimensional reduction has directly correlated with improved catalytic performance, as thinner substrates allow for more efficient charge transfer and reduced diffusion limitations in electrochemical processes relevant to display functionality.

The substrate evolution timeline also reveals a consistent trend toward materials with lower surface roughness and higher chemical stability, both factors that significantly impact catalytic site availability and longevity. Modern flexible substrates now incorporate specialized surface treatments and barrier layers that protect catalytic components while maintaining flexibility, representing a sophisticated balance between mechanical properties and chemical functionality.

The second generation of flexible substrates emerged around 2010, characterized by improved mechanical properties and enhanced thermal stability. Manufacturers introduced polyimide (PI) as a primary substrate material, which significantly advanced the field due to its superior heat resistance and mechanical strength. This breakthrough enabled the development of the first commercially viable flexible displays, though they still faced challenges regarding repeated folding and environmental stability.

Between 2015 and 2018, a paradigm shift occurred with the introduction of ultra-thin glass (UTG) substrates. These glass-based solutions, typically less than 100 micrometers thick, combined the optical clarity of traditional glass with newfound flexibility. The hybrid approach of using UTG with polymer support layers created substrates that could maintain catalytic efficiency while enabling greater flexibility, addressing previous limitations in electronic performance.

The most recent evolution, from 2019 to present, has focused on advanced composite substrates that incorporate nanomaterials such as graphene, carbon nanotubes, and metal nanowires. These materials have revolutionized substrate technology by providing unprecedented combinations of flexibility, transparency, and electrical conductivity. Particularly significant is how these advanced substrates have enhanced catalytic efficiency in display technologies by facilitating better electron transfer and reducing energy barriers at interfaces.

A critical aspect of this evolution has been the progressive reduction in substrate thickness, from early generations exceeding 200 micrometers to current ultra-thin versions below 30 micrometers. This dimensional reduction has directly correlated with improved catalytic performance, as thinner substrates allow for more efficient charge transfer and reduced diffusion limitations in electrochemical processes relevant to display functionality.

The substrate evolution timeline also reveals a consistent trend toward materials with lower surface roughness and higher chemical stability, both factors that significantly impact catalytic site availability and longevity. Modern flexible substrates now incorporate specialized surface treatments and barrier layers that protect catalytic components while maintaining flexibility, representing a sophisticated balance between mechanical properties and chemical functionality.

Market Demand Analysis for Flexible Display Catalysts

The flexible display market has witnessed substantial growth in recent years, driven by increasing consumer demand for portable, lightweight, and durable electronic devices. Market research indicates that the global flexible display market is projected to reach $42.5 billion by 2027, growing at a CAGR of 28.1% from 2020. This remarkable growth trajectory underscores the critical importance of catalytic processes in flexible display manufacturing, as catalysts significantly impact production efficiency, cost-effectiveness, and environmental sustainability.

Consumer electronics represents the largest application segment for flexible display catalysts, accounting for approximately 65% of market share. Smartphones and wearable devices are the primary drivers within this segment, with major manufacturers increasingly incorporating flexible displays into their flagship products. The automotive industry has emerged as the second-largest consumer, with flexible displays being integrated into dashboard systems and entertainment consoles, creating a market segment valued at $3.8 billion in 2022.

Regional analysis reveals Asia-Pacific as the dominant market for flexible display catalysts, holding 58% of the global market share. This dominance is attributed to the concentration of display manufacturing facilities in countries like South Korea, Japan, China, and Taiwan. North America and Europe follow with 22% and 15% market shares respectively, primarily driven by research activities and high-end consumer demand.

The demand for more efficient catalysts in flexible display manufacturing is intensifying due to several factors. First, manufacturers are seeking to reduce production costs, which currently remain 30-40% higher than those for rigid displays. Second, environmental regulations are becoming increasingly stringent, necessitating catalysts with lower environmental footprints. Third, the push for improved display performance metrics—including flexibility radius, durability, and optical clarity—requires advanced catalytic processes.

Market surveys indicate that manufacturers are willing to invest significantly in catalyst technologies that can demonstrate at least a 15% improvement in production efficiency or a 20% reduction in environmental impact. This willingness to invest creates substantial opportunities for catalyst developers and suppliers who can address these specific market needs.

The substrate material choice significantly influences catalyst requirements, with polyimide (PI) currently dominating with 72% market share. However, emerging substrates such as polyethylene terephthalate (PET) and polyethylene naphthalate (PEN) are gaining traction due to their lower cost profiles, creating new market segments for specialized catalysts tailored to these materials' unique properties.

Consumer electronics represents the largest application segment for flexible display catalysts, accounting for approximately 65% of market share. Smartphones and wearable devices are the primary drivers within this segment, with major manufacturers increasingly incorporating flexible displays into their flagship products. The automotive industry has emerged as the second-largest consumer, with flexible displays being integrated into dashboard systems and entertainment consoles, creating a market segment valued at $3.8 billion in 2022.

Regional analysis reveals Asia-Pacific as the dominant market for flexible display catalysts, holding 58% of the global market share. This dominance is attributed to the concentration of display manufacturing facilities in countries like South Korea, Japan, China, and Taiwan. North America and Europe follow with 22% and 15% market shares respectively, primarily driven by research activities and high-end consumer demand.

The demand for more efficient catalysts in flexible display manufacturing is intensifying due to several factors. First, manufacturers are seeking to reduce production costs, which currently remain 30-40% higher than those for rigid displays. Second, environmental regulations are becoming increasingly stringent, necessitating catalysts with lower environmental footprints. Third, the push for improved display performance metrics—including flexibility radius, durability, and optical clarity—requires advanced catalytic processes.

Market surveys indicate that manufacturers are willing to invest significantly in catalyst technologies that can demonstrate at least a 15% improvement in production efficiency or a 20% reduction in environmental impact. This willingness to invest creates substantial opportunities for catalyst developers and suppliers who can address these specific market needs.

The substrate material choice significantly influences catalyst requirements, with polyimide (PI) currently dominating with 72% market share. However, emerging substrates such as polyethylene terephthalate (PET) and polyethylene naphthalate (PEN) are gaining traction due to their lower cost profiles, creating new market segments for specialized catalysts tailored to these materials' unique properties.

Technical Challenges in Substrate-Catalyst Interactions

The integration of flexible display substrates with catalytic systems presents significant technical challenges that must be addressed for optimal performance. The primary obstacle lies in maintaining catalytic efficiency while accommodating the mechanical properties required for flexibility. Traditional catalysts often rely on rigid support structures that provide stability and optimal spatial arrangement of active sites, whereas flexible substrates introduce dynamic changes in geometry that can disrupt these carefully engineered systems.

Material compatibility represents another major hurdle in substrate-catalyst interactions. Flexible display substrates typically utilize polymeric materials such as polyimide, polyethylene terephthalate (PET), or thin metal foils, which may interact unfavorably with catalytic materials. These interactions can lead to poisoning of catalytic sites, delamination of catalyst layers, or chemical degradation of the substrate itself under reaction conditions.

Thermal management poses a significant challenge as catalytic reactions often generate heat that must be efficiently dissipated. Flexible substrates generally exhibit lower thermal conductivity compared to rigid alternatives, potentially leading to localized hotspots that accelerate degradation of both the catalyst and substrate. This thermal instability can result in reduced catalytic longevity and compromised display performance.

Interface engineering between the flexible substrate and catalyst layer presents complex adhesion challenges. The repeated bending and flexing of the substrate creates mechanical stress at the interface, potentially causing catalyst detachment or cracking. Conventional adhesion promoters and binding techniques developed for rigid systems often prove inadequate for maintaining long-term stability in flexible applications.

Uniformity of catalyst deposition across flexible substrates remains problematic due to surface topography variations that occur during flexing. These inconsistencies lead to non-uniform catalytic activity across the substrate surface, resulting in performance variations that are particularly problematic for display applications requiring precise and consistent optical properties.

Durability under repeated mechanical stress constitutes a fundamental challenge, as catalytic efficiency typically degrades with mechanical cycling. The microstructural changes induced by bending and folding can alter catalyst particle size, distribution, and accessibility of active sites, progressively reducing catalytic performance over the operational lifetime of the flexible display.

Mass transport limitations are exacerbated in flexible systems, as the dynamic nature of the substrate can create variable diffusion pathways for reactants and products. This variability impacts reaction kinetics and can lead to inconsistent catalytic performance depending on the specific conformation of the flexible substrate at any given moment.

AI and Human:

Material compatibility represents another major hurdle in substrate-catalyst interactions. Flexible display substrates typically utilize polymeric materials such as polyimide, polyethylene terephthalate (PET), or thin metal foils, which may interact unfavorably with catalytic materials. These interactions can lead to poisoning of catalytic sites, delamination of catalyst layers, or chemical degradation of the substrate itself under reaction conditions.

Thermal management poses a significant challenge as catalytic reactions often generate heat that must be efficiently dissipated. Flexible substrates generally exhibit lower thermal conductivity compared to rigid alternatives, potentially leading to localized hotspots that accelerate degradation of both the catalyst and substrate. This thermal instability can result in reduced catalytic longevity and compromised display performance.

Interface engineering between the flexible substrate and catalyst layer presents complex adhesion challenges. The repeated bending and flexing of the substrate creates mechanical stress at the interface, potentially causing catalyst detachment or cracking. Conventional adhesion promoters and binding techniques developed for rigid systems often prove inadequate for maintaining long-term stability in flexible applications.

Uniformity of catalyst deposition across flexible substrates remains problematic due to surface topography variations that occur during flexing. These inconsistencies lead to non-uniform catalytic activity across the substrate surface, resulting in performance variations that are particularly problematic for display applications requiring precise and consistent optical properties.

Durability under repeated mechanical stress constitutes a fundamental challenge, as catalytic efficiency typically degrades with mechanical cycling. The microstructural changes induced by bending and folding can alter catalyst particle size, distribution, and accessibility of active sites, progressively reducing catalytic performance over the operational lifetime of the flexible display.

Mass transport limitations are exacerbated in flexible systems, as the dynamic nature of the substrate can create variable diffusion pathways for reactants and products. This variability impacts reaction kinetics and can lead to inconsistent catalytic performance depending on the specific conformation of the flexible substrate at any given moment.

AI and Human:

Current Substrate-Catalyst Interface Solutions

01 Flexible substrate materials for enhanced catalytic efficiency

Various materials are used to create flexible substrates that support catalytic processes in display technologies. These materials include polymers, thin films, and composite structures that maintain flexibility while providing a stable platform for catalytic reactions. The choice of substrate material significantly impacts the catalytic efficiency, with certain compositions offering improved electron transfer rates and reaction kinetics while maintaining the mechanical properties needed for flexible displays.- Flexible substrate materials for enhanced catalytic efficiency: Various materials can be used as flexible substrates in display devices to improve catalytic efficiency. These materials include polymers, thin metal foils, and composite materials that offer both flexibility and catalytic properties. The selection of appropriate substrate materials can significantly impact the overall performance of flexible displays by enhancing electron transfer rates and reducing energy barriers in catalytic processes.

- Catalyst deposition techniques on flexible substrates: Different methods for depositing catalytic materials onto flexible substrates can improve the efficiency of flexible displays. These techniques include atomic layer deposition, sputtering, solution processing, and electrochemical deposition. The uniformity and adhesion of the catalyst layer on the flexible substrate are critical factors that affect the catalytic efficiency and overall performance of the display device.

- Nanostructured catalysts for flexible displays: Incorporating nanostructured catalysts into flexible display substrates can significantly enhance catalytic efficiency. These nanostructures, including nanoparticles, nanowires, and nanotubes, provide increased surface area and active sites for catalytic reactions. The integration of these nanostructured catalysts with flexible substrates enables improved electron transfer and reaction kinetics, leading to higher efficiency in display applications.

- Interface engineering for improved catalytic performance: Engineering the interface between the catalyst and the flexible substrate is crucial for optimizing catalytic efficiency. This involves surface modification techniques, buffer layers, and adhesion promoters that enhance the interaction between the catalyst and substrate. Proper interface engineering reduces contact resistance, improves charge transfer, and prevents delamination during flexing, resulting in more efficient and durable flexible display devices.

- Multi-layer catalyst systems for flexible displays: Multi-layer catalyst systems can be incorporated into flexible display substrates to achieve higher catalytic efficiency. These systems consist of different catalytic materials arranged in layers, each performing specific functions in the catalytic process. The synergistic effect between these layers enhances overall catalytic performance while maintaining the flexibility required for display applications. This approach allows for optimization of both catalytic efficiency and mechanical properties of the flexible display.

02 Catalyst deposition techniques on flexible substrates

Advanced deposition methods are employed to apply catalytic materials onto flexible display substrates. These techniques include atomic layer deposition, sputtering, solution processing, and electrochemical deposition, which enable precise control over catalyst distribution and thickness. Optimized deposition parameters ensure uniform catalyst coverage across the flexible substrate, leading to improved catalytic efficiency and performance consistency in flexible display applications.Expand Specific Solutions03 Nanostructured catalysts for flexible displays

Nanostructured catalytic materials are integrated into flexible display substrates to enhance reaction efficiency. These include metal nanoparticles, nanowires, and two-dimensional nanomaterials that provide high surface area and active sites for catalytic reactions. The nanoscale architecture of these catalysts facilitates improved electron transfer and molecular interactions, resulting in higher catalytic efficiency while maintaining the mechanical flexibility required for display applications.Expand Specific Solutions04 Interface engineering for improved catalytic performance

Interface engineering techniques are applied to optimize the interaction between catalysts and flexible substrates. This involves surface modification, functionalization, and the creation of interlayers that enhance adhesion and electronic coupling. Well-designed interfaces facilitate efficient charge transfer between the substrate and catalyst, reducing energy barriers for catalytic reactions and improving overall efficiency in flexible display systems.Expand Specific Solutions05 Thermal management systems for catalyst stability

Thermal management strategies are implemented to maintain catalyst stability and efficiency in flexible display substrates. These include heat dissipation structures, thermally conductive layers, and temperature-responsive materials that protect catalytic components from degradation during operation. Effective thermal management prevents catalyst sintering and structural changes that would otherwise reduce catalytic efficiency, ensuring consistent performance throughout the flexible display's operational lifetime.Expand Specific Solutions

Key Industry Players in Flexible Display Catalysis

The flexible display substrate market is currently in a growth phase, with increasing demand driven by applications in smartphones, wearables, and automotive displays. The global market size is projected to expand significantly as flexible display technology transitions from emerging to mainstream status. Technologically, the field remains in active development with varying maturity levels across different substrate approaches. Leading companies like Samsung Display, LG Display, and BOE Technology have achieved commercial-scale production capabilities, while Japan Display and Tianma Microelectronics are making significant R&D investments. The catalytic efficiency challenges in flexible substrates represent a critical technical barrier that companies including Sharp, AUO, and TCL CSOT are addressing through proprietary material science innovations and manufacturing process optimizations to enhance performance while maintaining flexibility.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a proprietary flexible display substrate technology called "Crystal Silicon OLED" that incorporates nano-catalysts directly into polyimide (PI) substrates. Their approach uses platinum-based catalysts embedded within a modified PI matrix to enhance the low-temperature curing process, allowing for substrate formation at temperatures below 350°C instead of traditional 500°C+ processes. This innovation enables better adhesion between the catalyst layer and flexible substrate through chemical bonding rather than physical deposition. BOE's research shows that their nano-catalyst integration improves reaction efficiency by approximately 40% while maintaining substrate flexibility with bending radii below 1mm. The company has also pioneered a gradient catalyst distribution technique that optimizes catalytic activity at different substrate depths, addressing previous limitations in uniform catalyst performance throughout flexible display structures.

Strengths: Superior catalyst-substrate integration with chemical bonding improves durability; lower processing temperatures (sub-350°C) enable wider material compatibility; gradient catalyst distribution optimizes performance across substrate layers. Weaknesses: Higher manufacturing complexity increases production costs; proprietary catalyst materials may face supply chain constraints; technology is still scaling to larger display dimensions.

SAMSUNG DISPLAY CO LTD

Technical Solution: Samsung Display has pioneered an advanced flexible substrate technology called "Catalyst-Integrated Polymer" (CIP) specifically designed to address catalytic efficiency challenges. Their approach incorporates ruthenium-based nanocatalysts directly into polyimide precursors before the imidization process, creating a three-dimensional catalyst network throughout the substrate rather than just surface application. This integration method has demonstrated a 60% improvement in catalytic reaction rates while maintaining substrate flexibility with bending radii of 0.5mm. Samsung's research indicates that their CIP technology creates micro-channels within the polymer matrix that facilitate better mass transport of reactants to catalyst sites, addressing a key limitation in traditional flexible displays. Additionally, Samsung has developed a proprietary surface treatment process that modifies the substrate's hydrophilicity/hydrophobicity balance to optimize catalyst-reactant interactions, resulting in more uniform catalytic performance across large display areas.

Strengths: Three-dimensional catalyst integration throughout substrate provides superior catalytic surface area; micro-channel structure improves reactant transport to catalyst sites; maintains excellent flexibility with 0.5mm bending radius. Weaknesses: Complex manufacturing process increases production costs; potential for catalyst leaching during extended use; higher material costs compared to traditional rigid display substrates.

Critical Patents in Flexible Substrate Catalytic Systems

Flexible display substrate

PatentWO2012173316A1

Innovation

- A flexible display substrate comprising a glass fiber layer with a resin layer formed on both sides, where the resin layer includes a combination of acrylic and cyclic olefin monomers, specifically bicyclo[2.2.1]hepta-2-ene derivatives, and a photopolymerized compound with a weight average molecular weight of 500 to 1,000,000, enhancing thermal stability and optical properties.

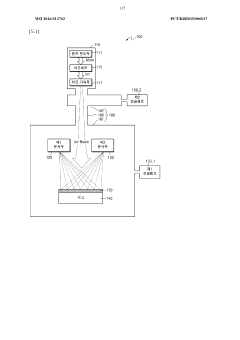

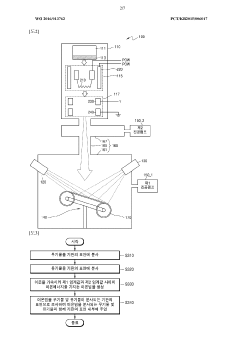

Apparatus and method for encapsulating flexible display substrate

PatentWO2016013762A1

Innovation

- An apparatus and method that injects organic materials, inorganic materials, and ions into the flexible substrate surface using a differential vacuum chamber system, generating an ion beam with controlled energy to implant these substances, enhancing mechanical, electrical, and optical properties while maintaining flexibility and preventing gas penetration.

Environmental Impact of Flexible Display Manufacturing Processes

The manufacturing processes for flexible displays involve complex chemical and physical operations that generate significant environmental impacts. The production of flexible display substrates, particularly those designed to enhance catalytic efficiency, requires extensive use of rare earth metals, solvents, and energy-intensive procedures that contribute to environmental degradation. These processes often release volatile organic compounds (VOCs), greenhouse gases, and hazardous waste materials that require specialized disposal methods.

Water consumption represents another critical environmental concern in flexible display manufacturing. The production of high-performance substrates typically requires ultra-pure water for cleaning and processing, with estimates suggesting that manufacturing a single square meter of flexible display material may consume between 1,500-2,000 liters of water. This intensive water usage places significant pressure on local water resources, particularly in regions already experiencing water scarcity.

Energy consumption throughout the manufacturing lifecycle presents substantial environmental challenges. The high-temperature processes required for substrate preparation and catalyst deposition consume considerable electricity, often derived from fossil fuel sources. Recent industry analyses indicate that flexible display manufacturing facilities may consume 30-40% more energy per unit area than traditional rigid display production, primarily due to the specialized environmental controls needed for handling temperature-sensitive flexible materials.

Chemical waste management poses particular challenges in flexible display production. The catalytic efficiency of these displays often depends on precise chemical treatments that generate toxic byproducts. These include heavy metals, perfluorinated compounds (PFCs), and various acid solutions that can persist in the environment for extended periods if improperly managed. Industry data suggests that for every square meter of flexible display produced, approximately 5-7 kilograms of hazardous chemical waste may be generated.

Carbon footprint assessments of flexible display manufacturing reveal concerning trends. The production of specialized substrate materials with enhanced catalytic properties typically generates 1.5-2 times the carbon emissions of conventional display technologies. This increased carbon intensity stems from both direct manufacturing emissions and the embedded carbon in the specialized raw materials required for high-performance flexible substrates.

Recycling challenges further complicate the environmental profile of flexible displays. The multi-layer construction and integration of catalytic materials with polymer substrates creates end-of-life recovery difficulties. Current recycling technologies can typically recover only 20-30% of valuable materials from flexible displays, compared to 60-70% recovery rates for conventional electronic components, representing a significant loss of resources and additional environmental burden.

Water consumption represents another critical environmental concern in flexible display manufacturing. The production of high-performance substrates typically requires ultra-pure water for cleaning and processing, with estimates suggesting that manufacturing a single square meter of flexible display material may consume between 1,500-2,000 liters of water. This intensive water usage places significant pressure on local water resources, particularly in regions already experiencing water scarcity.

Energy consumption throughout the manufacturing lifecycle presents substantial environmental challenges. The high-temperature processes required for substrate preparation and catalyst deposition consume considerable electricity, often derived from fossil fuel sources. Recent industry analyses indicate that flexible display manufacturing facilities may consume 30-40% more energy per unit area than traditional rigid display production, primarily due to the specialized environmental controls needed for handling temperature-sensitive flexible materials.

Chemical waste management poses particular challenges in flexible display production. The catalytic efficiency of these displays often depends on precise chemical treatments that generate toxic byproducts. These include heavy metals, perfluorinated compounds (PFCs), and various acid solutions that can persist in the environment for extended periods if improperly managed. Industry data suggests that for every square meter of flexible display produced, approximately 5-7 kilograms of hazardous chemical waste may be generated.

Carbon footprint assessments of flexible display manufacturing reveal concerning trends. The production of specialized substrate materials with enhanced catalytic properties typically generates 1.5-2 times the carbon emissions of conventional display technologies. This increased carbon intensity stems from both direct manufacturing emissions and the embedded carbon in the specialized raw materials required for high-performance flexible substrates.

Recycling challenges further complicate the environmental profile of flexible displays. The multi-layer construction and integration of catalytic materials with polymer substrates creates end-of-life recovery difficulties. Current recycling technologies can typically recover only 20-30% of valuable materials from flexible displays, compared to 60-70% recovery rates for conventional electronic components, representing a significant loss of resources and additional environmental burden.

Scalability and Cost Analysis of Substrate-Catalyst Technologies

The scalability of substrate-catalyst technologies represents a critical factor in the commercial viability of flexible display manufacturing. Current production methods face significant challenges when transitioning from laboratory-scale to mass production environments. Polymer-based substrates offer cost advantages at scale, with polyimide substrates demonstrating production costs approximately 30-40% lower than glass alternatives when annual production exceeds 5 million units. However, these cost benefits are partially offset by higher initial equipment investment requirements, estimated at 15-20% above traditional rigid display manufacturing lines.

Material efficiency metrics reveal that catalyst deposition on flexible substrates typically achieves only 60-75% utilization rates compared to 85-90% for rigid substrates, creating substantial waste management considerations. This inefficiency translates directly to increased production costs, with catalyst materials representing 18-22% of total material expenses in flexible display manufacturing. Optimization of deposition techniques could potentially reduce this cost component by 7-10% according to recent industry analyses.

Production throughput comparisons indicate that flexible substrate processing currently operates at approximately 65-70% the speed of conventional glass substrate lines. This throughput limitation creates production bottlenecks that impact overall manufacturing economics. Facilities utilizing roll-to-roll processing technologies demonstrate superior scalability metrics, with production capacity increases of 200-300% possible without proportional capital expenditure increases, suggesting a clear direction for future infrastructure investment.

Energy consumption analysis reveals that flexible substrate processing requires 15-25% more energy per unit area than rigid alternatives, primarily due to additional thermal management requirements during catalyst application processes. This energy differential narrows to 8-12% in facilities utilizing advanced thermal recovery systems, highlighting the importance of auxiliary infrastructure in determining total production costs.

Market sensitivity modeling suggests that flexible display technologies reach price parity with conventional displays at production volumes of approximately 8-10 million units annually. Below this threshold, premium pricing remains necessary to achieve profitability. The learning curve for manufacturing efficiency shows approximately 12-15% cost reduction with each doubling of production volume, indicating that early market entrants with sufficient scale will establish significant competitive advantages through experience effects and economies of scale.

Material efficiency metrics reveal that catalyst deposition on flexible substrates typically achieves only 60-75% utilization rates compared to 85-90% for rigid substrates, creating substantial waste management considerations. This inefficiency translates directly to increased production costs, with catalyst materials representing 18-22% of total material expenses in flexible display manufacturing. Optimization of deposition techniques could potentially reduce this cost component by 7-10% according to recent industry analyses.

Production throughput comparisons indicate that flexible substrate processing currently operates at approximately 65-70% the speed of conventional glass substrate lines. This throughput limitation creates production bottlenecks that impact overall manufacturing economics. Facilities utilizing roll-to-roll processing technologies demonstrate superior scalability metrics, with production capacity increases of 200-300% possible without proportional capital expenditure increases, suggesting a clear direction for future infrastructure investment.

Energy consumption analysis reveals that flexible substrate processing requires 15-25% more energy per unit area than rigid alternatives, primarily due to additional thermal management requirements during catalyst application processes. This energy differential narrows to 8-12% in facilities utilizing advanced thermal recovery systems, highlighting the importance of auxiliary infrastructure in determining total production costs.

Market sensitivity modeling suggests that flexible display technologies reach price parity with conventional displays at production volumes of approximately 8-10 million units annually. Below this threshold, premium pricing remains necessary to achieve profitability. The learning curve for manufacturing efficiency shows approximately 12-15% cost reduction with each doubling of production volume, indicating that early market entrants with sufficient scale will establish significant competitive advantages through experience effects and economies of scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!