Thermal Stress Testing in Flexible Display Substrate Applications

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Display Thermal Stress Background and Objectives

Flexible display technology has evolved significantly over the past decade, transitioning from laboratory curiosity to commercial reality. The development trajectory began with early prototypes in the early 2000s, followed by limited commercial applications around 2013, and has now entered a phase of accelerated adoption across multiple industries. This evolution has been driven by consumer demand for more durable, lightweight, and versatile display solutions that can be integrated into non-traditional form factors such as foldable smartphones, rollable televisions, and wearable devices.

Thermal stress represents one of the most critical challenges in flexible display substrate development. Unlike rigid displays, flexible substrates must maintain performance integrity while being subjected to repeated bending, folding, and temperature fluctuations. The technical goal of thermal stress testing is to develop substrates that can withstand operational temperatures ranging from -40°C to 85°C without degradation in optical properties, mechanical flexibility, or electronic performance.

Current flexible display substrates primarily utilize polyimide films, which offer good thermal stability but still face limitations when exposed to extreme temperature cycling. The industry aims to achieve substrates with coefficient of thermal expansion (CTE) values below 10 ppm/°C, significantly lower than current materials which typically range from 15-30 ppm/°C. This reduction would minimize thermal mismatch between substrate layers and reduce stress-induced delamination and cracking.

The technological trajectory indicates a shift toward composite materials that combine organic polymers with inorganic fillers to achieve enhanced thermal stability. Recent research has focused on graphene-reinforced polymers and ceramic-polymer composites that demonstrate promising thermal performance while maintaining flexibility. These advanced materials aim to extend operational lifetimes from the current industry standard of approximately 200,000 folding cycles to over 1 million cycles under varying thermal conditions.

Another emerging trend is the development of adaptive substrates with temperature-responsive properties that can actively compensate for thermal stress. These smart materials represent a paradigm shift from passive resistance to active management of thermal challenges, potentially enabling displays that operate reliably in extreme environments from arctic to desert conditions.

The ultimate objective of thermal stress testing in flexible displays is to establish standardized protocols that accurately predict real-world performance and longevity. Current testing methodologies vary significantly across manufacturers, creating inconsistencies in reported specifications and performance expectations. The industry is moving toward unified testing standards that incorporate both static thermal resistance and dynamic thermal cycling under mechanical stress, providing more reliable indicators of long-term durability in consumer applications.

Thermal stress represents one of the most critical challenges in flexible display substrate development. Unlike rigid displays, flexible substrates must maintain performance integrity while being subjected to repeated bending, folding, and temperature fluctuations. The technical goal of thermal stress testing is to develop substrates that can withstand operational temperatures ranging from -40°C to 85°C without degradation in optical properties, mechanical flexibility, or electronic performance.

Current flexible display substrates primarily utilize polyimide films, which offer good thermal stability but still face limitations when exposed to extreme temperature cycling. The industry aims to achieve substrates with coefficient of thermal expansion (CTE) values below 10 ppm/°C, significantly lower than current materials which typically range from 15-30 ppm/°C. This reduction would minimize thermal mismatch between substrate layers and reduce stress-induced delamination and cracking.

The technological trajectory indicates a shift toward composite materials that combine organic polymers with inorganic fillers to achieve enhanced thermal stability. Recent research has focused on graphene-reinforced polymers and ceramic-polymer composites that demonstrate promising thermal performance while maintaining flexibility. These advanced materials aim to extend operational lifetimes from the current industry standard of approximately 200,000 folding cycles to over 1 million cycles under varying thermal conditions.

Another emerging trend is the development of adaptive substrates with temperature-responsive properties that can actively compensate for thermal stress. These smart materials represent a paradigm shift from passive resistance to active management of thermal challenges, potentially enabling displays that operate reliably in extreme environments from arctic to desert conditions.

The ultimate objective of thermal stress testing in flexible displays is to establish standardized protocols that accurately predict real-world performance and longevity. Current testing methodologies vary significantly across manufacturers, creating inconsistencies in reported specifications and performance expectations. The industry is moving toward unified testing standards that incorporate both static thermal resistance and dynamic thermal cycling under mechanical stress, providing more reliable indicators of long-term durability in consumer applications.

Market Analysis for Thermal-Resistant Flexible Displays

The flexible display market is experiencing robust growth, with a projected market value expected to reach 15 billion USD by 2025, growing at a CAGR of approximately 35% from 2020. This accelerated growth is primarily driven by increasing consumer demand for foldable smartphones, wearable devices, and automotive display applications. Thermal-resistant flexible displays represent a premium segment within this market, commanding higher price points due to their enhanced durability and performance under varying temperature conditions.

Consumer electronics remains the dominant application sector, accounting for nearly 60% of the thermal-resistant flexible display market. Within this sector, smartphones and wearable technology are the primary growth drivers. The automotive industry represents the second-largest market segment, with increasing integration of flexible displays in vehicle interiors and information systems requiring high thermal stability.

Geographically, East Asia dominates both production and consumption of thermal-resistant flexible displays, with South Korea, Japan, and China collectively representing approximately 70% of global market share. North America and Europe follow as significant consumption markets, particularly for high-end applications where thermal performance is critical.

Market research indicates that consumers are willing to pay a 15-20% premium for devices with displays that maintain consistent performance across wider temperature ranges. This price elasticity is particularly evident in outdoor-use devices, automotive applications, and industrial equipment where operational environments can be demanding.

The supply chain for thermal-resistant flexible displays remains concentrated among a few key manufacturers with advanced technical capabilities. This concentration has created potential bottlenecks in production scaling, which presents both a challenge for market growth and an opportunity for new entrants with innovative thermal management solutions.

Industry analysts have identified several key market drivers for thermal-resistant flexible displays: increasing adoption of foldable smartphones, growing demand for wearable health monitoring devices, expansion of automotive display applications, and emerging industrial use cases. The compound annual growth rate for thermal-resistant variants specifically is outpacing the broader flexible display market by approximately 5-7 percentage points.

Customer feedback and warranty claim analysis reveal that thermal performance issues account for approximately 22% of display-related failures in flexible devices, highlighting the market need for improved thermal stress resistance. This represents a significant opportunity for manufacturers who can effectively address these thermal management challenges.

Consumer electronics remains the dominant application sector, accounting for nearly 60% of the thermal-resistant flexible display market. Within this sector, smartphones and wearable technology are the primary growth drivers. The automotive industry represents the second-largest market segment, with increasing integration of flexible displays in vehicle interiors and information systems requiring high thermal stability.

Geographically, East Asia dominates both production and consumption of thermal-resistant flexible displays, with South Korea, Japan, and China collectively representing approximately 70% of global market share. North America and Europe follow as significant consumption markets, particularly for high-end applications where thermal performance is critical.

Market research indicates that consumers are willing to pay a 15-20% premium for devices with displays that maintain consistent performance across wider temperature ranges. This price elasticity is particularly evident in outdoor-use devices, automotive applications, and industrial equipment where operational environments can be demanding.

The supply chain for thermal-resistant flexible displays remains concentrated among a few key manufacturers with advanced technical capabilities. This concentration has created potential bottlenecks in production scaling, which presents both a challenge for market growth and an opportunity for new entrants with innovative thermal management solutions.

Industry analysts have identified several key market drivers for thermal-resistant flexible displays: increasing adoption of foldable smartphones, growing demand for wearable health monitoring devices, expansion of automotive display applications, and emerging industrial use cases. The compound annual growth rate for thermal-resistant variants specifically is outpacing the broader flexible display market by approximately 5-7 percentage points.

Customer feedback and warranty claim analysis reveal that thermal performance issues account for approximately 22% of display-related failures in flexible devices, highlighting the market need for improved thermal stress resistance. This represents a significant opportunity for manufacturers who can effectively address these thermal management challenges.

Current Challenges in Flexible Substrate Thermal Performance

Despite significant advancements in flexible display technology, thermal performance remains one of the most critical challenges facing the industry. Flexible substrates, typically composed of polymeric materials such as polyimide (PI), polyethylene terephthalate (PET), or polyethylene naphthalate (PEN), exhibit fundamentally different thermal behaviors compared to traditional rigid glass substrates. These materials generally have lower thermal conductivity, higher coefficients of thermal expansion (CTE), and lower thermal stability thresholds.

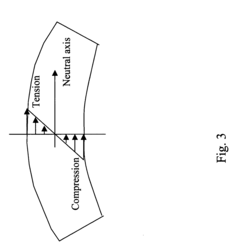

The primary challenge lies in the inherent thermal expansion mismatch between different layers in flexible displays. When subjected to temperature fluctuations during operation or manufacturing processes, these mismatches create internal stresses that can lead to delamination, cracking, or permanent deformation of the display structure. For instance, the CTE of polyimide (around 20-30 ppm/°C) is significantly higher than that of inorganic electronic components (typically 3-10 ppm/°C), creating substantial interfacial stress during thermal cycling.

Thermal management during high-temperature processing presents another significant hurdle. Many essential manufacturing steps, such as thin-film transistor (TFT) deposition or encapsulation, require temperatures that approach or exceed the glass transition temperature (Tg) of polymer substrates. This narrow processing window severely constrains manufacturing options and yield rates. For example, polyimide can typically withstand temperatures up to 300-350°C, but only for limited durations before degradation occurs.

Heat dissipation during device operation represents a persistent challenge that impacts both performance and longevity. Unlike rigid displays that can incorporate substantial heat sinks or thermal management systems, flexible displays must maintain their bendable nature, limiting cooling options. Localized heating in flexible displays can create "hot spots" that accelerate material degradation, particularly in organic light-emitting diode (OLED) displays where pixel degradation is temperature-sensitive.

Environmental resilience poses additional thermal challenges. Flexible displays must maintain performance across wider temperature ranges than their rigid counterparts, especially in wearable or outdoor applications. Repeated thermal cycling between extreme temperatures (-20°C to 70°C) can accelerate mechanical fatigue in flexible substrates, leading to premature failure through mechanisms like crack propagation or adhesion loss between layers.

Current testing methodologies themselves present limitations. Traditional thermal stress testing protocols developed for rigid electronics often fail to adequately characterize the unique failure modes of flexible displays. There is a critical need for standardized testing procedures that specifically address the combined thermal-mechanical stresses experienced during bending while under thermal load.

The primary challenge lies in the inherent thermal expansion mismatch between different layers in flexible displays. When subjected to temperature fluctuations during operation or manufacturing processes, these mismatches create internal stresses that can lead to delamination, cracking, or permanent deformation of the display structure. For instance, the CTE of polyimide (around 20-30 ppm/°C) is significantly higher than that of inorganic electronic components (typically 3-10 ppm/°C), creating substantial interfacial stress during thermal cycling.

Thermal management during high-temperature processing presents another significant hurdle. Many essential manufacturing steps, such as thin-film transistor (TFT) deposition or encapsulation, require temperatures that approach or exceed the glass transition temperature (Tg) of polymer substrates. This narrow processing window severely constrains manufacturing options and yield rates. For example, polyimide can typically withstand temperatures up to 300-350°C, but only for limited durations before degradation occurs.

Heat dissipation during device operation represents a persistent challenge that impacts both performance and longevity. Unlike rigid displays that can incorporate substantial heat sinks or thermal management systems, flexible displays must maintain their bendable nature, limiting cooling options. Localized heating in flexible displays can create "hot spots" that accelerate material degradation, particularly in organic light-emitting diode (OLED) displays where pixel degradation is temperature-sensitive.

Environmental resilience poses additional thermal challenges. Flexible displays must maintain performance across wider temperature ranges than their rigid counterparts, especially in wearable or outdoor applications. Repeated thermal cycling between extreme temperatures (-20°C to 70°C) can accelerate mechanical fatigue in flexible substrates, leading to premature failure through mechanisms like crack propagation or adhesion loss between layers.

Current testing methodologies themselves present limitations. Traditional thermal stress testing protocols developed for rigid electronics often fail to adequately characterize the unique failure modes of flexible displays. There is a critical need for standardized testing procedures that specifically address the combined thermal-mechanical stresses experienced during bending while under thermal load.

Current Thermal Stress Testing Methodologies

01 Thermal stress testing methods for electronic components

Various methods for conducting thermal stress tests on electronic components to evaluate their reliability and performance under extreme temperature conditions. These methods involve subjecting the components to controlled temperature cycles, monitoring their electrical parameters during testing, and analyzing the results to identify potential failure modes. The testing procedures help in determining the thermal endurance limits of components such as integrated circuits, memory devices, and semiconductor chips.- Thermal stress testing methods for electronic components: Various methods for conducting thermal stress tests on electronic components to evaluate their reliability and performance under extreme temperature conditions. These methods involve subjecting the components to controlled temperature cycles, monitoring their behavior during thermal stress, and analyzing the results to identify potential failure modes. The testing procedures help in determining the thermal endurance limits of electronic devices and ensuring their functionality in diverse operating environments.

- Thermal stress testing equipment and apparatus: Specialized equipment and apparatus designed for conducting thermal stress tests, including thermal chambers, temperature controllers, and monitoring systems. These devices provide controlled environments for subjecting test specimens to precise temperature variations and thermal cycling. The equipment features capabilities for rapid temperature changes, uniform heat distribution, and accurate measurement of thermal parameters to ensure reliable and reproducible test results.

- Thermal stress analysis and simulation techniques: Advanced techniques for analyzing and simulating thermal stress in materials and structures, including computational methods, finite element analysis, and predictive modeling. These approaches enable engineers to predict how materials will respond to thermal loading without physical testing, optimize designs for thermal performance, and identify potential failure points. The simulation techniques account for various factors such as material properties, geometry, and boundary conditions to provide comprehensive thermal stress assessments.

- Thermal stress monitoring and measurement systems: Systems and methods for real-time monitoring and measurement of thermal stress in materials and components during testing or operation. These systems utilize various sensors, imaging technologies, and data acquisition methods to capture temperature distributions, thermal gradients, and resulting mechanical stresses. The monitoring capabilities enable detection of thermal anomalies, validation of thermal models, and assessment of thermal management strategies to prevent failures due to thermal stress.

- Thermal stress testing for specific applications: Specialized thermal stress testing methodologies tailored for specific applications such as semiconductor devices, automotive components, aerospace materials, and consumer electronics. These application-specific approaches consider the unique operating conditions, failure mechanisms, and performance requirements of different industries. The testing protocols incorporate industry standards and regulatory requirements while addressing the particular thermal challenges faced in each application domain.

02 Thermal stress testing equipment and apparatus

Specialized equipment and apparatus designed for thermal stress testing, including thermal chambers, temperature control systems, and measurement instruments. These systems provide precise temperature regulation, rapid thermal cycling capabilities, and integrated monitoring functions. The equipment may include features such as automated test sequence control, real-time data acquisition, and safety mechanisms to prevent damage during extreme temperature testing.Expand Specific Solutions03 Thermal stress analysis and simulation techniques

Computational methods and software tools for analyzing and simulating thermal stress in materials and structures. These techniques involve finite element analysis, thermal modeling, and predictive algorithms to estimate how components will respond to thermal loading. The simulation approaches help in optimizing designs before physical testing, reducing development time and costs while improving reliability prediction accuracy.Expand Specific Solutions04 Thermal stress testing for semiconductor devices

Specific thermal stress testing methodologies tailored for semiconductor devices, including wafer-level testing, package-level reliability assessment, and burn-in procedures. These tests evaluate how semiconductor components respond to thermal cycling, thermal shock, and prolonged exposure to high temperatures. The testing protocols help identify manufacturing defects, weak bonds, and potential failure mechanisms in integrated circuits and other semiconductor products.Expand Specific Solutions05 Thermal stress monitoring and data analysis systems

Systems for continuous monitoring of thermal stress conditions and analyzing the resulting data to identify patterns, trends, and anomalies. These systems incorporate sensors, data acquisition hardware, and analytical software to process thermal test results. Advanced features may include machine learning algorithms for predictive failure analysis, automated reporting tools, and integration with quality management systems to improve product reliability.Expand Specific Solutions

Leading Companies in Flexible Display Thermal Technology

The thermal stress testing market in flexible display substrates is currently in a growth phase, with increasing demand driven by the expanding flexible display industry. Market size is projected to grow significantly as consumer electronics manufacturers adopt flexible display technologies. In terms of technological maturity, industry leaders like Samsung Display, BOE Technology, and LG Display have established advanced thermal stress testing capabilities, while companies such as Corning and Nitto Denko focus on specialized substrate materials that can withstand thermal stress. Emerging players including Tianma Microelectronics and Visionox are rapidly developing their testing protocols. The competitive landscape shows a mix of established electronics giants and specialized materials companies working to address thermal reliability challenges in next-generation flexible displays.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has implemented a comprehensive thermal stress testing framework for flexible display substrates that emphasizes real-world usage scenarios. Their methodology incorporates multi-environmental factor testing that combines thermal cycling (-30°C to 75°C), humidity variation (10-95% RH), and UV exposure to simulate outdoor usage conditions for flexible displays. BOE utilizes a proprietary "thermal interface stress mapping" technique that employs micro-sensors embedded between substrate layers to measure stress distribution during thermal cycling with precision of ±0.01 MPa. The company has developed automated visual inspection systems that use AI algorithms to detect microscopic deformations, delamination, or color shifts during and after thermal stress testing, enabling quantitative assessment of visual performance degradation. BOE's testing protocol includes specialized thermal gradient testing that evaluates how non-uniform temperature distribution (common in real-world usage) affects flexible display performance and durability. Their methodology incorporates accelerated thermal aging at elevated temperatures (up to 95°C) for extended periods (500-2000 hours) to predict long-term reliability and color stability of flexible display materials.

Strengths: Holistic testing approach that incorporates multiple environmental factors provides more realistic performance predictions. Automated AI-based visual inspection systems enable objective quantification of display quality degradation. Weaknesses: The complex multi-factor testing approach makes it difficult to isolate specific failure mechanisms related solely to thermal stress. The extensive testing protocol extends development timelines compared to more focused approaches.

SAMSUNG DISPLAY CO LTD

Technical Solution: Samsung Display has developed a comprehensive thermal stress testing methodology specifically for flexible OLED displays that incorporates both static and dynamic thermal cycling protocols. Their approach utilizes specialized thermal chambers capable of precise temperature control from -40°C to 85°C with controlled ramp rates of 2-5°C/minute to simulate real-world thermal stresses. The company employs a proprietary multi-layer stress distribution analysis that examines the interface between the flexible substrate (typically polyimide) and the thin-film transistor (TFT) layers during thermal expansion and contraction. Samsung's testing includes continuous 1000-hour thermal aging tests combined with mechanical folding cycles to evaluate the long-term reliability of their flexible displays under combined thermal and mechanical stress conditions. Their methodology incorporates real-time electrical performance monitoring during thermal cycling to detect early signs of delamination or circuit degradation before visible failure occurs.

Strengths: Industry-leading comprehensive testing methodology that combines thermal, mechanical, and electrical performance evaluation in a single protocol. Advanced data analytics for failure prediction. Weaknesses: Testing protocols are highly proprietary and require specialized equipment, making standardization across the industry difficult. The lengthy testing cycles (1000+ hours) extend product development timelines.

Key Patents in Flexible Substrate Thermal Resistance

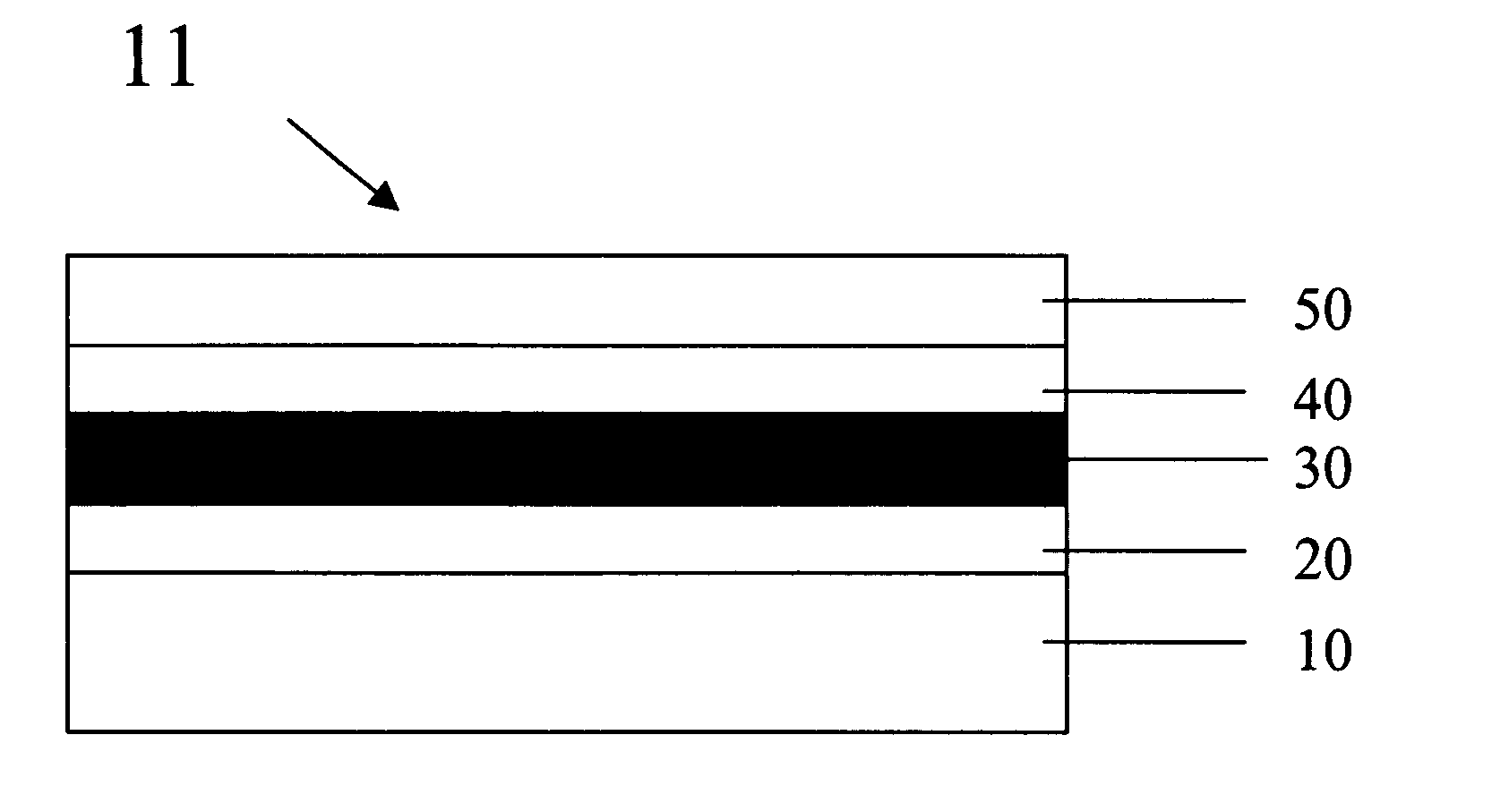

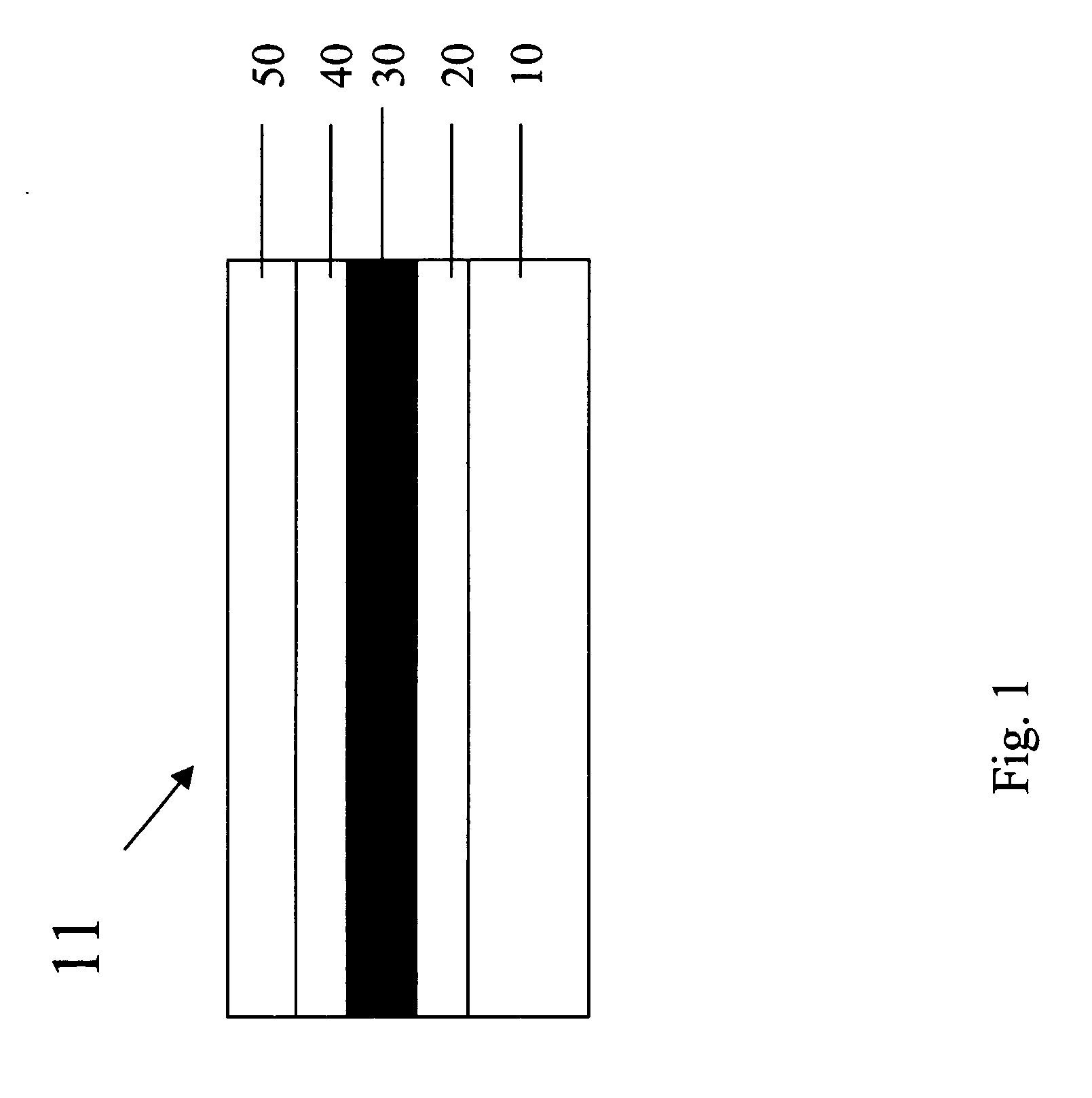

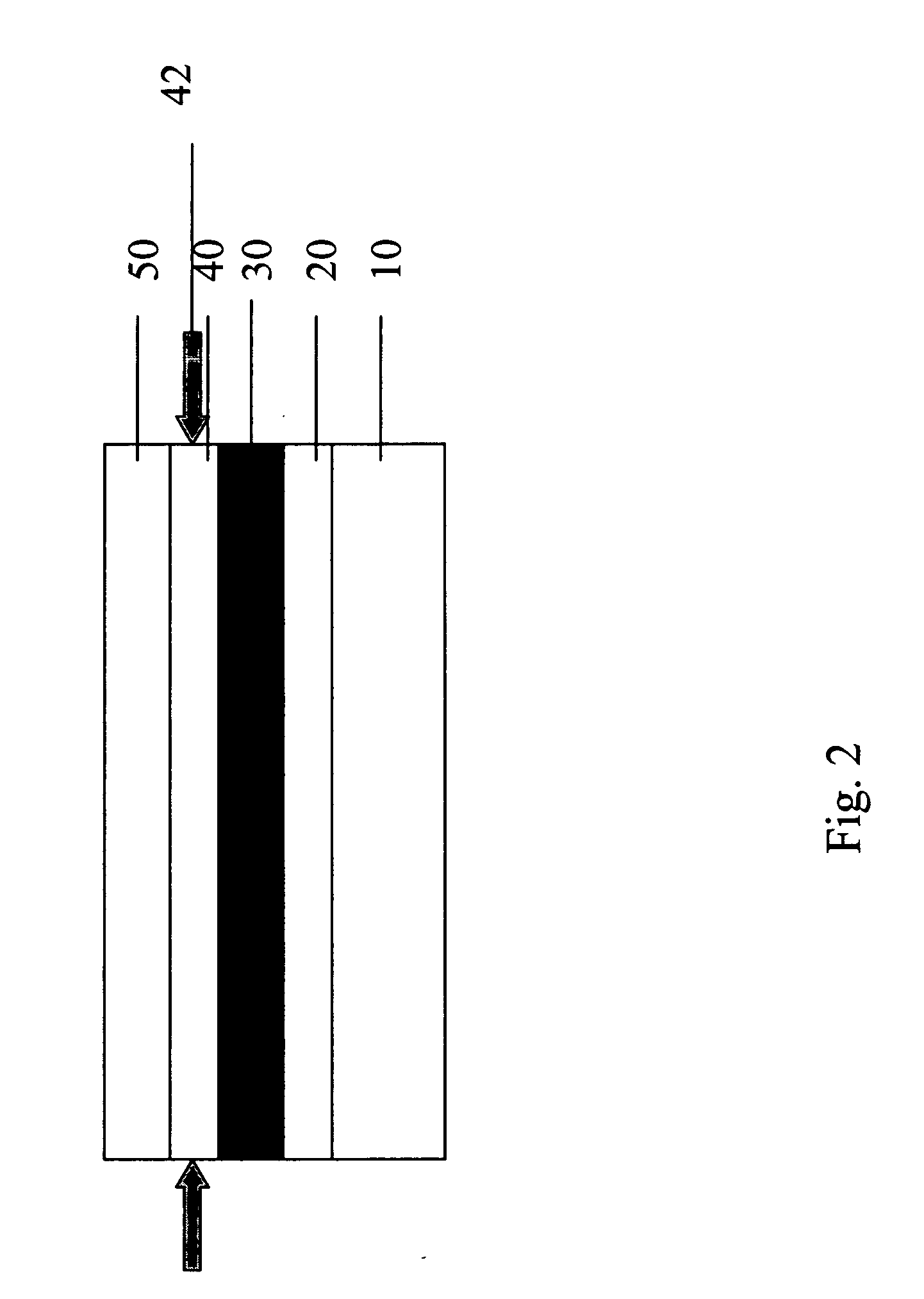

Method and display element with reduced thermal stress

PatentInactiveUS20060132027A1

Innovation

- A flexible display design comprising a substrate, conductive layers, a flexible light-emitting layer, and a superstrate, where the properties of each layer, such as modulus, thermal expansion coefficients, and dimensions, are carefully selected to balance stress, ensuring the layer most susceptible to damage is stress-free at operating temperatures.

Substrate for Flexible Displays

PatentActiveUS20070224366A1

Innovation

- A substrate comprising a resin composition layer with an inorganic layer compound, such as clay minerals, dispersed in a solvent, where the inorganic layer compound constitutes between 10 weight % and 70 weight % of the total composition, providing a low thermal expansion coefficient and high visible light transmittance.

Materials Science Advancements for Thermal Stability

Recent advancements in materials science have significantly contributed to enhancing the thermal stability of flexible display substrates. Traditional polymer substrates such as polyimide (PI) and polyethylene terephthalate (PET) have inherent limitations in withstanding high-temperature processes required for display manufacturing. However, the development of novel composite materials has revolutionized this landscape.

Thermally-resistant polymer blends incorporating ceramic nanoparticles have demonstrated remarkable improvements in heat deflection temperatures, increasing from approximately 200°C to over 300°C in laboratory conditions. These composites maintain flexibility while providing superior dimensional stability under thermal stress, a critical requirement for flexible display manufacturing processes.

Surface modification techniques have emerged as another promising approach. The application of silane coupling agents and other surface treatments creates stronger interfacial bonding between organic and inorganic components, resulting in enhanced thermal resistance. Research indicates that properly treated substrates can withstand up to 50% more thermal cycles before showing signs of degradation compared to untreated counterparts.

Cross-linking technology represents another significant advancement. By introducing additional chemical bonds within polymer structures, researchers have developed substrates with improved thermal resistance without sacrificing flexibility. These materials exhibit glass transition temperatures approximately 30-40°C higher than conventional substrates, expanding the processing window for display manufacturers.

Graphene and carbon nanotube reinforcements have demonstrated exceptional potential for thermal stability enhancement. When incorporated at concentrations of 1-5% by weight, these carbon allotropes can improve thermal conductivity by 200-300%, facilitating more efficient heat dissipation during operation and manufacturing processes. This prevents localized heating that often leads to substrate deformation.

Bio-inspired materials represent the cutting edge of thermal stability research. Drawing inspiration from heat-resistant biological structures, scientists have developed synthetic polymers with self-healing capabilities and programmed thermal responses. These materials can actively redistribute stress during thermal cycling, potentially extending the operational lifetime of flexible displays by 30-40% according to accelerated aging tests.

The integration of phase-change materials (PCMs) within substrate layers offers another innovative approach to thermal management. These materials absorb and release thermal energy during phase transitions, effectively buffering temperature fluctuations. Recent studies demonstrate that PCM-enhanced substrates can maintain temperature variations within ±5°C even when external temperatures fluctuate by ±25°C.

Thermally-resistant polymer blends incorporating ceramic nanoparticles have demonstrated remarkable improvements in heat deflection temperatures, increasing from approximately 200°C to over 300°C in laboratory conditions. These composites maintain flexibility while providing superior dimensional stability under thermal stress, a critical requirement for flexible display manufacturing processes.

Surface modification techniques have emerged as another promising approach. The application of silane coupling agents and other surface treatments creates stronger interfacial bonding between organic and inorganic components, resulting in enhanced thermal resistance. Research indicates that properly treated substrates can withstand up to 50% more thermal cycles before showing signs of degradation compared to untreated counterparts.

Cross-linking technology represents another significant advancement. By introducing additional chemical bonds within polymer structures, researchers have developed substrates with improved thermal resistance without sacrificing flexibility. These materials exhibit glass transition temperatures approximately 30-40°C higher than conventional substrates, expanding the processing window for display manufacturers.

Graphene and carbon nanotube reinforcements have demonstrated exceptional potential for thermal stability enhancement. When incorporated at concentrations of 1-5% by weight, these carbon allotropes can improve thermal conductivity by 200-300%, facilitating more efficient heat dissipation during operation and manufacturing processes. This prevents localized heating that often leads to substrate deformation.

Bio-inspired materials represent the cutting edge of thermal stability research. Drawing inspiration from heat-resistant biological structures, scientists have developed synthetic polymers with self-healing capabilities and programmed thermal responses. These materials can actively redistribute stress during thermal cycling, potentially extending the operational lifetime of flexible displays by 30-40% according to accelerated aging tests.

The integration of phase-change materials (PCMs) within substrate layers offers another innovative approach to thermal management. These materials absorb and release thermal energy during phase transitions, effectively buffering temperature fluctuations. Recent studies demonstrate that PCM-enhanced substrates can maintain temperature variations within ±5°C even when external temperatures fluctuate by ±25°C.

Industry Standards and Certification Requirements

The flexible display industry has established comprehensive standards and certification requirements for thermal stress testing, reflecting the critical nature of thermal performance in these applications. The International Electrotechnical Commission (IEC) has developed the IEC 62715 series specifically for flexible display devices, with section 62715-6-1 addressing environmental testing methods including thermal stress. This standard prescribes specific temperature cycling protocols, typically ranging from -40°C to +85°C, with defined ramp rates and dwell times to simulate real-world thermal conditions.

ASTM International complements these standards with ASTM D7027, which focuses on the thermomechanical properties of polymeric materials used in flexible substrates. This standard outlines procedures for measuring dimensional stability and mechanical integrity under thermal stress, essential parameters for flexible display manufacturers to validate their substrate materials.

The JEDEC JESD22-A104 standard, though originally developed for semiconductor reliability testing, has been adapted for flexible display applications, particularly for thermal cycling tests that evaluate solder joint reliability and interface adhesion in flexible display modules. These tests typically require 500-1000 cycles to ensure long-term reliability.

Military and aerospace applications follow the more stringent MIL-STD-810G standard, which includes Method 503.5 for temperature shock testing. Flexible displays intended for these environments must demonstrate resilience to extreme temperature variations without performance degradation.

Certification bodies like UL (Underwriters Laboratories) and TÜV have established specific certification programs for flexible display technologies. UL's 2054 standard addresses battery-integrated flexible displays, while TÜV's Performance Mark certification evaluates overall thermal reliability. These certifications have become essential market entry requirements in many regions.

The Consumer Technology Association (CTA) has recently introduced the CTA-2042 standard specifically for foldable and flexible display devices, which includes thermal stress requirements focused on consumer use scenarios. This standard emphasizes testing at temperature transition points where material properties change significantly.

Regional variations exist in certification requirements, with China's GB/T 38464-2020 standard imposing stricter thermal cycling requirements for flexible displays, while the European IEC EN 62368-1 standard focuses more on safety aspects under thermal stress conditions. Manufacturers targeting global markets must navigate this complex landscape of overlapping but distinct requirements.

ASTM International complements these standards with ASTM D7027, which focuses on the thermomechanical properties of polymeric materials used in flexible substrates. This standard outlines procedures for measuring dimensional stability and mechanical integrity under thermal stress, essential parameters for flexible display manufacturers to validate their substrate materials.

The JEDEC JESD22-A104 standard, though originally developed for semiconductor reliability testing, has been adapted for flexible display applications, particularly for thermal cycling tests that evaluate solder joint reliability and interface adhesion in flexible display modules. These tests typically require 500-1000 cycles to ensure long-term reliability.

Military and aerospace applications follow the more stringent MIL-STD-810G standard, which includes Method 503.5 for temperature shock testing. Flexible displays intended for these environments must demonstrate resilience to extreme temperature variations without performance degradation.

Certification bodies like UL (Underwriters Laboratories) and TÜV have established specific certification programs for flexible display technologies. UL's 2054 standard addresses battery-integrated flexible displays, while TÜV's Performance Mark certification evaluates overall thermal reliability. These certifications have become essential market entry requirements in many regions.

The Consumer Technology Association (CTA) has recently introduced the CTA-2042 standard specifically for foldable and flexible display devices, which includes thermal stress requirements focused on consumer use scenarios. This standard emphasizes testing at temperature transition points where material properties change significantly.

Regional variations exist in certification requirements, with China's GB/T 38464-2020 standard imposing stricter thermal cycling requirements for flexible displays, while the European IEC EN 62368-1 standard focuses more on safety aspects under thermal stress conditions. Manufacturers targeting global markets must navigate this complex landscape of overlapping but distinct requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!