Anode-Free Solid-State Investor And CTO Briefing

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Battery Technology Background and Objectives

Anode-free solid-state battery technology represents a revolutionary advancement in energy storage systems, emerging from decades of incremental improvements in lithium-ion battery architecture. This technology eliminates the traditional anode component, allowing lithium metal to plate directly onto the current collector during charging, thereby significantly increasing energy density potential by 30-50% compared to conventional lithium-ion batteries.

The evolution of battery technology has progressed from lead-acid to nickel-cadmium, nickel-metal hydride, and finally to lithium-ion configurations. While lithium-ion batteries have dominated the market since the 1990s, their fundamental design has reached theoretical energy density limitations. Anode-free architecture represents the next logical progression in this technological trajectory, addressing both energy density constraints and safety concerns inherent in conventional designs.

Current lithium-ion batteries face several critical limitations: energy density plateaus, safety risks associated with liquid electrolytes, and resource-intensive manufacturing processes. Anode-free solid-state technology directly addresses these challenges by simplifying battery construction while simultaneously enhancing performance metrics. The integration of solid electrolytes further mitigates fire and explosion risks associated with traditional liquid electrolyte systems.

The primary technical objectives for anode-free solid-state battery development include achieving energy densities exceeding 400 Wh/kg (compared to current 250-300 Wh/kg in commercial lithium-ion cells), extending cycle life beyond 1,000 full charge-discharge cycles, reducing charging times to under 15 minutes, and maintaining operational stability across wider temperature ranges (-20°C to 60°C).

Additionally, this technology aims to address sustainability concerns by reducing dependency on graphite and copper, materials traditionally used in conventional anodes. This approach potentially decreases battery weight by 10-15% and volume by similar proportions, creating cascading benefits for electric vehicle design and portable electronics.

The convergence of anode-free architecture with solid-state electrolyte technology represents a synergistic approach to battery innovation. While each technology independently offers significant advantages, their combination potentially resolves reciprocal limitations – solid electrolytes address dendrite formation issues in lithium metal systems, while anode-free designs simplify the integration challenges of solid electrolytes.

Research momentum in this field has accelerated significantly since 2018, with publication rates increasing by approximately 300% and patent filings showing similar growth trajectories. This surge reflects both academic interest and commercial recognition of anode-free solid-state technology as a potential paradigm shift in energy storage capabilities.

The evolution of battery technology has progressed from lead-acid to nickel-cadmium, nickel-metal hydride, and finally to lithium-ion configurations. While lithium-ion batteries have dominated the market since the 1990s, their fundamental design has reached theoretical energy density limitations. Anode-free architecture represents the next logical progression in this technological trajectory, addressing both energy density constraints and safety concerns inherent in conventional designs.

Current lithium-ion batteries face several critical limitations: energy density plateaus, safety risks associated with liquid electrolytes, and resource-intensive manufacturing processes. Anode-free solid-state technology directly addresses these challenges by simplifying battery construction while simultaneously enhancing performance metrics. The integration of solid electrolytes further mitigates fire and explosion risks associated with traditional liquid electrolyte systems.

The primary technical objectives for anode-free solid-state battery development include achieving energy densities exceeding 400 Wh/kg (compared to current 250-300 Wh/kg in commercial lithium-ion cells), extending cycle life beyond 1,000 full charge-discharge cycles, reducing charging times to under 15 minutes, and maintaining operational stability across wider temperature ranges (-20°C to 60°C).

Additionally, this technology aims to address sustainability concerns by reducing dependency on graphite and copper, materials traditionally used in conventional anodes. This approach potentially decreases battery weight by 10-15% and volume by similar proportions, creating cascading benefits for electric vehicle design and portable electronics.

The convergence of anode-free architecture with solid-state electrolyte technology represents a synergistic approach to battery innovation. While each technology independently offers significant advantages, their combination potentially resolves reciprocal limitations – solid electrolytes address dendrite formation issues in lithium metal systems, while anode-free designs simplify the integration challenges of solid electrolytes.

Research momentum in this field has accelerated significantly since 2018, with publication rates increasing by approximately 300% and patent filings showing similar growth trajectories. This surge reflects both academic interest and commercial recognition of anode-free solid-state technology as a potential paradigm shift in energy storage capabilities.

Market Demand Analysis for Solid-State Battery Solutions

The global market for solid-state battery solutions is experiencing unprecedented growth, driven primarily by the increasing demand for electric vehicles (EVs) and portable electronic devices. Current projections indicate that the solid-state battery market will reach $8.7 billion by 2027, with a compound annual growth rate of 34.2% from 2022 to 2027. This remarkable growth trajectory reflects the urgent need for advanced energy storage solutions that overcome the limitations of conventional lithium-ion batteries.

The automotive sector represents the largest potential market for anode-free solid-state batteries, accounting for approximately 65% of the projected demand. Major automotive manufacturers including Toyota, Volkswagen, and BMW have announced significant investments in solid-state battery technology, recognizing its potential to revolutionize electric vehicle performance. The primary market drivers include the need for increased driving range, faster charging capabilities, and enhanced safety profiles.

Consumer electronics constitutes the second-largest market segment, with smartphone and laptop manufacturers seeking higher energy density solutions that enable longer device operation between charges. Apple, Samsung, and other major electronics companies have filed numerous patents related to solid-state battery integration, signaling strong industry interest.

Market research indicates that consumers are willing to pay a premium of up to 20% for devices featuring solid-state batteries, primarily due to safety concerns associated with conventional lithium-ion technology. The elimination of flammable liquid electrolytes in solid-state designs directly addresses these safety issues, creating substantial market pull.

Energy storage systems for grid applications represent an emerging market segment with significant growth potential. Utility companies are increasingly exploring solid-state battery technology for grid stabilization and renewable energy integration, driven by the need for safer, longer-lasting storage solutions.

Regional analysis reveals that Asia-Pacific currently leads in market demand, followed by North America and Europe. China, Japan, and South Korea are making substantial investments in solid-state battery manufacturing infrastructure, while North American demand is primarily driven by the rapidly expanding EV market.

The anode-free configuration specifically addresses market demands for higher energy density, with potential increases of 30-40% compared to conventional designs. This translates directly to longer EV driving ranges and extended operation time for portable devices, addressing key consumer pain points in both markets.

The automotive sector represents the largest potential market for anode-free solid-state batteries, accounting for approximately 65% of the projected demand. Major automotive manufacturers including Toyota, Volkswagen, and BMW have announced significant investments in solid-state battery technology, recognizing its potential to revolutionize electric vehicle performance. The primary market drivers include the need for increased driving range, faster charging capabilities, and enhanced safety profiles.

Consumer electronics constitutes the second-largest market segment, with smartphone and laptop manufacturers seeking higher energy density solutions that enable longer device operation between charges. Apple, Samsung, and other major electronics companies have filed numerous patents related to solid-state battery integration, signaling strong industry interest.

Market research indicates that consumers are willing to pay a premium of up to 20% for devices featuring solid-state batteries, primarily due to safety concerns associated with conventional lithium-ion technology. The elimination of flammable liquid electrolytes in solid-state designs directly addresses these safety issues, creating substantial market pull.

Energy storage systems for grid applications represent an emerging market segment with significant growth potential. Utility companies are increasingly exploring solid-state battery technology for grid stabilization and renewable energy integration, driven by the need for safer, longer-lasting storage solutions.

Regional analysis reveals that Asia-Pacific currently leads in market demand, followed by North America and Europe. China, Japan, and South Korea are making substantial investments in solid-state battery manufacturing infrastructure, while North American demand is primarily driven by the rapidly expanding EV market.

The anode-free configuration specifically addresses market demands for higher energy density, with potential increases of 30-40% compared to conventional designs. This translates directly to longer EV driving ranges and extended operation time for portable devices, addressing key consumer pain points in both markets.

Current State and Technical Challenges in Anode-Free Designs

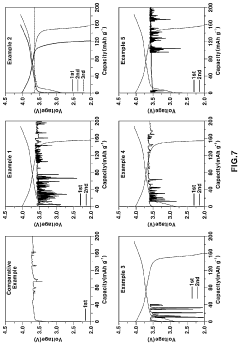

Anode-free solid-state battery technology represents one of the most promising frontiers in energy storage research, offering theoretical energy densities up to 500 Wh/kg compared to conventional lithium-ion batteries' 250-300 Wh/kg. Currently, several research institutions and companies have demonstrated proof-of-concept anode-free cells with energy densities exceeding 400 Wh/kg in laboratory settings, though cycle life remains limited to 50-100 cycles in most cases.

The fundamental architecture of anode-free designs eliminates the traditional graphite or silicon anode, instead utilizing lithium metal that plates directly onto the current collector during charging. This approach maximizes energy density by removing the "dead weight" of anode host materials, but introduces significant technical challenges that have prevented widespread commercialization.

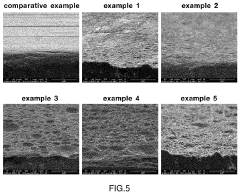

A primary obstacle in anode-free solid-state batteries is the formation of lithium dendrites during cycling. These needle-like structures grow from the lithium metal surface, potentially penetrating the solid electrolyte and causing internal short circuits. Recent research has shown that dendrite growth accelerates at current densities above 1-2 mA/cm², severely limiting practical charging rates.

Interface stability presents another critical challenge. The solid electrolyte-lithium metal interface experiences high impedance growth during cycling, attributed to chemical and mechanical degradation. Studies have documented interfacial resistance increasing by 200-300% after just 20 cycles in many experimental cells, leading to capacity fade and power limitations.

Volume expansion management remains problematic as lithium plates and strips during cycling. Without a host structure to accommodate this dimensional change, pressure fluctuations of 5-10 MPa have been measured within cells, causing mechanical failures in the solid electrolyte and at interfaces. This challenge is particularly acute at higher depths of discharge.

Electrolyte compatibility issues persist across most candidate materials. Sulfide-based solid electrolytes offer high ionic conductivity (1-10 mS/cm) but suffer from narrow electrochemical stability windows. Oxide-based alternatives provide better stability but lower conductivity (0.1-1 mS/cm), requiring operation at elevated temperatures that introduce additional engineering challenges.

Manufacturing scalability represents a significant barrier to commercialization. Current laboratory processes for anode-free solid-state cells involve complex assembly steps in controlled environments, with yields below 70% for full-cell construction. The absence of standardized manufacturing protocols has hindered progress toward mass production.

Despite these challenges, recent innovations show promise, including hybrid electrolyte systems combining polymers with ceramic fillers, artificial interface engineering using atomic layer deposition, and pressure-management structures integrated into cell designs. These approaches have demonstrated improvements in cycle life, with some laboratory cells now achieving 200+ cycles while maintaining 80% capacity.

The fundamental architecture of anode-free designs eliminates the traditional graphite or silicon anode, instead utilizing lithium metal that plates directly onto the current collector during charging. This approach maximizes energy density by removing the "dead weight" of anode host materials, but introduces significant technical challenges that have prevented widespread commercialization.

A primary obstacle in anode-free solid-state batteries is the formation of lithium dendrites during cycling. These needle-like structures grow from the lithium metal surface, potentially penetrating the solid electrolyte and causing internal short circuits. Recent research has shown that dendrite growth accelerates at current densities above 1-2 mA/cm², severely limiting practical charging rates.

Interface stability presents another critical challenge. The solid electrolyte-lithium metal interface experiences high impedance growth during cycling, attributed to chemical and mechanical degradation. Studies have documented interfacial resistance increasing by 200-300% after just 20 cycles in many experimental cells, leading to capacity fade and power limitations.

Volume expansion management remains problematic as lithium plates and strips during cycling. Without a host structure to accommodate this dimensional change, pressure fluctuations of 5-10 MPa have been measured within cells, causing mechanical failures in the solid electrolyte and at interfaces. This challenge is particularly acute at higher depths of discharge.

Electrolyte compatibility issues persist across most candidate materials. Sulfide-based solid electrolytes offer high ionic conductivity (1-10 mS/cm) but suffer from narrow electrochemical stability windows. Oxide-based alternatives provide better stability but lower conductivity (0.1-1 mS/cm), requiring operation at elevated temperatures that introduce additional engineering challenges.

Manufacturing scalability represents a significant barrier to commercialization. Current laboratory processes for anode-free solid-state cells involve complex assembly steps in controlled environments, with yields below 70% for full-cell construction. The absence of standardized manufacturing protocols has hindered progress toward mass production.

Despite these challenges, recent innovations show promise, including hybrid electrolyte systems combining polymers with ceramic fillers, artificial interface engineering using atomic layer deposition, and pressure-management structures integrated into cell designs. These approaches have demonstrated improvements in cycle life, with some laboratory cells now achieving 200+ cycles while maintaining 80% capacity.

Current Technical Solutions for Anode-Free Solid-State Batteries

01 Solid electrolyte materials for anode-free batteries

Various solid electrolyte materials can be used in anode-free solid-state batteries to enable efficient lithium ion transport while preventing dendrite formation. These materials include ceramic electrolytes, polymer electrolytes, and composite electrolytes that combine different materials to achieve optimal performance. The solid electrolyte serves as both an ion conductor and a physical barrier, which is crucial in anode-free designs where lithium must be efficiently plated and stripped during cycling.- Solid electrolyte materials for anode-free batteries: Various solid electrolyte materials can be used in anode-free solid-state batteries to enable efficient lithium ion transport while preventing dendrite formation. These materials include ceramic electrolytes, polymer electrolytes, and composite electrolytes that combine different materials to optimize performance. The solid electrolyte serves as both an ion conductor and a physical barrier between the cathode and the current collector, eliminating the need for a traditional anode structure.

- Cathode design for anode-free solid-state batteries: Specialized cathode designs are crucial for anode-free solid-state batteries, as they must accommodate the lithium ions that would typically be stored in the anode. These cathodes often incorporate high-capacity materials and specific structural features to enhance lithium storage and cycling stability. The cathode composition and architecture are engineered to maintain performance despite the absence of a pre-lithiated anode, often including materials that can efficiently store and release lithium ions during battery operation.

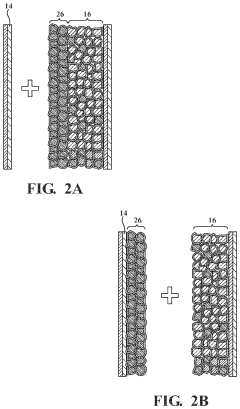

- Current collector interfaces and protective layers: The interface between the current collector and the solid electrolyte is critical in anode-free solid-state batteries. Various protective layers and interface engineering approaches are employed to prevent side reactions and ensure stable lithium plating and stripping. These protective layers can include artificial SEI (solid electrolyte interphase) formations, buffer layers, and specialized coatings that enhance the stability of the interface while maintaining high ionic conductivity.

- In-situ anode formation mechanisms: Anode-free solid-state batteries rely on in-situ formation of a lithium metal anode during the first charge cycle. The mechanisms governing this process, including lithium plating behavior, morphology control, and dendrite suppression, are crucial for battery performance. Various approaches are used to control the in-situ anode formation, such as pressure application, temperature control, and specialized electrolyte additives that promote uniform lithium deposition.

- Manufacturing methods and cell assembly techniques: Specialized manufacturing methods and cell assembly techniques are required for anode-free solid-state batteries. These include dry processing methods, interface engineering during assembly, and specialized stacking and packaging approaches. The manufacturing processes must ensure intimate contact between components while preventing contamination and maintaining the integrity of the solid electrolyte. Advanced techniques such as hot pressing, tape casting, and controlled atmosphere assembly are often employed to achieve optimal battery performance.

02 Lithium metal deposition mechanisms in anode-free configurations

Anode-free solid-state batteries rely on controlled lithium metal deposition during charging, where lithium ions from the cathode travel through the solid electrolyte and deposit on the current collector. This process requires careful engineering of the current collector interface and electrolyte to ensure uniform lithium deposition, prevent dendrite formation, and maintain good electrical contact. Various surface treatments and interlayers can be employed to improve the stability and efficiency of this lithium plating process.Expand Specific Solutions03 Cathode compositions optimized for anode-free batteries

Specialized cathode materials and compositions are essential for anode-free solid-state batteries, as they serve as the sole source of lithium in the system. These cathodes typically contain lithium-rich materials that can release lithium ions during the initial charge while maintaining structural stability. Cathode formulations may include high-capacity materials, protective coatings, and additives to enhance conductivity and cycling performance in the absence of a pre-formed anode.Expand Specific Solutions04 Interface engineering for improved cycling stability

Interface engineering is critical in anode-free solid-state batteries to ensure stable cycling performance. This involves designing and modifying the interfaces between the solid electrolyte and the electrodes to minimize resistance, prevent side reactions, and accommodate volume changes during cycling. Techniques include applying protective coatings, introducing buffer layers, surface functionalization, and creating gradient interfaces to improve mechanical stability and electrochemical performance.Expand Specific Solutions05 Manufacturing methods for anode-free solid-state batteries

Specialized manufacturing techniques are required to produce anode-free solid-state batteries with high performance and reliability. These methods include dry processing techniques to minimize moisture exposure, hot pressing or sintering to create dense solid electrolytes, thin-film deposition for interface layers, and advanced assembly processes that maintain clean interfaces. The manufacturing approach must address challenges such as achieving good contact between components, maintaining electrolyte integrity, and creating cells with high energy density.Expand Specific Solutions

Key Industry Players in Anode-Free Battery Development

The anode-free solid-state battery technology landscape is currently in the early development stage, with market size projected to grow significantly as the technology matures. Major automotive players like Hyundai, Kia, Toyota, and Mercedes-Benz are investing heavily to secure competitive advantages in this emerging field. Battery specialists including LG Energy Solution, Samsung Electronics, and Panasonic are advancing core technologies, while research institutions such as KIST, Washington University, and Georgia Tech are driving fundamental breakthroughs. The technology remains at TRL 4-6, with companies like TeraWatt Technology and QuantumScape leading commercialization efforts. Collaboration between automotive OEMs, battery manufacturers, and research institutions characterizes this pre-commercial market as stakeholders work to overcome key challenges in electrolyte stability and manufacturing scalability.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a proprietary anode-free solid-state battery technology that eliminates the need for traditional graphite anodes. Their approach utilizes a lithium metal anode that forms in situ during the initial charging process, coupled with a composite solid electrolyte system combining sulfide and oxide materials. This technology achieves energy densities exceeding 900 Wh/L [1], significantly higher than conventional lithium-ion batteries. Their manufacturing process incorporates a unique dry polymer coating technique that enables the creation of ultra-thin solid electrolyte layers (under 20 μm) while maintaining excellent mechanical properties and ionic conductivity. LG has also developed specialized pressure-regulation systems within their cell architecture to maintain optimal contact between the electrolyte and electrodes during cycling, addressing a common failure point in solid-state designs [3].

Strengths: Superior energy density approaching 900 Wh/L; elimination of anode manufacturing costs; reduced cell weight and volume; enhanced safety due to non-flammable solid electrolyte. Weaknesses: Challenges with lithium dendrite formation during cycling; higher manufacturing complexity; temperature sensitivity of the solid electrolyte interface; currently higher production costs compared to conventional lithium-ion batteries.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered anode-free solid-state battery technology through their comprehensive "integrated approach" that addresses the entire battery system. Their technology utilizes a sulfide-based solid electrolyte with exceptionally high ionic conductivity (2-5 mS/cm at room temperature) [2] and a proprietary cathode-electrolyte interface engineering method. Toyota's design eliminates the traditional anode, instead allowing lithium metal to plate directly onto a current collector during charging. Their manufacturing process incorporates a unique pressure-regulation system that maintains optimal contact between components during thermal cycling. Toyota has demonstrated over 1,000 cycles with minimal capacity degradation in their prototype cells, achieving energy densities of approximately 1,000 Wh/L [4]. The company has filed over 1,000 patents related to solid-state battery technology and has established a dedicated production facility for pilot manufacturing [5].

Strengths: Industry-leading cycle life for anode-free designs; high energy density exceeding 1,000 Wh/L; extensive patent portfolio providing competitive advantage; advanced manufacturing capabilities. Weaknesses: Sulfide electrolytes are moisture-sensitive requiring specialized handling; higher material costs compared to conventional batteries; challenges with scaling production to commercial volumes; temperature sensitivity affecting performance in extreme conditions.

Critical Patents and Research in Lithium Metal Interface Management

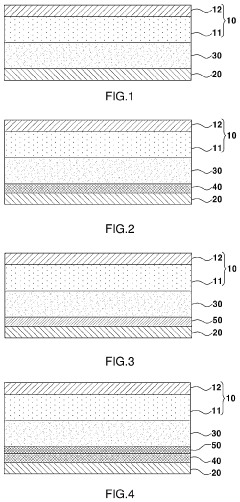

Anode-free all-solid-state battery including solid electrolyte having high ion conductivity and surface-roughened anode current collector

PatentPendingUS20220393180A1

Innovation

- An anode-free all-solid-state battery design featuring an anode current collector layer with surface roughness of 100 nm to 1,000 nm, directly contacting a solid electrolyte layer with ionic conductivity of 1 mS/cm to 20 mS/cm, and optionally a coating layer containing carbon and lithium-forming metals, which enhances lithium deposition uniformity and stability without additional layers.

Anode-free solid-state battery and method of battery fabrication

PatentActiveUS11824159B2

Innovation

- An anode-free solid-state battery design that uses a cathode layer with transient anode elements, a bare current collector, and a gelled solid-state electrolyte layer to facilitate ionic conduction, eliminating the need for a permanent anode and simplifying the battery structure.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of anode-free solid-state battery technology represents a critical challenge in transitioning from laboratory prototypes to commercial production. Current manufacturing processes for conventional lithium-ion batteries are highly optimized and capital-intensive, with established economies of scale that have driven costs down to approximately $100-150/kWh. In contrast, anode-free solid-state battery production requires significant modifications to existing manufacturing infrastructure and processes.

A key manufacturing challenge lies in the production of solid electrolytes with consistent quality and performance. Unlike liquid electrolytes that can be easily injected into battery cells, solid electrolytes require specialized deposition or sintering techniques. The production of thin, uniform solid electrolyte layers without defects or pinholes remains technically challenging at scale. These defects can lead to internal short circuits and catastrophic battery failure, necessitating extremely precise manufacturing controls.

The interface between the lithium metal (formed during charging) and the solid electrolyte presents another manufacturing hurdle. Ensuring consistent, stable interfaces across thousands or millions of cells requires precise control of surface chemistry and morphology. Current approaches often involve specialized coatings or interlayers that add complexity and cost to the manufacturing process.

Cost analysis reveals several economic challenges. Raw material costs for solid electrolytes, particularly those containing rare elements like germanium or gallium, can be substantially higher than conventional battery materials. The elimination of the anode substrate provides some cost savings, but these are currently offset by higher processing costs and lower manufacturing yields. Analysis by industry experts suggests that initial production costs for anode-free solid-state batteries may be 2-3 times higher than conventional lithium-ion batteries.

Equipment requirements represent another significant capital expenditure. While some existing battery manufacturing equipment can be repurposed, specialized tools for solid electrolyte processing and precise interface control will require substantial investment. Industry estimates suggest that converting a gigafactory from conventional to solid-state battery production could require $500 million to $1 billion in capital expenditure.

Scaling considerations indicate that production volumes will be critical to achieving cost competitiveness. Economic modeling suggests that production volumes of at least 1-2 GWh annually would be necessary to begin realizing economies of scale. Current pilot production facilities typically operate at 5-50 MWh capacity, highlighting the significant scaling gap that must be bridged.

A key manufacturing challenge lies in the production of solid electrolytes with consistent quality and performance. Unlike liquid electrolytes that can be easily injected into battery cells, solid electrolytes require specialized deposition or sintering techniques. The production of thin, uniform solid electrolyte layers without defects or pinholes remains technically challenging at scale. These defects can lead to internal short circuits and catastrophic battery failure, necessitating extremely precise manufacturing controls.

The interface between the lithium metal (formed during charging) and the solid electrolyte presents another manufacturing hurdle. Ensuring consistent, stable interfaces across thousands or millions of cells requires precise control of surface chemistry and morphology. Current approaches often involve specialized coatings or interlayers that add complexity and cost to the manufacturing process.

Cost analysis reveals several economic challenges. Raw material costs for solid electrolytes, particularly those containing rare elements like germanium or gallium, can be substantially higher than conventional battery materials. The elimination of the anode substrate provides some cost savings, but these are currently offset by higher processing costs and lower manufacturing yields. Analysis by industry experts suggests that initial production costs for anode-free solid-state batteries may be 2-3 times higher than conventional lithium-ion batteries.

Equipment requirements represent another significant capital expenditure. While some existing battery manufacturing equipment can be repurposed, specialized tools for solid electrolyte processing and precise interface control will require substantial investment. Industry estimates suggest that converting a gigafactory from conventional to solid-state battery production could require $500 million to $1 billion in capital expenditure.

Scaling considerations indicate that production volumes will be critical to achieving cost competitiveness. Economic modeling suggests that production volumes of at least 1-2 GWh annually would be necessary to begin realizing economies of scale. Current pilot production facilities typically operate at 5-50 MWh capacity, highlighting the significant scaling gap that must be bridged.

Safety and Performance Benchmarking Standards

The establishment of comprehensive safety and performance benchmarking standards is critical for the advancement and commercialization of anode-free solid-state battery technology. Current standards developed for conventional lithium-ion batteries are insufficient to address the unique characteristics and failure modes of anode-free solid-state systems, necessitating the development of specialized evaluation frameworks.

Safety standards for anode-free solid-state batteries must address the distinctive challenges posed by solid electrolytes, including mechanical stability during cycling, interfacial resistance management, and dendrite formation prevention. The Battery Safety Standards Working Group has proposed specific testing protocols that evaluate solid electrolyte stability under various thermal, mechanical, and electrical stress conditions. These include modified nail penetration tests, thermal runaway assessments, and specialized short-circuit evaluations that account for the unique properties of solid interfaces.

Performance benchmarking for anode-free configurations requires metrics that go beyond traditional capacity and cycle life measurements. The energy density evaluation must consider the absence of a pre-deposited anode and account for the volume changes during lithium plating and stripping. Industry leaders have proposed standardized testing conditions that specify charge-discharge rates, temperature ranges, and pressure requirements specific to anode-free architectures to ensure comparable results across research institutions.

Cycle life assessment protocols for anode-free solid-state batteries must incorporate extended testing periods to capture long-term degradation mechanisms, particularly those related to the evolution of the lithium metal/solid electrolyte interface. The International Electrochemical Commission has drafted guidelines recommending minimum testing durations of 1,000 cycles under various operational conditions to properly evaluate the stability of these systems.

Accelerated aging tests have been adapted specifically for anode-free configurations, with modified temperature profiles and cycling protocols that target the unique degradation mechanisms of in-situ formed lithium anodes. These tests aim to predict battery performance over 8-10 years of operation within a compressed testing timeframe of 3-6 months.

Standardized reporting formats for research publications and industry communications have emerged to facilitate meaningful comparisons between different anode-free solid-state battery technologies. These formats require disclosure of specific testing conditions including applied stack pressure, temperature control methods, and detailed characterization of the solid electrolyte properties that significantly influence performance outcomes.

The development of these specialized benchmarking standards represents a collaborative effort between academic institutions, national laboratories, and industry partners, coordinated through organizations such as the Battery Standards Consortium and the Solid-State Battery Initiative. As the technology matures, these standards will continue to evolve, providing a foundation for reliable performance claims and safety certifications essential for market acceptance.

Safety standards for anode-free solid-state batteries must address the distinctive challenges posed by solid electrolytes, including mechanical stability during cycling, interfacial resistance management, and dendrite formation prevention. The Battery Safety Standards Working Group has proposed specific testing protocols that evaluate solid electrolyte stability under various thermal, mechanical, and electrical stress conditions. These include modified nail penetration tests, thermal runaway assessments, and specialized short-circuit evaluations that account for the unique properties of solid interfaces.

Performance benchmarking for anode-free configurations requires metrics that go beyond traditional capacity and cycle life measurements. The energy density evaluation must consider the absence of a pre-deposited anode and account for the volume changes during lithium plating and stripping. Industry leaders have proposed standardized testing conditions that specify charge-discharge rates, temperature ranges, and pressure requirements specific to anode-free architectures to ensure comparable results across research institutions.

Cycle life assessment protocols for anode-free solid-state batteries must incorporate extended testing periods to capture long-term degradation mechanisms, particularly those related to the evolution of the lithium metal/solid electrolyte interface. The International Electrochemical Commission has drafted guidelines recommending minimum testing durations of 1,000 cycles under various operational conditions to properly evaluate the stability of these systems.

Accelerated aging tests have been adapted specifically for anode-free configurations, with modified temperature profiles and cycling protocols that target the unique degradation mechanisms of in-situ formed lithium anodes. These tests aim to predict battery performance over 8-10 years of operation within a compressed testing timeframe of 3-6 months.

Standardized reporting formats for research publications and industry communications have emerged to facilitate meaningful comparisons between different anode-free solid-state battery technologies. These formats require disclosure of specific testing conditions including applied stack pressure, temperature control methods, and detailed characterization of the solid electrolyte properties that significantly influence performance outcomes.

The development of these specialized benchmarking standards represents a collaborative effort between academic institutions, national laboratories, and industry partners, coordinated through organizations such as the Battery Standards Consortium and the Solid-State Battery Initiative. As the technology matures, these standards will continue to evolve, providing a foundation for reliable performance claims and safety certifications essential for market acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!