Structural dynamics in high-revving V16 racing engines

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The evolution of V16 racing engines represents a fascinating journey in automotive engineering, particularly in the realm of high-performance motorsports. The V16 configuration, characterized by its 16 cylinders arranged in a V-shape, has been a pinnacle of power and engineering prowess since its inception in the early 20th century.

The roots of V16 engines can be traced back to the 1910s, with early prototypes developed for aircraft applications. However, it wasn't until the 1930s that V16 engines made their mark in the automotive world. Luxury car manufacturers like Cadillac and Marmon introduced V16 engines in their flagship models, showcasing the configuration's potential for smooth operation and impressive power output.

In the realm of racing, the V16 engine's evolution took a significant leap forward in the 1930s and 1940s. Auto Union, under the guidance of Ferdinand Porsche, developed a series of Grand Prix cars featuring V16 engines. These engines, with their compact design and high power-to-weight ratio, set new standards in racing performance and pushed the boundaries of what was possible in engine design.

The post-war era saw a decline in V16 usage due to regulatory changes and the increasing complexity of maintaining such large engines. However, the concept never entirely disappeared from the racing world. In the 1960s and 1970s, there were sporadic attempts to revive the V16 configuration in various motorsport categories, though with limited success.

A renaissance of sorts occurred in the late 1980s and early 1990s with the development of the BRM P15 V16 Formula One engine. This engine, while never raced in competition, demonstrated the enduring appeal and potential of the V16 configuration in high-performance applications.

In recent years, advancements in materials science, computer-aided design, and manufacturing techniques have reignited interest in V16 engines for racing applications. Modern V16 racing engines benefit from lightweight alloys, advanced fuel injection systems, and sophisticated engine management electronics, allowing for unprecedented levels of power and efficiency.

The evolution of V16 racing engines has been marked by continuous improvements in areas such as combustion efficiency, thermal management, and structural integrity. Engineers have focused on optimizing cylinder head designs, valve train components, and crankshaft configurations to handle the extreme stresses associated with high-revving operations.

Today, while not common in mainstream racing series due to regulatory restrictions, V16 engines continue to fascinate engineers and enthusiasts alike. They serve as testbeds for cutting-edge technologies and push the limits of internal combustion engine design, contributing valuable insights that often trickle down to more conventional engine configurations.

The roots of V16 engines can be traced back to the 1910s, with early prototypes developed for aircraft applications. However, it wasn't until the 1930s that V16 engines made their mark in the automotive world. Luxury car manufacturers like Cadillac and Marmon introduced V16 engines in their flagship models, showcasing the configuration's potential for smooth operation and impressive power output.

In the realm of racing, the V16 engine's evolution took a significant leap forward in the 1930s and 1940s. Auto Union, under the guidance of Ferdinand Porsche, developed a series of Grand Prix cars featuring V16 engines. These engines, with their compact design and high power-to-weight ratio, set new standards in racing performance and pushed the boundaries of what was possible in engine design.

The post-war era saw a decline in V16 usage due to regulatory changes and the increasing complexity of maintaining such large engines. However, the concept never entirely disappeared from the racing world. In the 1960s and 1970s, there were sporadic attempts to revive the V16 configuration in various motorsport categories, though with limited success.

A renaissance of sorts occurred in the late 1980s and early 1990s with the development of the BRM P15 V16 Formula One engine. This engine, while never raced in competition, demonstrated the enduring appeal and potential of the V16 configuration in high-performance applications.

In recent years, advancements in materials science, computer-aided design, and manufacturing techniques have reignited interest in V16 engines for racing applications. Modern V16 racing engines benefit from lightweight alloys, advanced fuel injection systems, and sophisticated engine management electronics, allowing for unprecedented levels of power and efficiency.

The evolution of V16 racing engines has been marked by continuous improvements in areas such as combustion efficiency, thermal management, and structural integrity. Engineers have focused on optimizing cylinder head designs, valve train components, and crankshaft configurations to handle the extreme stresses associated with high-revving operations.

Today, while not common in mainstream racing series due to regulatory restrictions, V16 engines continue to fascinate engineers and enthusiasts alike. They serve as testbeds for cutting-edge technologies and push the limits of internal combustion engine design, contributing valuable insights that often trickle down to more conventional engine configurations.

Racing Market Demands

The racing market demands for high-revving V16 engines are driven by the pursuit of ultimate performance and technological superiority in motorsports. These engines represent the pinnacle of engineering excellence, catering to a niche but highly influential segment of the racing industry. The market for such engines is primarily focused on top-tier racing categories, including Formula 1, endurance racing, and specialized high-performance vehicle applications.

In recent years, there has been a growing interest in pushing the boundaries of engine technology, with V16 configurations gaining attention for their potential to deliver exceptional power output and unique sound characteristics. This demand is fueled by racing teams and manufacturers seeking a competitive edge, as well as by enthusiasts and collectors who value the exclusivity and engineering prowess associated with these complex powerplants.

The racing market for high-revving V16 engines is characterized by its emphasis on power-to-weight ratio, fuel efficiency, and reliability under extreme conditions. Teams and manufacturers are constantly seeking ways to extract maximum performance while adhering to stringent regulations and safety standards. This has led to increased investment in research and development, focusing on advanced materials, precision manufacturing techniques, and innovative design solutions to address the unique challenges posed by high-revving V16 configurations.

Furthermore, the market demand extends beyond just the engines themselves. There is a significant need for specialized components, testing equipment, and simulation tools tailored to the development and optimization of these engines. This has created opportunities for suppliers and technology providers to develop cutting-edge solutions specifically for the high-revving V16 racing engine market.

The demand for these engines also reflects a broader trend in the racing industry towards showcasing technological innovation and pushing the limits of what is possible in internal combustion engine design. This aligns with the interests of sponsors and manufacturers who see high-revving V16 engines as a platform for demonstrating their engineering capabilities and brand prestige.

However, it is important to note that the market for high-revving V16 racing engines is relatively small and highly specialized. The high costs associated with development, production, and maintenance of these engines limit their adoption to only the most well-funded racing programs and exclusive vehicle projects. Despite this, the technological advancements and engineering solutions developed for these engines often have broader applications, influencing the design of more mainstream racing and high-performance road car engines.

In recent years, there has been a growing interest in pushing the boundaries of engine technology, with V16 configurations gaining attention for their potential to deliver exceptional power output and unique sound characteristics. This demand is fueled by racing teams and manufacturers seeking a competitive edge, as well as by enthusiasts and collectors who value the exclusivity and engineering prowess associated with these complex powerplants.

The racing market for high-revving V16 engines is characterized by its emphasis on power-to-weight ratio, fuel efficiency, and reliability under extreme conditions. Teams and manufacturers are constantly seeking ways to extract maximum performance while adhering to stringent regulations and safety standards. This has led to increased investment in research and development, focusing on advanced materials, precision manufacturing techniques, and innovative design solutions to address the unique challenges posed by high-revving V16 configurations.

Furthermore, the market demand extends beyond just the engines themselves. There is a significant need for specialized components, testing equipment, and simulation tools tailored to the development and optimization of these engines. This has created opportunities for suppliers and technology providers to develop cutting-edge solutions specifically for the high-revving V16 racing engine market.

The demand for these engines also reflects a broader trend in the racing industry towards showcasing technological innovation and pushing the limits of what is possible in internal combustion engine design. This aligns with the interests of sponsors and manufacturers who see high-revving V16 engines as a platform for demonstrating their engineering capabilities and brand prestige.

However, it is important to note that the market for high-revving V16 racing engines is relatively small and highly specialized. The high costs associated with development, production, and maintenance of these engines limit their adoption to only the most well-funded racing programs and exclusive vehicle projects. Despite this, the technological advancements and engineering solutions developed for these engines often have broader applications, influencing the design of more mainstream racing and high-performance road car engines.

Structural Challenges

High-revving V16 racing engines present a unique set of structural challenges due to their complex design and extreme operating conditions. The primary concern is the management of vibration and stress distribution throughout the engine block and components. At high RPMs, these engines experience significant dynamic loads, which can lead to fatigue and potential failure if not properly addressed.

One of the key structural challenges is maintaining the rigidity of the engine block while minimizing weight. The extended length of a V16 configuration increases the potential for flexing and torsional vibrations. Engineers must employ advanced materials and design techniques to create a structure that can withstand the forces generated during operation without compromising performance or adding excessive mass.

Crankshaft design poses another critical challenge. The long crankshaft required for a V16 engine is particularly susceptible to bending and torsional vibrations. These vibrations can lead to bearing wear, reduced power output, and even catastrophic failure. Innovative solutions, such as split crankshafts or advanced damping systems, are often necessary to mitigate these issues.

The valvetrain in high-revving V16 engines also faces significant structural challenges. At extreme RPMs, valve float becomes a serious concern, potentially leading to valve-to-piston contact and engine damage. Engineers must develop lightweight, yet durable valve components and implement advanced valve control systems to maintain proper valve timing and prevent float.

Thermal management presents another structural challenge. The intense heat generated by a high-revving V16 engine can cause thermal expansion and distortion of components. This can lead to changes in clearances, affecting engine performance and reliability. Sophisticated cooling systems and materials with appropriate thermal properties must be employed to maintain structural integrity under these extreme conditions.

Balancing is a critical aspect of V16 engine design. The large number of cylinders and moving parts creates complex harmonic vibrations that can resonate throughout the engine and vehicle structure. Careful consideration must be given to the placement of counterweights and the design of engine mounts to minimize these vibrations and prevent structural fatigue.

Lastly, the integration of ancillary systems such as fuel injection, turbocharging, and exhaust systems presents additional structural challenges. These components must be securely mounted and designed to withstand the high-frequency vibrations and thermal cycling inherent in high-revving V16 engines. Failure to adequately address these challenges can result in reduced performance, reliability issues, and potential safety hazards.

One of the key structural challenges is maintaining the rigidity of the engine block while minimizing weight. The extended length of a V16 configuration increases the potential for flexing and torsional vibrations. Engineers must employ advanced materials and design techniques to create a structure that can withstand the forces generated during operation without compromising performance or adding excessive mass.

Crankshaft design poses another critical challenge. The long crankshaft required for a V16 engine is particularly susceptible to bending and torsional vibrations. These vibrations can lead to bearing wear, reduced power output, and even catastrophic failure. Innovative solutions, such as split crankshafts or advanced damping systems, are often necessary to mitigate these issues.

The valvetrain in high-revving V16 engines also faces significant structural challenges. At extreme RPMs, valve float becomes a serious concern, potentially leading to valve-to-piston contact and engine damage. Engineers must develop lightweight, yet durable valve components and implement advanced valve control systems to maintain proper valve timing and prevent float.

Thermal management presents another structural challenge. The intense heat generated by a high-revving V16 engine can cause thermal expansion and distortion of components. This can lead to changes in clearances, affecting engine performance and reliability. Sophisticated cooling systems and materials with appropriate thermal properties must be employed to maintain structural integrity under these extreme conditions.

Balancing is a critical aspect of V16 engine design. The large number of cylinders and moving parts creates complex harmonic vibrations that can resonate throughout the engine and vehicle structure. Careful consideration must be given to the placement of counterweights and the design of engine mounts to minimize these vibrations and prevent structural fatigue.

Lastly, the integration of ancillary systems such as fuel injection, turbocharging, and exhaust systems presents additional structural challenges. These components must be securely mounted and designed to withstand the high-frequency vibrations and thermal cycling inherent in high-revving V16 engines. Failure to adequately address these challenges can result in reduced performance, reliability issues, and potential safety hazards.

Current V16 Designs

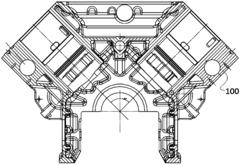

01 Engine block design for V16 racing engines

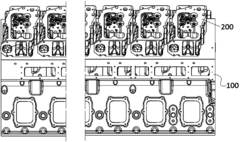

Specialized engine block designs for V16 racing engines focus on optimizing structural integrity and weight distribution. These designs incorporate advanced materials and manufacturing techniques to enhance rigidity while minimizing overall mass. The layout of cylinders and supporting structures is carefully engineered to manage vibrations and improve power delivery.- Engine block design for V16 racing engines: The structural design of V16 racing engine blocks focuses on optimizing weight distribution, reducing vibration, and enhancing overall performance. Advanced materials and manufacturing techniques are employed to create lightweight yet durable engine blocks that can withstand the high stresses of racing conditions. The design also considers thermal management and oil circulation to maintain optimal operating temperatures and lubrication.

- Crankshaft and connecting rod dynamics: The crankshaft and connecting rods in V16 racing engines are critical components that require careful design to manage the high forces and rotational speeds involved. Advanced materials and precision manufacturing techniques are used to create lightweight, high-strength parts that can withstand the extreme conditions of racing. Balancing and vibration damping techniques are employed to minimize stress on engine components and improve overall performance.

- Valve train and camshaft dynamics: The valve train and camshaft system in V16 racing engines are designed to optimize airflow and combustion efficiency at high RPMs. Advanced materials and designs are used to reduce reciprocating mass and minimize valve float. Variable valve timing and lift systems may be incorporated to enhance performance across a wide range of engine speeds. The dynamics of these components are carefully tuned to maximize power output while maintaining reliability.

- Intake and exhaust system dynamics: The intake and exhaust systems of V16 racing engines are engineered to optimize airflow and scavenging effects. Advanced computational fluid dynamics simulations are used to design intake manifolds, plenums, and exhaust headers that maximize volumetric efficiency and power output. Tuned-length runners and variable geometry systems may be employed to enhance performance across a wide RPM range. Materials and construction techniques focus on reducing weight while maintaining durability under high-temperature conditions.

- Vibration and noise reduction techniques: Managing vibration and noise in V16 racing engines is crucial for both performance and reliability. Advanced computer modeling and analysis techniques are used to identify and mitigate sources of vibration. This may include the use of balance shafts, tuned mass dampers, and advanced engine mounting systems. Acoustic engineering is applied to reduce noise while maintaining optimal performance, which can involve the use of specially designed exhaust systems and engine covers.

02 Vibration damping systems in high-performance engines

Innovative vibration damping systems are crucial for V16 racing engines to maintain structural stability during high-speed operation. These systems may include active and passive damping technologies, specialized mounting solutions, and materials with superior vibration absorption properties. The goal is to minimize harmful resonances and improve overall engine performance and longevity.Expand Specific Solutions03 Crankshaft and connecting rod dynamics

The design and optimization of crankshafts and connecting rods play a critical role in V16 racing engine structural dynamics. Advanced modeling and simulation techniques are used to analyze stress distribution, fatigue resistance, and rotational balance. Lightweight materials and innovative geometries are employed to reduce inertial forces and improve engine responsiveness.Expand Specific Solutions04 Thermal management and structural integrity

Effective thermal management is essential for maintaining structural integrity in V16 racing engines. This involves advanced cooling systems, heat-resistant materials, and strategic component placement to manage thermal expansion and prevent distortion. Integrated thermal analysis is used to optimize engine design for both performance and reliability under extreme operating conditions.Expand Specific Solutions05 Advanced materials and manufacturing for engine components

The use of advanced materials and manufacturing techniques is crucial for enhancing the structural dynamics of V16 racing engines. This includes the application of composite materials, additive manufacturing, and precision machining to create lightweight yet strong engine components. These innovations allow for complex geometries that optimize stiffness, reduce weight, and improve overall engine performance.Expand Specific Solutions

Key Engine Manufacturers

The structural dynamics of high-revving V16 racing engines represent a niche but highly advanced sector in automotive engineering. This field is currently in a mature development stage, with a relatively small but specialized market. The technology's maturity is evident in the involvement of established automotive giants like Toyota, BMW, and Audi, who possess the resources and expertise for such high-performance engine development. Companies like Guangxi Yuchai Machinery and Hino Motors contribute to the competitive landscape, focusing on heavy-duty engine applications. The market size remains limited due to the specialized nature of V16 engines, primarily used in motorsports and ultra-luxury vehicles. Ongoing research by these companies aims to push the boundaries of power output, efficiency, and reliability in high-revving engines.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced structural dynamics solutions for high-revving engines, including their V16 racing engine used in Formula 1. Their approach involves using lightweight materials such as titanium and carbon fiber composites to reduce reciprocating mass[1]. They have implemented a dry sump lubrication system to minimize oil movement and improve engine stability at high RPMs[2]. Toyota's engine features a pneumatic valve system that allows for higher rev limits by eliminating valve float[3]. Additionally, they use advanced computer modeling and simulation techniques to optimize component design and predict structural behavior under extreme conditions[4].

Strengths: Extensive experience in motorsports, access to cutting-edge materials and technologies, strong R&D capabilities. Weaknesses: High development costs, limited applicability to mass-market vehicles.

Bayerische Motoren Werke AG

Technical Solution: BMW has made significant advancements in structural dynamics for high-performance engines, including V16 configurations. Their approach focuses on reducing internal friction and optimizing weight distribution. BMW utilizes a combination of lightweight alloys and carbon fiber reinforced plastics (CFRP) to minimize engine mass while maintaining structural integrity[5]. They have developed a variable valve timing and lift system (VANOS) that enhances engine performance across the RPM range[6]. BMW's engine block design incorporates closed-deck construction for improved rigidity and reduced vibration at high speeds[7]. Advanced balancing techniques, including counterweighted crankshafts and harmonic balancers, are employed to mitigate vibration issues in multi-cylinder configurations[8].

Strengths: Strong heritage in high-performance engines, innovative materials usage, advanced vibration control techniques. Weaknesses: Complexity of systems may lead to higher maintenance costs, potential reliability concerns in extreme racing conditions.

Vibration Mitigation

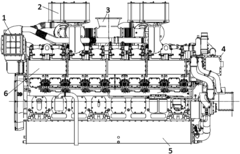

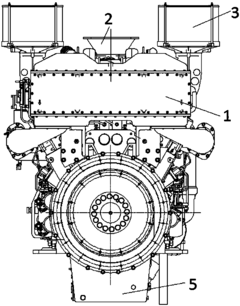

High-power V16 diesel engine

PatentActiveCN108194198A

Innovation

- A high-power V-shaped 16-cylinder diesel engine is designed, which uses a V-shaped cylinder block, 16 single cylinder heads, four turbochargers and an intercooler, combined with a cooling system of high and low temperature water circulation loops, to achieve turbocharging through Technology and classified cooling systems increase air density and lower temperatures to meet the needs of high power and torque.

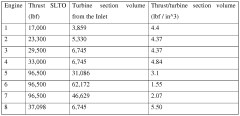

Geared turbofan engine with counter-rotating shafts

PatentWO2013130187A1

Innovation

- A geared turbofan engine design with counter-rotating shafts, where the fan is driven by the low-pressure turbine through a speed reduction mechanism, allowing the fan and low-pressure compressor to rotate at different speeds, and incorporating a mid-turbine frame with vanes to redirect airflow efficiently, resulting in a more compact and efficient engine.

Aerodynamic Integration

Aerodynamic integration plays a crucial role in the performance and efficiency of high-revving V16 racing engines. The complex interplay between engine dynamics and aerodynamics necessitates a holistic approach to design and optimization. In the context of structural dynamics, aerodynamic considerations become even more critical due to the high rotational speeds and intense vibrations experienced by these powerful engines.

One of the primary challenges in aerodynamic integration for V16 racing engines is managing the airflow around the engine block and associated components. The large size and unique configuration of a V16 engine create significant aerodynamic drag, which can negatively impact overall vehicle performance. To address this, engineers employ advanced computational fluid dynamics (CFD) simulations to analyze and optimize airflow patterns around the engine.

The integration of aerodynamic elements within the engine bay is essential for effective heat management. High-revving V16 engines generate substantial heat, which must be efficiently dissipated to maintain optimal performance and prevent component failure. Carefully designed air intakes, vents, and ducting systems are incorporated to direct cool air towards critical areas while extracting hot air from the engine compartment.

Structural dynamics considerations in aerodynamic integration focus on minimizing vibration-induced aerodynamic disturbances. The high-frequency oscillations produced by a V16 engine can create localized pressure fluctuations and turbulence, potentially affecting the vehicle's overall aerodynamic performance. Engineers employ advanced materials and damping technologies to mitigate these effects and maintain aerodynamic stability.

The design of engine covers and underbody panels is another crucial aspect of aerodynamic integration. These components not only serve to protect the engine but also play a significant role in shaping the airflow around the vehicle. Careful attention is paid to their contours and surface finishes to reduce drag and improve overall aerodynamic efficiency.

In recent years, active aerodynamic systems have been integrated into high-performance racing engines, including V16 configurations. These systems can dynamically adjust airflow characteristics based on engine speed, vehicle dynamics, and track conditions. Such adaptive aerodynamics help optimize performance across a wide range of operating conditions, balancing the need for cooling, drag reduction, and downforce generation.

The integration of aerodynamics with engine structural dynamics also extends to the exhaust system design. The pulsating nature of exhaust gases from a V16 engine can be harnessed to create beneficial aerodynamic effects, such as reducing drag or enhancing downforce. Careful tuning of exhaust geometry and placement can contribute to overall vehicle performance improvements.

One of the primary challenges in aerodynamic integration for V16 racing engines is managing the airflow around the engine block and associated components. The large size and unique configuration of a V16 engine create significant aerodynamic drag, which can negatively impact overall vehicle performance. To address this, engineers employ advanced computational fluid dynamics (CFD) simulations to analyze and optimize airflow patterns around the engine.

The integration of aerodynamic elements within the engine bay is essential for effective heat management. High-revving V16 engines generate substantial heat, which must be efficiently dissipated to maintain optimal performance and prevent component failure. Carefully designed air intakes, vents, and ducting systems are incorporated to direct cool air towards critical areas while extracting hot air from the engine compartment.

Structural dynamics considerations in aerodynamic integration focus on minimizing vibration-induced aerodynamic disturbances. The high-frequency oscillations produced by a V16 engine can create localized pressure fluctuations and turbulence, potentially affecting the vehicle's overall aerodynamic performance. Engineers employ advanced materials and damping technologies to mitigate these effects and maintain aerodynamic stability.

The design of engine covers and underbody panels is another crucial aspect of aerodynamic integration. These components not only serve to protect the engine but also play a significant role in shaping the airflow around the vehicle. Careful attention is paid to their contours and surface finishes to reduce drag and improve overall aerodynamic efficiency.

In recent years, active aerodynamic systems have been integrated into high-performance racing engines, including V16 configurations. These systems can dynamically adjust airflow characteristics based on engine speed, vehicle dynamics, and track conditions. Such adaptive aerodynamics help optimize performance across a wide range of operating conditions, balancing the need for cooling, drag reduction, and downforce generation.

The integration of aerodynamics with engine structural dynamics also extends to the exhaust system design. The pulsating nature of exhaust gases from a V16 engine can be harnessed to create beneficial aerodynamic effects, such as reducing drag or enhancing downforce. Careful tuning of exhaust geometry and placement can contribute to overall vehicle performance improvements.

Fuel Efficiency Factors

Fuel efficiency is a critical factor in the design and operation of high-revving V16 racing engines. These powerful engines, while capable of producing immense horsepower, face significant challenges in maintaining optimal fuel consumption. The structural dynamics of these engines play a crucial role in determining their fuel efficiency.

One of the primary factors affecting fuel efficiency in V16 racing engines is the combustion process. The high-revving nature of these engines requires precise fuel injection timing and optimal air-fuel mixture ratios. Advanced fuel injection systems, coupled with sophisticated engine management systems, are employed to ensure that fuel is delivered efficiently and combusted completely. This minimizes waste and maximizes energy extraction from each fuel molecule.

The design of the combustion chamber also significantly impacts fuel efficiency. Engineers strive to create chamber geometries that promote rapid and complete fuel burning. This includes optimizing the piston crown shape, valve positioning, and spark plug location to enhance turbulence and improve flame propagation. These design considerations help to extract maximum energy from the fuel while reducing unburned fuel emissions.

Friction reduction is another key area of focus for improving fuel efficiency in V16 racing engines. The high number of moving parts in these engines can lead to substantial frictional losses. Advanced materials and coatings are utilized to reduce friction between components such as pistons, rings, and cylinder walls. Additionally, innovative bearing designs and low-viscosity lubricants are employed to minimize energy losses due to friction.

The structural dynamics of the engine block and components also play a role in fuel efficiency. Lightweight materials and advanced manufacturing techniques are used to reduce overall engine weight while maintaining structural integrity. This weight reduction contributes to improved fuel efficiency by decreasing the energy required to accelerate and maintain high engine speeds.

Thermal management is another critical aspect of fuel efficiency in high-revving V16 engines. Efficient cooling systems are essential to maintain optimal operating temperatures and prevent power-robbing heat buildup. Advanced cooling strategies, such as precision-controlled coolant flow and targeted cooling of critical components, help to maintain thermal efficiency and prevent fuel-wasting power losses.

Lastly, the integration of energy recovery systems, such as regenerative braking and exhaust heat recovery, can contribute to overall fuel efficiency in racing applications. These systems capture and repurpose energy that would otherwise be lost, effectively increasing the overall efficiency of the powertrain system.

One of the primary factors affecting fuel efficiency in V16 racing engines is the combustion process. The high-revving nature of these engines requires precise fuel injection timing and optimal air-fuel mixture ratios. Advanced fuel injection systems, coupled with sophisticated engine management systems, are employed to ensure that fuel is delivered efficiently and combusted completely. This minimizes waste and maximizes energy extraction from each fuel molecule.

The design of the combustion chamber also significantly impacts fuel efficiency. Engineers strive to create chamber geometries that promote rapid and complete fuel burning. This includes optimizing the piston crown shape, valve positioning, and spark plug location to enhance turbulence and improve flame propagation. These design considerations help to extract maximum energy from the fuel while reducing unburned fuel emissions.

Friction reduction is another key area of focus for improving fuel efficiency in V16 racing engines. The high number of moving parts in these engines can lead to substantial frictional losses. Advanced materials and coatings are utilized to reduce friction between components such as pistons, rings, and cylinder walls. Additionally, innovative bearing designs and low-viscosity lubricants are employed to minimize energy losses due to friction.

The structural dynamics of the engine block and components also play a role in fuel efficiency. Lightweight materials and advanced manufacturing techniques are used to reduce overall engine weight while maintaining structural integrity. This weight reduction contributes to improved fuel efficiency by decreasing the energy required to accelerate and maintain high engine speeds.

Thermal management is another critical aspect of fuel efficiency in high-revving V16 engines. Efficient cooling systems are essential to maintain optimal operating temperatures and prevent power-robbing heat buildup. Advanced cooling strategies, such as precision-controlled coolant flow and targeted cooling of critical components, help to maintain thermal efficiency and prevent fuel-wasting power losses.

Lastly, the integration of energy recovery systems, such as regenerative braking and exhaust heat recovery, can contribute to overall fuel efficiency in racing applications. These systems capture and repurpose energy that would otherwise be lost, effectively increasing the overall efficiency of the powertrain system.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!