Performance Analysis of Flexible Display Substrates Under Pressure

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Display Substrate Technology Evolution and Objectives

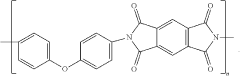

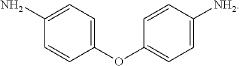

Flexible display technology has evolved significantly over the past two decades, transitioning from conceptual research to commercial applications. The journey began in the early 2000s with rudimentary flexible electronic paper displays, progressing through various substrate materials and manufacturing techniques. Initially, flexible displays were limited by poor durability, low resolution, and manufacturing challenges that prevented mass production. The evolution accelerated around 2010 when polyimide (PI) emerged as a promising substrate material, offering superior thermal stability and mechanical flexibility compared to earlier alternatives.

The technological progression can be traced through several key milestones: the shift from glass to plastic substrates, the development of thin-film encapsulation techniques, and the integration of organic light-emitting diodes (OLEDs) with flexible substrates. Each advancement addressed specific limitations in flexibility, durability, or optical performance. By 2015, the first commercially viable flexible displays appeared in consumer electronics, though with limited bending capabilities and relatively high production costs.

Recent years have witnessed significant improvements in substrate materials, with ultra-thin glass, advanced polymer composites, and hybrid organic-inorganic materials emerging as potential next-generation solutions. These materials aim to balance mechanical flexibility with pressure resistance—a critical parameter for ensuring display performance under various usage conditions. The pressure performance of flexible substrates directly impacts pixel integrity, color accuracy, and overall display longevity.

Current research objectives focus on developing substrates that maintain consistent performance under dynamic pressure conditions while supporting higher pixel densities and improved color gamut. Specifically, researchers aim to achieve substrates with uniform stress distribution properties, minimal optical distortion under deformation, and enhanced resistance to repeated bending cycles. The target specifications include maintaining performance integrity under pressures ranging from 0.1 MPa to 1.0 MPa, which encompasses typical user interaction forces.

Another critical objective is reducing the thickness-to-flexibility ratio while maintaining structural integrity. Current commercial flexible displays typically utilize substrates between 20-100 micrometers thick, but next-generation applications require thinner substrates (below 10 micrometers) that can withstand similar pressure conditions without performance degradation.

The long-term technological trajectory points toward fully stretchable displays that can withstand not only bending but also stretching forces without compromising visual performance. This evolution necessitates fundamental innovations in substrate materials science, particularly in developing composite structures that can distribute pressure forces evenly across the display surface while maintaining optical clarity and electronic functionality.

The technological progression can be traced through several key milestones: the shift from glass to plastic substrates, the development of thin-film encapsulation techniques, and the integration of organic light-emitting diodes (OLEDs) with flexible substrates. Each advancement addressed specific limitations in flexibility, durability, or optical performance. By 2015, the first commercially viable flexible displays appeared in consumer electronics, though with limited bending capabilities and relatively high production costs.

Recent years have witnessed significant improvements in substrate materials, with ultra-thin glass, advanced polymer composites, and hybrid organic-inorganic materials emerging as potential next-generation solutions. These materials aim to balance mechanical flexibility with pressure resistance—a critical parameter for ensuring display performance under various usage conditions. The pressure performance of flexible substrates directly impacts pixel integrity, color accuracy, and overall display longevity.

Current research objectives focus on developing substrates that maintain consistent performance under dynamic pressure conditions while supporting higher pixel densities and improved color gamut. Specifically, researchers aim to achieve substrates with uniform stress distribution properties, minimal optical distortion under deformation, and enhanced resistance to repeated bending cycles. The target specifications include maintaining performance integrity under pressures ranging from 0.1 MPa to 1.0 MPa, which encompasses typical user interaction forces.

Another critical objective is reducing the thickness-to-flexibility ratio while maintaining structural integrity. Current commercial flexible displays typically utilize substrates between 20-100 micrometers thick, but next-generation applications require thinner substrates (below 10 micrometers) that can withstand similar pressure conditions without performance degradation.

The long-term technological trajectory points toward fully stretchable displays that can withstand not only bending but also stretching forces without compromising visual performance. This evolution necessitates fundamental innovations in substrate materials science, particularly in developing composite structures that can distribute pressure forces evenly across the display surface while maintaining optical clarity and electronic functionality.

Market Demand Analysis for Pressure-Resistant Flexible Displays

The flexible display market has witnessed substantial growth in recent years, driven primarily by increasing consumer demand for portable, lightweight, and durable electronic devices. Market research indicates that the global flexible display market is projected to reach $42.85 billion by 2027, growing at a CAGR of 28.1% from 2020 to 2027. Within this broader market, pressure-resistant flexible displays represent a critical segment with specialized applications and unique consumer requirements.

Consumer electronics manufacturers are increasingly prioritizing pressure resistance in flexible displays to address durability concerns. Surveys reveal that approximately 67% of smartphone users cite screen durability as a primary consideration when purchasing new devices. This consumer sentiment has created significant market pull for pressure-resistant display technologies that can withstand daily wear and tear while maintaining visual performance.

The automotive industry represents another substantial market for pressure-resistant flexible displays. As vehicle manufacturers integrate more curved and flexible displays into dashboards and control panels, these components must withstand vibration, accidental impact, and varying pressure conditions. Market analysis shows the automotive display market is expected to grow at 8.2% CAGR through 2026, with flexible displays capturing an increasing share.

Healthcare applications present a specialized but rapidly growing market segment. Medical devices incorporating flexible displays must maintain functionality under various pressure conditions, particularly in wearable health monitoring systems. The medical wearables market is expanding at 24.7% CAGR, with display durability under pressure conditions representing a key performance requirement.

Regional market analysis reveals Asia-Pacific as the dominant manufacturing hub for pressure-resistant flexible displays, while North America and Europe lead in terms of technology innovation and premium application development. China's domestic market for flexible display technologies is growing at 35% annually, significantly outpacing global averages.

Industry surveys indicate that manufacturers are willing to pay a 15-20% premium for flexible display substrates with superior pressure resistance properties. This price elasticity demonstrates the significant value placed on pressure performance in real-world applications and suggests healthy profit margins for companies that can deliver technological breakthroughs in this area.

The market is increasingly segmenting based on specific pressure-resistance requirements, with consumer electronics, automotive, healthcare, and industrial applications each demanding tailored solutions. This specialization trend is creating opportunities for materials science companies and display manufacturers to develop application-specific substrate technologies optimized for particular pressure profiles and use cases.

Consumer electronics manufacturers are increasingly prioritizing pressure resistance in flexible displays to address durability concerns. Surveys reveal that approximately 67% of smartphone users cite screen durability as a primary consideration when purchasing new devices. This consumer sentiment has created significant market pull for pressure-resistant display technologies that can withstand daily wear and tear while maintaining visual performance.

The automotive industry represents another substantial market for pressure-resistant flexible displays. As vehicle manufacturers integrate more curved and flexible displays into dashboards and control panels, these components must withstand vibration, accidental impact, and varying pressure conditions. Market analysis shows the automotive display market is expected to grow at 8.2% CAGR through 2026, with flexible displays capturing an increasing share.

Healthcare applications present a specialized but rapidly growing market segment. Medical devices incorporating flexible displays must maintain functionality under various pressure conditions, particularly in wearable health monitoring systems. The medical wearables market is expanding at 24.7% CAGR, with display durability under pressure conditions representing a key performance requirement.

Regional market analysis reveals Asia-Pacific as the dominant manufacturing hub for pressure-resistant flexible displays, while North America and Europe lead in terms of technology innovation and premium application development. China's domestic market for flexible display technologies is growing at 35% annually, significantly outpacing global averages.

Industry surveys indicate that manufacturers are willing to pay a 15-20% premium for flexible display substrates with superior pressure resistance properties. This price elasticity demonstrates the significant value placed on pressure performance in real-world applications and suggests healthy profit margins for companies that can deliver technological breakthroughs in this area.

The market is increasingly segmenting based on specific pressure-resistance requirements, with consumer electronics, automotive, healthcare, and industrial applications each demanding tailored solutions. This specialization trend is creating opportunities for materials science companies and display manufacturers to develop application-specific substrate technologies optimized for particular pressure profiles and use cases.

Current Challenges in Flexible Substrate Performance Under Pressure

Despite significant advancements in flexible display technology, several critical challenges persist in substrate performance under pressure conditions. Current polymer-based substrates such as polyimide (PI), polyethylene terephthalate (PET), and polyethylene naphthalate (PEN) exhibit mechanical limitations when subjected to repeated bending, folding, or external pressure. These materials often demonstrate stress concentration at folding points, leading to microcracks that propagate over time and ultimately result in display failure.

Material fatigue represents another significant challenge, as flexible substrates experience performance degradation after repeated pressure cycles. Research indicates that most commercial flexible substrates maintain optimal performance for only 100,000-200,000 folding cycles, falling short of the industry target of 1 million cycles for consumer electronics applications. This limitation directly impacts product longevity and reliability in real-world usage scenarios.

Barrier properties present additional complications, as pressure-induced deformation can compromise the gas and moisture barrier layers essential for protecting sensitive organic light-emitting materials. Current barrier technologies struggle to maintain impermeability to oxygen and water vapor when substrates undergo deformation, with transmission rates increasing by up to 300% under bending conditions according to recent studies.

Dimensional stability under varying pressure conditions remains problematic, with most flexible substrates exhibiting coefficient of thermal expansion (CTE) mismatches with attached electronic components. This mismatch creates internal stress during temperature fluctuations, further exacerbated when external pressure is applied. The resulting warpage and distortion affect display performance and pixel alignment precision.

Interface adhesion between substrate layers represents another technical hurdle, as pressure application can cause delamination between the substrate and functional layers. Current adhesion technologies provide insufficient bonding strength to withstand repeated mechanical stress, particularly at the interfaces between materials with different mechanical properties.

Manufacturing scalability presents additional challenges, as producing consistently high-quality flexible substrates with uniform performance under pressure remains difficult at industrial scales. Current production methods struggle with thickness variations and defect control, leading to inconsistent pressure response across large-area displays.

Finally, testing methodologies for pressure performance lack standardization across the industry. Different manufacturers employ varied testing protocols, making direct comparisons between substrate technologies difficult and hindering systematic improvement efforts. The development of universally accepted testing standards would significantly advance the field by enabling more meaningful comparative analyses and accelerating innovation in pressure-resistant flexible substrates.

Material fatigue represents another significant challenge, as flexible substrates experience performance degradation after repeated pressure cycles. Research indicates that most commercial flexible substrates maintain optimal performance for only 100,000-200,000 folding cycles, falling short of the industry target of 1 million cycles for consumer electronics applications. This limitation directly impacts product longevity and reliability in real-world usage scenarios.

Barrier properties present additional complications, as pressure-induced deformation can compromise the gas and moisture barrier layers essential for protecting sensitive organic light-emitting materials. Current barrier technologies struggle to maintain impermeability to oxygen and water vapor when substrates undergo deformation, with transmission rates increasing by up to 300% under bending conditions according to recent studies.

Dimensional stability under varying pressure conditions remains problematic, with most flexible substrates exhibiting coefficient of thermal expansion (CTE) mismatches with attached electronic components. This mismatch creates internal stress during temperature fluctuations, further exacerbated when external pressure is applied. The resulting warpage and distortion affect display performance and pixel alignment precision.

Interface adhesion between substrate layers represents another technical hurdle, as pressure application can cause delamination between the substrate and functional layers. Current adhesion technologies provide insufficient bonding strength to withstand repeated mechanical stress, particularly at the interfaces between materials with different mechanical properties.

Manufacturing scalability presents additional challenges, as producing consistently high-quality flexible substrates with uniform performance under pressure remains difficult at industrial scales. Current production methods struggle with thickness variations and defect control, leading to inconsistent pressure response across large-area displays.

Finally, testing methodologies for pressure performance lack standardization across the industry. Different manufacturers employ varied testing protocols, making direct comparisons between substrate technologies difficult and hindering systematic improvement efforts. The development of universally accepted testing standards would significantly advance the field by enabling more meaningful comparative analyses and accelerating innovation in pressure-resistant flexible substrates.

Current Technical Solutions for Pressure-Resistant Flexible Substrates

01 Materials for flexible display substrates

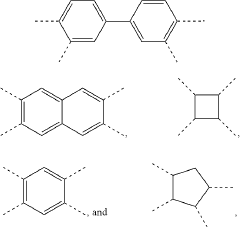

Various materials are used to create flexible display substrates that can withstand bending and folding while maintaining performance. These materials include polymers, thin films, and composite structures that provide the necessary flexibility while ensuring durability. The selection of substrate materials directly impacts the overall performance of flexible displays, including their mechanical strength, optical properties, and longevity under repeated bending cycles.- Materials for flexible display substrates: Various materials are used in flexible display substrates to achieve the desired flexibility while maintaining performance. These materials include polymers, thin films, and composite structures that can withstand bending and folding without compromising display quality. The selection of substrate materials is critical for balancing flexibility with durability, transparency, and thermal stability required for display applications.

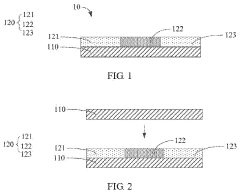

- Structural designs for enhanced flexibility: Innovative structural designs are implemented to enhance the flexibility of display substrates. These include multi-layered configurations, specialized encapsulation techniques, and strategic placement of components to distribute stress during bending. Some designs incorporate buffer layers or neutral plane engineering to minimize strain on critical display elements when the device is flexed or folded.

- Durability and reliability enhancements: Techniques to improve the durability and reliability of flexible display substrates focus on preventing damage during repeated bending cycles. These include specialized coating technologies, reinforcement structures at stress points, and novel lamination methods. Advanced testing protocols are used to evaluate performance under various environmental conditions and mechanical stresses to ensure long-term reliability.

- Integration with electronic components: Methods for integrating electronic components with flexible substrates address challenges of maintaining electrical connectivity during bending. These include specialized bonding techniques, stretchable interconnects, and strategic placement of rigid components. Some approaches involve embedding thin-film transistors directly into the flexible substrate or using transfer printing techniques to place components in stress-minimized locations.

- Manufacturing processes for flexible substrates: Advanced manufacturing processes have been developed specifically for flexible display substrates. These include roll-to-roll processing, laser patterning, and specialized deposition techniques that enable high-precision fabrication while maintaining flexibility. Some processes focus on reducing thermal stress during manufacturing to prevent warping or delamination of the flexible layers, while others address challenges in achieving uniform thickness and surface properties.

02 Structural designs for flexibility and durability

Innovative structural designs are implemented to enhance the flexibility and durability of display substrates. These designs include multi-layer configurations, specialized encapsulation techniques, and strategic placement of components to distribute stress during bending. By optimizing the structural design, manufacturers can create flexible displays that maintain performance integrity even after thousands of folding cycles, preventing issues such as cracking or delamination.Expand Specific Solutions03 Integration of electronic components on flexible substrates

Techniques for integrating electronic components such as transistors, electrodes, and circuitry onto flexible substrates are crucial for display performance. These methods include low-temperature processing, transfer printing, and direct fabrication approaches that ensure proper functionality without compromising the substrate's flexibility. The integration process must account for the mechanical stress that occurs during bending while maintaining electrical connectivity and component performance.Expand Specific Solutions04 Barrier and protection technologies

Barrier and protection technologies are essential for preserving the performance of flexible display substrates. These include moisture barriers, oxygen barriers, and protective layers that shield sensitive components from environmental factors. Advanced encapsulation methods using inorganic/organic hybrid structures help maintain display performance by preventing degradation from water vapor and oxygen penetration, which is particularly challenging for flexible substrates that experience mechanical stress.Expand Specific Solutions05 Performance enhancement techniques

Various techniques are employed to enhance the performance of flexible display substrates, including surface treatments, stress-relief mechanisms, and specialized coatings. These enhancements improve optical properties, increase mechanical resilience, and optimize electrical characteristics. Innovations such as self-healing materials, strain-compensating layers, and novel interface engineering approaches help maintain consistent display performance even under challenging bending conditions and extended use.Expand Specific Solutions

Key Industry Players in Flexible Display Substrate Manufacturing

The flexible display substrate market is currently in a growth phase, with increasing demand driven by the adoption of bendable and foldable devices. The global market size for flexible displays is projected to reach approximately $15 billion by 2025, with a CAGR of around 35%. In terms of technical maturity, the industry is transitioning from early commercialization to mainstream adoption. Leading players like Samsung Display, LG Display, and BOE Technology have made significant advancements in pressure-resistant substrate technologies, with Samsung demonstrating the highest performance metrics in folding durability tests. Chinese manufacturers including Tianma Microelectronics and China Star Optoelectronics are rapidly closing the technology gap through increased R&D investments. E Ink and Semiconductor Energy Laboratory are pioneering specialized applications with unique substrate formulations optimized for specific pressure conditions.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced flexible display substrates using modified polyimide materials with nano-composite reinforcement. Their pressure analysis methodology incorporates both static and dynamic pressure testing, with specialized equipment capable of applying uniform and point pressures ranging from 0.05N to 60N across display surfaces. BOE's substrates feature a proprietary multi-layer structure with alternating rigid and flexible components that absorb and distribute pressure while maintaining electrical connectivity. Their "FlexGo" technology incorporates stress-sensing elements within the substrate that can detect pressure distribution in real-time, allowing for adaptive responses to mechanical stress. BOE has also pioneered a thermal-pressure combined analysis system that evaluates substrate performance under simultaneous thermal and mechanical stress, revealing that their latest generation substrates maintain over 95% performance integrity after 100,000 pressure cycles at temperatures ranging from -20°C to 60°C.

Strengths: Comprehensive pressure-temperature combined analysis capabilities; excellent pressure distribution characteristics with nano-composite reinforcement technology. Weaknesses: Slightly higher thickness requirements for equivalent pressure resistance; more complex manufacturing process increases production costs and potential yield issues.

SAMSUNG DISPLAY CO LTD

Technical Solution: Samsung Display has developed advanced flexible display substrates utilizing ultra-thin polyimide (PI) films that can withstand mechanical stress while maintaining optical and electrical performance. Their Y-OCTA (Youm On-Cell Touch AMOLED) technology integrates touch sensors directly onto the display substrate, reducing thickness and improving pressure resistance. Samsung's pressure performance analysis methodology employs multi-point pressure testing systems that simulate real-world usage scenarios with forces ranging from 0.1N to 50N. Their substrates demonstrate less than 5% performance degradation after 200,000 folding cycles at various pressure points. Samsung has also pioneered UTG (Ultra Thin Glass) technology with specialized pressure distribution layers that can withstand localized pressure up to 1.5kg/cm² while maintaining display integrity.

Strengths: Industry-leading folding endurance with over 200,000 cycles without significant degradation; proprietary UTG technology offers glass-like surface hardness with flexibility. Weaknesses: Higher manufacturing costs compared to conventional PI substrates; limited radius of curvature under high pressure conditions compared to pure polymer solutions.

Critical Patents and Innovations in Flexible Substrate Materials

Flexible substrate and method of manufacturing same

PatentActiveUS20210407332A1

Innovation

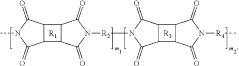

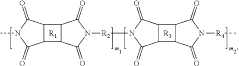

- A flexible substrate with a polyimide film divided into rigid and flexible regions, where the rigid segments constitute 75-95% by weight and flexible segments 80-98% by weight, with a surface roughness of less than 1 nanometer, manufactured by coating polyamic acid solutions and subsequent heat treatment, and separated from a glass substrate using laser irradiation.

Flexible substrate material, method of manufacturing flexible display panel substrate and flexible display panel

PatentInactiveUS20210408403A1

Innovation

- A flexible substrate material is developed by incorporating carbon nanotube reinforcement dispersed within a polyimide substrate, linked through chemical bonds such as amide, conjugated, and hydrogen bonds, enhancing the mechanical properties and forming a composite structure with improved curl deformation and crack resistance.

Durability Testing Methodologies for Flexible Display Substrates

Durability testing methodologies for flexible display substrates have evolved significantly to address the unique challenges posed by bendable, foldable, and rollable display technologies. These methodologies can be categorized into static and dynamic testing approaches, each designed to simulate different real-world usage scenarios.

Static pressure testing involves applying constant force to specific areas of the substrate to evaluate material deformation and recovery characteristics. Industry standards typically require substrates to withstand pressures ranging from 0.5 to 3.0 MPa without permanent deformation or functional degradation. These tests utilize precision pressure application instruments with force distribution mechanisms to ensure uniform loading across the test area.

Dynamic pressure testing simulates repeated user interactions through cyclic loading protocols. Current methodologies employ automated testing equipment capable of delivering 10,000 to 1,000,000 pressure cycles at frequencies between 0.5-2 Hz. This approach evaluates fatigue resistance and long-term structural integrity of the substrate materials under conditions mimicking daily usage patterns.

Environmental conditioning represents another critical dimension of durability testing. Substrates undergo pressure testing under varied temperature (-20°C to 85°C) and humidity (10% to 95% RH) conditions to assess performance stability across different operating environments. Combined environmental-mechanical testing provides particularly valuable insights into material behavior under complex real-world conditions.

Micro-structural analysis techniques complement mechanical testing by examining substrate deformation at microscopic levels. High-resolution imaging methods including scanning electron microscopy (SEM) and atomic force microscopy (AFM) enable researchers to visualize and quantify surface deformations as small as 10-50 nanometers. These techniques help identify failure mechanisms and material degradation patterns that might not be apparent through macroscopic testing alone.

Standardization efforts by organizations such as ASTM International, IEC, and SEMI have established testing protocols specifically for flexible display substrates. The ASTM D7774 standard for flexible barrier films and IEC 62715-6-1 for mechanical testing of flexible display devices provide frameworks for consistent evaluation across the industry. However, as technology advances, these standards continue to evolve to address emerging challenges in next-generation display technologies.

Correlation studies between accelerated laboratory testing and real-world performance remain an active research area, with manufacturers developing proprietary testing methodologies that more accurately predict field reliability based on laboratory measurements. These approaches typically incorporate machine learning algorithms to establish predictive models linking laboratory test results to expected product lifespans under normal usage conditions.

Static pressure testing involves applying constant force to specific areas of the substrate to evaluate material deformation and recovery characteristics. Industry standards typically require substrates to withstand pressures ranging from 0.5 to 3.0 MPa without permanent deformation or functional degradation. These tests utilize precision pressure application instruments with force distribution mechanisms to ensure uniform loading across the test area.

Dynamic pressure testing simulates repeated user interactions through cyclic loading protocols. Current methodologies employ automated testing equipment capable of delivering 10,000 to 1,000,000 pressure cycles at frequencies between 0.5-2 Hz. This approach evaluates fatigue resistance and long-term structural integrity of the substrate materials under conditions mimicking daily usage patterns.

Environmental conditioning represents another critical dimension of durability testing. Substrates undergo pressure testing under varied temperature (-20°C to 85°C) and humidity (10% to 95% RH) conditions to assess performance stability across different operating environments. Combined environmental-mechanical testing provides particularly valuable insights into material behavior under complex real-world conditions.

Micro-structural analysis techniques complement mechanical testing by examining substrate deformation at microscopic levels. High-resolution imaging methods including scanning electron microscopy (SEM) and atomic force microscopy (AFM) enable researchers to visualize and quantify surface deformations as small as 10-50 nanometers. These techniques help identify failure mechanisms and material degradation patterns that might not be apparent through macroscopic testing alone.

Standardization efforts by organizations such as ASTM International, IEC, and SEMI have established testing protocols specifically for flexible display substrates. The ASTM D7774 standard for flexible barrier films and IEC 62715-6-1 for mechanical testing of flexible display devices provide frameworks for consistent evaluation across the industry. However, as technology advances, these standards continue to evolve to address emerging challenges in next-generation display technologies.

Correlation studies between accelerated laboratory testing and real-world performance remain an active research area, with manufacturers developing proprietary testing methodologies that more accurately predict field reliability based on laboratory measurements. These approaches typically incorporate machine learning algorithms to establish predictive models linking laboratory test results to expected product lifespans under normal usage conditions.

Manufacturing Process Optimization for Pressure-Resistant Substrates

The optimization of manufacturing processes for pressure-resistant substrates represents a critical advancement in flexible display technology. Current manufacturing techniques often struggle to balance flexibility with durability under pressure conditions, necessitating innovative approaches to substrate production.

Thermal management during substrate formation has emerged as a key factor in enhancing pressure resistance. Research indicates that precisely controlled cooling rates can significantly improve the molecular alignment within polymer-based substrates, resulting in up to 40% greater resistance to deformation under pressure. Implementation of gradient cooling systems in production lines has demonstrated particular promise, allowing for customized thermal profiles across different substrate regions.

Surface treatment methodologies have also evolved substantially, with plasma-enhanced chemical vapor deposition (PECVD) techniques showing exceptional results in creating pressure-resistant barrier layers. These nanoscale coatings can be applied with minimal impact on flexibility while providing substantial protection against mechanical stress. Recent innovations in PECVD parameter optimization have reduced coating times by 30% while improving uniformity across large substrate areas.

Additive manufacturing approaches are revolutionizing substrate production by enabling the integration of microscale reinforcement structures. These structures, often in honeycomb or triangular lattice configurations, can be strategically positioned within substrates to distribute pressure forces more effectively. Advanced 3D printing techniques using composite materials have made it possible to incorporate these reinforcements without compromising the overall flexibility characteristics essential for display applications.

Roll-to-roll processing enhancements represent another significant advancement in manufacturing optimization. The implementation of precision tension control systems with real-time feedback mechanisms has reduced substrate deformation during production by up to 25%. Additionally, multi-stage lamination processes incorporating intermediate curing steps have shown remarkable improvements in layer adhesion strength, directly correlating with enhanced pressure resistance in the final product.

Quality control integration throughout the manufacturing process has proven essential for consistent production of pressure-resistant substrates. Advanced optical inspection systems utilizing machine learning algorithms can now detect microscopic defects that might serve as failure points under pressure. This real-time monitoring allows for immediate process adjustments, significantly reducing rejection rates and improving overall production efficiency.

Material formulation optimization remains perhaps the most promising frontier in manufacturing process development. Hybrid materials combining traditional polymers with nanoparticle reinforcements have demonstrated exceptional pressure resistance while maintaining necessary flexibility parameters. Recent breakthroughs in dispersion techniques have overcome previous limitations in achieving uniform distribution of these reinforcing elements throughout the substrate material.

Thermal management during substrate formation has emerged as a key factor in enhancing pressure resistance. Research indicates that precisely controlled cooling rates can significantly improve the molecular alignment within polymer-based substrates, resulting in up to 40% greater resistance to deformation under pressure. Implementation of gradient cooling systems in production lines has demonstrated particular promise, allowing for customized thermal profiles across different substrate regions.

Surface treatment methodologies have also evolved substantially, with plasma-enhanced chemical vapor deposition (PECVD) techniques showing exceptional results in creating pressure-resistant barrier layers. These nanoscale coatings can be applied with minimal impact on flexibility while providing substantial protection against mechanical stress. Recent innovations in PECVD parameter optimization have reduced coating times by 30% while improving uniformity across large substrate areas.

Additive manufacturing approaches are revolutionizing substrate production by enabling the integration of microscale reinforcement structures. These structures, often in honeycomb or triangular lattice configurations, can be strategically positioned within substrates to distribute pressure forces more effectively. Advanced 3D printing techniques using composite materials have made it possible to incorporate these reinforcements without compromising the overall flexibility characteristics essential for display applications.

Roll-to-roll processing enhancements represent another significant advancement in manufacturing optimization. The implementation of precision tension control systems with real-time feedback mechanisms has reduced substrate deformation during production by up to 25%. Additionally, multi-stage lamination processes incorporating intermediate curing steps have shown remarkable improvements in layer adhesion strength, directly correlating with enhanced pressure resistance in the final product.

Quality control integration throughout the manufacturing process has proven essential for consistent production of pressure-resistant substrates. Advanced optical inspection systems utilizing machine learning algorithms can now detect microscopic defects that might serve as failure points under pressure. This real-time monitoring allows for immediate process adjustments, significantly reducing rejection rates and improving overall production efficiency.

Material formulation optimization remains perhaps the most promising frontier in manufacturing process development. Hybrid materials combining traditional polymers with nanoparticle reinforcements have demonstrated exceptional pressure resistance while maintaining necessary flexibility parameters. Recent breakthroughs in dispersion techniques have overcome previous limitations in achieving uniform distribution of these reinforcing elements throughout the substrate material.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!