Analyzing the potential of V16 engines for multifuel capabilities

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Multifuel Evolution

The evolution of V16 engines towards multifuel capabilities represents a significant technological advancement in the automotive and power generation industries. This progression has been driven by the need for increased fuel flexibility, improved efficiency, and reduced environmental impact.

In the early stages of V16 engine development, these powerplants were primarily designed for high-performance applications, focusing on maximum power output and speed. However, as environmental concerns and fuel efficiency became more prominent, engineers began exploring ways to adapt V16 engines to operate on multiple fuel types.

The first major step in this evolution was the development of dual-fuel systems, allowing V16 engines to run on both diesel and natural gas. This innovation opened up new possibilities for applications in marine propulsion and stationary power generation, where fuel flexibility could provide significant operational advantages.

As research progressed, engineers tackled the challenge of expanding the range of compatible fuels. Advanced fuel injection systems and sophisticated engine management computers were developed to accommodate varying fuel properties and combustion characteristics. These technologies enabled V16 engines to efficiently utilize a wider array of fuels, including biodiesel, ethanol blends, and even hydrogen.

Concurrently, materials science advancements played a crucial role in enhancing the multifuel capabilities of V16 engines. New alloys and coatings were developed to withstand the corrosive effects of alternative fuels and the higher temperatures associated with their combustion.

The integration of variable valve timing and lift systems further improved the adaptability of V16 engines to different fuel types. These systems allowed for real-time optimization of engine performance based on the specific fuel being used, maximizing efficiency and power output across a broad range of operating conditions.

Recent developments have focused on hybridization and electrification, with V16 engines being combined with electric motors to create highly flexible powertrains. These hybrid systems can seamlessly switch between different fuel types and electric power, further expanding the multifuel capabilities of V16 engines.

Looking ahead, the evolution of V16 engines for multifuel capabilities is likely to continue, with research focusing on advanced combustion strategies, such as homogeneous charge compression ignition (HCCI) and low-temperature combustion. These technologies promise to further enhance fuel flexibility while simultaneously reducing emissions and improving overall engine efficiency.

In the early stages of V16 engine development, these powerplants were primarily designed for high-performance applications, focusing on maximum power output and speed. However, as environmental concerns and fuel efficiency became more prominent, engineers began exploring ways to adapt V16 engines to operate on multiple fuel types.

The first major step in this evolution was the development of dual-fuel systems, allowing V16 engines to run on both diesel and natural gas. This innovation opened up new possibilities for applications in marine propulsion and stationary power generation, where fuel flexibility could provide significant operational advantages.

As research progressed, engineers tackled the challenge of expanding the range of compatible fuels. Advanced fuel injection systems and sophisticated engine management computers were developed to accommodate varying fuel properties and combustion characteristics. These technologies enabled V16 engines to efficiently utilize a wider array of fuels, including biodiesel, ethanol blends, and even hydrogen.

Concurrently, materials science advancements played a crucial role in enhancing the multifuel capabilities of V16 engines. New alloys and coatings were developed to withstand the corrosive effects of alternative fuels and the higher temperatures associated with their combustion.

The integration of variable valve timing and lift systems further improved the adaptability of V16 engines to different fuel types. These systems allowed for real-time optimization of engine performance based on the specific fuel being used, maximizing efficiency and power output across a broad range of operating conditions.

Recent developments have focused on hybridization and electrification, with V16 engines being combined with electric motors to create highly flexible powertrains. These hybrid systems can seamlessly switch between different fuel types and electric power, further expanding the multifuel capabilities of V16 engines.

Looking ahead, the evolution of V16 engines for multifuel capabilities is likely to continue, with research focusing on advanced combustion strategies, such as homogeneous charge compression ignition (HCCI) and low-temperature combustion. These technologies promise to further enhance fuel flexibility while simultaneously reducing emissions and improving overall engine efficiency.

Market Demand Analysis

The market demand for V16 engines with multifuel capabilities is driven by several factors in the current automotive and industrial landscape. As environmental regulations become increasingly stringent, there is a growing need for engines that can operate efficiently on various fuel types, reducing emissions and improving overall sustainability.

In the automotive sector, luxury and high-performance vehicle manufacturers are showing interest in V16 engines with multifuel capabilities. These engines offer the potential to combine power and prestige with environmental responsibility, appealing to a niche market of affluent consumers who demand both performance and eco-friendliness. The ability to switch between different fuel types also provides flexibility in regions where certain fuels may be more readily available or cost-effective.

The marine industry represents another significant market for multifuel V16 engines. Large ships and yachts require powerful engines that can operate efficiently over long distances. The ability to use multiple fuel types allows for greater operational flexibility and compliance with varying environmental regulations in different maritime zones. This adaptability is particularly valuable for vessels that operate internationally.

In the power generation sector, there is a growing demand for flexible and efficient large-scale generators. Multifuel V16 engines can serve as the heart of these systems, providing the ability to switch between different fuel sources based on availability and cost. This flexibility is especially valuable in remote locations or areas with unreliable fuel supply chains, where the ability to use alternative fuels can ensure continuous power generation.

The aviation industry, particularly in the realm of experimental and specialized aircraft, may also present a niche market for multifuel V16 engines. The combination of high power output and fuel flexibility could be attractive for certain aviation applications where weight is less of a concern.

Market analysis indicates that while the overall demand for V16 engines is relatively small compared to more common engine configurations, the multifuel capability adds a unique selling point that could expand their potential applications. The market size for these specialized engines is expected to grow moderately in the coming years, driven by the increasing focus on fuel efficiency and environmental sustainability across various industries.

However, it's important to note that the market for V16 multifuel engines faces competition from alternative technologies, such as electric powertrains and hydrogen fuel cells. The long-term viability of this market will depend on the ability of V16 multifuel engines to offer compelling advantages in terms of power output, fuel flexibility, and overall efficiency compared to these emerging technologies.

In the automotive sector, luxury and high-performance vehicle manufacturers are showing interest in V16 engines with multifuel capabilities. These engines offer the potential to combine power and prestige with environmental responsibility, appealing to a niche market of affluent consumers who demand both performance and eco-friendliness. The ability to switch between different fuel types also provides flexibility in regions where certain fuels may be more readily available or cost-effective.

The marine industry represents another significant market for multifuel V16 engines. Large ships and yachts require powerful engines that can operate efficiently over long distances. The ability to use multiple fuel types allows for greater operational flexibility and compliance with varying environmental regulations in different maritime zones. This adaptability is particularly valuable for vessels that operate internationally.

In the power generation sector, there is a growing demand for flexible and efficient large-scale generators. Multifuel V16 engines can serve as the heart of these systems, providing the ability to switch between different fuel sources based on availability and cost. This flexibility is especially valuable in remote locations or areas with unreliable fuel supply chains, where the ability to use alternative fuels can ensure continuous power generation.

The aviation industry, particularly in the realm of experimental and specialized aircraft, may also present a niche market for multifuel V16 engines. The combination of high power output and fuel flexibility could be attractive for certain aviation applications where weight is less of a concern.

Market analysis indicates that while the overall demand for V16 engines is relatively small compared to more common engine configurations, the multifuel capability adds a unique selling point that could expand their potential applications. The market size for these specialized engines is expected to grow moderately in the coming years, driven by the increasing focus on fuel efficiency and environmental sustainability across various industries.

However, it's important to note that the market for V16 multifuel engines faces competition from alternative technologies, such as electric powertrains and hydrogen fuel cells. The long-term viability of this market will depend on the ability of V16 multifuel engines to offer compelling advantages in terms of power output, fuel flexibility, and overall efficiency compared to these emerging technologies.

Technical Challenges

The development of V16 engines with multifuel capabilities faces several significant technical challenges. One of the primary obstacles is the complexity of designing a combustion system that can efficiently handle various fuel types. Each fuel has unique chemical properties, energy densities, and combustion characteristics, requiring a sophisticated engine management system to optimize performance across different fuel compositions.

Fuel injection systems pose another major challenge. Developing injectors capable of precisely metering and atomizing diverse fuels while maintaining durability under varying combustion conditions is a complex engineering task. The system must adapt to changes in fuel viscosity, density, and volatility to ensure consistent engine performance and emissions control.

Material selection and durability present additional hurdles. The engine components must withstand the corrosive effects of different fuels and their combustion byproducts. This necessitates the use of advanced materials and coatings that can resist wear, corrosion, and thermal stress across a wide range of operating conditions.

Emissions control is a critical area of concern. Meeting stringent environmental regulations while accommodating multiple fuel types requires innovative exhaust aftertreatment systems. These systems must be capable of effectively treating varying exhaust compositions and temperatures resulting from different fuel combustion processes.

Thermal management presents another significant challenge. The varying heat release rates and combustion temperatures of different fuels necessitate a robust cooling system that can maintain optimal engine temperatures across diverse operating conditions. This may require advanced thermal modeling and adaptive cooling strategies.

Lubrication systems must also be designed to cope with the varying chemical compositions of different fuels. The engine oil must maintain its protective properties and resist degradation when exposed to fuel dilution from multiple sources, each with its own potential contaminants and byproducts.

The development of a flexible and robust engine control unit (ECU) is crucial. The ECU must be capable of real-time fuel detection, adaptive combustion control, and seamless switching between fuel types. This requires sophisticated sensors, algorithms, and processing power to optimize engine performance, efficiency, and emissions for each fuel type.

Lastly, the challenge of maintaining high power output and efficiency across various fuels cannot be understated. The engine design must strike a balance between the conflicting requirements of different fuels, potentially necessitating variable compression ratios or other adaptive technologies to optimize performance for each fuel type.

Fuel injection systems pose another major challenge. Developing injectors capable of precisely metering and atomizing diverse fuels while maintaining durability under varying combustion conditions is a complex engineering task. The system must adapt to changes in fuel viscosity, density, and volatility to ensure consistent engine performance and emissions control.

Material selection and durability present additional hurdles. The engine components must withstand the corrosive effects of different fuels and their combustion byproducts. This necessitates the use of advanced materials and coatings that can resist wear, corrosion, and thermal stress across a wide range of operating conditions.

Emissions control is a critical area of concern. Meeting stringent environmental regulations while accommodating multiple fuel types requires innovative exhaust aftertreatment systems. These systems must be capable of effectively treating varying exhaust compositions and temperatures resulting from different fuel combustion processes.

Thermal management presents another significant challenge. The varying heat release rates and combustion temperatures of different fuels necessitate a robust cooling system that can maintain optimal engine temperatures across diverse operating conditions. This may require advanced thermal modeling and adaptive cooling strategies.

Lubrication systems must also be designed to cope with the varying chemical compositions of different fuels. The engine oil must maintain its protective properties and resist degradation when exposed to fuel dilution from multiple sources, each with its own potential contaminants and byproducts.

The development of a flexible and robust engine control unit (ECU) is crucial. The ECU must be capable of real-time fuel detection, adaptive combustion control, and seamless switching between fuel types. This requires sophisticated sensors, algorithms, and processing power to optimize engine performance, efficiency, and emissions for each fuel type.

Lastly, the challenge of maintaining high power output and efficiency across various fuels cannot be understated. The engine design must strike a balance between the conflicting requirements of different fuels, potentially necessitating variable compression ratios or other adaptive technologies to optimize performance for each fuel type.

Current Multifuel Solutions

01 V16 engine design for multi-fuel operation

V16 engines can be designed to operate on multiple fuel types, enhancing their versatility and efficiency. This capability allows for the use of various fuel sources, including gasoline, diesel, and alternative fuels, without significant modifications to the engine structure.- V16 engine design for multi-fuel operation: V16 engines can be designed to operate on multiple fuel types, enhancing their versatility and efficiency. This capability allows for the use of various fuel sources, including gasoline, diesel, and alternative fuels, without significant modifications to the engine structure. The multi-fuel capability is achieved through advanced fuel injection systems and combustion chamber designs that can accommodate different fuel properties.

- Fuel system adaptations for multi-fuel V16 engines: Specialized fuel systems are developed to enable V16 engines to run on multiple fuel types. These systems may include adjustable fuel injectors, variable fuel pressure regulators, and advanced fuel mixing technologies. The adaptations allow for optimal fuel delivery and combustion across different fuel types, maintaining engine performance and efficiency regardless of the fuel used.

- Electronic control systems for multi-fuel V16 engines: Advanced electronic control units (ECUs) are employed in multi-fuel V16 engines to manage fuel selection, injection timing, and combustion parameters. These systems use sensors to detect fuel type and quality, adjusting engine operation in real-time to optimize performance and emissions. The ECUs also manage the transition between different fuel types seamlessly during operation.

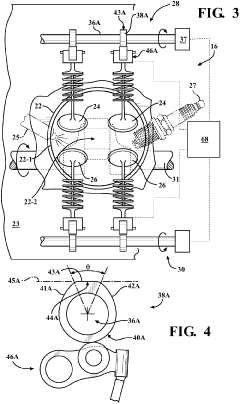

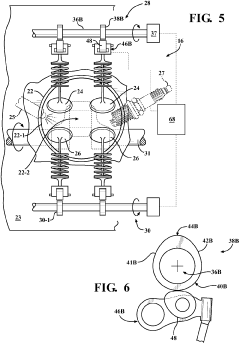

- Combustion chamber design for multi-fuel compatibility: Specialized combustion chamber designs are developed for V16 engines to accommodate multiple fuel types. These designs may include variable compression ratio mechanisms, advanced piston geometries, and optimized cylinder head configurations. The goal is to maintain efficient combustion and power output across different fuel types with varying octane or cetane ratings.

- Emissions control for multi-fuel V16 engines: Multi-fuel V16 engines require sophisticated emissions control systems to meet environmental regulations across different fuel types. These may include adaptive catalytic converters, particulate filters, and exhaust gas recirculation systems that can adjust to varying exhaust compositions. Advanced sensors and control algorithms are used to optimize emissions reduction strategies based on the fuel being used.

02 Fuel injection systems for multi-fuel V16 engines

Advanced fuel injection systems are crucial for V16 engines with multi-fuel capabilities. These systems can adjust fuel delivery and timing based on the type of fuel being used, ensuring optimal performance and combustion efficiency across different fuel types.Expand Specific Solutions03 Electronic control units for multi-fuel management

Sophisticated electronic control units (ECUs) are essential for managing the operation of multi-fuel V16 engines. These ECUs can detect the fuel type, adjust engine parameters, and optimize performance in real-time, ensuring smooth operation regardless of the fuel being used.Expand Specific Solutions04 Combustion chamber design for multi-fuel compatibility

The combustion chamber design of V16 engines can be optimized to accommodate multiple fuel types. This may include variable compression ratio systems, advanced piston designs, and specialized cylinder head configurations to ensure efficient combustion across different fuel properties.Expand Specific Solutions05 Exhaust aftertreatment systems for multi-fuel V16 engines

Multi-fuel V16 engines require versatile exhaust aftertreatment systems to handle emissions from various fuel types. These systems may incorporate adaptive catalytic converters, particulate filters, and selective catalytic reduction technologies to ensure compliance with emission standards across different fuels.Expand Specific Solutions

Key Industry Players

The development of V16 engines with multifuel capabilities is in an early stage, with a relatively small market size but growing potential. The technology is not yet mature, with major players like Toyota, Honda, and Ford investing in research and development. Companies such as Guangxi Yuchai Machinery and Caterpillar are exploring applications in heavy-duty and industrial sectors. The competitive landscape is characterized by a mix of established automotive manufacturers and specialized engine producers, each leveraging their expertise to advance multifuel V16 technology. As environmental regulations tighten, this field is expected to see increased innovation and market expansion.

Toyota Motor Corp.

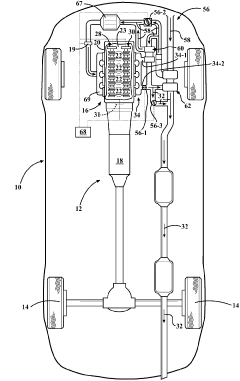

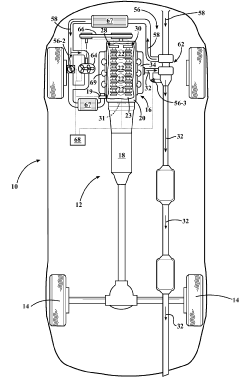

Technical Solution: Toyota has been exploring the potential of V16 engines for multifuel capabilities, focusing on their GD engine series. They have developed a flexible fuel system that allows the V16 engine to operate on various fuel types, including gasoline, diesel, and biofuels[1]. The engine incorporates advanced fuel injection technology and variable valve timing to optimize combustion for different fuel types. Toyota's approach includes a sophisticated engine control unit (ECU) that can detect the fuel type and adjust engine parameters accordingly[3]. This system also features a dual-fuel tank design, allowing for seamless switching between fuel types without compromising performance[5].

Strengths: Versatility in fuel usage, reduced dependency on a single fuel type, and potential for lower emissions. Weaknesses: Increased complexity in engine design and potentially higher manufacturing costs.

Honda Motor Co., Ltd.

Technical Solution: Honda's research into V16 engines with multifuel capabilities has led to the development of their i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) technology adapted for larger displacement engines. This system allows for precise control of valve timing and lift, enabling efficient combustion across various fuel types[2]. Honda has integrated a multi-port fuel injection system that can handle different fuel compositions, from gasoline to ethanol blends and even compressed natural gas (CNG)[4]. The company has also implemented an advanced sensors array to continuously monitor fuel quality and adjust engine parameters in real-time, ensuring optimal performance and emissions control regardless of the fuel used[6].

Strengths: High efficiency across multiple fuel types, advanced engine management system. Weaknesses: Potential increase in engine weight and complexity, which may affect vehicle dynamics.

Core V16 Innovations

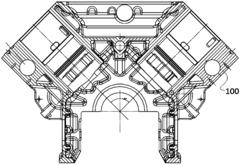

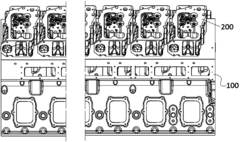

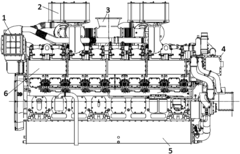

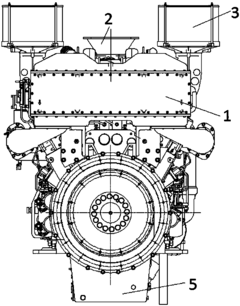

High-power V16 diesel engine

PatentActiveCN108194198A

Innovation

- A high-power V-shaped 16-cylinder diesel engine is designed, which uses a V-shaped cylinder block, 16 single cylinder heads, four turbochargers and an intercooler, combined with a cooling system of high and low temperature water circulation loops, to achieve turbocharging through Technology and classified cooling systems increase air density and lower temperatures to meet the needs of high power and torque.

Elevated compression ratio internal combustion engine with multi-stage boosting

PatentWO2016145570A8

Innovation

- Multi-stage boosting system incorporating turbochargers and a supercharger for enhanced engine performance.

- Integration of charge-air coolers for each boosting stage to increase intake air density and volumetric efficiency.

- Programmable controller for precise regulation of fuel injection and air-fuel mixture in conjunction with the multi-stage boosting system.

Environmental Impact

The environmental impact of V16 engines with multifuel capabilities is a critical consideration in the development and adoption of this technology. These engines, while offering flexibility in fuel usage, also present unique challenges and opportunities in terms of emissions and overall ecological footprint.

One of the primary advantages of multifuel V16 engines is their potential to reduce dependence on a single fuel source, which can lead to more sustainable energy practices. By allowing the use of various fuel types, including biofuels and synthetic fuels, these engines can potentially lower greenhouse gas emissions compared to traditional single-fuel engines. This flexibility also enables the utilization of locally available fuel sources, potentially reducing the environmental impact associated with fuel transportation.

However, the environmental benefits of multifuel V16 engines are not without caveats. The combustion of different fuel types can result in varying emission profiles, potentially complicating emission control strategies. This variability may require more sophisticated exhaust aftertreatment systems to ensure compliance with stringent environmental regulations across different fuel types.

The manufacturing process of multifuel V16 engines also warrants consideration from an environmental perspective. The complexity of these engines may require additional resources and energy in production, potentially offsetting some of the environmental gains achieved during operation. Life cycle assessments would be crucial in determining the overall environmental impact of these engines from production to end-of-life.

Noise pollution is another environmental factor to consider. V16 engines are known for their power output, which often correlates with increased noise levels. While multifuel capabilities may not directly affect noise production, the potential for these engines to be used in various applications could expand their impact on noise pollution in different environments.

The disposal and recycling of multifuel V16 engines present both challenges and opportunities. The diverse materials used in these complex engines may complicate recycling processes. However, their longevity and potential for refurbishment could extend their useful life, reducing the frequency of disposal and the associated environmental impact.

In conclusion, while multifuel V16 engines offer promising environmental benefits through fuel flexibility and potential emission reductions, their overall environmental impact is complex and multifaceted. Comprehensive studies and ongoing technological advancements will be crucial in maximizing the environmental benefits of these engines while mitigating potential drawbacks.

One of the primary advantages of multifuel V16 engines is their potential to reduce dependence on a single fuel source, which can lead to more sustainable energy practices. By allowing the use of various fuel types, including biofuels and synthetic fuels, these engines can potentially lower greenhouse gas emissions compared to traditional single-fuel engines. This flexibility also enables the utilization of locally available fuel sources, potentially reducing the environmental impact associated with fuel transportation.

However, the environmental benefits of multifuel V16 engines are not without caveats. The combustion of different fuel types can result in varying emission profiles, potentially complicating emission control strategies. This variability may require more sophisticated exhaust aftertreatment systems to ensure compliance with stringent environmental regulations across different fuel types.

The manufacturing process of multifuel V16 engines also warrants consideration from an environmental perspective. The complexity of these engines may require additional resources and energy in production, potentially offsetting some of the environmental gains achieved during operation. Life cycle assessments would be crucial in determining the overall environmental impact of these engines from production to end-of-life.

Noise pollution is another environmental factor to consider. V16 engines are known for their power output, which often correlates with increased noise levels. While multifuel capabilities may not directly affect noise production, the potential for these engines to be used in various applications could expand their impact on noise pollution in different environments.

The disposal and recycling of multifuel V16 engines present both challenges and opportunities. The diverse materials used in these complex engines may complicate recycling processes. However, their longevity and potential for refurbishment could extend their useful life, reducing the frequency of disposal and the associated environmental impact.

In conclusion, while multifuel V16 engines offer promising environmental benefits through fuel flexibility and potential emission reductions, their overall environmental impact is complex and multifaceted. Comprehensive studies and ongoing technological advancements will be crucial in maximizing the environmental benefits of these engines while mitigating potential drawbacks.

Fuel Supply Infrastructure

The development of V16 engines with multifuel capabilities necessitates a comprehensive analysis of the existing fuel supply infrastructure and its potential for adaptation. Currently, the global fuel supply network is predominantly designed to support conventional fossil fuels, with gasoline and diesel being the most widely available options. This infrastructure includes refineries, storage facilities, transportation systems, and retail distribution points.

For V16 engines to effectively utilize multiple fuel types, significant modifications to the existing fuel supply chain may be required. One of the primary challenges is the need for separate storage and distribution systems for different fuel types, as mixing or contamination could lead to engine performance issues or damage. This would involve the installation of additional storage tanks, fuel lines, and dispensing equipment at fueling stations.

The expansion of alternative fuel availability is crucial for the widespread adoption of multifuel V16 engines. This includes the development of infrastructure for biofuels, synthetic fuels, and potentially hydrogen. Biofuel production and distribution networks are growing, particularly for ethanol and biodiesel, but their availability varies significantly by region. Synthetic fuel infrastructure is still in its infancy and would require substantial investment to scale up.

Hydrogen fuel cell technology, while promising for its zero-emission potential, faces significant hurdles in terms of infrastructure development. The creation of a hydrogen distribution network, including production facilities, transportation systems, and fueling stations, would require extensive capital investment and technological advancements in storage and safety protocols.

The integration of smart technologies into the fuel supply infrastructure could greatly enhance the feasibility of multifuel V16 engines. IoT-enabled sensors and real-time monitoring systems could help manage fuel quality, optimize distribution, and provide valuable data on fuel consumption patterns. This would allow for more efficient supply chain management and better alignment with consumer demand for various fuel types.

Regulatory frameworks and government policies play a crucial role in shaping the fuel supply infrastructure. Incentives for alternative fuel production and distribution, as well as mandates for fuel diversification, could accelerate the development of a more versatile fuel supply network. However, these policies must be carefully balanced with economic considerations and technological readiness to ensure a smooth transition.

In conclusion, the potential for V16 engines with multifuel capabilities is closely tied to the evolution of the fuel supply infrastructure. While significant challenges exist, ongoing advancements in fuel production, distribution technologies, and supportive policies are paving the way for a more diverse and flexible fuel supply ecosystem that could support the widespread adoption of multifuel V16 engines.

For V16 engines to effectively utilize multiple fuel types, significant modifications to the existing fuel supply chain may be required. One of the primary challenges is the need for separate storage and distribution systems for different fuel types, as mixing or contamination could lead to engine performance issues or damage. This would involve the installation of additional storage tanks, fuel lines, and dispensing equipment at fueling stations.

The expansion of alternative fuel availability is crucial for the widespread adoption of multifuel V16 engines. This includes the development of infrastructure for biofuels, synthetic fuels, and potentially hydrogen. Biofuel production and distribution networks are growing, particularly for ethanol and biodiesel, but their availability varies significantly by region. Synthetic fuel infrastructure is still in its infancy and would require substantial investment to scale up.

Hydrogen fuel cell technology, while promising for its zero-emission potential, faces significant hurdles in terms of infrastructure development. The creation of a hydrogen distribution network, including production facilities, transportation systems, and fueling stations, would require extensive capital investment and technological advancements in storage and safety protocols.

The integration of smart technologies into the fuel supply infrastructure could greatly enhance the feasibility of multifuel V16 engines. IoT-enabled sensors and real-time monitoring systems could help manage fuel quality, optimize distribution, and provide valuable data on fuel consumption patterns. This would allow for more efficient supply chain management and better alignment with consumer demand for various fuel types.

Regulatory frameworks and government policies play a crucial role in shaping the fuel supply infrastructure. Incentives for alternative fuel production and distribution, as well as mandates for fuel diversification, could accelerate the development of a more versatile fuel supply network. However, these policies must be carefully balanced with economic considerations and technological readiness to ensure a smooth transition.

In conclusion, the potential for V16 engines with multifuel capabilities is closely tied to the evolution of the fuel supply infrastructure. While significant challenges exist, ongoing advancements in fuel production, distribution technologies, and supportive policies are paving the way for a more diverse and flexible fuel supply ecosystem that could support the widespread adoption of multifuel V16 engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!