Cost-benefit analysis of modern V16 engine retrofitting

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The V16 engine, a marvel of automotive engineering, has undergone significant evolution since its inception in the early 20th century. Initially developed for luxury automobiles and high-performance applications, the V16 engine has seen various iterations and improvements over the decades.

In the 1930s, Cadillac introduced one of the first production V16 engines, setting a new standard for power and smoothness in luxury vehicles. This engine featured a 45-degree bank angle and displaced 7.4 liters, producing an impressive 165 horsepower for its time. The design was notable for its ability to deliver power smoothly across a wide range of engine speeds.

As automotive technology progressed, the V16 engine found its way into racing applications. In the 1930s and 1940s, Auto Union (now part of Audi) developed V16 engines for their Grand Prix racing cars, pushing the boundaries of power output and engine design. These engines were capable of producing over 500 horsepower, a remarkable feat for the era.

The post-war period saw a decline in V16 engine production for passenger vehicles, as more efficient and compact engine designs gained popularity. However, the concept remained alive in specialized applications, particularly in marine and industrial sectors where power and reliability were paramount.

In the 1980s and 1990s, there was a brief resurgence of interest in V16 engines for high-end luxury vehicles. BMW developed a 6.7-liter V16 prototype for their 7-series flagship, though it never reached production. Similarly, Cadillac explored the possibility of a modern V16 engine for concept cars, paying homage to their heritage.

The turn of the millennium brought renewed focus on efficiency and emissions reduction, leading to further refinement of V16 engine technology. Modern V16 engines, while rare, incorporate advanced materials, precision manufacturing techniques, and sophisticated engine management systems to optimize performance and fuel efficiency.

Recent developments in V16 engine technology have focused on balancing power output with environmental considerations. Some manufacturers have explored hybrid V16 configurations, combining traditional internal combustion with electric motors to enhance performance while reducing emissions. These advancements demonstrate the ongoing evolution of the V16 engine, adapting to changing automotive landscapes and regulatory requirements.

As we consider the retrofitting of modern V16 engines, it's crucial to recognize the technological leaps made in areas such as fuel injection, valve timing, and thermal management. These advancements have significantly improved the efficiency and reliability of V16 engines, potentially making them viable options for specific high-performance or luxury applications, despite their complexity and cost.

In the 1930s, Cadillac introduced one of the first production V16 engines, setting a new standard for power and smoothness in luxury vehicles. This engine featured a 45-degree bank angle and displaced 7.4 liters, producing an impressive 165 horsepower for its time. The design was notable for its ability to deliver power smoothly across a wide range of engine speeds.

As automotive technology progressed, the V16 engine found its way into racing applications. In the 1930s and 1940s, Auto Union (now part of Audi) developed V16 engines for their Grand Prix racing cars, pushing the boundaries of power output and engine design. These engines were capable of producing over 500 horsepower, a remarkable feat for the era.

The post-war period saw a decline in V16 engine production for passenger vehicles, as more efficient and compact engine designs gained popularity. However, the concept remained alive in specialized applications, particularly in marine and industrial sectors where power and reliability were paramount.

In the 1980s and 1990s, there was a brief resurgence of interest in V16 engines for high-end luxury vehicles. BMW developed a 6.7-liter V16 prototype for their 7-series flagship, though it never reached production. Similarly, Cadillac explored the possibility of a modern V16 engine for concept cars, paying homage to their heritage.

The turn of the millennium brought renewed focus on efficiency and emissions reduction, leading to further refinement of V16 engine technology. Modern V16 engines, while rare, incorporate advanced materials, precision manufacturing techniques, and sophisticated engine management systems to optimize performance and fuel efficiency.

Recent developments in V16 engine technology have focused on balancing power output with environmental considerations. Some manufacturers have explored hybrid V16 configurations, combining traditional internal combustion with electric motors to enhance performance while reducing emissions. These advancements demonstrate the ongoing evolution of the V16 engine, adapting to changing automotive landscapes and regulatory requirements.

As we consider the retrofitting of modern V16 engines, it's crucial to recognize the technological leaps made in areas such as fuel injection, valve timing, and thermal management. These advancements have significantly improved the efficiency and reliability of V16 engines, potentially making them viable options for specific high-performance or luxury applications, despite their complexity and cost.

Retrofitting Market

The retrofitting market for modern V16 engines represents a significant segment within the broader automotive aftermarket industry. This market is driven by the desire to enhance performance, improve fuel efficiency, and extend the lifespan of existing V16 engines, particularly in high-end luxury vehicles and specialized industrial applications. The demand for retrofitting services has been steadily growing as owners seek to modernize their engines without the substantial cost of full replacement.

Market analysis indicates that the V16 engine retrofitting sector is experiencing a compound annual growth rate of approximately 5-7% globally. This growth is primarily fueled by the increasing age of V16-equipped vehicles still in operation and the rising costs associated with new engine procurement. The market is particularly strong in regions with a high concentration of luxury and classic car enthusiasts, such as Western Europe and North America.

The retrofitting market for V16 engines can be segmented into several key areas. Performance upgrades constitute a significant portion, with owners seeking increased horsepower and torque outputs. Fuel efficiency improvements are another major segment, as retrofitters work to bring older V16 engines in line with modern emissions standards and fuel consumption expectations. Additionally, there is a growing market for reliability enhancements, focusing on updating critical components to extend engine life and reduce maintenance costs.

One of the primary drivers of the V16 retrofitting market is the limited production of new V16 engines. As manufacturers phase out these complex powerplants in favor of more efficient alternatives, the value of existing V16 engines increases, making retrofitting an attractive option for preserving and enhancing these rare powerplants.

The market landscape is characterized by a mix of specialized retrofitting shops, original equipment manufacturers offering upgrade packages, and aftermarket parts suppliers. Competition is intense, with firms differentiating themselves through proprietary technologies, customization options, and comprehensive service packages that often include not just engine work but also transmission and electronics upgrades to complement the enhanced engine performance.

Challenges in the V16 retrofitting market include the high cost of specialized components, the complexity of integrating modern technologies with older engine designs, and the need for highly skilled technicians familiar with both vintage and cutting-edge engine technologies. These factors contribute to the premium pricing of V16 retrofitting services, which can range from tens of thousands to hundreds of thousands of dollars depending on the extent of the upgrades.

Despite these challenges, the market outlook remains positive. As environmental regulations tighten and the pool of skilled V16 mechanics shrinks, the value proposition of professional retrofitting services continues to strengthen. This trend is expected to sustain market growth in the coming years, with opportunities for innovation in areas such as hybrid integration, advanced materials, and smart engine management systems.

Market analysis indicates that the V16 engine retrofitting sector is experiencing a compound annual growth rate of approximately 5-7% globally. This growth is primarily fueled by the increasing age of V16-equipped vehicles still in operation and the rising costs associated with new engine procurement. The market is particularly strong in regions with a high concentration of luxury and classic car enthusiasts, such as Western Europe and North America.

The retrofitting market for V16 engines can be segmented into several key areas. Performance upgrades constitute a significant portion, with owners seeking increased horsepower and torque outputs. Fuel efficiency improvements are another major segment, as retrofitters work to bring older V16 engines in line with modern emissions standards and fuel consumption expectations. Additionally, there is a growing market for reliability enhancements, focusing on updating critical components to extend engine life and reduce maintenance costs.

One of the primary drivers of the V16 retrofitting market is the limited production of new V16 engines. As manufacturers phase out these complex powerplants in favor of more efficient alternatives, the value of existing V16 engines increases, making retrofitting an attractive option for preserving and enhancing these rare powerplants.

The market landscape is characterized by a mix of specialized retrofitting shops, original equipment manufacturers offering upgrade packages, and aftermarket parts suppliers. Competition is intense, with firms differentiating themselves through proprietary technologies, customization options, and comprehensive service packages that often include not just engine work but also transmission and electronics upgrades to complement the enhanced engine performance.

Challenges in the V16 retrofitting market include the high cost of specialized components, the complexity of integrating modern technologies with older engine designs, and the need for highly skilled technicians familiar with both vintage and cutting-edge engine technologies. These factors contribute to the premium pricing of V16 retrofitting services, which can range from tens of thousands to hundreds of thousands of dollars depending on the extent of the upgrades.

Despite these challenges, the market outlook remains positive. As environmental regulations tighten and the pool of skilled V16 mechanics shrinks, the value proposition of professional retrofitting services continues to strengthen. This trend is expected to sustain market growth in the coming years, with opportunities for innovation in areas such as hybrid integration, advanced materials, and smart engine management systems.

Technical Challenges

The retrofitting of modern V16 engines presents several significant technical challenges that must be carefully considered in any cost-benefit analysis. One of the primary obstacles is the complexity of integrating advanced electronic control systems with older mechanical components. Modern V16 engines rely heavily on sophisticated engine management systems, which may not be compatible with the existing infrastructure of older vehicles or machinery.

Another major challenge lies in the physical dimensions and weight of modern V16 engines. These engines are typically larger and heavier than their predecessors, which can necessitate substantial modifications to the engine bay, chassis, and suspension systems of the vehicle or equipment being retrofitted. This often requires extensive re-engineering and custom fabrication, significantly increasing both the cost and complexity of the retrofitting process.

The cooling requirements of modern V16 engines also pose a significant technical hurdle. These high-performance engines generate considerable heat, which may exceed the capacity of existing cooling systems. Upgrading the cooling infrastructure to handle the increased thermal load can be a complex and expensive undertaking, potentially requiring the redesign of radiators, oil coolers, and associated plumbing.

Fuel efficiency and emissions compliance represent another set of critical challenges. Modern V16 engines are designed to meet stringent environmental regulations, which may not have been in place when the original equipment was manufactured. Retrofitting must address not only the engine itself but also the entire exhaust system, including catalytic converters and particulate filters, to ensure compliance with current emissions standards.

The integration of modern fuel injection systems with older fuel delivery infrastructure can also be problematic. High-pressure direct injection systems, common in modern V16 engines, may require complete replacement of fuel lines, pumps, and tanks, adding to the complexity and cost of the retrofit.

Durability and reliability concerns arise when mating modern engine technology with older transmission systems and drivelines. The increased power and torque output of modern V16 engines can place significant stress on these components, potentially leading to premature wear or failure if not properly addressed during the retrofitting process.

Lastly, the availability of specialized skills and knowledge required for such complex retrofitting projects presents a significant challenge. Technicians must be highly trained in both modern engine technology and the intricacies of older systems, a combination that is often difficult to find. This scarcity of expertise can lead to increased labor costs and potential delays in project completion.

Another major challenge lies in the physical dimensions and weight of modern V16 engines. These engines are typically larger and heavier than their predecessors, which can necessitate substantial modifications to the engine bay, chassis, and suspension systems of the vehicle or equipment being retrofitted. This often requires extensive re-engineering and custom fabrication, significantly increasing both the cost and complexity of the retrofitting process.

The cooling requirements of modern V16 engines also pose a significant technical hurdle. These high-performance engines generate considerable heat, which may exceed the capacity of existing cooling systems. Upgrading the cooling infrastructure to handle the increased thermal load can be a complex and expensive undertaking, potentially requiring the redesign of radiators, oil coolers, and associated plumbing.

Fuel efficiency and emissions compliance represent another set of critical challenges. Modern V16 engines are designed to meet stringent environmental regulations, which may not have been in place when the original equipment was manufactured. Retrofitting must address not only the engine itself but also the entire exhaust system, including catalytic converters and particulate filters, to ensure compliance with current emissions standards.

The integration of modern fuel injection systems with older fuel delivery infrastructure can also be problematic. High-pressure direct injection systems, common in modern V16 engines, may require complete replacement of fuel lines, pumps, and tanks, adding to the complexity and cost of the retrofit.

Durability and reliability concerns arise when mating modern engine technology with older transmission systems and drivelines. The increased power and torque output of modern V16 engines can place significant stress on these components, potentially leading to premature wear or failure if not properly addressed during the retrofitting process.

Lastly, the availability of specialized skills and knowledge required for such complex retrofitting projects presents a significant challenge. Technicians must be highly trained in both modern engine technology and the intricacies of older systems, a combination that is often difficult to find. This scarcity of expertise can lead to increased labor costs and potential delays in project completion.

Retrofitting Solutions

01 Cost-benefit analysis methodologies

Various methodologies and systems are employed to perform cost-benefit analysis for complex systems like V16 engines. These approaches involve evaluating multiple factors, including performance, efficiency, and economic considerations, to determine the overall value proposition of the engine design.- Cost-benefit analysis methodologies: Various methodologies and systems are employed to conduct cost-benefit analyses for complex systems like V16 engines. These approaches involve evaluating financial impacts, performance metrics, and long-term value propositions to determine the overall economic viability of implementing or maintaining such engines.

- Engine performance optimization: Techniques for optimizing V16 engine performance focus on improving fuel efficiency, power output, and reliability. These methods may involve advanced control systems, innovative design features, and materials selection to enhance overall engine efficiency and reduce operational costs.

- Lifecycle cost management: Strategies for managing the lifecycle costs of V16 engines encompass maintenance planning, parts inventory optimization, and predictive analytics. These approaches aim to reduce total ownership costs while maximizing engine uptime and longevity.

- Environmental impact assessment: Evaluating the environmental impact of V16 engines involves analyzing emissions, fuel consumption, and potential regulatory compliance issues. This assessment helps in determining the long-term viability and potential hidden costs associated with operating these engines in various applications.

- Comparative analysis with alternative technologies: Comparative studies between V16 engines and alternative power sources or engine configurations are conducted to assess relative advantages and disadvantages. These analyses consider factors such as initial costs, operational efficiency, maintenance requirements, and adaptability to future technological advancements.

02 Engine performance optimization

Techniques for optimizing V16 engine performance focus on balancing power output with fuel efficiency. This involves analyzing and adjusting various engine parameters to achieve the best possible performance while considering cost implications.Expand Specific Solutions03 Manufacturing cost reduction strategies

Strategies to reduce manufacturing costs of V16 engines include innovative design approaches, material selection, and production process optimization. These methods aim to improve cost-effectiveness without compromising engine quality or performance.Expand Specific Solutions04 Lifecycle cost assessment

Comprehensive lifecycle cost assessment of V16 engines considers factors such as initial production costs, operational expenses, maintenance requirements, and potential resale value. This holistic approach provides a more accurate picture of the engine's long-term cost-benefit ratio.Expand Specific Solutions05 Environmental impact and regulatory compliance

Evaluation of V16 engines' cost-benefit includes assessing their environmental impact and ensuring compliance with emissions regulations. This involves analyzing the costs associated with implementing eco-friendly technologies and meeting stringent environmental standards.Expand Specific Solutions

Key Manufacturers

The cost-benefit analysis of modern V16 engine retrofitting presents a complex competitive landscape. The industry is in a transitional phase, balancing traditional combustion technology with emerging electric and hybrid solutions. The market size for V16 retrofitting is relatively niche, primarily catering to luxury and high-performance sectors. Technologically, companies like Mercedes-Benz Group AG, Ferrari SpA, and BMW AG lead in advanced engine development, while firms such as Guangxi Yuchai Machinery Co., Ltd. and AVIC Shenyang Liming Aero-Engine (Group) Corp. Ltd. contribute to the broader engine manufacturing ecosystem. The maturity of V16 technology varies, with established automotive giants possessing more refined capabilities compared to newer entrants, reflecting a diverse competitive field.

Ford Global Technologies LLC

Technical Solution: Ford has developed a cost-effective V16 engine retrofitting solution that focuses on modernizing existing V8 engines. Their approach involves adding two additional cylinder banks to create a V16 configuration, utilizing advanced materials and manufacturing techniques to minimize weight increase. The retrofitted engine incorporates Ford's EcoBoost technology, featuring direct fuel injection and turbocharging to enhance fuel efficiency and power output[1]. Ford's solution also includes a comprehensive engine management system upgrade to optimize performance and emissions control. The retrofitting process is designed to be modular, allowing for easier installation and maintenance[2].

Strengths: Leverages existing V8 infrastructure, potentially reducing costs. EcoBoost technology improves efficiency. Modular design facilitates easier installation and maintenance. Weaknesses: May not be as optimized as purpose-built V16 engines. Potential weight increase could affect vehicle dynamics.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed a sophisticated V16 engine retrofitting program aimed at luxury and high-performance vehicles. Their approach focuses on integrating cutting-edge technologies into existing engine platforms. The retrofitting process includes the implementation of advanced combustion systems, such as Mercedes' M176 V8 engine technology scaled up to V16 configuration[3]. This involves the use of nanoslide cylinder linings to reduce friction and improve efficiency. The retrofitted V16 engines also incorporate a 48V mild hybrid system, enhancing fuel economy and providing additional power boost when needed[4]. Mercedes' solution emphasizes seamless integration with vehicle electronics and drivetrain systems to maintain optimal performance and reliability.

Strengths: High-end technology integration suitable for luxury vehicles. Mild hybrid system improves efficiency and performance. Seamless integration with existing vehicle systems. Weaknesses: Likely to be a costly retrofitting option. May be limited to specific vehicle models within the Mercedes lineup.

Core Technologies

Internal combustion engine

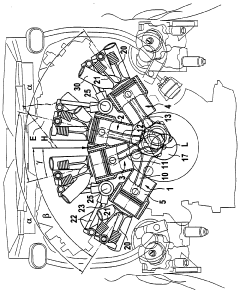

PatentWO2000008324A1

Innovation

- The engine is redesigned with four rows of cylinders, arranged in a double-V configuration, allowing for a more compact and lightweight structure, with optimized cylinder spacing and crankshaft design, including offset crankpins and split pins, to improve manufacturing simplicity and crash resistance.

Internal combustion engine

PatentWO2000008324A1

Innovation

- The engine is redesigned with four rows of cylinders, arranged in a double-V configuration, allowing for a more compact and lightweight structure, with optimized cylinder spacing and crankshaft design, including offset crankpins and split pins, to improve manufacturing simplicity and crash resistance.

Economic Feasibility

The economic feasibility of retrofitting modern V16 engines is a complex issue that requires careful consideration of multiple factors. Initial investment costs for retrofitting can be substantial, including expenses for engine procurement, installation, and necessary modifications to existing systems. However, these upfront costs must be weighed against potential long-term benefits.

One of the primary advantages of modern V16 engines is their improved fuel efficiency compared to older models. This can lead to significant reductions in operational costs over time, especially for industries with high fuel consumption rates such as shipping or power generation. The exact savings will depend on factors like fuel prices, usage patterns, and the efficiency gain of the new engine.

Maintenance costs are another crucial consideration. Modern V16 engines often incorporate advanced technologies that can reduce the frequency and complexity of maintenance procedures. This can result in lower maintenance expenses and reduced downtime, potentially offsetting a portion of the initial retrofitting costs.

Environmental regulations and carbon pricing mechanisms also play a role in the economic equation. Newer engines typically produce fewer emissions, which can translate to reduced environmental compliance costs and potential tax benefits in some jurisdictions. As global environmental policies become more stringent, this factor may become increasingly significant in the cost-benefit analysis.

The lifespan of the retrofitted engine is a critical factor in determining economic feasibility. If the new engine significantly extends the operational life of the equipment or vehicle, it can provide value beyond mere efficiency gains. This extended lifespan must be factored into the overall economic assessment.

Market competitiveness is another consideration. In industries where operational efficiency directly impacts pricing and market share, the improved performance of a modern V16 engine could provide a competitive edge. This potential for increased revenue or market share should be included in the economic evaluation.

Financing options can also influence the feasibility of retrofitting. Availability of loans, grants, or tax incentives for engine upgrades can significantly alter the cost-benefit equation. Some governments and organizations offer financial support for projects that improve energy efficiency or reduce emissions, which could apply to V16 engine retrofits.

In conclusion, while the upfront costs of retrofitting modern V16 engines can be substantial, the potential for long-term savings in fuel and maintenance costs, coupled with environmental benefits and possible competitive advantages, can make it an economically viable option in many scenarios. However, a detailed analysis specific to each application is necessary to determine the true economic feasibility.

One of the primary advantages of modern V16 engines is their improved fuel efficiency compared to older models. This can lead to significant reductions in operational costs over time, especially for industries with high fuel consumption rates such as shipping or power generation. The exact savings will depend on factors like fuel prices, usage patterns, and the efficiency gain of the new engine.

Maintenance costs are another crucial consideration. Modern V16 engines often incorporate advanced technologies that can reduce the frequency and complexity of maintenance procedures. This can result in lower maintenance expenses and reduced downtime, potentially offsetting a portion of the initial retrofitting costs.

Environmental regulations and carbon pricing mechanisms also play a role in the economic equation. Newer engines typically produce fewer emissions, which can translate to reduced environmental compliance costs and potential tax benefits in some jurisdictions. As global environmental policies become more stringent, this factor may become increasingly significant in the cost-benefit analysis.

The lifespan of the retrofitted engine is a critical factor in determining economic feasibility. If the new engine significantly extends the operational life of the equipment or vehicle, it can provide value beyond mere efficiency gains. This extended lifespan must be factored into the overall economic assessment.

Market competitiveness is another consideration. In industries where operational efficiency directly impacts pricing and market share, the improved performance of a modern V16 engine could provide a competitive edge. This potential for increased revenue or market share should be included in the economic evaluation.

Financing options can also influence the feasibility of retrofitting. Availability of loans, grants, or tax incentives for engine upgrades can significantly alter the cost-benefit equation. Some governments and organizations offer financial support for projects that improve energy efficiency or reduce emissions, which could apply to V16 engine retrofits.

In conclusion, while the upfront costs of retrofitting modern V16 engines can be substantial, the potential for long-term savings in fuel and maintenance costs, coupled with environmental benefits and possible competitive advantages, can make it an economically viable option in many scenarios. However, a detailed analysis specific to each application is necessary to determine the true economic feasibility.

Environmental Impact

The environmental impact of retrofitting modern V16 engines is a critical consideration in the cost-benefit analysis. These large, powerful engines are typically found in heavy-duty applications such as marine vessels, locomotives, and industrial generators. While retrofitting can extend the lifespan of existing equipment, it also presents significant environmental challenges and opportunities.

Emissions reduction is a primary focus when evaluating the environmental impact of V16 engine retrofitting. Modern retrofits often incorporate advanced emission control technologies, such as selective catalytic reduction (SCR) systems and diesel particulate filters (DPF). These upgrades can substantially reduce harmful emissions, including nitrogen oxides (NOx), particulate matter (PM), and sulfur dioxide (SO2). In some cases, retrofitted engines can achieve emission levels comparable to newer models, contributing to improved air quality and reduced health risks in surrounding communities.

Fuel efficiency improvements are another crucial aspect of the environmental impact assessment. Retrofitting often involves upgrading fuel injection systems, turbochargers, and engine control units. These enhancements can lead to more efficient fuel combustion, resulting in lower fuel consumption and reduced greenhouse gas emissions. The potential for significant reductions in carbon dioxide (CO2) emissions over the extended life of the retrofitted engine must be weighed against the environmental costs of manufacturing and installing new components.

The lifecycle environmental impact of retrofitting versus replacement is an essential consideration. Retrofitting extends the useful life of existing engines, potentially reducing the demand for new engine production and the associated environmental costs of manufacturing and transportation. However, this must be balanced against the potential for newer engines to offer superior environmental performance over their entire lifespan.

Waste reduction and resource conservation are additional environmental factors to consider. Retrofitting allows for the reuse of major engine components, reducing the amount of waste sent to landfills or recycling facilities. This approach aligns with circular economy principles, promoting resource efficiency and minimizing the environmental impact of raw material extraction and processing for new engine production.

Noise pollution reduction is often an ancillary benefit of V16 engine retrofitting. Modern components and improved engine designs can lead to quieter operation, potentially reducing noise pollution in urban areas, ports, and industrial zones where these engines are commonly used.

The environmental impact of retrofitting must also consider the specific application and operating conditions of the V16 engine. For marine applications, retrofits may need to address issues such as ballast water management and oil spill prevention to minimize impacts on aquatic ecosystems. In stationary power generation, the integration of renewable energy sources alongside retrofitted engines may offer additional environmental benefits.

Emissions reduction is a primary focus when evaluating the environmental impact of V16 engine retrofitting. Modern retrofits often incorporate advanced emission control technologies, such as selective catalytic reduction (SCR) systems and diesel particulate filters (DPF). These upgrades can substantially reduce harmful emissions, including nitrogen oxides (NOx), particulate matter (PM), and sulfur dioxide (SO2). In some cases, retrofitted engines can achieve emission levels comparable to newer models, contributing to improved air quality and reduced health risks in surrounding communities.

Fuel efficiency improvements are another crucial aspect of the environmental impact assessment. Retrofitting often involves upgrading fuel injection systems, turbochargers, and engine control units. These enhancements can lead to more efficient fuel combustion, resulting in lower fuel consumption and reduced greenhouse gas emissions. The potential for significant reductions in carbon dioxide (CO2) emissions over the extended life of the retrofitted engine must be weighed against the environmental costs of manufacturing and installing new components.

The lifecycle environmental impact of retrofitting versus replacement is an essential consideration. Retrofitting extends the useful life of existing engines, potentially reducing the demand for new engine production and the associated environmental costs of manufacturing and transportation. However, this must be balanced against the potential for newer engines to offer superior environmental performance over their entire lifespan.

Waste reduction and resource conservation are additional environmental factors to consider. Retrofitting allows for the reuse of major engine components, reducing the amount of waste sent to landfills or recycling facilities. This approach aligns with circular economy principles, promoting resource efficiency and minimizing the environmental impact of raw material extraction and processing for new engine production.

Noise pollution reduction is often an ancillary benefit of V16 engine retrofitting. Modern components and improved engine designs can lead to quieter operation, potentially reducing noise pollution in urban areas, ports, and industrial zones where these engines are commonly used.

The environmental impact of retrofitting must also consider the specific application and operating conditions of the V16 engine. For marine applications, retrofits may need to address issues such as ballast water management and oil spill prevention to minimize impacts on aquatic ecosystems. In stationary power generation, the integration of renewable energy sources alongside retrofitted engines may offer additional environmental benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!