Prospects of V16 engines in breakthrough fuel technologies

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The V16 engine, a marvel of automotive engineering, has undergone significant evolution since its inception in the early 20th century. Initially developed for luxury automobiles and high-performance racing cars, the V16 configuration has seen various iterations and improvements over the decades.

In the 1930s, Cadillac introduced one of the first production V16 engines, setting a new standard for power and smoothness in luxury vehicles. This 7.4-liter engine produced an impressive 165 horsepower, a remarkable feat for its time. The Cadillac V16 became a symbol of automotive excellence and engineering prowess.

During World War II, the development of V16 engines shifted towards aviation applications. The Allies utilized V16 engines in various aircraft, including the Napier Sabre, which powered fighter planes like the Hawker Typhoon. These engines demonstrated the potential for high power output in a relatively compact package.

Post-war, the automotive industry saw a resurgence of interest in V16 engines for high-end luxury vehicles. Notably, BMW experimented with a 6.7-liter V16 engine in the 1980s for their flagship 7-Series, though it never reached production. This period marked a shift towards exploring the limits of engine design and performance.

In recent years, the focus of V16 engine development has turned towards integrating advanced technologies and addressing environmental concerns. Manufacturers have explored ways to improve fuel efficiency and reduce emissions while maintaining the power and prestige associated with V16 engines. This has led to the incorporation of technologies such as direct fuel injection, variable valve timing, and cylinder deactivation.

The advent of hybrid and electric powertrains has also influenced V16 engine evolution. Some concept cars have showcased V16 engines paired with electric motors, creating hybrid powertrains that offer both high performance and improved fuel economy. This trend reflects the industry's move towards more sustainable yet powerful propulsion systems.

As we look towards the future, the evolution of V16 engines is likely to continue in the realm of breakthrough fuel technologies. Research into alternative fuels such as hydrogen and synthetic fuels presents new opportunities for V16 engine design. These advancements could potentially allow V16 engines to maintain their status as pinnacles of automotive engineering while meeting increasingly stringent environmental regulations.

In the 1930s, Cadillac introduced one of the first production V16 engines, setting a new standard for power and smoothness in luxury vehicles. This 7.4-liter engine produced an impressive 165 horsepower, a remarkable feat for its time. The Cadillac V16 became a symbol of automotive excellence and engineering prowess.

During World War II, the development of V16 engines shifted towards aviation applications. The Allies utilized V16 engines in various aircraft, including the Napier Sabre, which powered fighter planes like the Hawker Typhoon. These engines demonstrated the potential for high power output in a relatively compact package.

Post-war, the automotive industry saw a resurgence of interest in V16 engines for high-end luxury vehicles. Notably, BMW experimented with a 6.7-liter V16 engine in the 1980s for their flagship 7-Series, though it never reached production. This period marked a shift towards exploring the limits of engine design and performance.

In recent years, the focus of V16 engine development has turned towards integrating advanced technologies and addressing environmental concerns. Manufacturers have explored ways to improve fuel efficiency and reduce emissions while maintaining the power and prestige associated with V16 engines. This has led to the incorporation of technologies such as direct fuel injection, variable valve timing, and cylinder deactivation.

The advent of hybrid and electric powertrains has also influenced V16 engine evolution. Some concept cars have showcased V16 engines paired with electric motors, creating hybrid powertrains that offer both high performance and improved fuel economy. This trend reflects the industry's move towards more sustainable yet powerful propulsion systems.

As we look towards the future, the evolution of V16 engines is likely to continue in the realm of breakthrough fuel technologies. Research into alternative fuels such as hydrogen and synthetic fuels presents new opportunities for V16 engine design. These advancements could potentially allow V16 engines to maintain their status as pinnacles of automotive engineering while meeting increasingly stringent environmental regulations.

Market Analysis

The market for V16 engines in breakthrough fuel technologies presents a complex landscape of challenges and opportunities. While traditional V16 engines have been primarily associated with luxury and high-performance vehicles, their potential in emerging fuel technologies opens new avenues for market growth and innovation.

The global automotive industry is experiencing a significant shift towards cleaner and more efficient propulsion systems. This transition is driven by stringent environmental regulations, increasing consumer awareness, and the need for sustainable transportation solutions. In this context, the market for V16 engines integrated with breakthrough fuel technologies is poised for potential expansion.

One of the key market drivers is the demand for high-performance vehicles that can meet both power requirements and environmental standards. Luxury car manufacturers and specialized vehicle producers are exploring ways to incorporate advanced fuel technologies into V16 engines to maintain their appeal while addressing sustainability concerns. This trend is particularly evident in markets where there is a strong preference for large, powerful engines combined with a growing emphasis on environmental responsibility.

The marine and aviation sectors also present significant market opportunities for V16 engines with breakthrough fuel technologies. Large vessels and aircraft require powerful propulsion systems, and the integration of innovative fuel solutions could provide a competitive edge in these industries. As these sectors face increasing pressure to reduce emissions, the development of V16 engines compatible with alternative fuels or hybrid systems could capture a substantial market share.

However, the market also faces notable challenges. The high cost associated with developing and producing V16 engines with breakthrough fuel technologies may limit their widespread adoption, particularly in mass-market vehicles. Additionally, the ongoing shift towards electric and hydrogen fuel cell technologies in the automotive sector could potentially overshadow the development of advanced internal combustion engines.

Despite these challenges, niche markets and specialized applications continue to drive demand for V16 engines. The racing industry, for instance, remains a significant consumer of high-performance engines and could serve as a testing ground for new fuel technologies in V16 configurations. Furthermore, the defense sector, which often requires powerful and reliable engines for various applications, could provide a stable market for advanced V16 engines.

The market potential for V16 engines with breakthrough fuel technologies is closely tied to ongoing research and development efforts. As new fuel formulations and combustion technologies emerge, the adaptability of V16 engines to these innovations will play a crucial role in determining their market viability. Collaborations between engine manufacturers, fuel technology companies, and research institutions are likely to shape the future market landscape for these advanced propulsion systems.

The global automotive industry is experiencing a significant shift towards cleaner and more efficient propulsion systems. This transition is driven by stringent environmental regulations, increasing consumer awareness, and the need for sustainable transportation solutions. In this context, the market for V16 engines integrated with breakthrough fuel technologies is poised for potential expansion.

One of the key market drivers is the demand for high-performance vehicles that can meet both power requirements and environmental standards. Luxury car manufacturers and specialized vehicle producers are exploring ways to incorporate advanced fuel technologies into V16 engines to maintain their appeal while addressing sustainability concerns. This trend is particularly evident in markets where there is a strong preference for large, powerful engines combined with a growing emphasis on environmental responsibility.

The marine and aviation sectors also present significant market opportunities for V16 engines with breakthrough fuel technologies. Large vessels and aircraft require powerful propulsion systems, and the integration of innovative fuel solutions could provide a competitive edge in these industries. As these sectors face increasing pressure to reduce emissions, the development of V16 engines compatible with alternative fuels or hybrid systems could capture a substantial market share.

However, the market also faces notable challenges. The high cost associated with developing and producing V16 engines with breakthrough fuel technologies may limit their widespread adoption, particularly in mass-market vehicles. Additionally, the ongoing shift towards electric and hydrogen fuel cell technologies in the automotive sector could potentially overshadow the development of advanced internal combustion engines.

Despite these challenges, niche markets and specialized applications continue to drive demand for V16 engines. The racing industry, for instance, remains a significant consumer of high-performance engines and could serve as a testing ground for new fuel technologies in V16 configurations. Furthermore, the defense sector, which often requires powerful and reliable engines for various applications, could provide a stable market for advanced V16 engines.

The market potential for V16 engines with breakthrough fuel technologies is closely tied to ongoing research and development efforts. As new fuel formulations and combustion technologies emerge, the adaptability of V16 engines to these innovations will play a crucial role in determining their market viability. Collaborations between engine manufacturers, fuel technology companies, and research institutions are likely to shape the future market landscape for these advanced propulsion systems.

Technical Challenges

The development of V16 engines in the context of breakthrough fuel technologies faces several significant technical challenges. One of the primary obstacles is the inherent complexity of V16 engine design, which requires precise engineering to ensure optimal performance and efficiency. The large number of cylinders and moving parts increases the potential for mechanical issues and wear, necessitating advanced materials and manufacturing techniques to maintain reliability.

Fuel efficiency remains a critical concern for V16 engines, particularly in an era focused on reducing carbon emissions. The sheer size and power output of these engines often result in higher fuel consumption compared to smaller configurations. Integrating breakthrough fuel technologies to improve efficiency while maintaining the characteristic power and performance of V16 engines presents a formidable engineering challenge.

Emissions control is another major hurdle for V16 engines. Stricter environmental regulations worldwide demand cleaner exhaust outputs, which is particularly challenging for large displacement engines. Developing effective aftertreatment systems that can handle the volume and composition of exhaust gases from a V16 engine without significantly impacting performance is a complex task.

The integration of breakthrough fuel technologies, such as hydrogen or synthetic fuels, into V16 engines introduces additional technical challenges. These may include redesigning fuel delivery systems, modifying combustion chambers, and developing new engine management systems to optimize performance with alternative fuels. Ensuring compatibility between advanced fuels and existing engine materials and components is crucial to prevent degradation and maintain longevity.

Thermal management presents another significant challenge for V16 engines, especially when considering breakthrough fuel technologies. The heat generated by 16 cylinders requires sophisticated cooling systems to prevent overheating and maintain optimal operating temperatures. This becomes even more critical when dealing with alternative fuels that may have different combustion characteristics and heat profiles.

Weight reduction is a persistent challenge in V16 engine development. The inherent mass of these large engines can negatively impact vehicle dynamics and overall efficiency. Engineers must explore innovative materials and design techniques to minimize weight without compromising structural integrity or performance.

Lastly, the cost-effectiveness of V16 engines in the context of breakthrough fuel technologies poses a significant challenge. The complexity of these engines, combined with the integration of cutting-edge fuel systems, can lead to high production and maintenance costs. Balancing the desire for high performance with economic viability and market demand requires careful consideration and innovative approaches to design and manufacturing.

Fuel efficiency remains a critical concern for V16 engines, particularly in an era focused on reducing carbon emissions. The sheer size and power output of these engines often result in higher fuel consumption compared to smaller configurations. Integrating breakthrough fuel technologies to improve efficiency while maintaining the characteristic power and performance of V16 engines presents a formidable engineering challenge.

Emissions control is another major hurdle for V16 engines. Stricter environmental regulations worldwide demand cleaner exhaust outputs, which is particularly challenging for large displacement engines. Developing effective aftertreatment systems that can handle the volume and composition of exhaust gases from a V16 engine without significantly impacting performance is a complex task.

The integration of breakthrough fuel technologies, such as hydrogen or synthetic fuels, into V16 engines introduces additional technical challenges. These may include redesigning fuel delivery systems, modifying combustion chambers, and developing new engine management systems to optimize performance with alternative fuels. Ensuring compatibility between advanced fuels and existing engine materials and components is crucial to prevent degradation and maintain longevity.

Thermal management presents another significant challenge for V16 engines, especially when considering breakthrough fuel technologies. The heat generated by 16 cylinders requires sophisticated cooling systems to prevent overheating and maintain optimal operating temperatures. This becomes even more critical when dealing with alternative fuels that may have different combustion characteristics and heat profiles.

Weight reduction is a persistent challenge in V16 engine development. The inherent mass of these large engines can negatively impact vehicle dynamics and overall efficiency. Engineers must explore innovative materials and design techniques to minimize weight without compromising structural integrity or performance.

Lastly, the cost-effectiveness of V16 engines in the context of breakthrough fuel technologies poses a significant challenge. The complexity of these engines, combined with the integration of cutting-edge fuel systems, can lead to high production and maintenance costs. Balancing the desire for high performance with economic viability and market demand requires careful consideration and innovative approaches to design and manufacturing.

Current V16 Solutions

01 V16 engine design and configuration

V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V-shape. These engines are typically used in high-performance vehicles, marine applications, and industrial machinery. The V-configuration allows for a more compact design compared to inline engines, while still providing significant power output.- V16 engine design and configuration: V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V-shape. These engines are typically used in high-performance vehicles, marine applications, and industrial machinery. The V-configuration allows for a more compact design compared to inline engines with the same number of cylinders, while still providing significant power output.

- V16 engine applications in vehicles: V16 engines are often employed in luxury and high-performance automobiles, as well as in some specialized racing vehicles. These engines provide exceptional power and torque, making them suitable for large, heavy vehicles that require significant propulsion. The use of V16 engines in vehicles often necessitates specialized cooling systems and reinforced chassis designs to accommodate the engine's size and power output.

- Historical development of V16 engines: The development of V16 engines dates back to the early 20th century, with various applications in automotive, marine, and aviation industries. Early V16 designs were often used in luxury automobiles and racing cars, showcasing the pinnacle of engineering capabilities at the time. Over the years, V16 engines have evolved in terms of efficiency, power output, and reliability, though their use has become more specialized due to their complexity and fuel consumption.

- V16 engine control systems: Modern V16 engines incorporate advanced control systems to manage their complex operation. These systems may include electronic fuel injection, variable valve timing, and sophisticated engine management computers. Such control systems are crucial for optimizing performance, fuel efficiency, and emissions in these large, powerful engines. Additionally, they may integrate with other vehicle systems for improved overall performance and diagnostics.

- V16 engine cooling and lubrication: Due to their size and power output, V16 engines require advanced cooling and lubrication systems. These may include high-capacity radiators, multiple oil pumps, and sophisticated oil circulation systems. Effective cooling and lubrication are essential for maintaining engine performance and longevity, particularly in high-performance applications where the engine may be subjected to extreme operating conditions.

02 V16 engine applications in vehicles

V16 engines are often employed in luxury and high-performance automobiles, as well as in some specialized vehicles such as racing cars and concept vehicles. These engines provide exceptional power and torque, making them suitable for vehicles that require outstanding performance characteristics.Expand Specific Solutions03 Historical development of V16 engines

The development of V16 engines dates back to the early 20th century, with various designs and improvements made over the years. Early applications included aircraft engines and luxury automobiles. The evolution of V16 engines has led to increased efficiency, power output, and reliability.Expand Specific Solutions04 V16 engine control systems and optimization

Modern V16 engines incorporate advanced control systems and optimization techniques to improve performance, fuel efficiency, and emissions. These may include electronic fuel injection, variable valve timing, and sophisticated engine management systems to ensure optimal operation across various operating conditions.Expand Specific Solutions05 V16 engine manufacturing and assembly

The manufacturing and assembly of V16 engines require specialized processes and equipment due to their complexity and size. This includes precision machining of components, advanced assembly techniques, and rigorous quality control measures to ensure the reliability and performance of these high-output engines.Expand Specific Solutions

Key Industry Players

The V16 engine technology in breakthrough fuel technologies is in an early development stage, with limited market size and low technological maturity. The competitive landscape is characterized by research efforts from major automotive manufacturers and academic institutions, rather than widespread commercial applications. Companies like Honda, Toyota, and Ford are likely focusing on R&D to explore potential advantages of V16 configurations in alternative fuel systems. However, the technology remains largely experimental, with challenges in efficiency, cost, and practicality compared to more established engine designs. As environmental regulations tighten, the future of V16 engines in breakthrough fuel technologies will depend on their ability to demonstrate significant performance or emissions benefits over existing solutions.

Toyota Motor Corp.

Technical Solution: Toyota is exploring the potential of V16 engines in breakthrough fuel technologies, focusing on hydrogen combustion engines. They have developed a prototype V16 hydrogen engine that combines the power of a large displacement engine with the environmental benefits of hydrogen fuel[1]. The engine utilizes direct hydrogen injection and advanced combustion control to achieve high power output while producing zero CO2 emissions. Toyota's approach involves modifying existing engine designs to run on hydrogen, potentially allowing for a smoother transition to cleaner technologies while leveraging current manufacturing capabilities[2]. The company is also investigating the use of synthetic fuels in V16 engines as a complementary strategy to hydrogen, aiming to create a diverse range of sustainable powertrain options[3].

Strengths: Leverages existing engine technology, zero CO2 emissions, high power output. Weaknesses: Limited hydrogen infrastructure, potential high costs of hydrogen production and storage.

Ford Global Technologies LLC

Technical Solution: Ford is investigating the potential of V16 engines in combination with advanced biofuels and synthetic fuels. Their research focuses on developing a high-efficiency V16 engine that can run on various sustainable fuel sources, including advanced ethanol blends and e-fuels[1]. The company is exploring cylinder deactivation technology to improve fuel efficiency in V16 engines when full power is not required[2]. Ford is also integrating hybrid technology with V16 engines, creating a system that combines the power of a large displacement engine with the efficiency benefits of electrification[3]. This approach aims to provide a transitional solution that offers both high performance and improved environmental credentials.

Strengths: Flexibility in fuel sources, potential for high power and efficiency. Weaknesses: Complexity of the hybrid system, potential high production costs.

Breakthrough Fuels

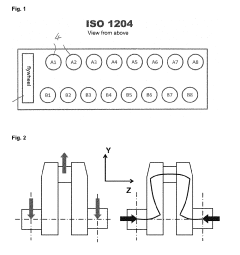

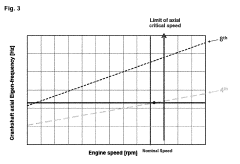

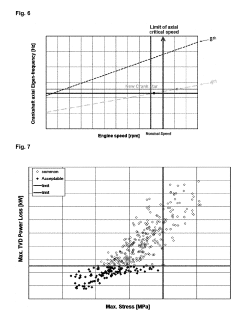

V16 crankstar and firing sequences

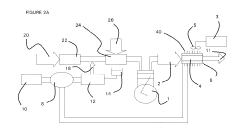

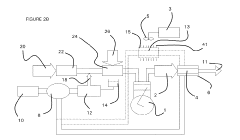

PatentActiveUS20190249598A1

Innovation

- The implementation of specific firing sequences and crankshaft designs with lengthwise symmetric or quasi-symmetric crank stars, combined with a torsional vibration damper, to optimize the angular sequence of crank throws and firing intervals, reducing axial and torsional vibrations and enhancing dynamic behavior.

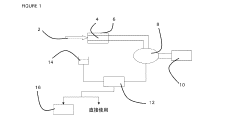

fuel generator

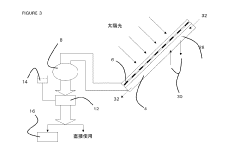

PatentInactiveJP2014529676A

Innovation

- A fuel generator system that converts waste heat from combustion devices into electrical energy to power a fuel cell for generating hydrogen (H2) or Brown's gas (HHO), using thermoelectric modules and a power supply means to optimize energy use without additional engine load.

Environmental Impact

The environmental impact of V16 engines in breakthrough fuel technologies is a critical consideration in the development and adoption of these advanced powertrains. While V16 engines have traditionally been associated with high performance and luxury vehicles, their potential in new fuel technologies presents both challenges and opportunities for environmental sustainability.

One of the primary environmental concerns with V16 engines is their fuel consumption. Historically, these large displacement engines have been known for their high fuel consumption rates, contributing to increased carbon emissions. However, breakthrough fuel technologies offer the potential to mitigate these effects. Advanced biofuels, synthetic fuels, and hydrogen combustion systems could significantly reduce the carbon footprint of V16 engines, aligning them more closely with global emissions reduction targets.

The manufacturing process of V16 engines also has environmental implications. The production of these complex powertrains typically requires more resources and energy compared to smaller engines. However, advancements in manufacturing techniques, such as 3D printing and the use of lightweight materials, could reduce the environmental impact of production. Additionally, the longevity and durability associated with V16 engines may offset some of the initial environmental costs over the engine's lifecycle.

Noise pollution is another environmental factor to consider. V16 engines are known for their distinctive sound, which can contribute to urban noise pollution. However, breakthrough fuel technologies may offer solutions to this issue. For instance, hydrogen-powered V16 engines could potentially operate more quietly than their traditional counterparts, reducing noise pollution in urban environments.

The recycling and end-of-life management of V16 engines also play a crucial role in their overall environmental impact. As these engines often contain valuable materials, developing efficient recycling processes for components and breakthrough fuel system parts could contribute to a more circular economy, reducing waste and resource consumption.

Lastly, the potential for V16 engines to serve as testbeds for breakthrough fuel technologies could have broader positive environmental implications. Innovations developed for these high-performance engines could trickle down to more mainstream applications, accelerating the adoption of cleaner technologies across the automotive industry. This could lead to a net positive environmental impact, despite the initial resource-intensive nature of V16 engines.

One of the primary environmental concerns with V16 engines is their fuel consumption. Historically, these large displacement engines have been known for their high fuel consumption rates, contributing to increased carbon emissions. However, breakthrough fuel technologies offer the potential to mitigate these effects. Advanced biofuels, synthetic fuels, and hydrogen combustion systems could significantly reduce the carbon footprint of V16 engines, aligning them more closely with global emissions reduction targets.

The manufacturing process of V16 engines also has environmental implications. The production of these complex powertrains typically requires more resources and energy compared to smaller engines. However, advancements in manufacturing techniques, such as 3D printing and the use of lightweight materials, could reduce the environmental impact of production. Additionally, the longevity and durability associated with V16 engines may offset some of the initial environmental costs over the engine's lifecycle.

Noise pollution is another environmental factor to consider. V16 engines are known for their distinctive sound, which can contribute to urban noise pollution. However, breakthrough fuel technologies may offer solutions to this issue. For instance, hydrogen-powered V16 engines could potentially operate more quietly than their traditional counterparts, reducing noise pollution in urban environments.

The recycling and end-of-life management of V16 engines also play a crucial role in their overall environmental impact. As these engines often contain valuable materials, developing efficient recycling processes for components and breakthrough fuel system parts could contribute to a more circular economy, reducing waste and resource consumption.

Lastly, the potential for V16 engines to serve as testbeds for breakthrough fuel technologies could have broader positive environmental implications. Innovations developed for these high-performance engines could trickle down to more mainstream applications, accelerating the adoption of cleaner technologies across the automotive industry. This could lead to a net positive environmental impact, despite the initial resource-intensive nature of V16 engines.

Economic Feasibility

The economic feasibility of V16 engines in breakthrough fuel technologies presents a complex landscape of challenges and opportunities. Initial development and production costs for V16 engines are significantly higher compared to more common engine configurations, primarily due to their increased complexity and lower production volumes. This cost factor has historically limited their adoption to high-end luxury and performance vehicles, as well as specialized industrial applications.

However, the potential integration of breakthrough fuel technologies could alter this economic equation. Advanced biofuels, synthetic fuels, or hydrogen combustion systems might leverage the V16 configuration's inherent advantages in power output and smoothness, potentially justifying the higher initial costs in specific market segments. The scalability of these new fuel technologies could also lead to economies of scale, gradually reducing production costs over time.

From an operational perspective, V16 engines traditionally face challenges in fuel efficiency due to their size and power output. Breakthrough fuel technologies could address this concern by offering improved energy density or combustion efficiency, potentially making V16 engines more economically viable in terms of long-term operational costs. This could expand their applicability beyond niche markets, particularly in sectors where high power output and reliability are critical factors.

The economic feasibility also depends on regulatory environments and market demands. Stringent emissions regulations might initially seem to disadvantage large displacement engines like V16s. However, if breakthrough fuel technologies can significantly reduce emissions or even achieve carbon neutrality, V16 engines could find new economic justifications in markets prioritizing both performance and environmental sustainability.

Investment in research and development for adapting V16 engines to new fuel technologies represents a significant economic consideration. While initial costs may be high, the potential for technological leadership and patent portfolios in this specialized field could offer long-term economic benefits for companies willing to invest. This could create new revenue streams through licensing or partnerships in various industrial sectors.

Market differentiation presents another economic aspect to consider. V16 engines, combined with breakthrough fuel technologies, could offer unique selling propositions in luxury, performance, and specialized industrial markets. This differentiation could command premium pricing, offsetting higher production costs and potentially yielding higher profit margins in select market segments.

However, the potential integration of breakthrough fuel technologies could alter this economic equation. Advanced biofuels, synthetic fuels, or hydrogen combustion systems might leverage the V16 configuration's inherent advantages in power output and smoothness, potentially justifying the higher initial costs in specific market segments. The scalability of these new fuel technologies could also lead to economies of scale, gradually reducing production costs over time.

From an operational perspective, V16 engines traditionally face challenges in fuel efficiency due to their size and power output. Breakthrough fuel technologies could address this concern by offering improved energy density or combustion efficiency, potentially making V16 engines more economically viable in terms of long-term operational costs. This could expand their applicability beyond niche markets, particularly in sectors where high power output and reliability are critical factors.

The economic feasibility also depends on regulatory environments and market demands. Stringent emissions regulations might initially seem to disadvantage large displacement engines like V16s. However, if breakthrough fuel technologies can significantly reduce emissions or even achieve carbon neutrality, V16 engines could find new economic justifications in markets prioritizing both performance and environmental sustainability.

Investment in research and development for adapting V16 engines to new fuel technologies represents a significant economic consideration. While initial costs may be high, the potential for technological leadership and patent portfolios in this specialized field could offer long-term economic benefits for companies willing to invest. This could create new revenue streams through licensing or partnerships in various industrial sectors.

Market differentiation presents another economic aspect to consider. V16 engines, combined with breakthrough fuel technologies, could offer unique selling propositions in luxury, performance, and specialized industrial markets. This differentiation could command premium pricing, offsetting higher production costs and potentially yielding higher profit margins in select market segments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!