Flexible Display Substrates: Enabling Aerospace Innovations

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Display Evolution and Aerospace Applications

Flexible display technology has undergone remarkable evolution over the past two decades, transforming from rigid glass-based displays to increasingly flexible and durable alternatives. The journey began with early experiments in flexible electronic paper displays in the early 2000s, followed by the introduction of plastic-based OLED displays around 2013. These initial flexible displays offered limited bending capabilities and faced significant durability challenges.

By 2015-2017, manufacturers achieved significant breakthroughs with polyimide substrates replacing traditional glass, enabling displays that could be repeatedly bent without damage. The subsequent years witnessed rapid advancement in flexibility, durability, and resolution quality, with major milestones including Samsung's foldable smartphone introduction in 2019 and LG's rollable OLED TV concepts.

In aerospace applications, flexible displays represent a paradigm shift from traditional rigid instrumentation panels. The integration began with simple curved displays in cockpits around 2018, providing improved ergonomics and information visibility. By 2020, more advanced implementations emerged, including conformal displays that could adapt to non-flat surfaces within aircraft cabins and cockpits.

The aerospace industry has embraced flexible display technology for several compelling reasons. Weight reduction remains paramount in aircraft design, with flexible displays offering up to 70% weight savings compared to traditional glass-based systems. The conformability to non-planar surfaces enables innovative design approaches previously impossible with rigid displays, allowing instrumentation to follow natural contours of cockpits and cabin interiors.

Durability improvements have been particularly significant for aerospace applications. Modern flexible displays incorporate specialized protective layers that enhance resistance to vibration, temperature fluctuations, and pressure changes—all critical factors in aerospace environments. Recent implementations have demonstrated operational stability across temperature ranges from -40°C to 85°C, meeting stringent aerospace requirements.

Energy efficiency represents another crucial advantage, with flexible OLED displays consuming approximately 30-40% less power than traditional LCD systems. This efficiency translates directly to reduced fuel consumption and extended operational range for aircraft. Additionally, the reduced thickness of flexible display systems (often less than 1mm) provides valuable space savings in the tightly constrained environments of aircraft interiors.

Looking forward, the convergence of flexible display technology with aerospace needs continues to accelerate. Current development focuses on enhancing sunlight readability, expanding operational temperature ranges, and integrating touch functionality that works reliably with gloved operation. The trajectory suggests that by 2025-2027, fully integrated flexible display systems may become standard in new commercial and military aircraft designs.

By 2015-2017, manufacturers achieved significant breakthroughs with polyimide substrates replacing traditional glass, enabling displays that could be repeatedly bent without damage. The subsequent years witnessed rapid advancement in flexibility, durability, and resolution quality, with major milestones including Samsung's foldable smartphone introduction in 2019 and LG's rollable OLED TV concepts.

In aerospace applications, flexible displays represent a paradigm shift from traditional rigid instrumentation panels. The integration began with simple curved displays in cockpits around 2018, providing improved ergonomics and information visibility. By 2020, more advanced implementations emerged, including conformal displays that could adapt to non-flat surfaces within aircraft cabins and cockpits.

The aerospace industry has embraced flexible display technology for several compelling reasons. Weight reduction remains paramount in aircraft design, with flexible displays offering up to 70% weight savings compared to traditional glass-based systems. The conformability to non-planar surfaces enables innovative design approaches previously impossible with rigid displays, allowing instrumentation to follow natural contours of cockpits and cabin interiors.

Durability improvements have been particularly significant for aerospace applications. Modern flexible displays incorporate specialized protective layers that enhance resistance to vibration, temperature fluctuations, and pressure changes—all critical factors in aerospace environments. Recent implementations have demonstrated operational stability across temperature ranges from -40°C to 85°C, meeting stringent aerospace requirements.

Energy efficiency represents another crucial advantage, with flexible OLED displays consuming approximately 30-40% less power than traditional LCD systems. This efficiency translates directly to reduced fuel consumption and extended operational range for aircraft. Additionally, the reduced thickness of flexible display systems (often less than 1mm) provides valuable space savings in the tightly constrained environments of aircraft interiors.

Looking forward, the convergence of flexible display technology with aerospace needs continues to accelerate. Current development focuses on enhancing sunlight readability, expanding operational temperature ranges, and integrating touch functionality that works reliably with gloved operation. The trajectory suggests that by 2025-2027, fully integrated flexible display systems may become standard in new commercial and military aircraft designs.

Market Analysis for Aerospace Flexible Display Solutions

The aerospace industry is witnessing a significant shift toward advanced display technologies, with flexible display substrates emerging as a critical enabler for next-generation cockpit systems, passenger entertainment interfaces, and mission-critical instrumentation. Current market analysis indicates the global aerospace flexible display market is valued at approximately 2.3 billion USD in 2023, with projections suggesting growth to reach 5.7 billion USD by 2030, representing a compound annual growth rate of 13.8%.

The demand drivers for flexible display solutions in aerospace applications are multifaceted. Primary among these is the industry-wide push for weight reduction, with flexible displays offering up to 70% weight savings compared to traditional rigid display systems. This translates directly to fuel efficiency improvements, with estimates suggesting that each kilogram of weight reduction can save between 14,000 and 22,000 gallons of fuel over an aircraft's operational lifetime.

Military aerospace represents the largest market segment, accounting for approximately 42% of current demand. Commercial aviation follows at 36%, with space applications comprising the remaining 22%. Regional analysis shows North America leading with 38% market share, followed by Europe (29%), Asia-Pacific (24%), and rest of world (9%). The dominance of North American and European markets reflects the concentration of major aerospace manufacturers and defense contractors in these regions.

Customer requirements analysis reveals distinct priorities across market segments. Military applications prioritize durability under extreme conditions, with displays required to maintain functionality across temperature ranges from -55°C to +85°C. Commercial aviation emphasizes reliability (99.99% uptime requirements) and passenger experience enhancement, while space applications demand radiation hardening and ultra-low power consumption.

Key purchasing decision factors include certification compliance (particularly DO-160 environmental conditions and DO-254 for hardware reliability), integration capabilities with existing avionics systems, and total cost of ownership calculations that factor in maintenance requirements and operational lifespan. The procurement cycle typically spans 18-36 months from initial specification to implementation, with extensive testing requirements adding complexity to market entry.

Market barriers include stringent certification requirements, which can add 2-3 years to product development timelines, and high customization needs that limit economies of scale. Additionally, the conservative nature of aerospace procurement processes favors established suppliers, with new entrants facing significant challenges in building credibility and demonstrating reliability records.

The demand drivers for flexible display solutions in aerospace applications are multifaceted. Primary among these is the industry-wide push for weight reduction, with flexible displays offering up to 70% weight savings compared to traditional rigid display systems. This translates directly to fuel efficiency improvements, with estimates suggesting that each kilogram of weight reduction can save between 14,000 and 22,000 gallons of fuel over an aircraft's operational lifetime.

Military aerospace represents the largest market segment, accounting for approximately 42% of current demand. Commercial aviation follows at 36%, with space applications comprising the remaining 22%. Regional analysis shows North America leading with 38% market share, followed by Europe (29%), Asia-Pacific (24%), and rest of world (9%). The dominance of North American and European markets reflects the concentration of major aerospace manufacturers and defense contractors in these regions.

Customer requirements analysis reveals distinct priorities across market segments. Military applications prioritize durability under extreme conditions, with displays required to maintain functionality across temperature ranges from -55°C to +85°C. Commercial aviation emphasizes reliability (99.99% uptime requirements) and passenger experience enhancement, while space applications demand radiation hardening and ultra-low power consumption.

Key purchasing decision factors include certification compliance (particularly DO-160 environmental conditions and DO-254 for hardware reliability), integration capabilities with existing avionics systems, and total cost of ownership calculations that factor in maintenance requirements and operational lifespan. The procurement cycle typically spans 18-36 months from initial specification to implementation, with extensive testing requirements adding complexity to market entry.

Market barriers include stringent certification requirements, which can add 2-3 years to product development timelines, and high customization needs that limit economies of scale. Additionally, the conservative nature of aerospace procurement processes favors established suppliers, with new entrants facing significant challenges in building credibility and demonstrating reliability records.

Technical Barriers in Aerospace-Grade Flexible Substrates

The development of aerospace-grade flexible display substrates faces significant technical challenges that must be overcome to meet the stringent requirements of aerospace applications. Current flexible substrate technologies, while advancing rapidly in consumer electronics, encounter substantial barriers when adapted for aerospace environments.

Material stability presents a primary challenge, as aerospace applications demand substrates that can withstand extreme temperature fluctuations ranging from -65°C to over 200°C. Conventional polymer-based flexible substrates such as polyimide (PI) and polyethylene terephthalate (PET) exhibit thermal expansion coefficients that compromise dimensional stability under these conditions, leading to potential delamination and circuit failures.

Radiation resistance constitutes another critical barrier. Space environments expose materials to high-energy cosmic rays, solar radiation, and charged particles that can degrade organic materials through chain scission and cross-linking mechanisms. Current flexible substrates lack sufficient radiation hardening, resulting in accelerated aging, color shifts, and mechanical property deterioration during extended missions.

Mechanical durability under aerospace conditions remains problematic. Flexible displays must maintain functionality while enduring vibration profiles exceeding 20G during launch and operational phases. Existing substrate technologies show fatigue failure at stress points after repeated flexing under such conditions, particularly at interconnection interfaces where rigid-flexible transitions occur.

Vacuum compatibility presents unique challenges, as many flexible substrate materials exhibit outgassing behaviors that can contaminate sensitive optical equipment and electronics. Studies indicate that conventional adhesives and plasticizers used in flexible display construction release volatile organic compounds (VOCs) at rates exceeding NASA's outgassing specifications of 1.0% TML (Total Mass Loss).

Weight considerations further complicate development efforts. While flexibility is inherently advantageous for weight reduction, aerospace-grade substrates require additional protective layers and reinforcements that offset these benefits. Current solutions add approximately 40-60% weight compared to consumer-grade equivalents, impacting fuel efficiency and payload capacity.

Manufacturing scalability presents significant barriers to widespread adoption. Aerospace applications require exceptional quality control with near-zero defect tolerance, yet current roll-to-roll processing techniques for flexible substrates demonstrate defect rates of 0.5-2 per square meter, significantly higher than the aerospace industry's acceptable threshold of 0.01 defects per square meter.

Integration with existing aerospace systems poses compatibility challenges, as flexible display substrates must interface with legacy systems while meeting MIL-STD-810 environmental requirements. Current interconnection technologies exhibit reliability issues at these interfaces, with failure rates increasing exponentially under combined thermal cycling and vibration stress.

Material stability presents a primary challenge, as aerospace applications demand substrates that can withstand extreme temperature fluctuations ranging from -65°C to over 200°C. Conventional polymer-based flexible substrates such as polyimide (PI) and polyethylene terephthalate (PET) exhibit thermal expansion coefficients that compromise dimensional stability under these conditions, leading to potential delamination and circuit failures.

Radiation resistance constitutes another critical barrier. Space environments expose materials to high-energy cosmic rays, solar radiation, and charged particles that can degrade organic materials through chain scission and cross-linking mechanisms. Current flexible substrates lack sufficient radiation hardening, resulting in accelerated aging, color shifts, and mechanical property deterioration during extended missions.

Mechanical durability under aerospace conditions remains problematic. Flexible displays must maintain functionality while enduring vibration profiles exceeding 20G during launch and operational phases. Existing substrate technologies show fatigue failure at stress points after repeated flexing under such conditions, particularly at interconnection interfaces where rigid-flexible transitions occur.

Vacuum compatibility presents unique challenges, as many flexible substrate materials exhibit outgassing behaviors that can contaminate sensitive optical equipment and electronics. Studies indicate that conventional adhesives and plasticizers used in flexible display construction release volatile organic compounds (VOCs) at rates exceeding NASA's outgassing specifications of 1.0% TML (Total Mass Loss).

Weight considerations further complicate development efforts. While flexibility is inherently advantageous for weight reduction, aerospace-grade substrates require additional protective layers and reinforcements that offset these benefits. Current solutions add approximately 40-60% weight compared to consumer-grade equivalents, impacting fuel efficiency and payload capacity.

Manufacturing scalability presents significant barriers to widespread adoption. Aerospace applications require exceptional quality control with near-zero defect tolerance, yet current roll-to-roll processing techniques for flexible substrates demonstrate defect rates of 0.5-2 per square meter, significantly higher than the aerospace industry's acceptable threshold of 0.01 defects per square meter.

Integration with existing aerospace systems poses compatibility challenges, as flexible display substrates must interface with legacy systems while meeting MIL-STD-810 environmental requirements. Current interconnection technologies exhibit reliability issues at these interfaces, with failure rates increasing exponentially under combined thermal cycling and vibration stress.

Current Flexible Substrate Solutions for Extreme Environments

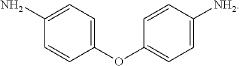

01 Polymer-based flexible substrates

Polymer materials such as polyimide, polyethylene terephthalate (PET), and polyethylene naphthalate (PEN) are widely used as flexible substrates for displays due to their excellent mechanical flexibility, lightweight properties, and thermal stability. These materials can withstand repeated bending and folding while maintaining their structural integrity, making them ideal for flexible display applications. Various surface treatments and coatings can be applied to enhance their barrier properties against moisture and oxygen.- Polymer-based flexible substrates: Polymer materials such as polyimide, polyethylene terephthalate (PET), and polyethylene naphthalate (PEN) are widely used as flexible substrates for displays due to their excellent mechanical flexibility, lightweight properties, and thermal stability. These materials can be processed into thin films that maintain their integrity when bent or folded, making them ideal for flexible display applications. Various surface treatments and coatings can be applied to enhance their barrier properties against moisture and oxygen.

- Thin-film transistor structures for flexible displays: Advanced thin-film transistor (TFT) structures are essential components of flexible displays, requiring special design considerations to maintain electrical performance when bent. These structures typically incorporate low-temperature processing techniques compatible with flexible substrates and may use materials such as amorphous silicon, low-temperature polysilicon, or metal oxide semiconductors. The TFT backplane design must accommodate mechanical stress during bending while maintaining stable electrical characteristics and uniform display performance.

- Barrier and encapsulation technologies: Effective barrier and encapsulation technologies are crucial for protecting flexible display components from environmental factors. Multi-layer barrier films combining organic and inorganic materials can achieve ultra-low water vapor and oxygen transmission rates necessary for OLED displays. Thin-film encapsulation techniques deposit alternating layers of inorganic barriers and organic buffer layers directly onto the display, providing protection while maintaining flexibility. These technologies extend device lifetime by preventing degradation of sensitive display materials.

- Transparent conductive electrodes for flexibility: Specialized transparent conductive electrodes are developed to maintain conductivity under mechanical deformation in flexible displays. Alternative materials to traditional indium tin oxide (ITO) include silver nanowires, carbon nanotubes, graphene, and metal mesh structures that offer better mechanical flexibility while maintaining high transparency and conductivity. These materials can withstand repeated bending cycles without significant degradation in electrical performance, which is essential for durable flexible display applications.

- Manufacturing processes for flexible display substrates: Specialized manufacturing processes have been developed for flexible display substrates, including roll-to-roll processing that enables continuous production of flexible displays on polymer films. Laser processing techniques allow precise patterning of flexible substrates without thermal damage. Low-temperature deposition methods compatible with temperature-sensitive flexible materials include plasma-enhanced chemical vapor deposition and solution processing techniques. These manufacturing innovations enable cost-effective mass production of flexible displays with consistent quality and performance.

02 Thin-film transistor structures for flexible displays

Advanced thin-film transistor (TFT) structures are essential components of flexible displays, designed to maintain electrical performance under mechanical stress. These structures often incorporate novel semiconductor materials and electrode configurations that can withstand bending without performance degradation. Low-temperature fabrication processes are employed to create these TFTs on temperature-sensitive flexible substrates, ensuring compatibility with the substrate material while maintaining high electron mobility and switching performance.Expand Specific Solutions03 Barrier and encapsulation technologies

Effective barrier and encapsulation technologies are crucial for protecting flexible display components from environmental factors such as moisture and oxygen. Multi-layer barrier films combining organic and inorganic materials can achieve ultra-low permeation rates while maintaining flexibility. Thin-film encapsulation techniques provide hermetic sealing of sensitive display elements without compromising the overall flexibility of the device, extending the operational lifetime of flexible displays even under challenging environmental conditions.Expand Specific Solutions04 Mechanical support and stress distribution systems

Specialized mechanical support structures and stress distribution systems are implemented to protect flexible displays during bending and folding operations. These systems include neutral plane engineering, where critical components are positioned at the neutral bending axis to minimize strain, and reinforcement layers that distribute mechanical stress evenly across the display surface. Innovative hinge mechanisms and folding zone designs allow for repeated folding while protecting the display components from excessive strain or damage.Expand Specific Solutions05 Manufacturing processes for flexible display substrates

Advanced manufacturing processes have been developed specifically for flexible display substrates, including roll-to-roll processing techniques that enable continuous, high-throughput production of large-area flexible substrates. These processes often incorporate laser patterning, solution-based deposition methods, and transfer printing technologies to create complex multilayer structures on flexible materials. Low-temperature processes are employed to prevent thermal damage to temperature-sensitive substrate materials while ensuring proper formation of functional layers and interfaces.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The flexible display substrate market for aerospace applications is in an early growth phase, characterized by increasing adoption but still evolving technological maturity. The market is expanding rapidly with projections suggesting significant growth as aerospace manufacturers seek lighter, more adaptable display solutions. Leading the technological development are established display manufacturers like Samsung Display, BOE Technology, and LG Display, who are leveraging their consumer electronics expertise for aerospace applications. These companies demonstrate varying levels of technological maturity, with Samsung and BOE showing advanced capabilities in flexible OLED technology. Aerospace specialists like Airbus Operations and Shanghai Institute of Aerospace Systems Engineering are partnering with display manufacturers to adapt these technologies to meet rigorous aerospace requirements, focusing on durability, reliability, and performance under extreme conditions.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced flexible display substrates specifically designed for aerospace applications, utilizing ultra-thin glass and polymer composite materials that can withstand extreme temperature variations (-65°C to +150°C) while maintaining structural integrity. Their proprietary Flexible AMOLED technology incorporates a multi-layer substrate design with specialized barrier films that provide exceptional resistance to cosmic radiation and vacuum environments. BOE's aerospace-grade flexible displays feature a thickness of less than 0.5mm and can achieve bend radii of up to 1.5mm without performance degradation. The company has implemented specialized encapsulation techniques that prevent oxygen and moisture penetration, extending the operational lifespan in harsh aerospace environments to over 50,000 hours. Their displays maintain 95% brightness uniformity even after 100,000 bending cycles, making them ideal for curved cockpit instrumentation and cabin entertainment systems.

Strengths: Industry-leading flexibility-to-durability ratio, exceptional radiation resistance, and proven reliability in extreme temperature conditions. Their manufacturing scale allows for cost-effective production compared to aerospace-specific competitors. Weaknesses: Higher power consumption compared to rigid display alternatives, and limited color gamut performance in high-brightness aerospace lighting conditions.

LG Display Co., Ltd.

Technical Solution: LG Display has pioneered aerospace-specific flexible display substrates using their P-OLED (Plastic OLED) technology platform. Their solution incorporates a polyimide base layer with specialized thermal management materials that can operate reliably in pressurized and non-pressurized aircraft compartments. LG's aerospace flexible displays utilize a proprietary thin-film encapsulation process that creates an ultra-thin (approximately 100μm) yet highly durable substrate capable of withstanding vibration profiles typical in aviation environments. The company has developed specialized optical bonding techniques that eliminate internal reflections, crucial for cockpit displays where readability in direct sunlight is essential. Their flexible substrates incorporate EMI shielding layers that prevent interference with critical aircraft systems while maintaining flexibility. LG Display's aerospace solutions have been tested to withstand altitude changes from sea level to 40,000 feet without delamination or performance degradation, and their displays maintain functionality after impact tests exceeding 20G.

Strengths: Superior optical performance in high-brightness environments, excellent EMI shielding capabilities, and proven reliability under rapid pressure changes. Their displays offer best-in-class power efficiency. Weaknesses: Higher production costs compared to consumer-grade flexible displays, and more limited form factor options than some competitors.

Key Patents and Materials Science Breakthroughs

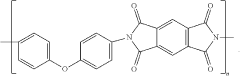

Flexible substrate material, method of manufacturing flexible display panel substrate and flexible display panel

PatentInactiveUS20210408403A1

Innovation

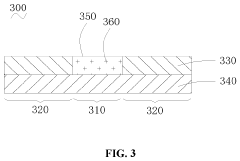

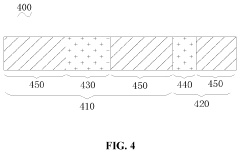

- A flexible substrate material is developed by incorporating carbon nanotube reinforcement dispersed within a polyimide substrate, linked through chemical bonds such as amide, conjugated, and hydrogen bonds, enhancing the mechanical properties and forming a composite structure with improved curl deformation and crack resistance.

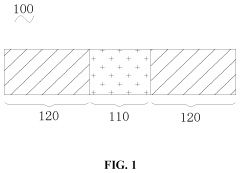

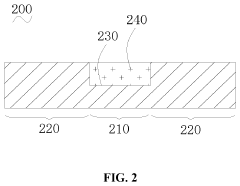

Flexible substrates and flexible display screen

PatentActiveUS11228008B2

Innovation

- A flexible substrate with distinct bending and non-bending zones, where the elastic modulus of the bending zone is lower than the non-bending zone, allowing the neutral layer to shift and reduce strain on the display unit, thereby improving the screen's operational reliability.

Reliability and Certification Standards for Aerospace Displays

The aerospace industry demands exceptionally high standards for all components, with display systems being particularly critical as they provide essential information to pilots and crew. For flexible display substrates to be viable in aerospace applications, they must meet stringent reliability requirements and certification standards that far exceed those of consumer electronics.

The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established comprehensive certification frameworks that any display technology must satisfy before implementation in aircraft. These include DO-160 Environmental Conditions and Test Procedures for Airborne Equipment, which outlines testing for temperature extremes, altitude, humidity, shock, vibration, and electromagnetic interference. Flexible displays must demonstrate resilience across all these parameters while maintaining optical performance.

Military standards such as MIL-STD-810 impose additional requirements for ruggedness and durability under extreme conditions. These standards require displays to function reliably in temperature ranges from -55°C to +85°C, withstand rapid decompression scenarios, and remain readable under intense vibration conditions typical during flight operations.

Reliability testing for aerospace flexible displays includes accelerated life testing, where displays undergo thousands of hours of operation in simulated harsh environments. Mean Time Between Failures (MTBF) metrics for aerospace displays typically need to exceed 50,000 hours, significantly higher than the 10,000-20,000 hours acceptable for commercial applications.

Optical performance standards present another certification challenge. SAE ARP4256 and MIL-STD-3009 define requirements for luminance, contrast ratio, and readability under various lighting conditions, including direct sunlight. Flexible displays must maintain consistent performance across their entire bendable surface, with minimal degradation over time.

Material certification represents a unique hurdle for flexible substrates. All materials must comply with flammability standards like FAR 25.853, which requires self-extinguishing properties and minimal toxic gas emission during combustion. Additionally, outgassing characteristics must be thoroughly documented to prevent cabin air contamination.

Emerging standards specifically addressing flexible display technologies are being developed by organizations like RTCA and SAE International. These standards aim to establish testing methodologies for evaluating the long-term reliability of flexible substrates under repeated bending cycles, extreme temperature variations, and prolonged UV exposure—conditions particularly relevant to aerospace applications.

The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established comprehensive certification frameworks that any display technology must satisfy before implementation in aircraft. These include DO-160 Environmental Conditions and Test Procedures for Airborne Equipment, which outlines testing for temperature extremes, altitude, humidity, shock, vibration, and electromagnetic interference. Flexible displays must demonstrate resilience across all these parameters while maintaining optical performance.

Military standards such as MIL-STD-810 impose additional requirements for ruggedness and durability under extreme conditions. These standards require displays to function reliably in temperature ranges from -55°C to +85°C, withstand rapid decompression scenarios, and remain readable under intense vibration conditions typical during flight operations.

Reliability testing for aerospace flexible displays includes accelerated life testing, where displays undergo thousands of hours of operation in simulated harsh environments. Mean Time Between Failures (MTBF) metrics for aerospace displays typically need to exceed 50,000 hours, significantly higher than the 10,000-20,000 hours acceptable for commercial applications.

Optical performance standards present another certification challenge. SAE ARP4256 and MIL-STD-3009 define requirements for luminance, contrast ratio, and readability under various lighting conditions, including direct sunlight. Flexible displays must maintain consistent performance across their entire bendable surface, with minimal degradation over time.

Material certification represents a unique hurdle for flexible substrates. All materials must comply with flammability standards like FAR 25.853, which requires self-extinguishing properties and minimal toxic gas emission during combustion. Additionally, outgassing characteristics must be thoroughly documented to prevent cabin air contamination.

Emerging standards specifically addressing flexible display technologies are being developed by organizations like RTCA and SAE International. These standards aim to establish testing methodologies for evaluating the long-term reliability of flexible substrates under repeated bending cycles, extreme temperature variations, and prolonged UV exposure—conditions particularly relevant to aerospace applications.

Weight-Performance Optimization Strategies

In aerospace applications, the optimization of weight-to-performance ratio represents a critical engineering challenge for flexible display substrates. Current aerospace-grade flexible displays must balance structural integrity with minimal mass contribution to the overall system. Advanced polymer composites have emerged as leading candidates, with polyimide-based substrates demonstrating exceptional thermal stability (withstanding temperatures from -200°C to +300°C) while maintaining a density approximately 80% lower than traditional glass substrates.

Material engineering approaches focus on strategic thinning of substrate layers without compromising mechanical durability. Recent innovations include the development of micro-lattice structures within polymer matrices, creating honeycomb-like reinforcement patterns that maximize strength while minimizing material usage. These architectures have demonstrated up to 40% weight reduction compared to solid substrates of equivalent performance specifications.

Carbon nanotube (CNT) and graphene reinforcement technologies represent another frontier in weight optimization. When incorporated into polymer substrates at concentrations of 0.5-2% by weight, these nanomaterials can improve tensile strength by 30-60% without significant mass increase. This approach has proven particularly valuable for displays intended for high-vibration aerospace environments where mechanical resilience is paramount.

Multi-layer lamination techniques utilizing alternating ultra-thin layers of different materials have shown promise in optimizing the weight-performance balance. By strategically combining layers with complementary properties—such as mechanical strength, flexibility, and barrier performance—engineers can achieve optimal characteristics with minimal material usage. Recent aerospace implementations have utilized five-layer structures with total thicknesses below 100 micrometers.

Surface treatment methodologies, including plasma modification and chemical functionalization, enable weight reduction by enhancing adhesion between display components. This allows for thinner substrate layers while maintaining structural integrity at interface points. Oxygen plasma treatments have demonstrated particular efficacy, increasing adhesion strength by up to 300% between substrate and subsequent electronic layers.

Computational modeling has accelerated optimization efforts through finite element analysis and materials simulation. These tools enable precise prediction of mechanical behavior under aerospace conditions, allowing engineers to identify minimum viable substrate thicknesses for specific application requirements. Recent modeling approaches have incorporated machine learning algorithms to predict long-term material performance based on accelerated testing data.

Material engineering approaches focus on strategic thinning of substrate layers without compromising mechanical durability. Recent innovations include the development of micro-lattice structures within polymer matrices, creating honeycomb-like reinforcement patterns that maximize strength while minimizing material usage. These architectures have demonstrated up to 40% weight reduction compared to solid substrates of equivalent performance specifications.

Carbon nanotube (CNT) and graphene reinforcement technologies represent another frontier in weight optimization. When incorporated into polymer substrates at concentrations of 0.5-2% by weight, these nanomaterials can improve tensile strength by 30-60% without significant mass increase. This approach has proven particularly valuable for displays intended for high-vibration aerospace environments where mechanical resilience is paramount.

Multi-layer lamination techniques utilizing alternating ultra-thin layers of different materials have shown promise in optimizing the weight-performance balance. By strategically combining layers with complementary properties—such as mechanical strength, flexibility, and barrier performance—engineers can achieve optimal characteristics with minimal material usage. Recent aerospace implementations have utilized five-layer structures with total thicknesses below 100 micrometers.

Surface treatment methodologies, including plasma modification and chemical functionalization, enable weight reduction by enhancing adhesion between display components. This allows for thinner substrate layers while maintaining structural integrity at interface points. Oxygen plasma treatments have demonstrated particular efficacy, increasing adhesion strength by up to 300% between substrate and subsequent electronic layers.

Computational modeling has accelerated optimization efforts through finite element analysis and materials simulation. These tools enable precise prediction of mechanical behavior under aerospace conditions, allowing engineers to identify minimum viable substrate thicknesses for specific application requirements. Recent modeling approaches have incorporated machine learning algorithms to predict long-term material performance based on accelerated testing data.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!